Patents

Literature

43results about How to "Reduce process pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

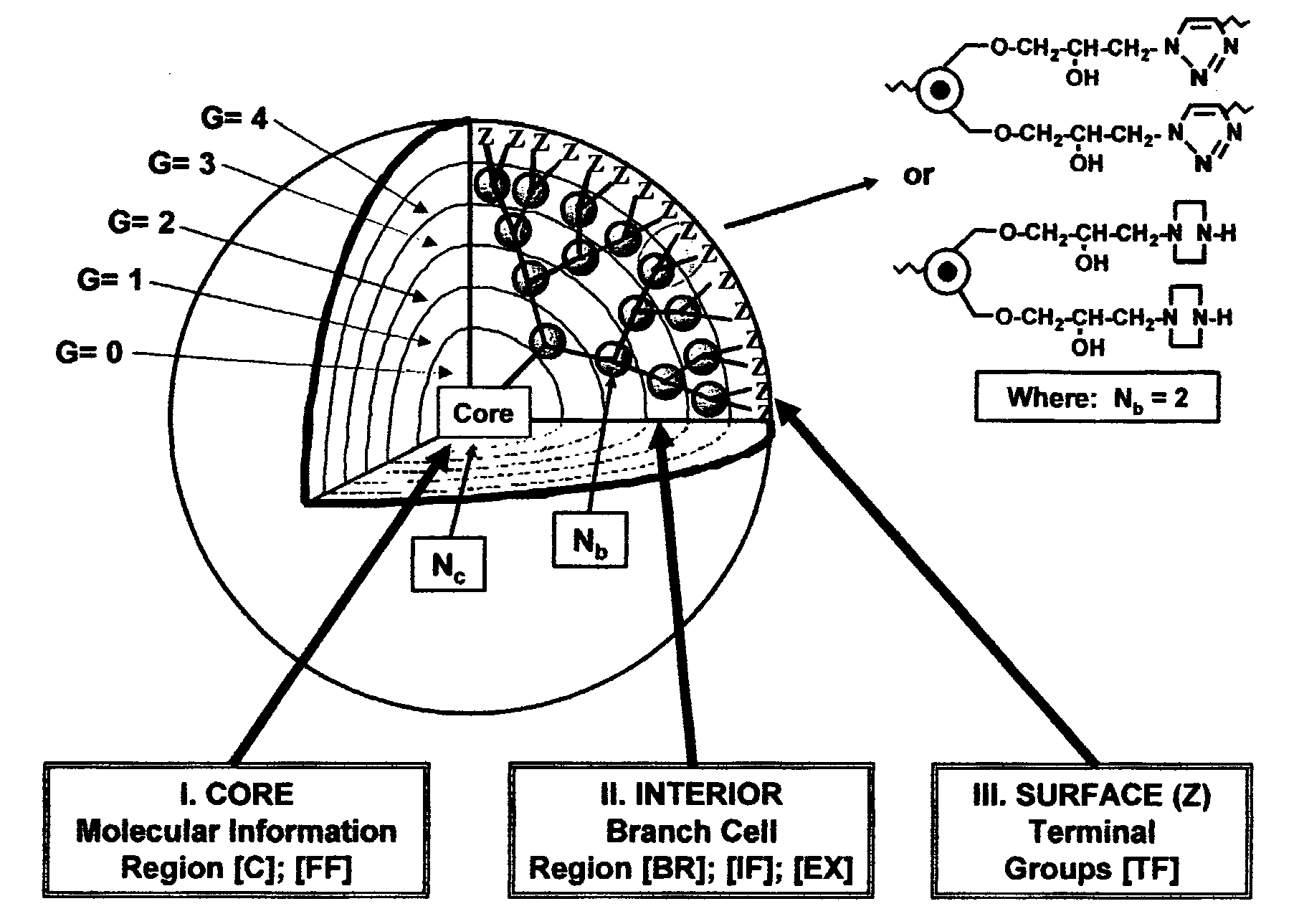

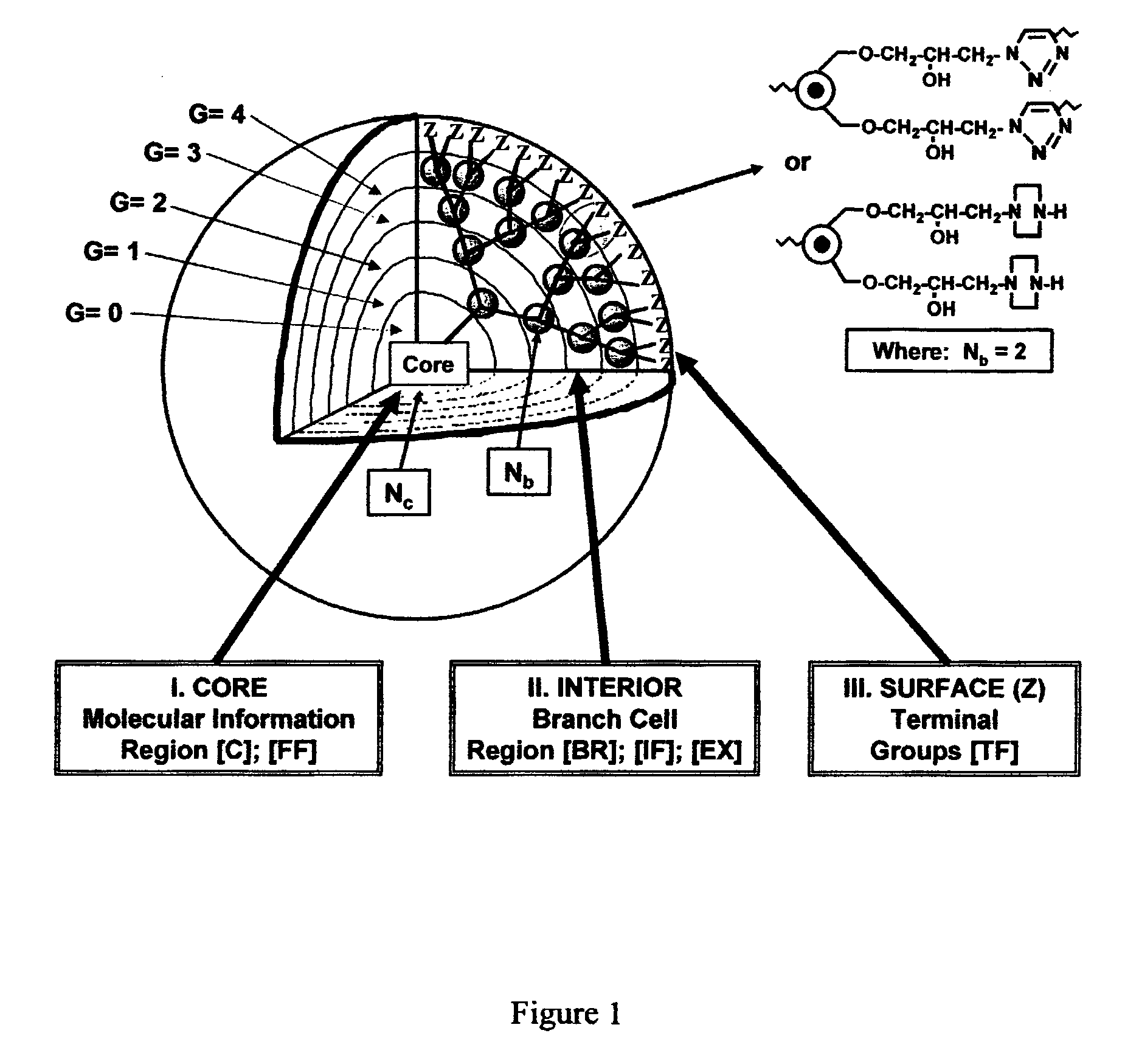

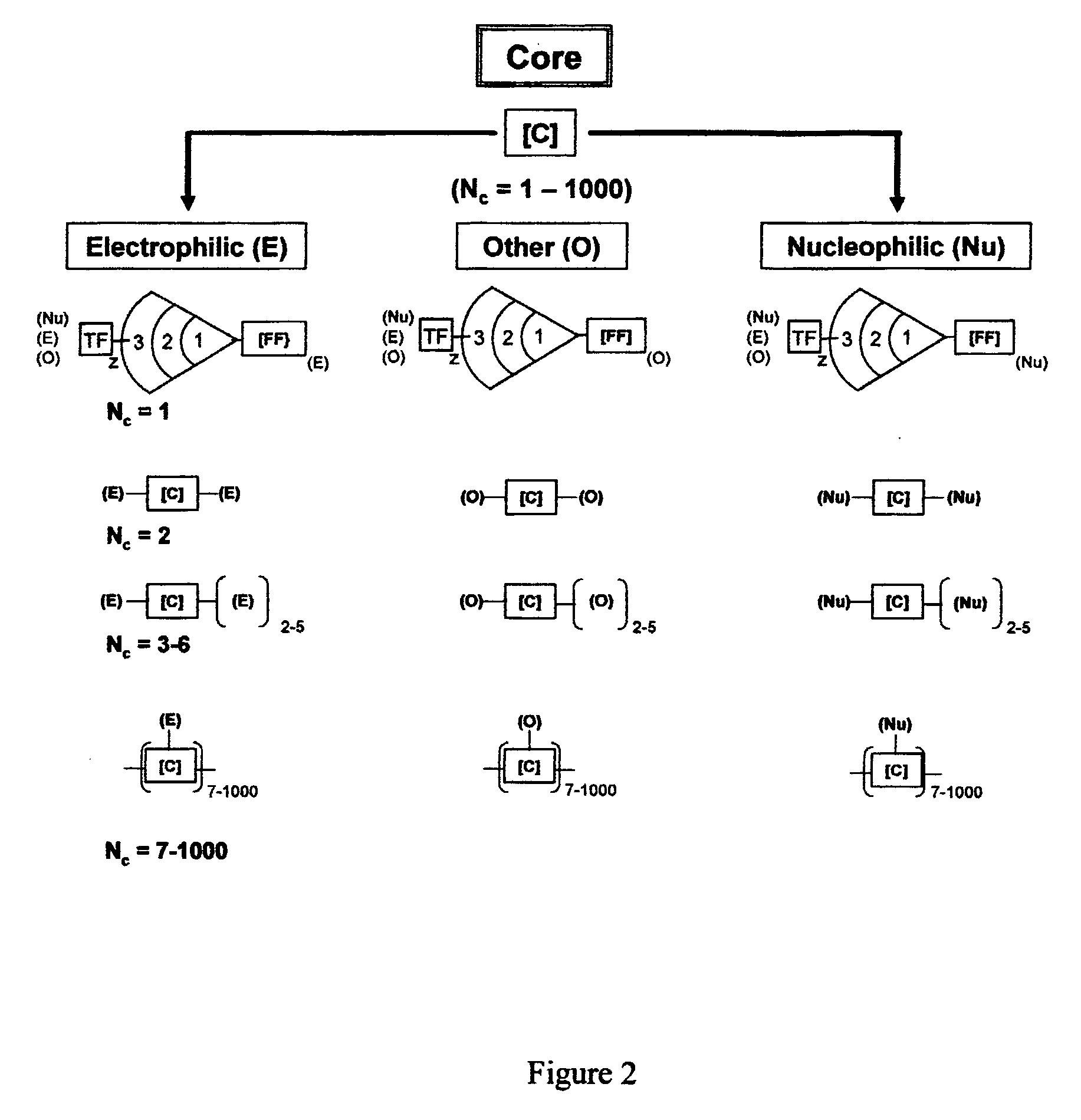

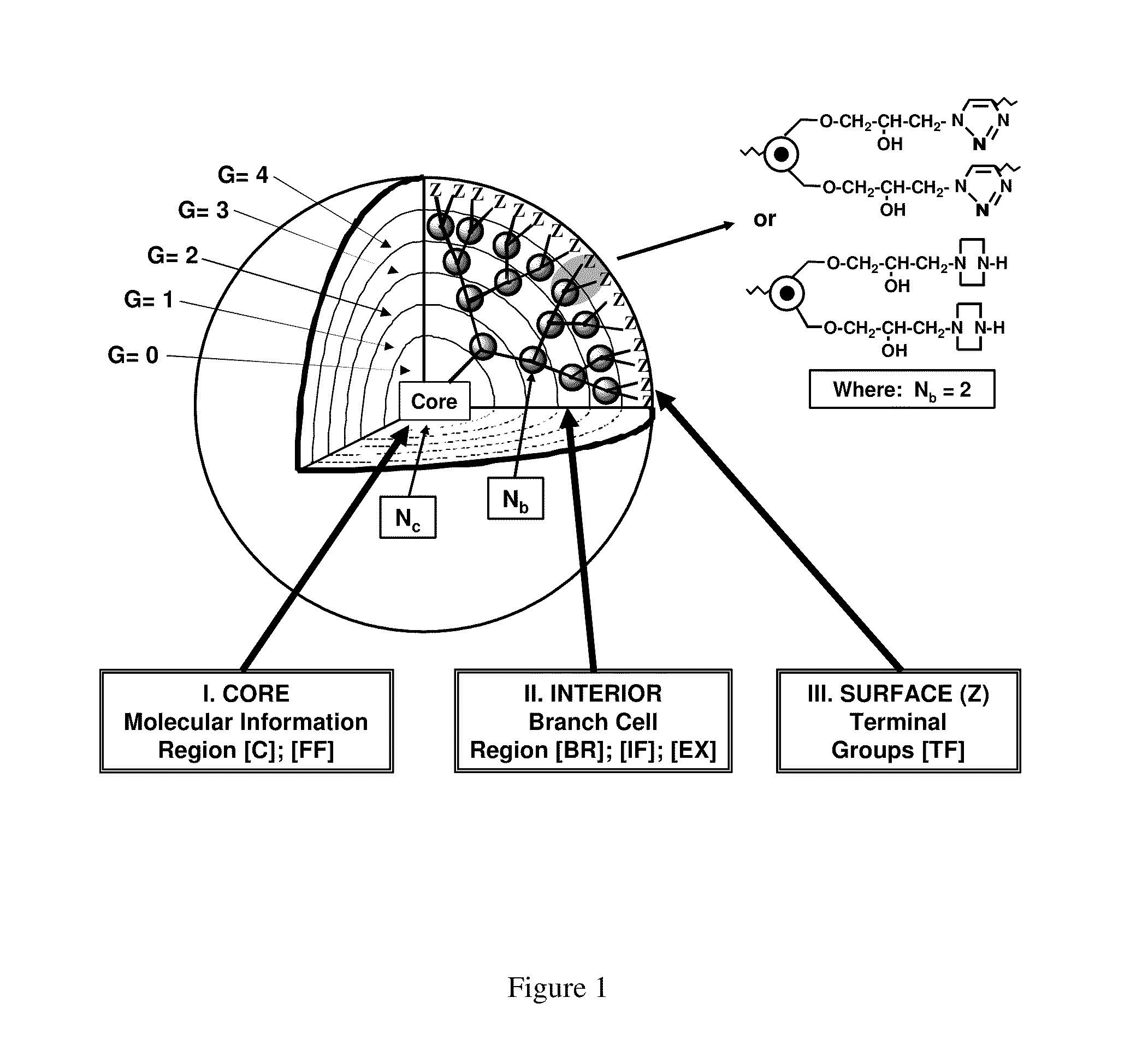

Dendritic Polymers With Enhanced Amplification and Interior Functionality

ActiveUS20070298006A1Reduced responseSizePowder deliveryOrganic active ingredientsCross-linkScavenger

