Self-dumping separator with a disc stack

An automatic unloading and separator technology, applied in centrifuges with rotating drums, centrifuges, etc., can solve the problem of purification effect, find pollutants and other problems, and achieve the effect of large purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

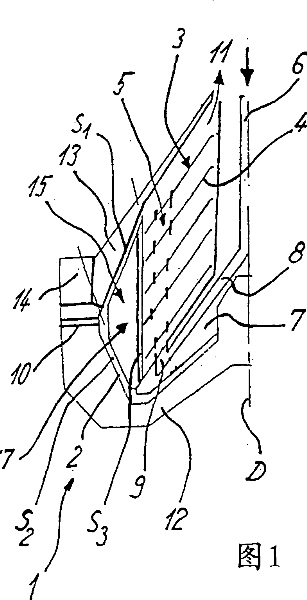

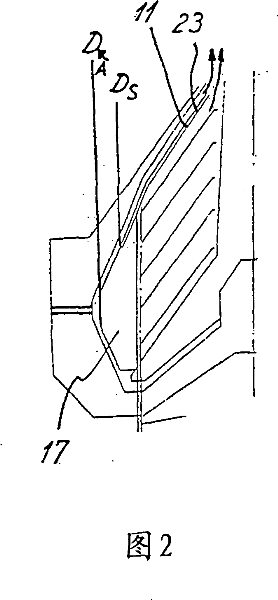

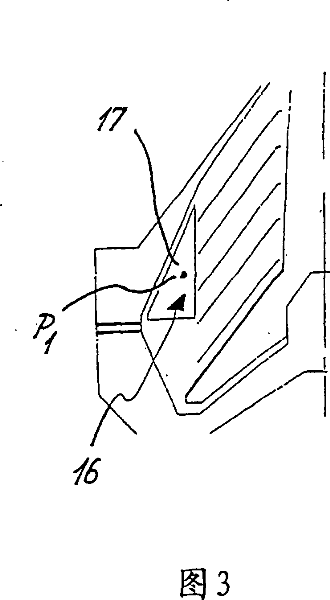

[0026] Figure 1 shows a greatly simplified representation of a drum 1 for a separator with a vertical axis of rotation D not otherwise shown with reference to its remaining components, such as drives, etc., wherein the drum delimits a centrifugal separator Chamber 2, in which is embedded a disc pack 3 comprising a plurality of conical discs 4, in which one or more ascending channels 5 are formed.

[0027] It should be noted in this connection that terms such as "above", "below", "front" or "rear" etc. relate only to the simplified exemplary embodiment shown and are not to be understood as being restricted thereto. Alternatively, an embodiment not shown here of the feed line can also be introduced into the drum from below, although FIG. 1 shows a variant in which the feed line is led into the drum from above.

[0028] From here, the central inlet line 6 first leads from above into a distributor 7 which has channels 8 which conduct the centrifuged material outwards as far as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com