Anaerobic reactor for treating waste water containing emulsified liquid

An anaerobic reactor and emulsion technology, which is applied in the direction of anaerobic digestion and treatment, can solve the problems that the total effluent water quality cannot be stably up to the standard, the treatment process pressure is high, and the COD removal rate is low, so as to achieve the total effluent water quality of the wastewater treatment system. The effect of stable standard, high removal rate and high sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

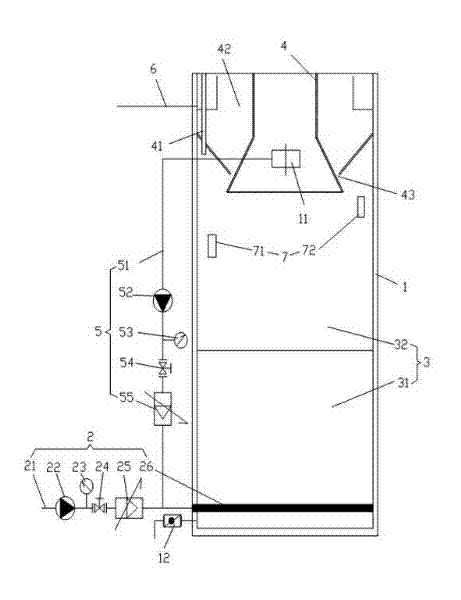

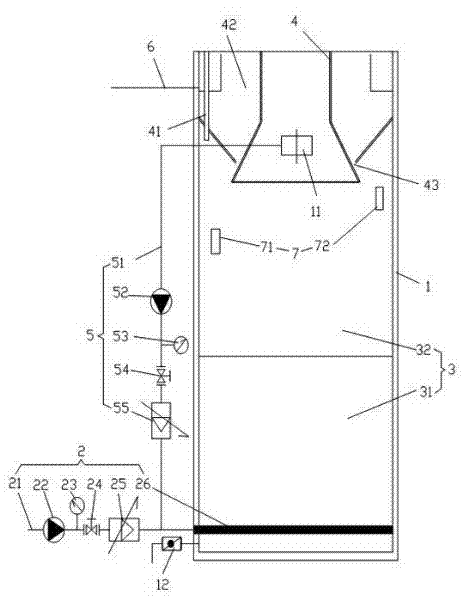

[0024] The anaerobic reactor for treating emulsion-containing wastewater of the present invention is an upflow anaerobic reactor, comprising a pool body 1, an inlet water distribution system 2, a reaction zone 3, a three-phase separator 4, a circulation system 5 and an outlet system 6 .

[0025] The tank body 1 is a cylinder or a cuboid container, which adopts an anti-corrosion steel or reinforced concrete structure; the ratio of the total height to the diameter of the tank body 1 (converted into a cylinder when the tank body is a cuboid) is greater than 3 to ensure the hydraulic retention time of the influent Over 48 hours. The upper part of the pool body 1 is provided with a circulation water intake 11, which is used for water intake by the circulation pipe to ensure stable water flow in the water intake area. The water intake 11 is set at 0.5 to 0.8 meters below the three-phase separator 4, generally selected at 0.5 meters below the three-phase separator 4.

[0026] The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com