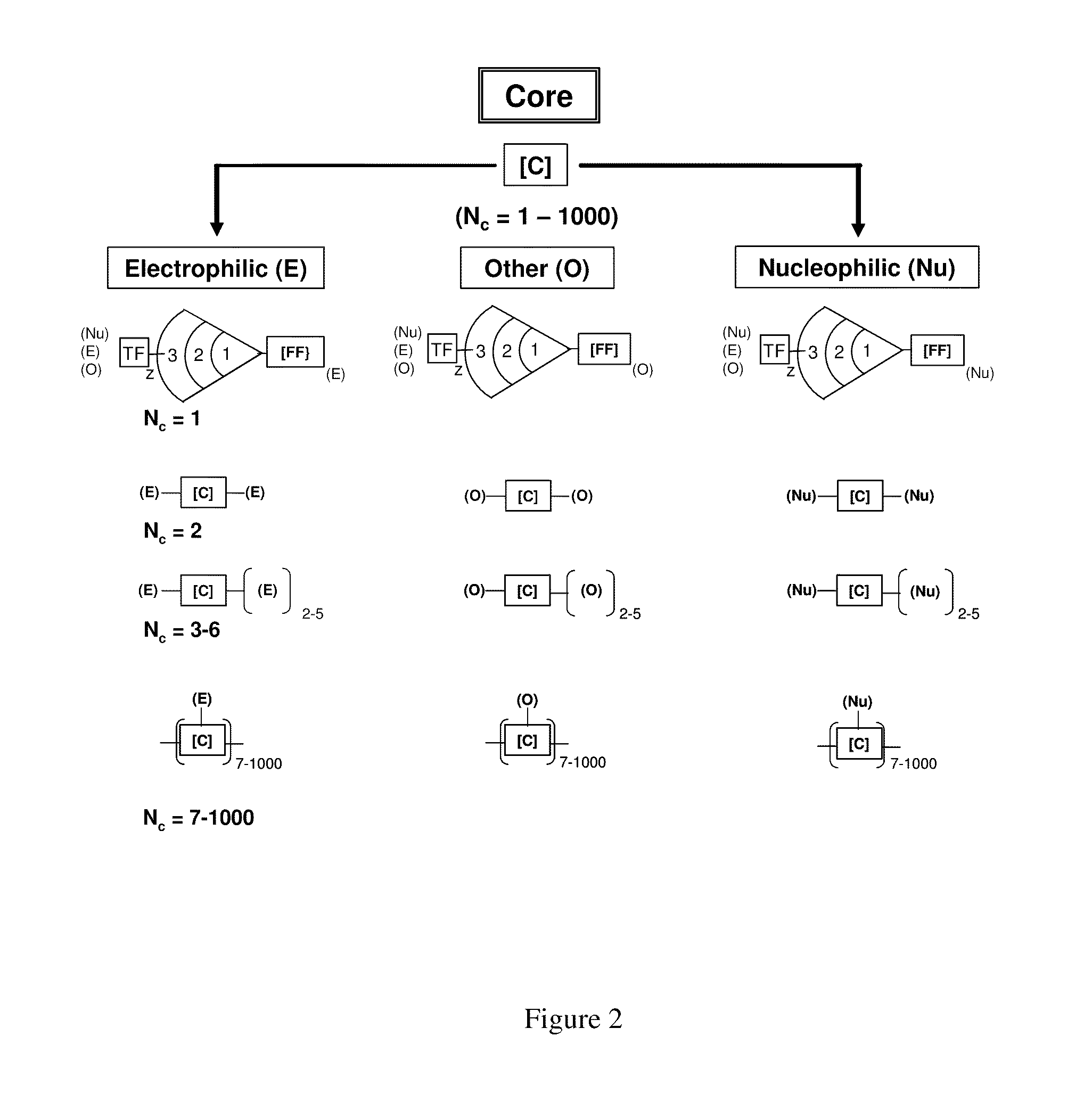

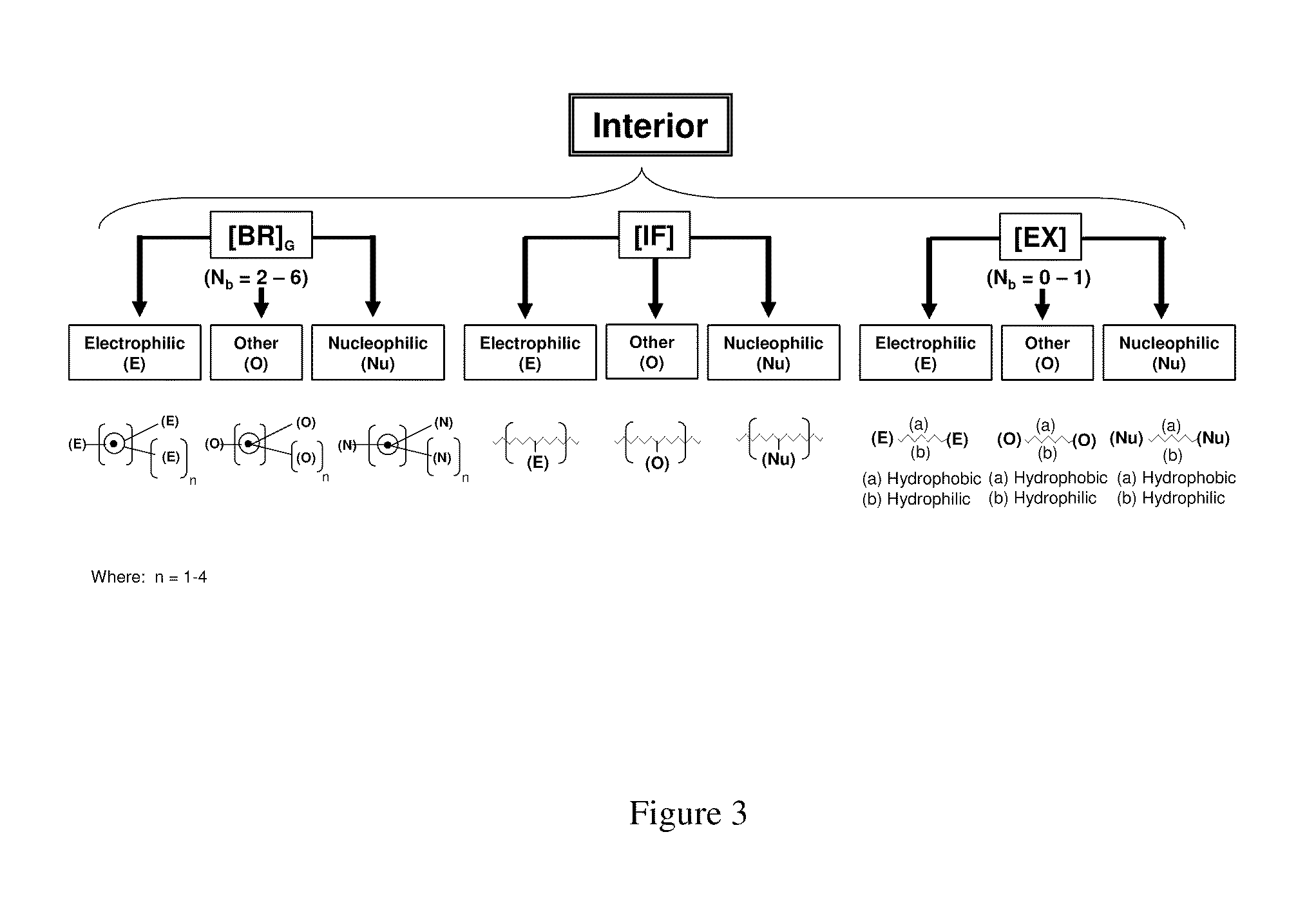

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

Dendritic polymers with enhanced amplification and interior functionality

ActiveUS7985424B2Increase productionSimple materialPowder deliveryCosmetic preparationsCross-linkChemical reaction

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

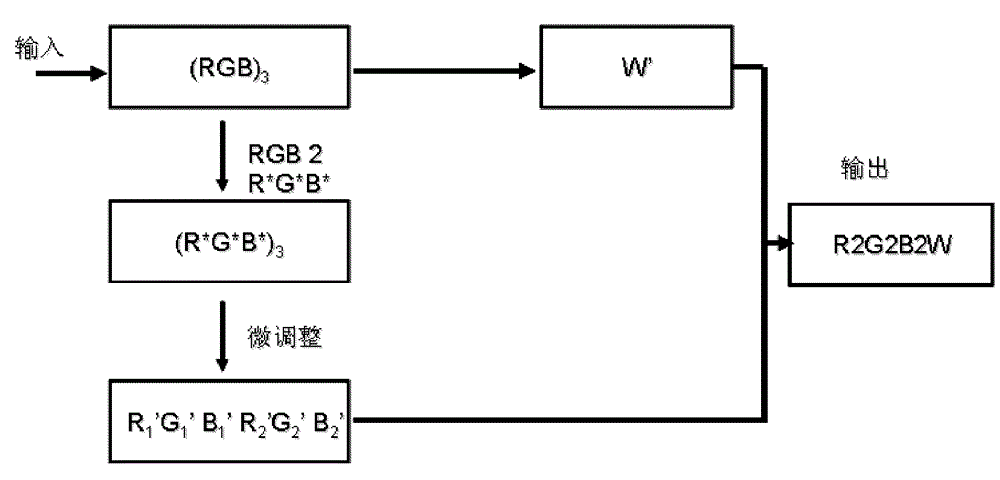

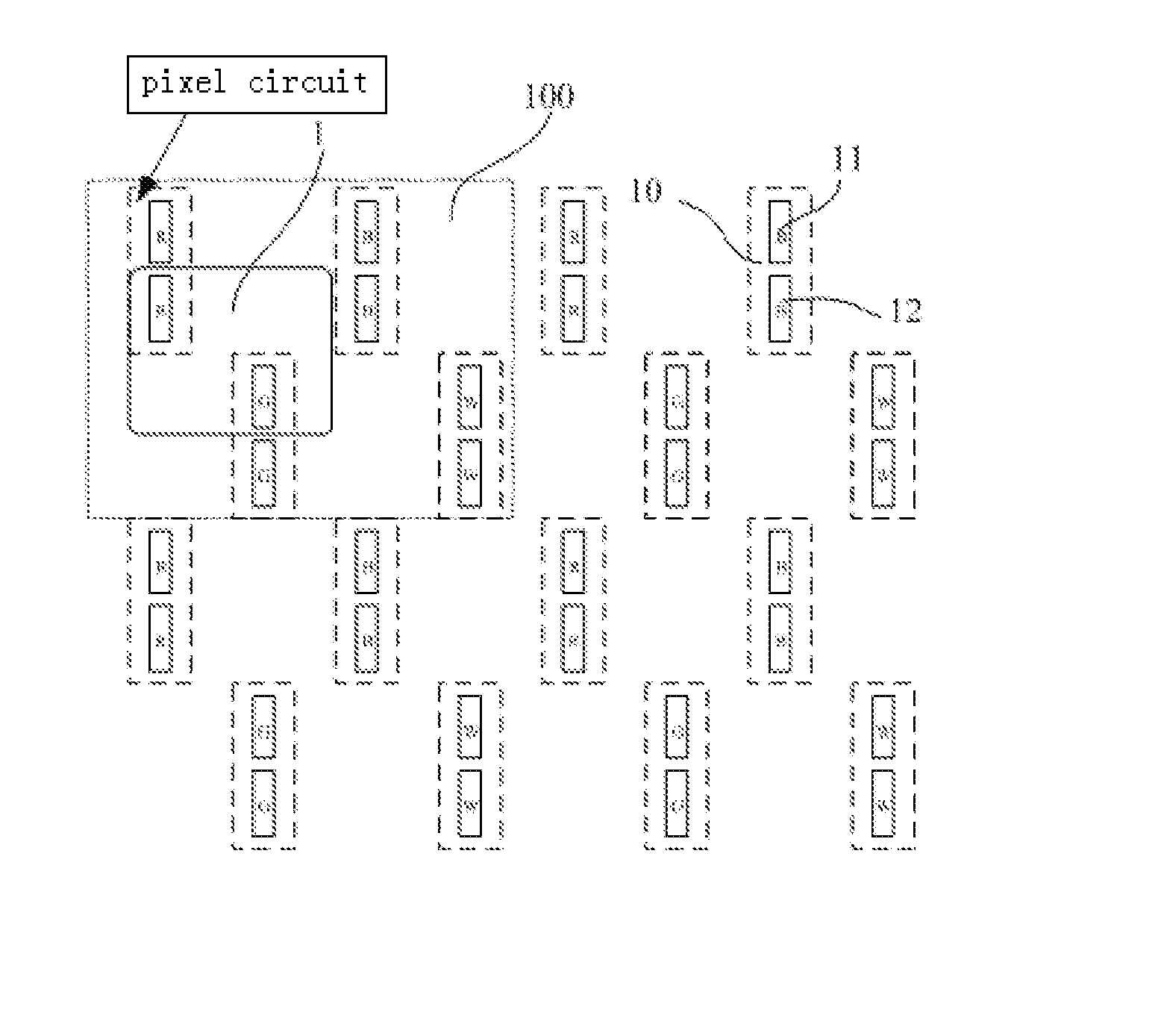

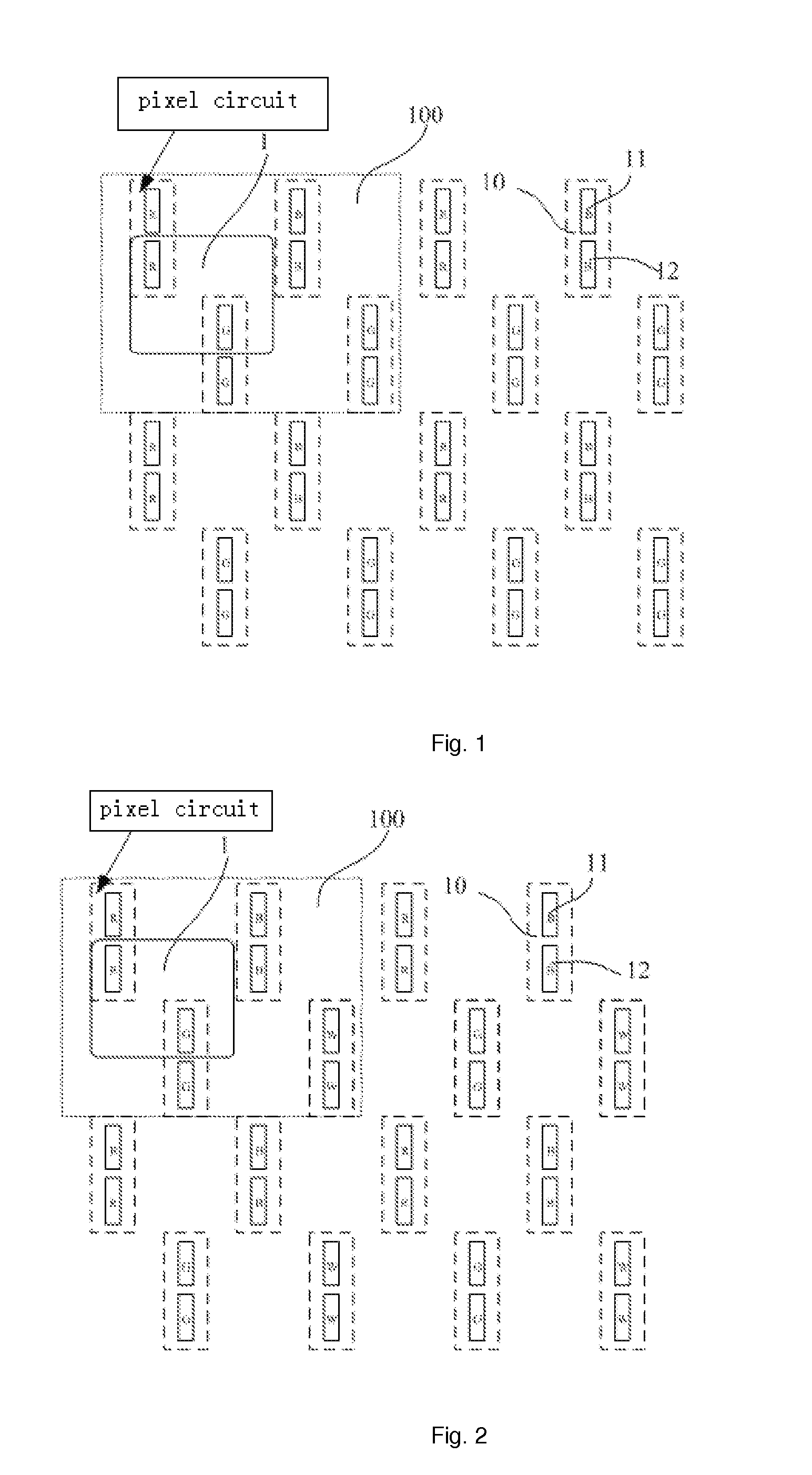

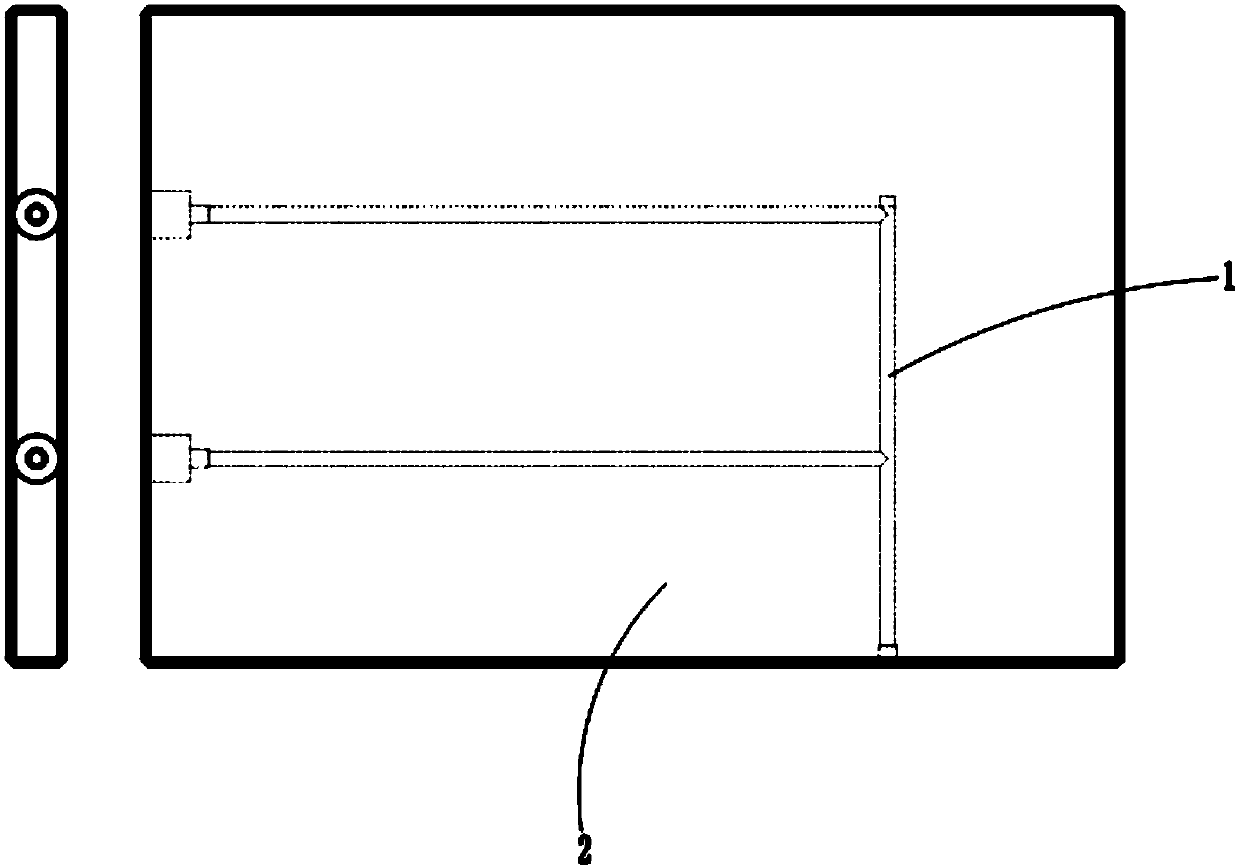

Pixel arrangement method, pixel rendering method and image display device

ActiveCN104680945AReduce power consumptionImprove color gamutCathode-ray tube indicatorsIdentification meansImage resolutionDisplay device

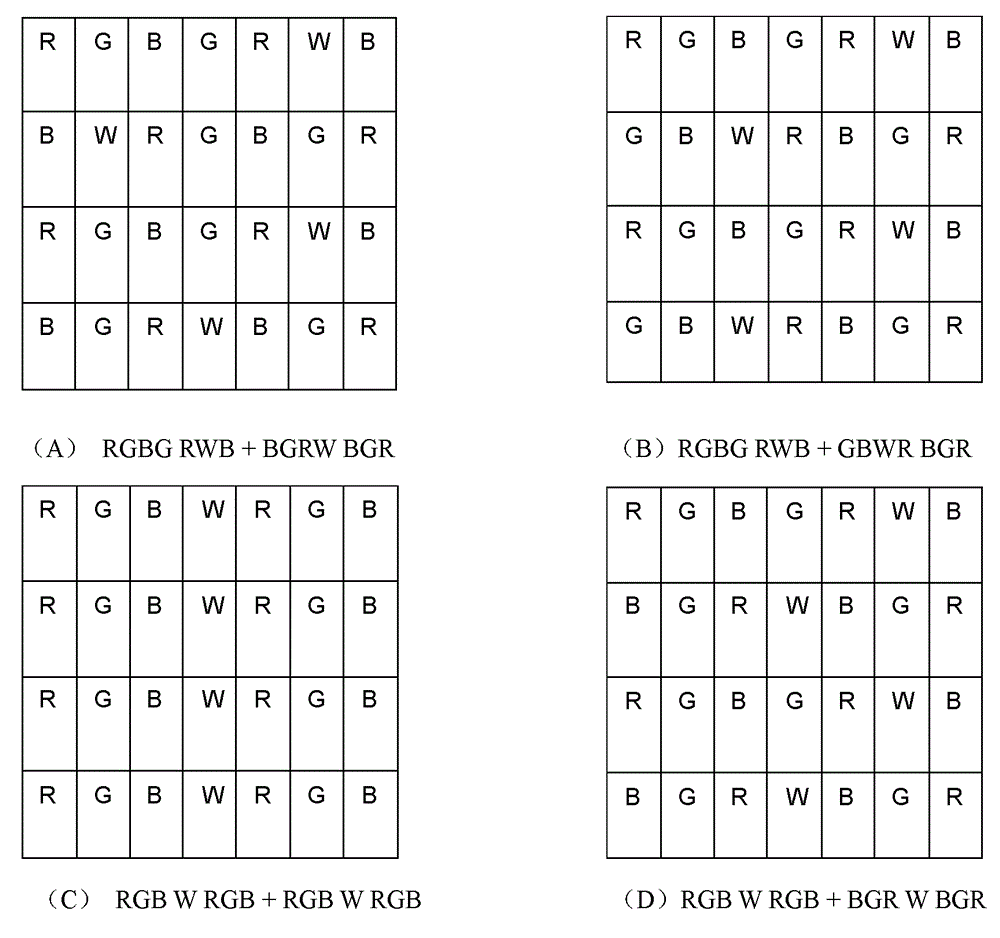

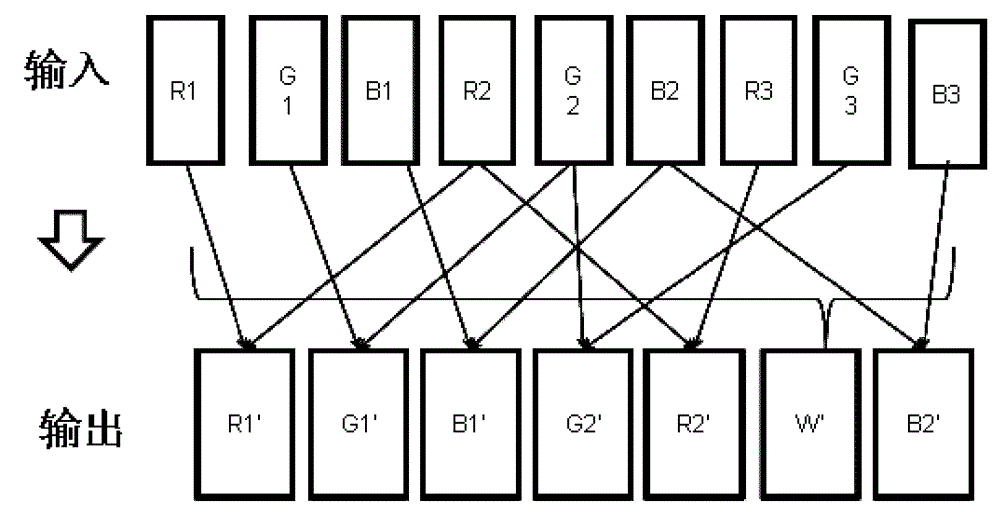

The invention relates to a pixel arrangement method. A first structure unit and a second structure unit form a repeating unit, are respectively repetitively arranged in the horizontal direction, and are arranged at intervals in the vertical direction; the first structure unit and the second structure unit respectively comprise seven sub pixels; the seven sub pixels comprise two first color sub pixels, two second color sub pixels, two third color sub pixels and one fourth sub pixel; or two first color sub pixels, one second color sub pixel, two third color sub pixels and two fourth sub pixels. The invention also relates to a sub pixel rendering method and an image display device. Under the condition of limited process technology, the resolution ratio is improved, and meanwhile, the power consumption is reduced.

Owner:BOE TECH GRP CO LTD

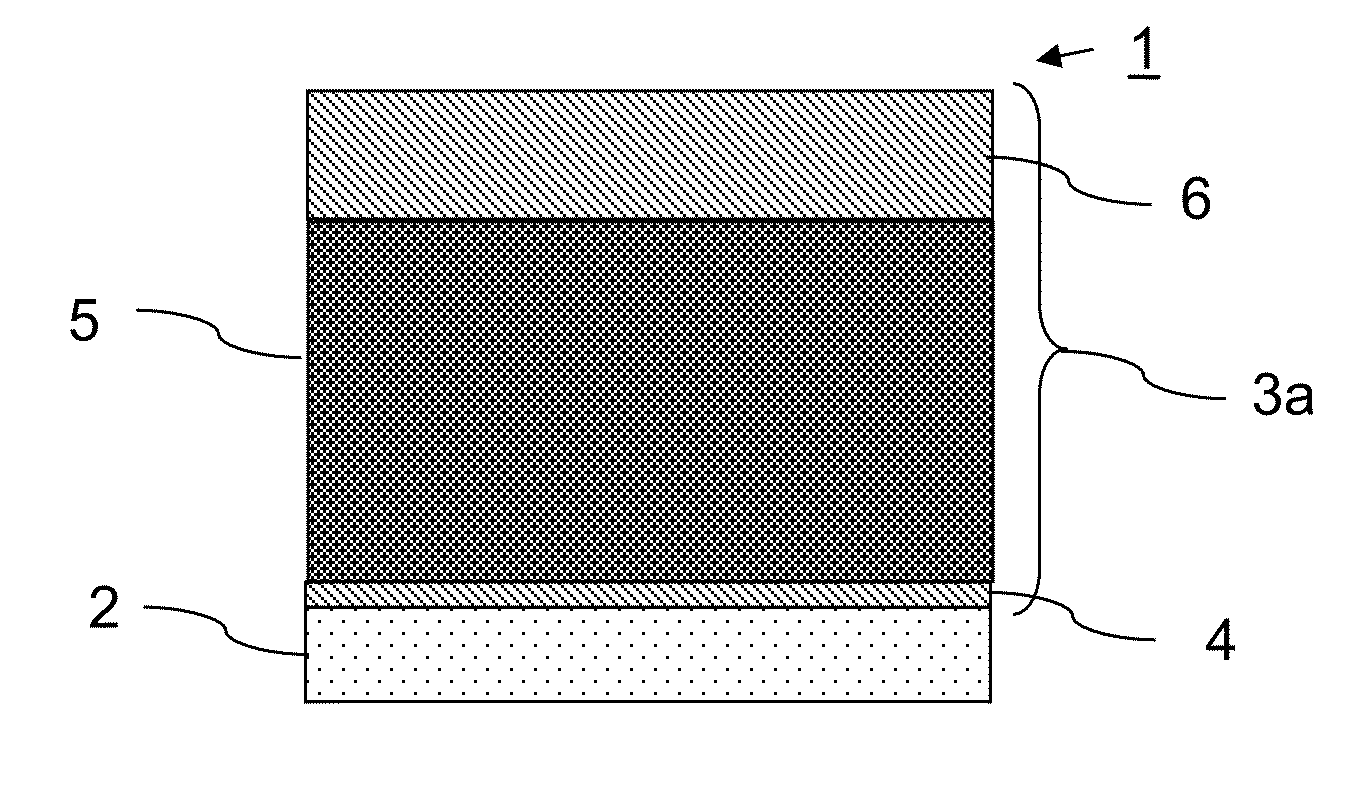

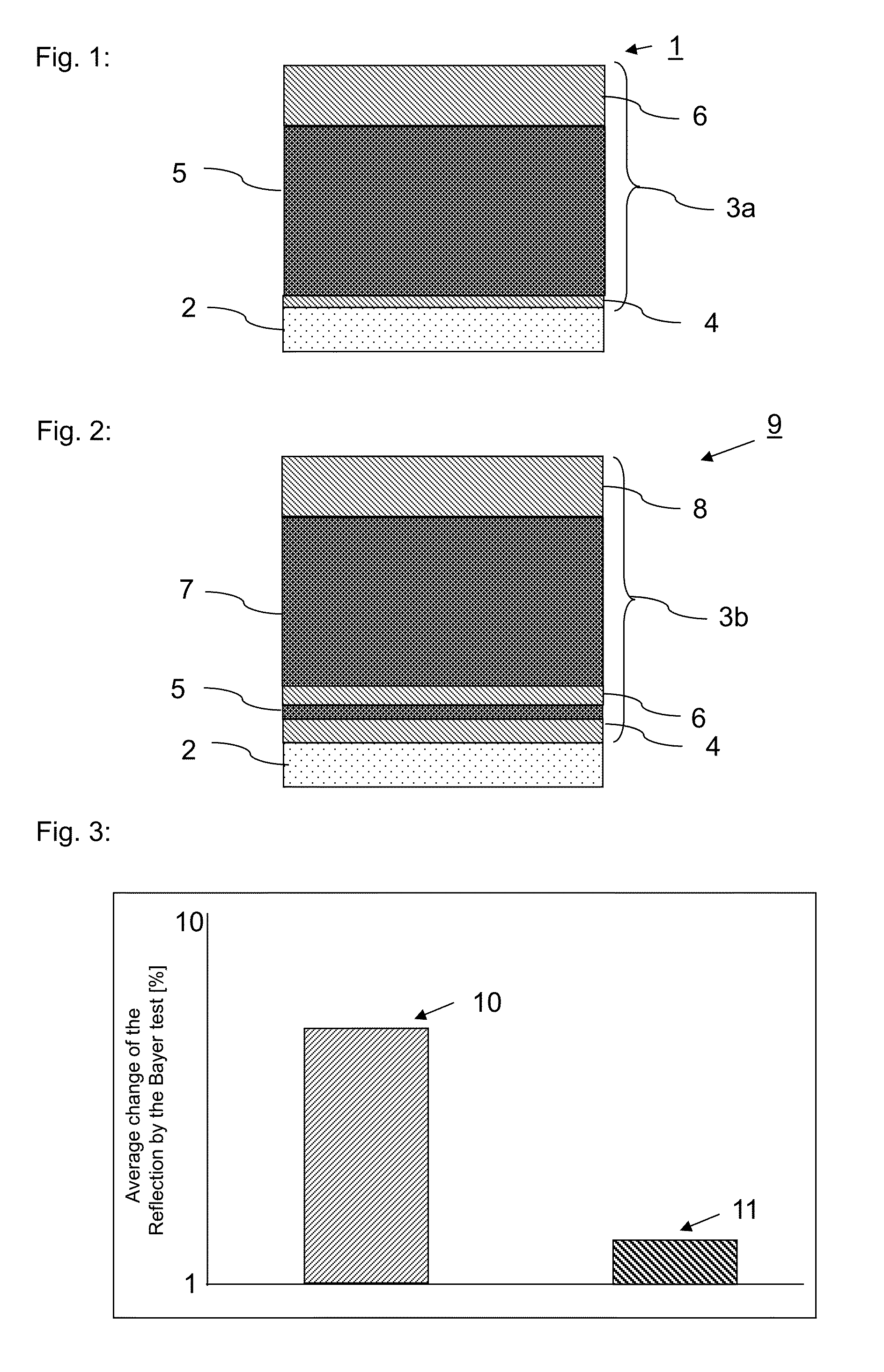

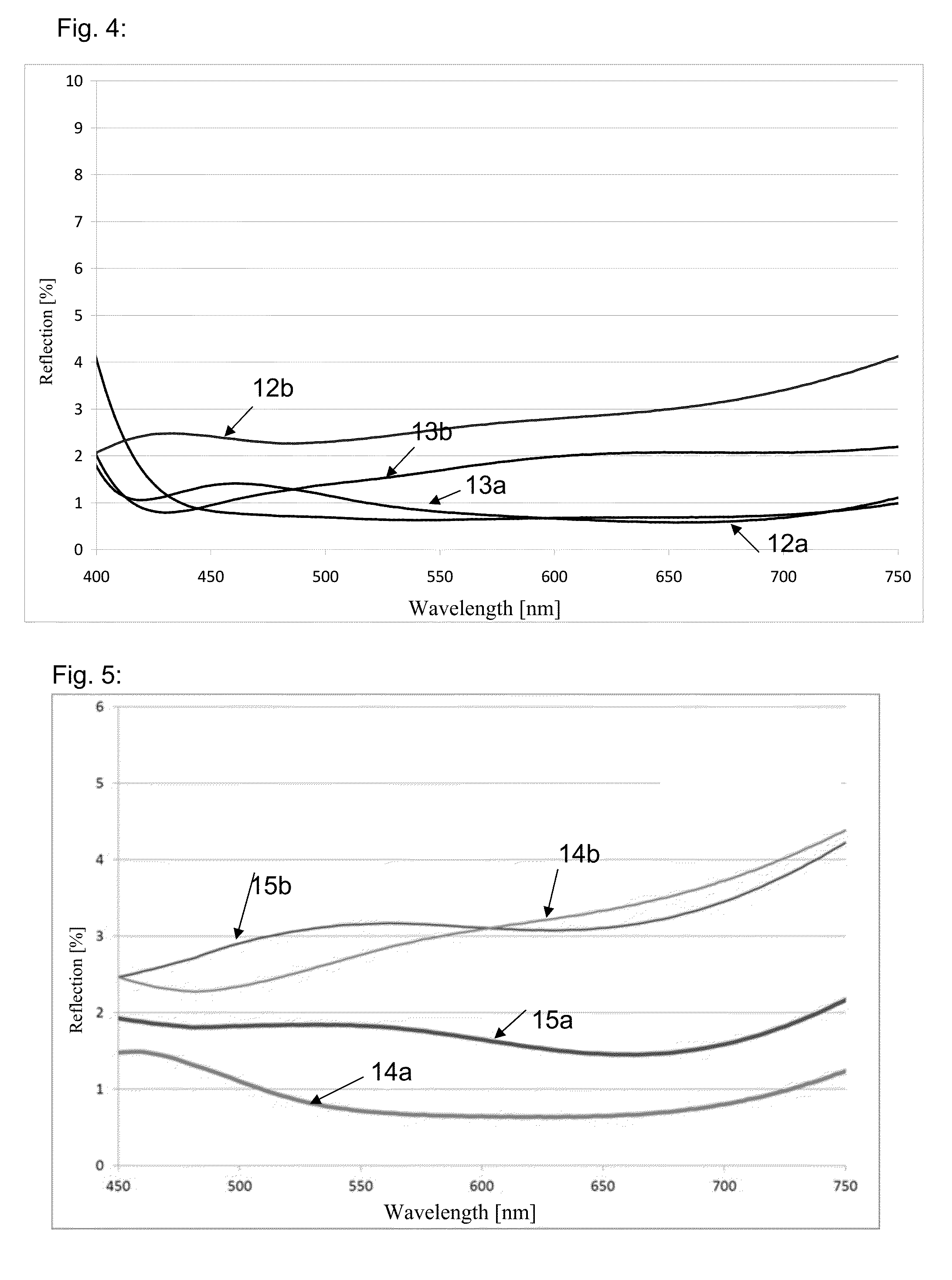

Hard Anti-reflective coatings and manufacturing and use thereof

InactiveUS20150355382A1Crystal formation can be enhancedImprove mechanical propertiesLayered productsVacuum evaporation coatingAnti-reflective coatingCrystal structure

A coated substrate is provided with a scratch-resistant anti-reflective coating. The anti-reflective coating is designed as an optical interference coating that has at least two low refractive index layers and at least one high refractive index layer. The high refractive index layer is a transparent hard material layer and includes crystalline aluminum nitride with a hexagonal crystal structure with a (001) preferred orientation. The low refractive index layers include SiO2. The low refractive index layers and high refractive index layers are arranged alternately.

Owner:SCHOTT AG

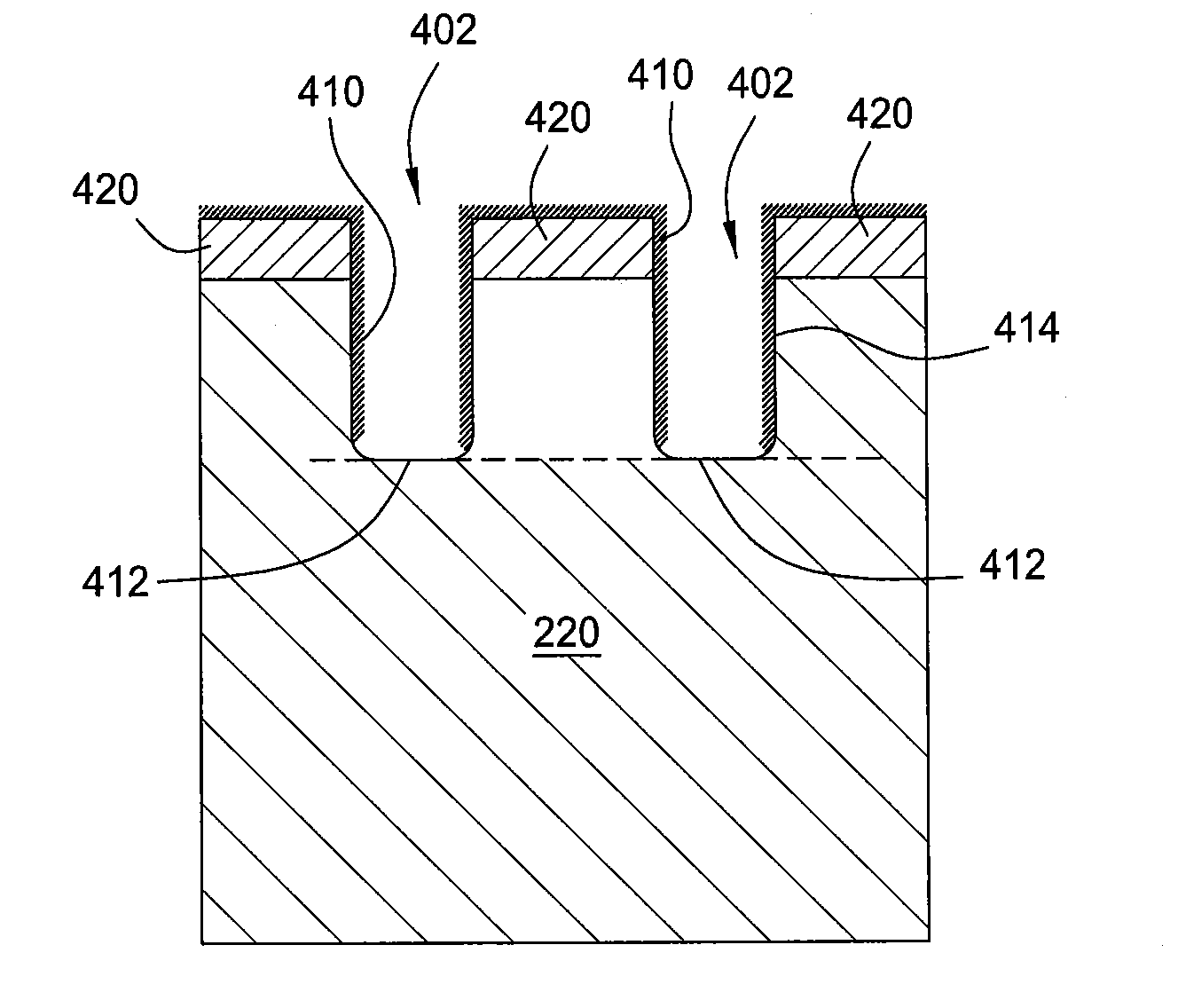

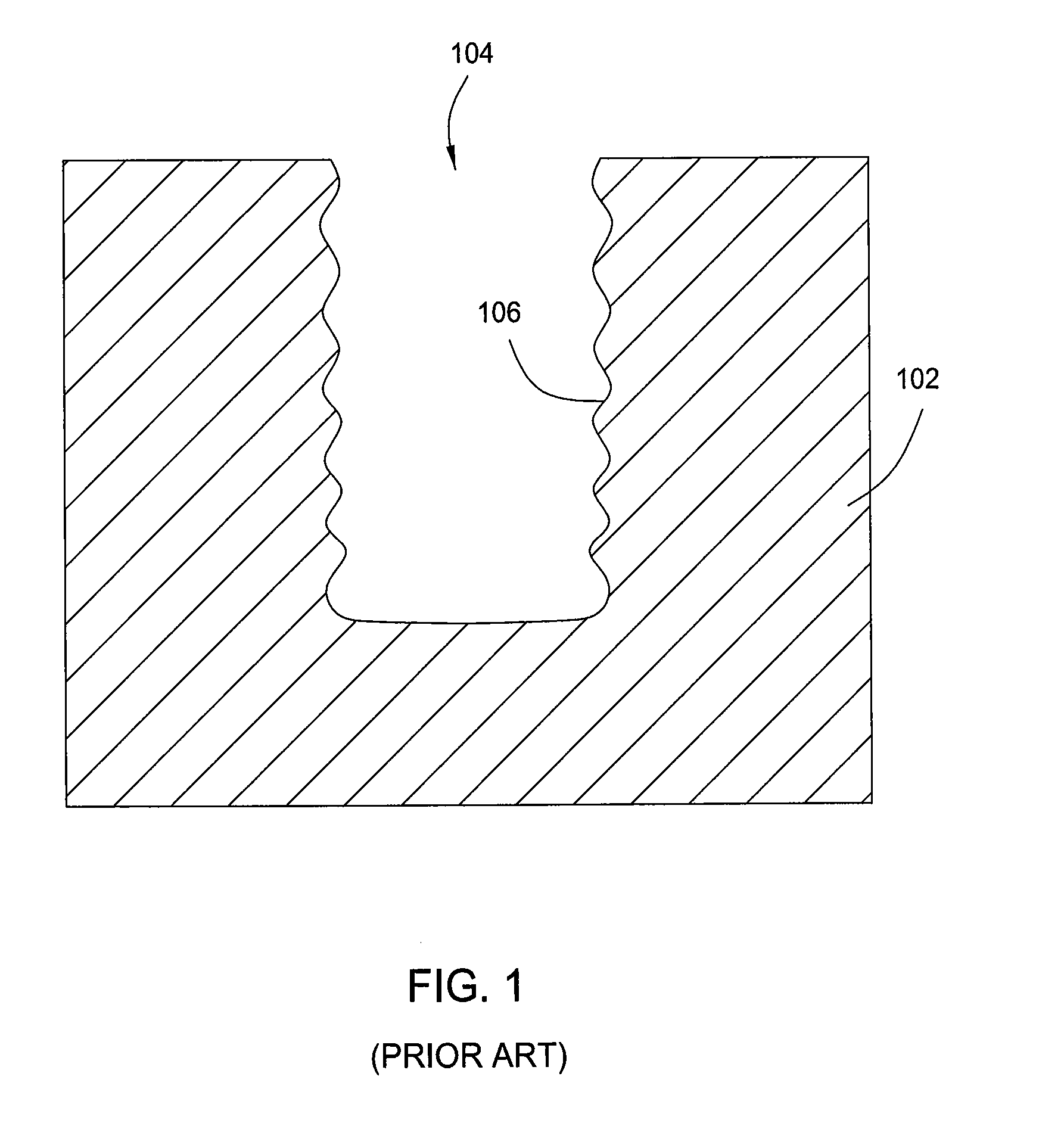

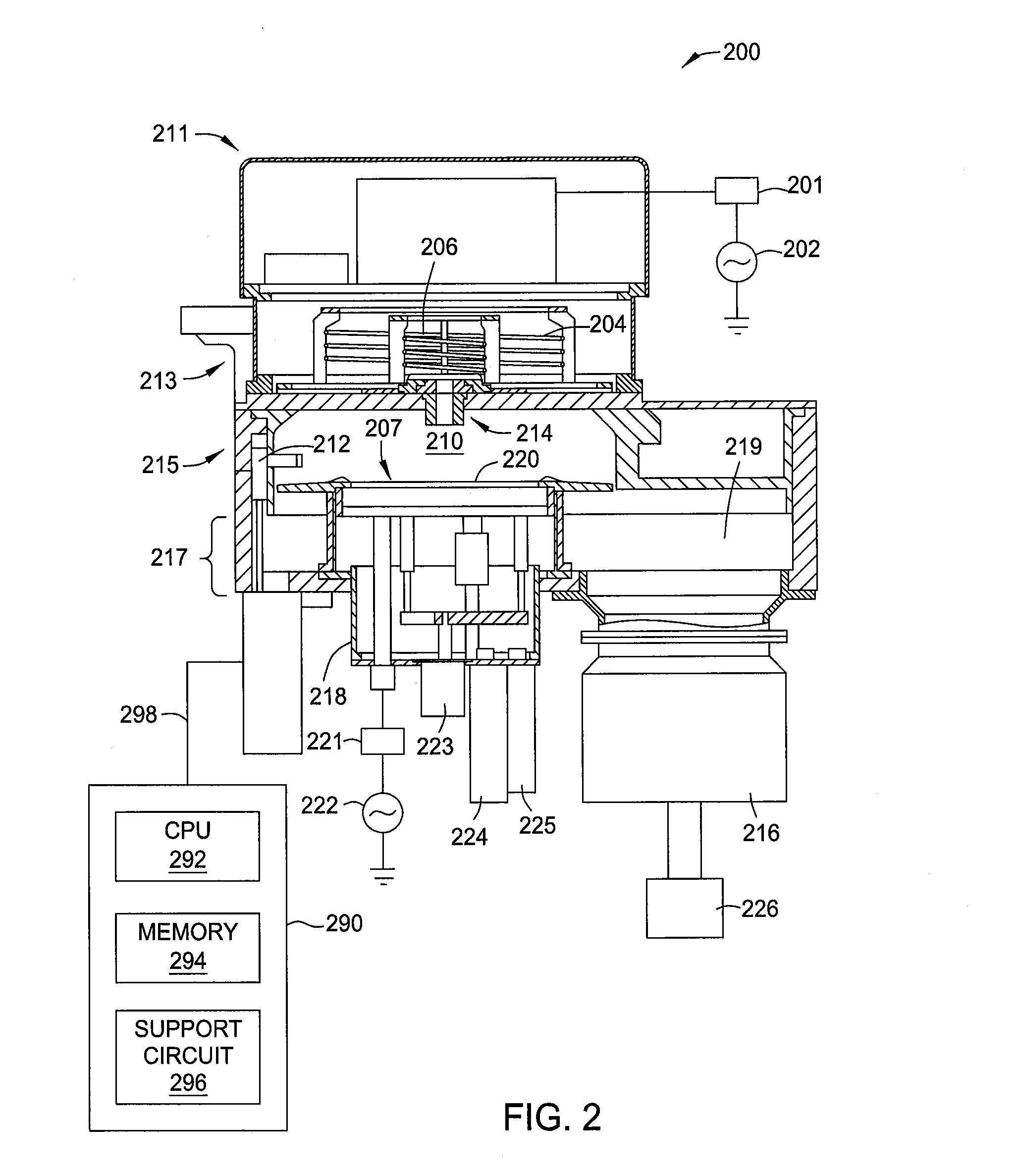

Methods for etching through-silicon vias with tunable profile angles

ActiveUS20120270404A1Enhance the imageReduce process pressureSemiconductor/solid-state device manufacturingPolymer scienceDeposition process

The present disclosure provides methods for etching through-silicon vias (TSVs) in a substrate. The method employs a cyclic polymer passivation layer deposition, depassivation process and plasma etching process. By alternating the duration performed in the plasma etching process and the polymer passivation deposition process during the TSVs formation process, a good sidewall profile and via depth control may be obtained.

Owner:APPLIED MATERIALS INC

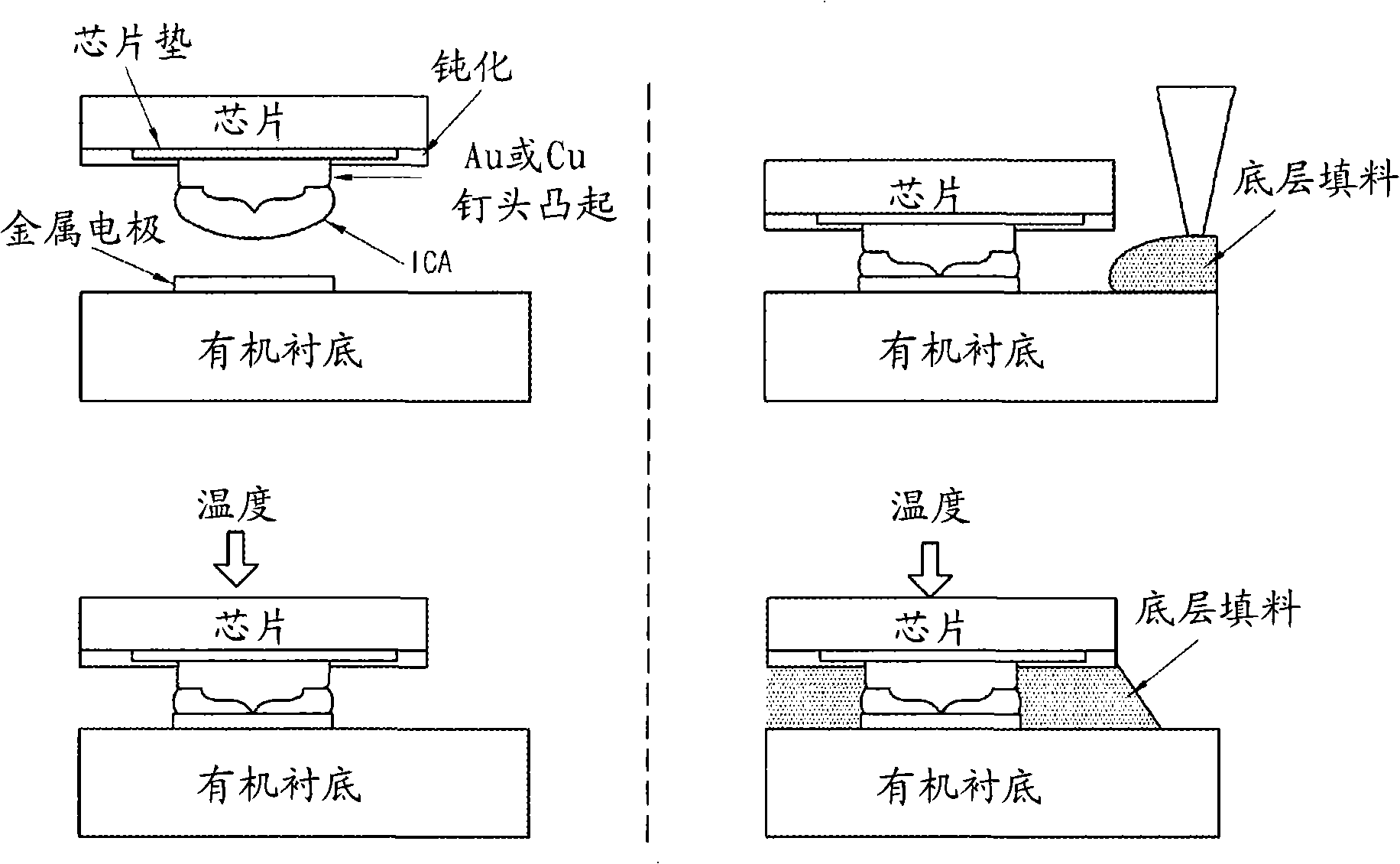

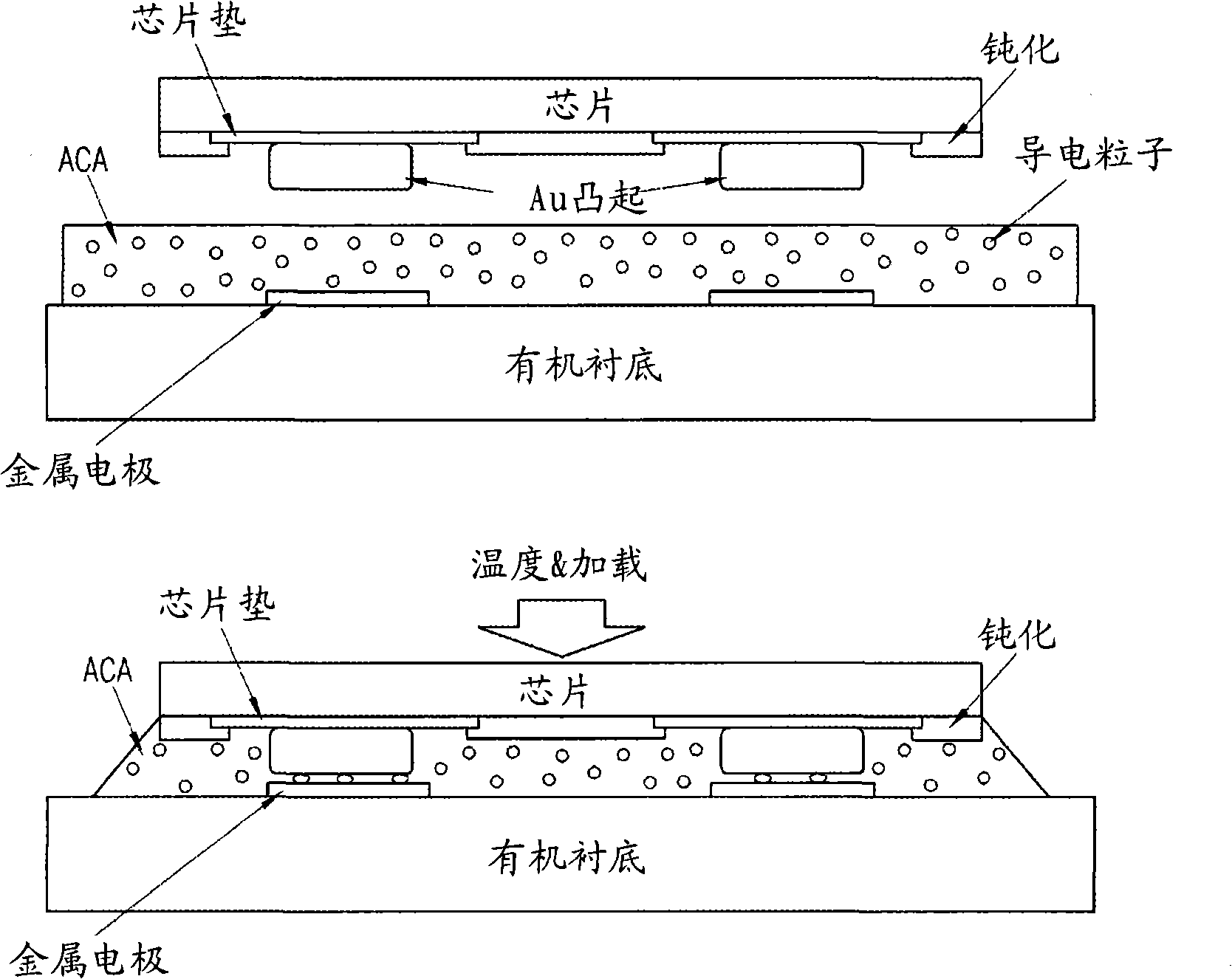

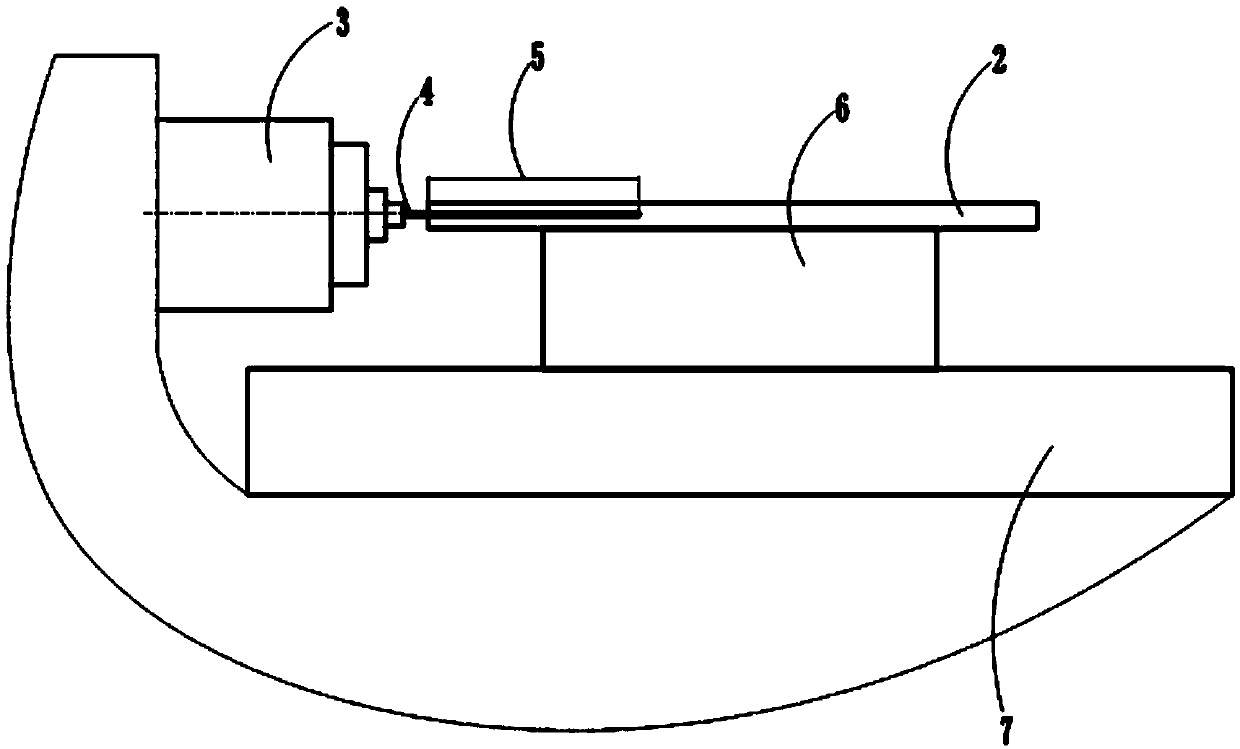

Method for bonding between electrical devices using ultrasonic vibration

ActiveCN101322233AReduce processing pressureIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

The present invention is to provide a method for bonding between electrical devices, including the steps of: aligning electrodes on a bonded area of an upper electrical device and a lower electrical device to be bonded; and curing of adhesives by applying ultrasonic energy to the adhesives between the upper electrical device and the lower electrical device.

Owner:KOREA ADVANCED INST OF SCI & TECH

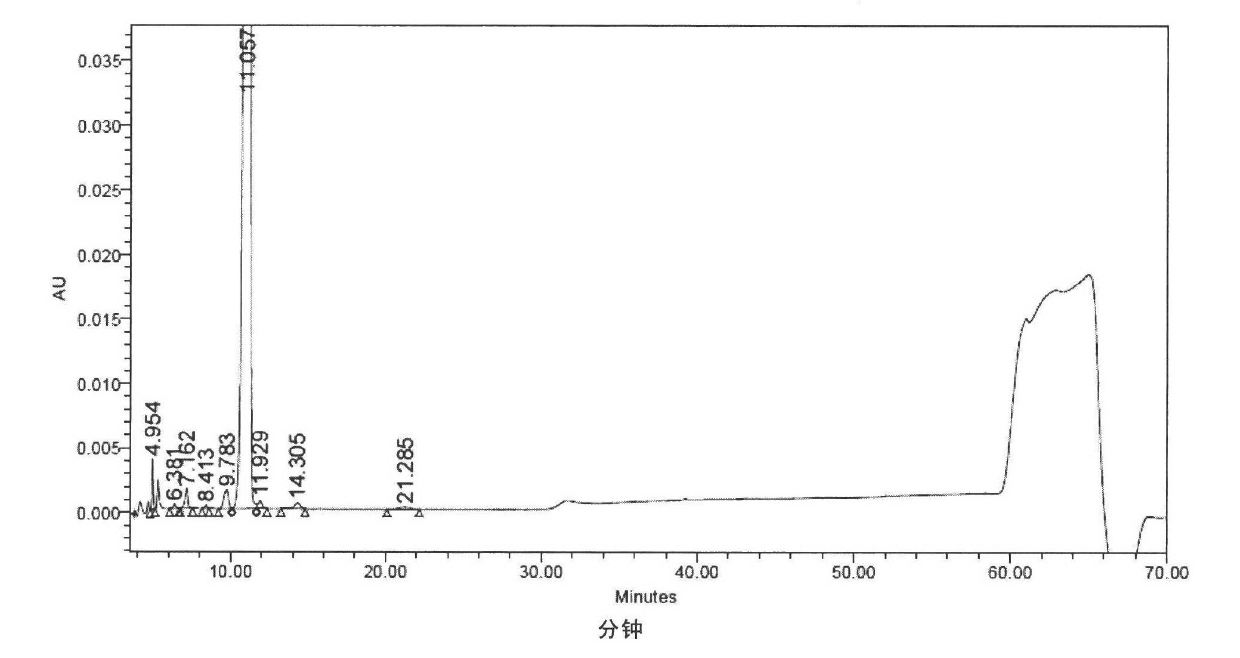

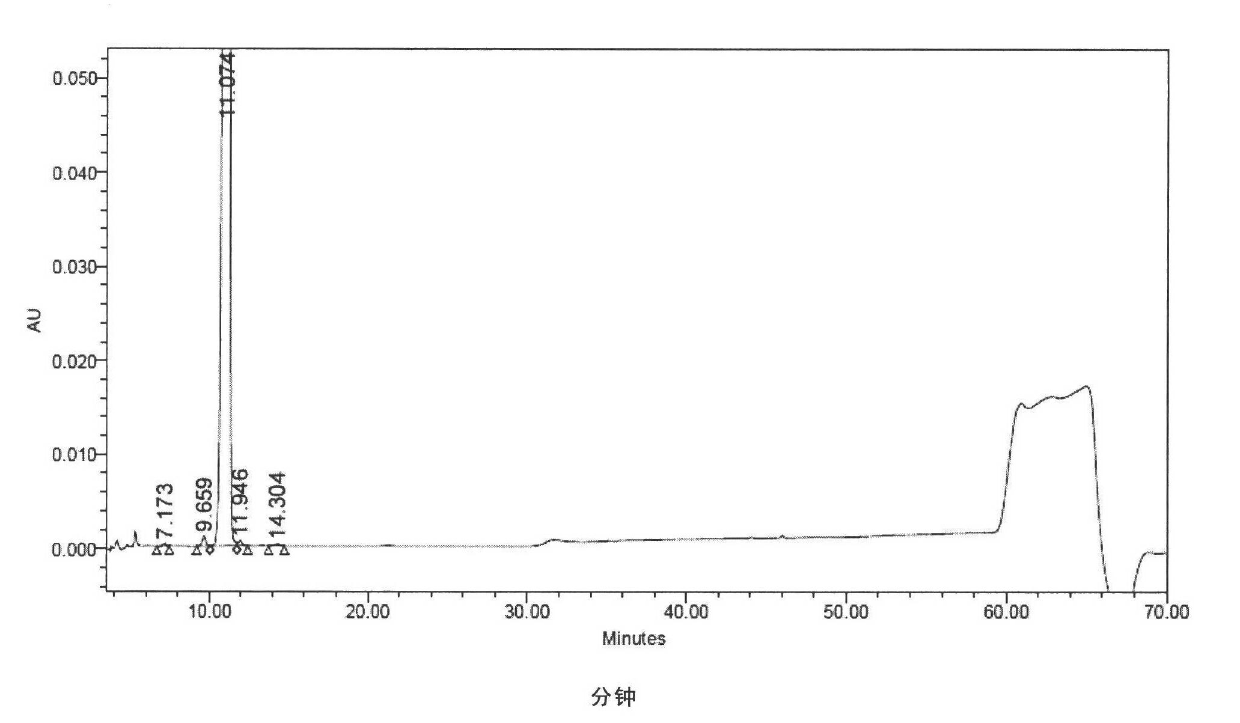

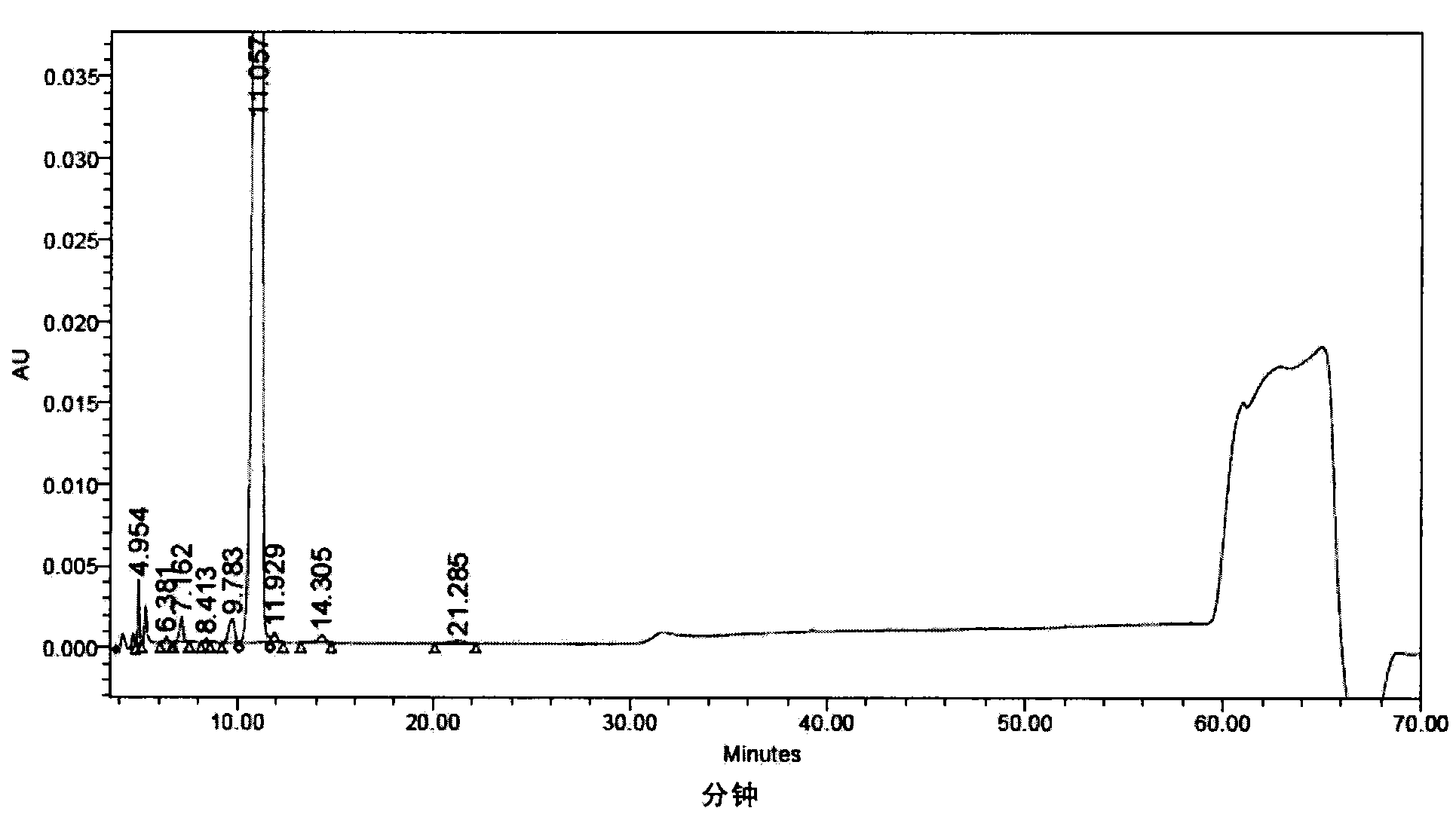

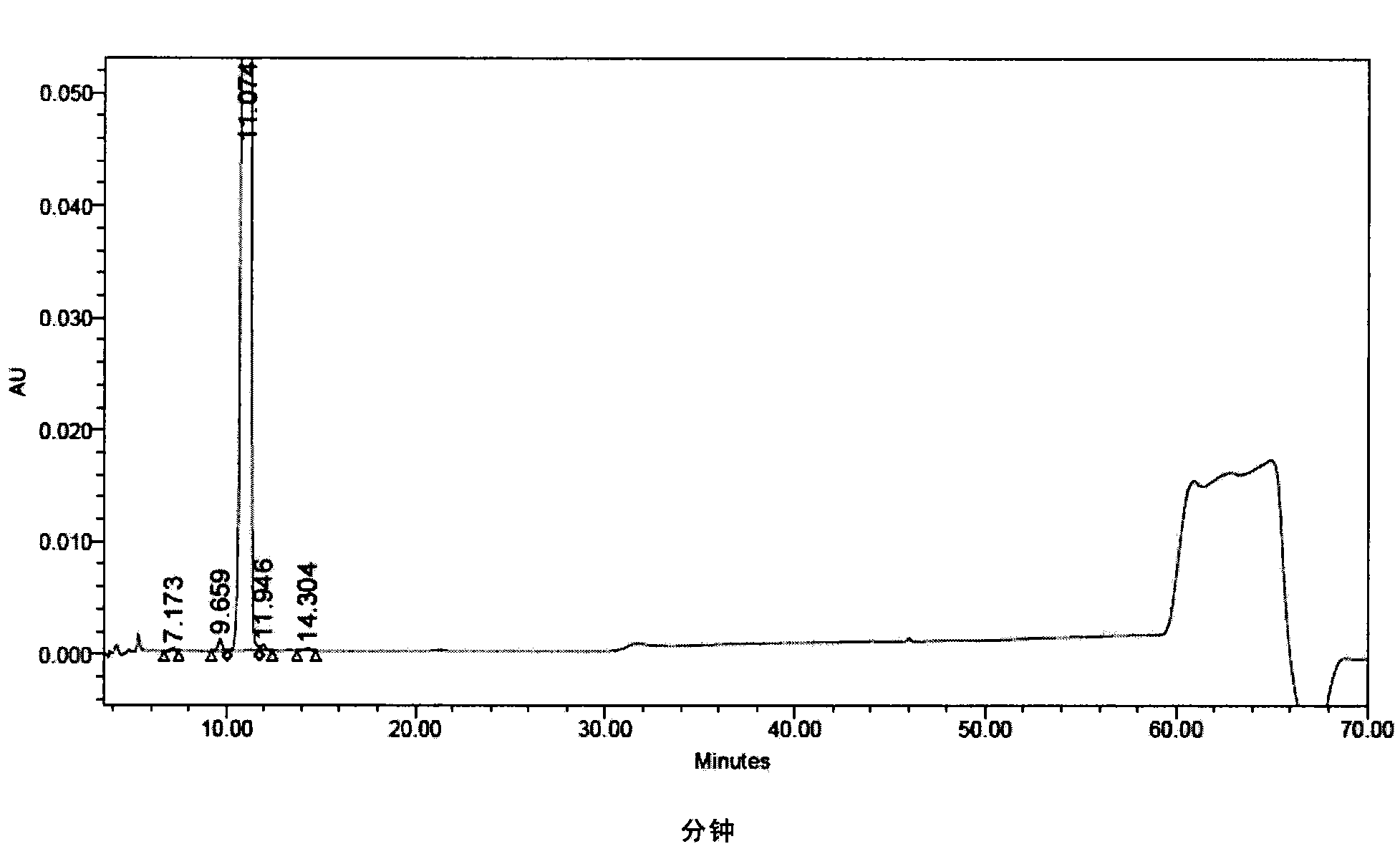

High purity cyclic peptide compound and preparation method and application thereof

ActiveCN102627688AHigh purityLess impuritiesAntimycoticsPeptide preparation methodsChemical structureCyclic peptide

The invention discloses a high purity cyclic peptide compound, and a chemical structure is illustrated in formula I. R represents H or a cation ion capable of forming salt acceptable in pharmacy, and the purity is larger than and equal to 99.0%. A preparation method and application of the high purity cyclic peptide compound are further disclosed.

Owner:SHANGHAI TECHWELL BIOPHARMACEUTICALS CO LTD

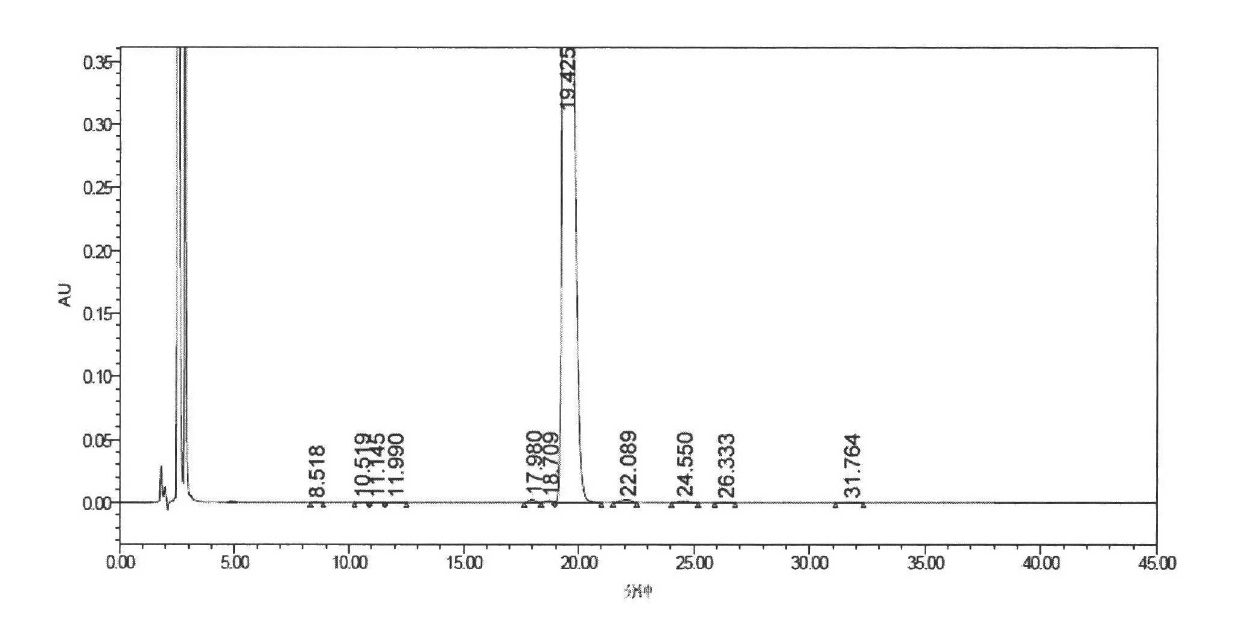

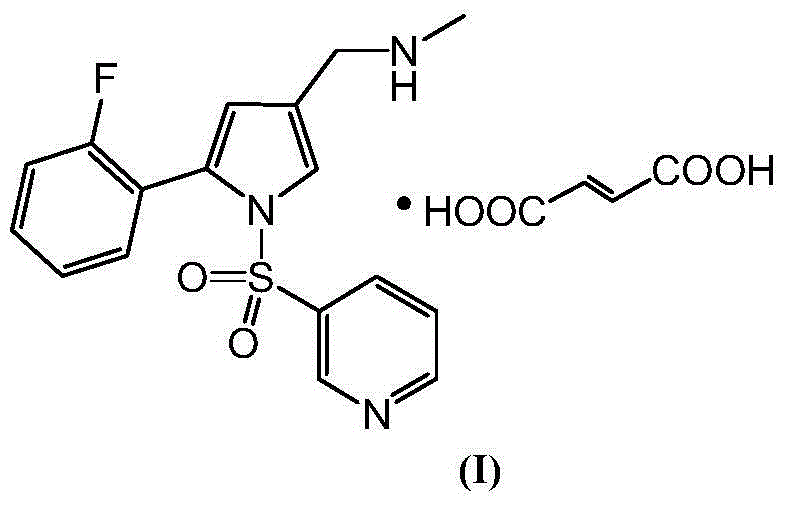

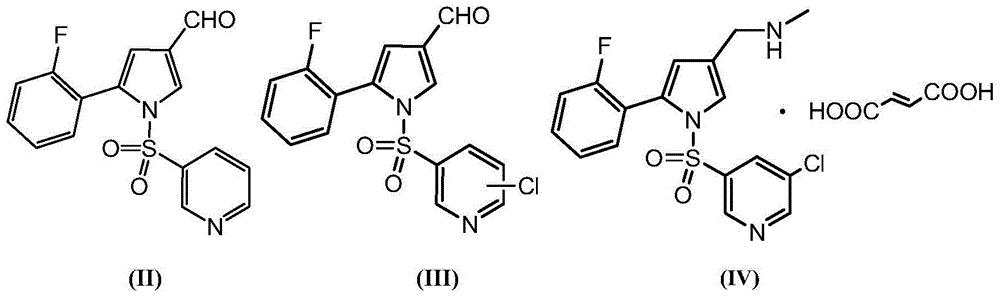

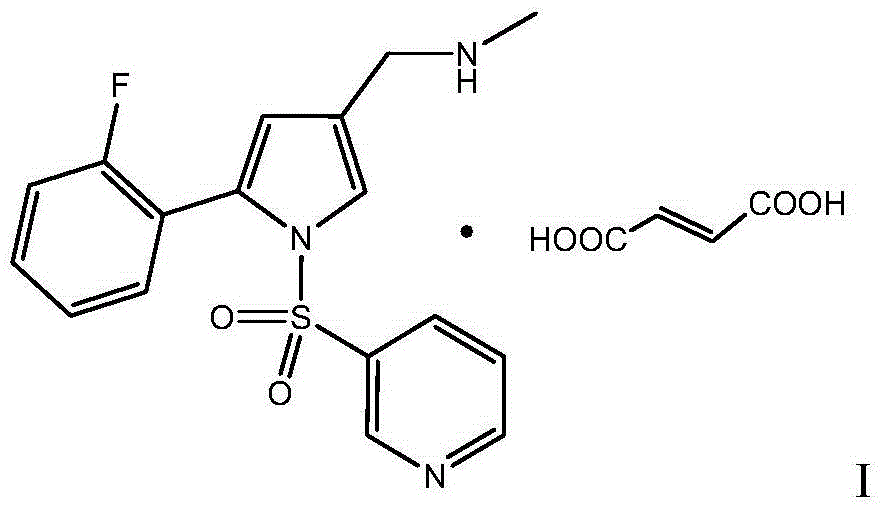

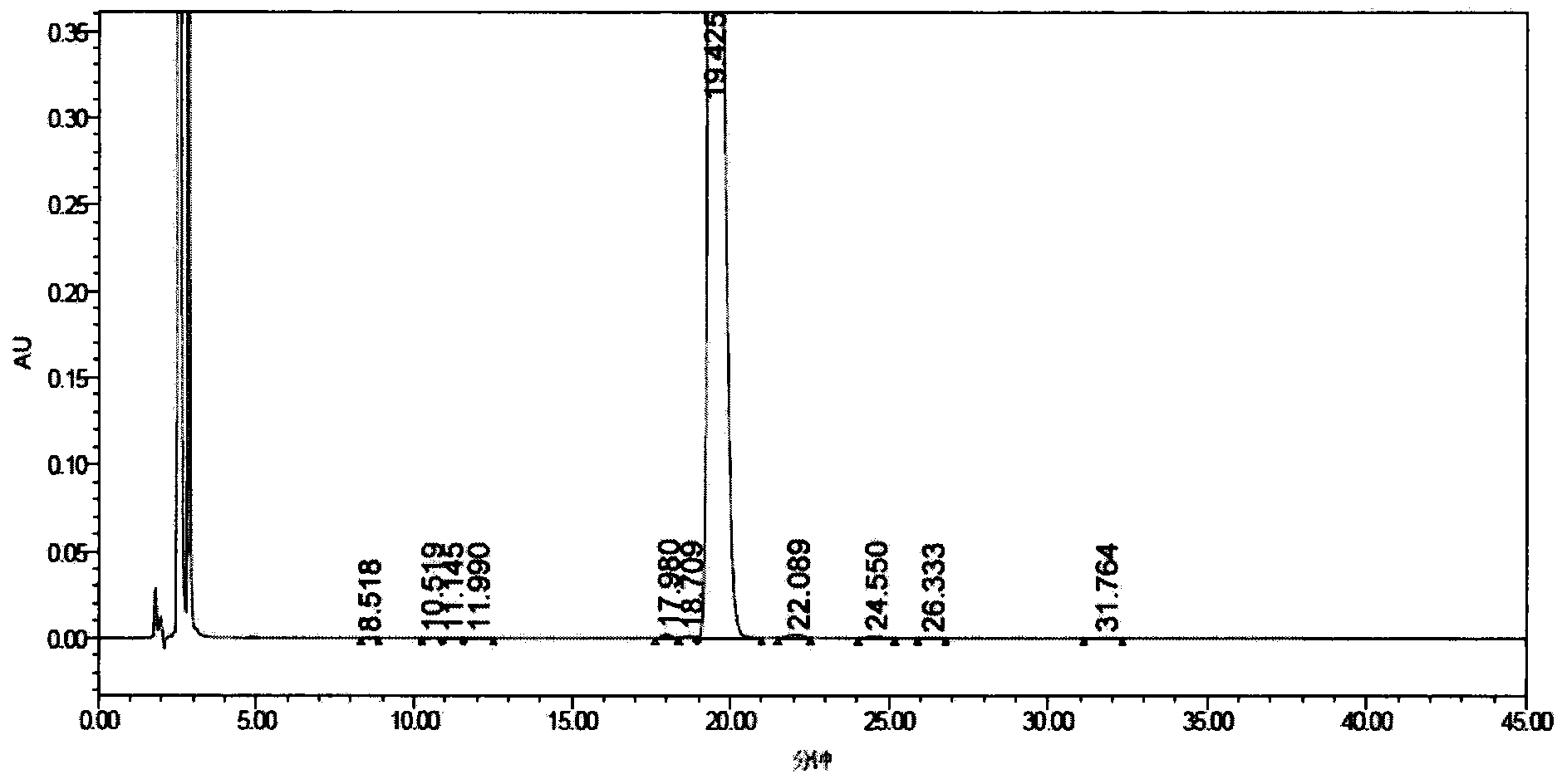

High-purity Vonoprazan Fumarate compound, intermediate and impurity thereof and preparation methods of high-purity Vonoprazan Fumarate compound, intermediate and impurity

ActiveCN104926790AAddressing Purity IssuesHigh purityOrganic chemistryCombinatorial chemistryStructural formula

The invention provides a high-purity Vonoprazan Fumarate compound and a preparation method thereof. The purity of the Vonoprazan Fumarate compound shown in structural formula I is higher than 99.6%, and the content of an impurity compound shown in formula IV is lower than 0.1%. The invention further provides an intermediate of the high-purity Vonoprazan Fumarate compound, a preparation method of the intermediate, the Vonoprazan Fumarate impurity compound and a preparation method thereof. Vonoprazan Fumarate products are high in purity and little in impurity content, and the preparation methods are simple and easy to operate, low in cost and little in energy consumption and are of great significance to industrial production.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

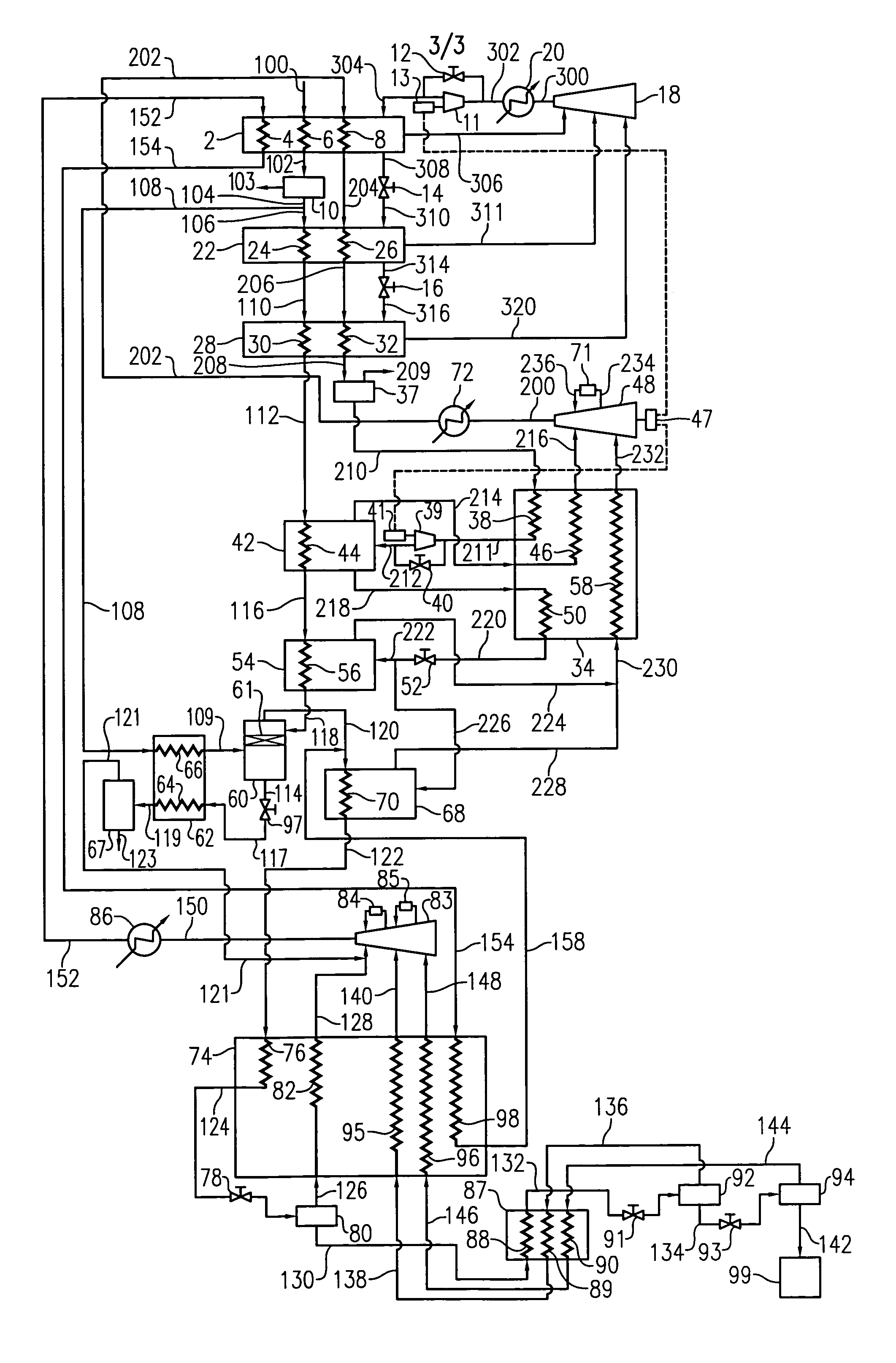

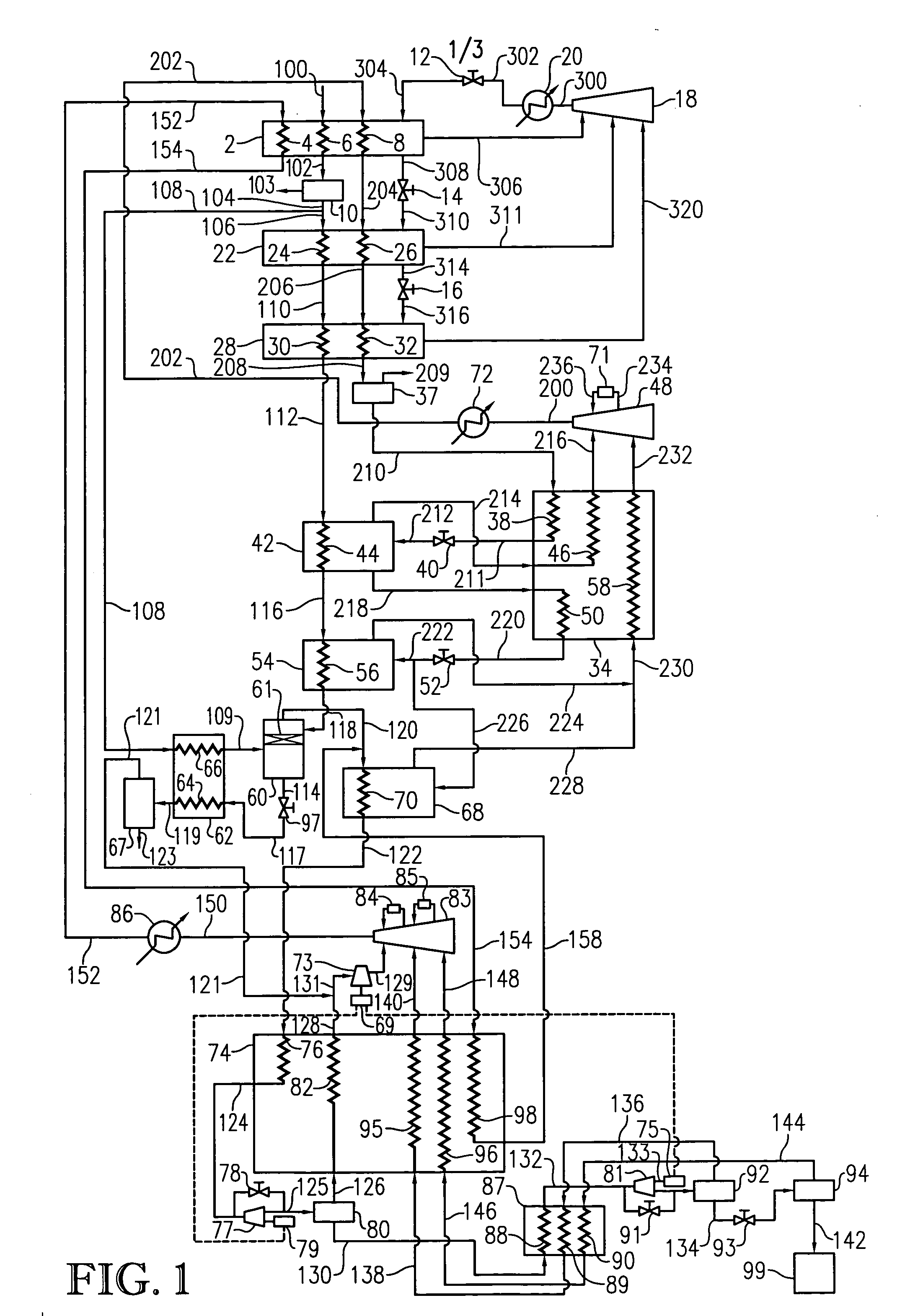

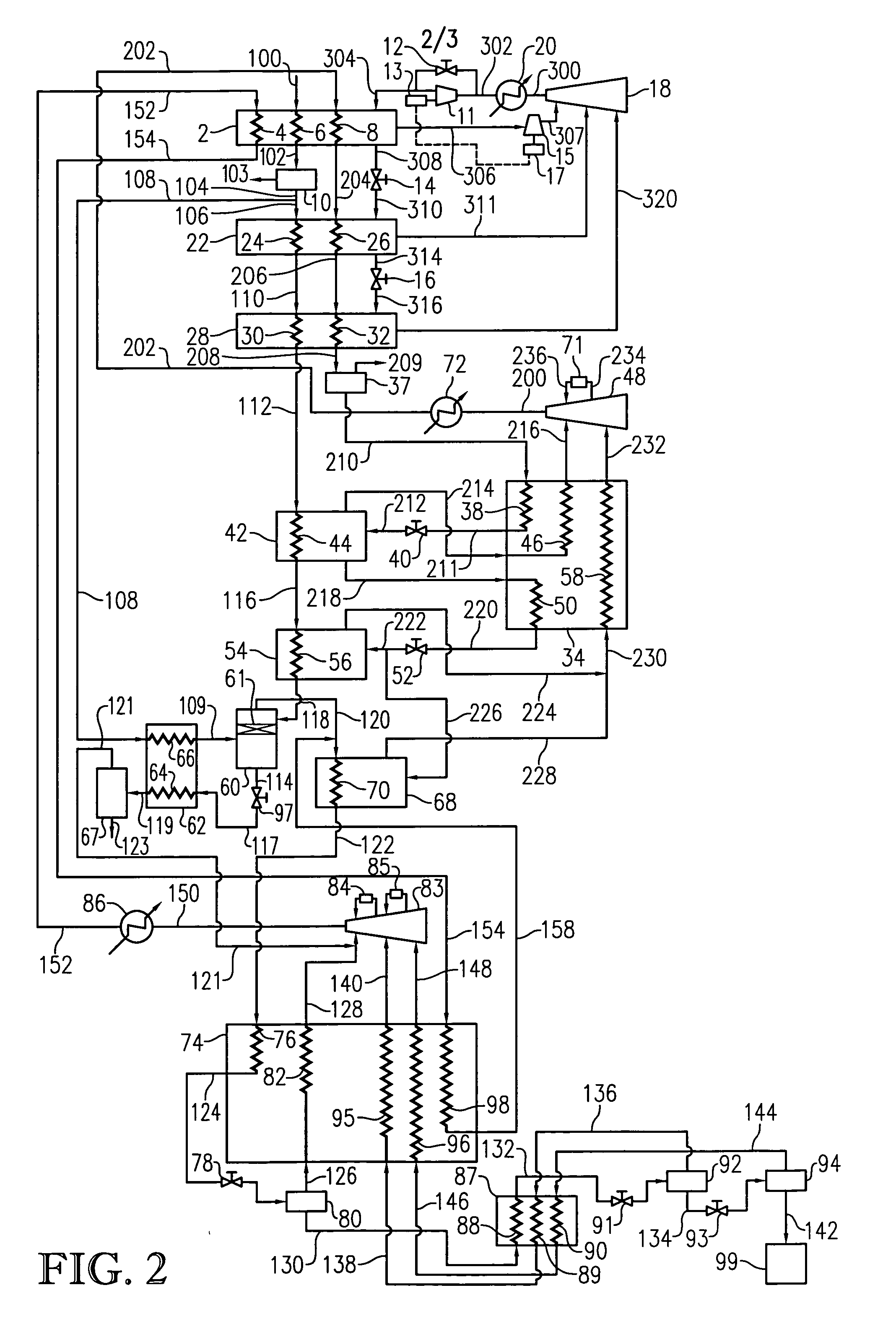

Optimized LNG system with liquid expander

ActiveUS20070113584A1Relieve pressureImprove facilitiesSolidificationLiquefactionElectricityProcess engineering

A process and apparatus for the liquefaction of natural gas including at least one liquid expander for providing expansion of a high-pressure stream and powering a generator capable of producing electricity to be used to drive a compressor located elsewhere in the liquefaction apparatus. Particularly, a liquid expander is used to expand a high-pressure refrigerant stream and to power an electrical generator. The electricity provided by the generator can be used to power a compressor located in the same or a different refrigeration cycle as the liquid expander.

Owner:CONOCOPHILLIPS CO

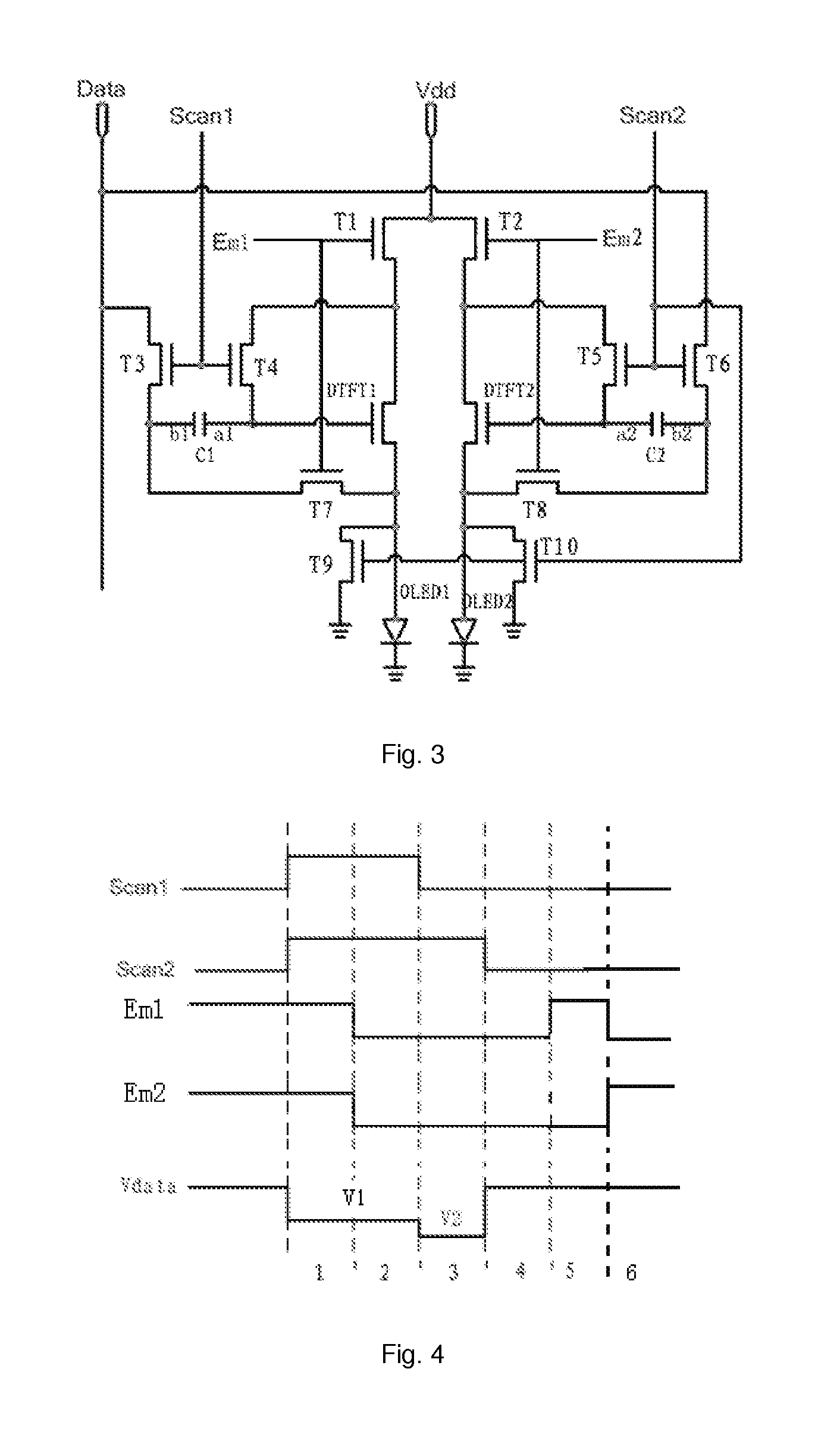

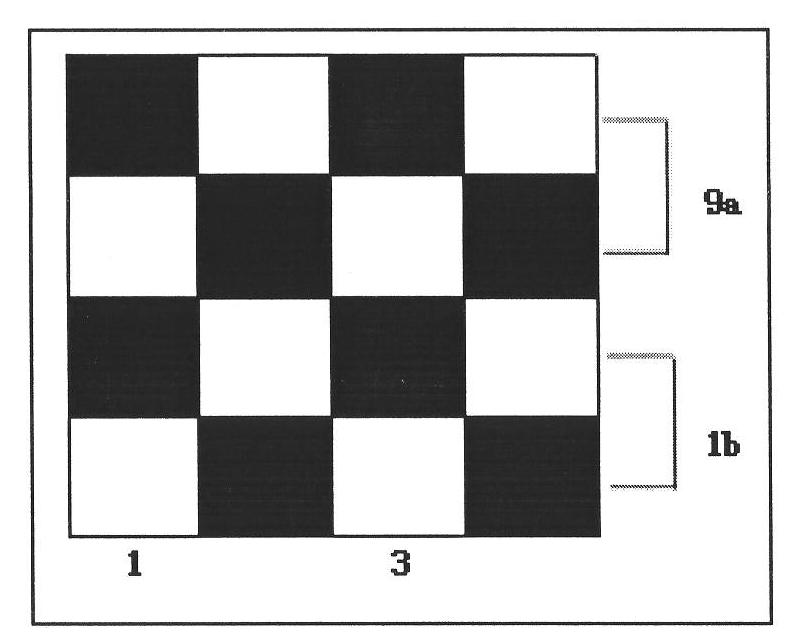

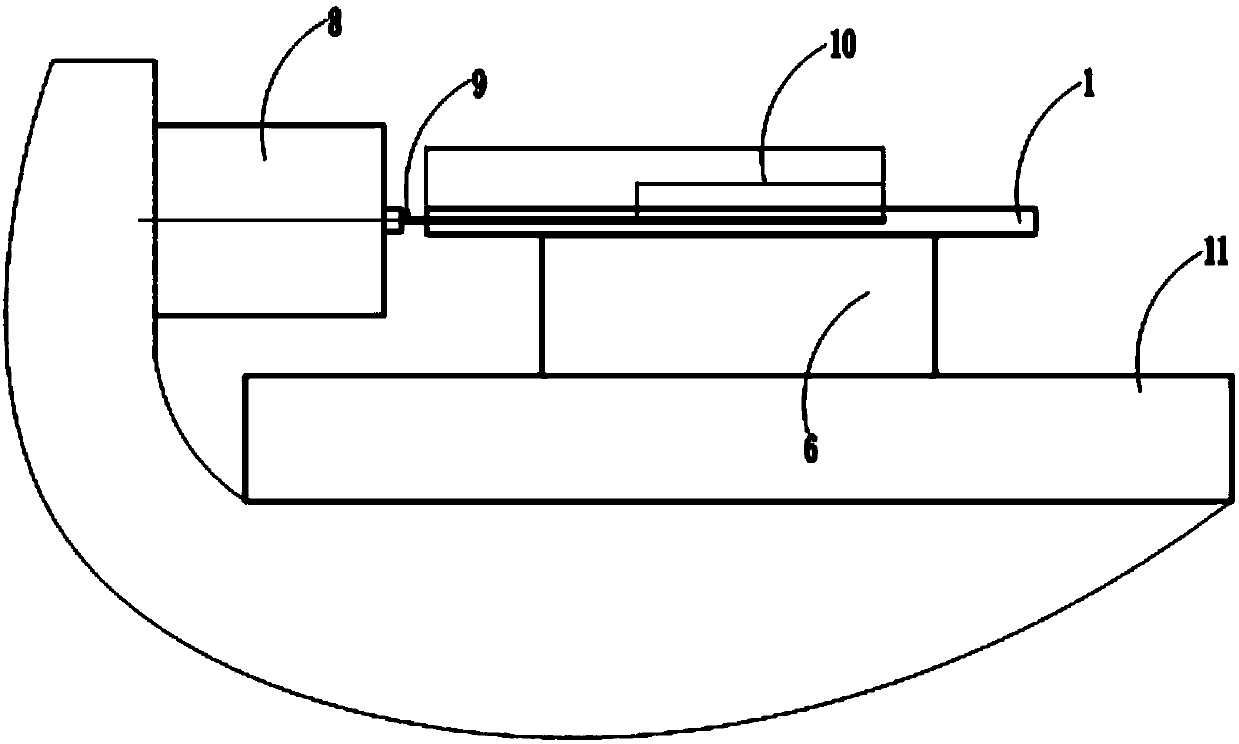

Array substrate and driving method thereof, display panel and display device

ActiveUS20160335937A1Reduce process pressureLow production costCathode-ray tube indicatorsNon-linear opticsDisplay deviceElectrical and Electronics engineering

The invention provides an array substrate and a driving method thereof, a display panel and a display device. The array substrate comprises a plurality of circulating units and a plurality of pixel circuits. Each circulating unit consists of four sub-pixel units located in four columns and two rows, sub-pixel units in any two adjacent columns are located in different rows and have different colors, and sub-pixel units in at least one row have different colors. Each sub-pixel unit is connected to one pixel circuit, and each sub-pixel unit comprises a first sub-pixel and a second sub-pixel located in the same column and having the same color. The pixel circuit is configured to drive the first sub-pixel when a first frame picture is displayed, and to drive the second sub-pixel when a second frame picture is displayed.

Owner:BOE TECH GRP CO LTD

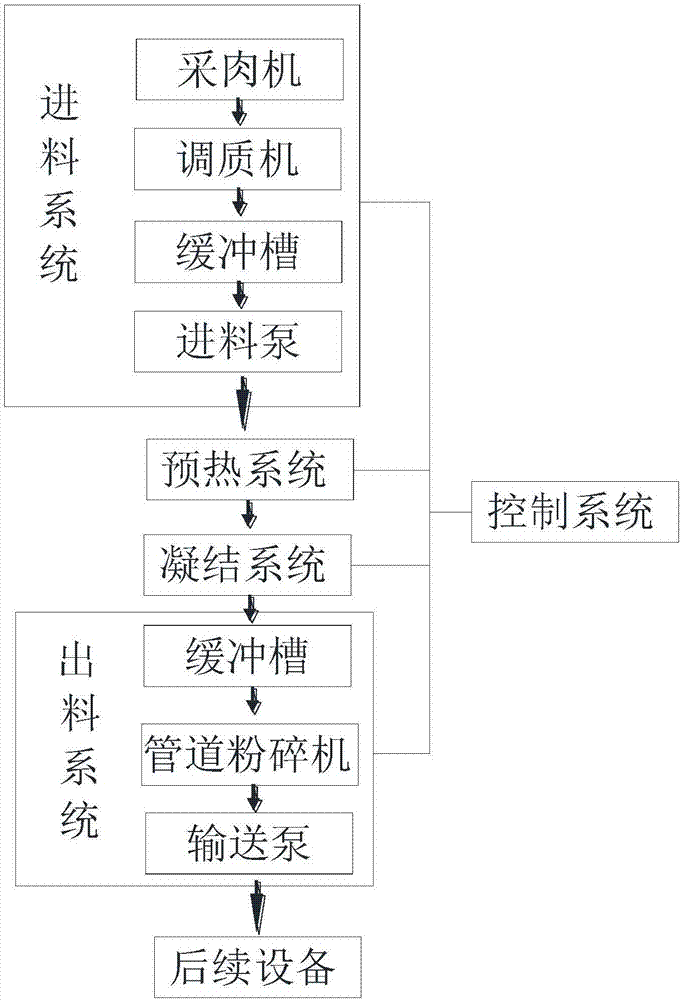

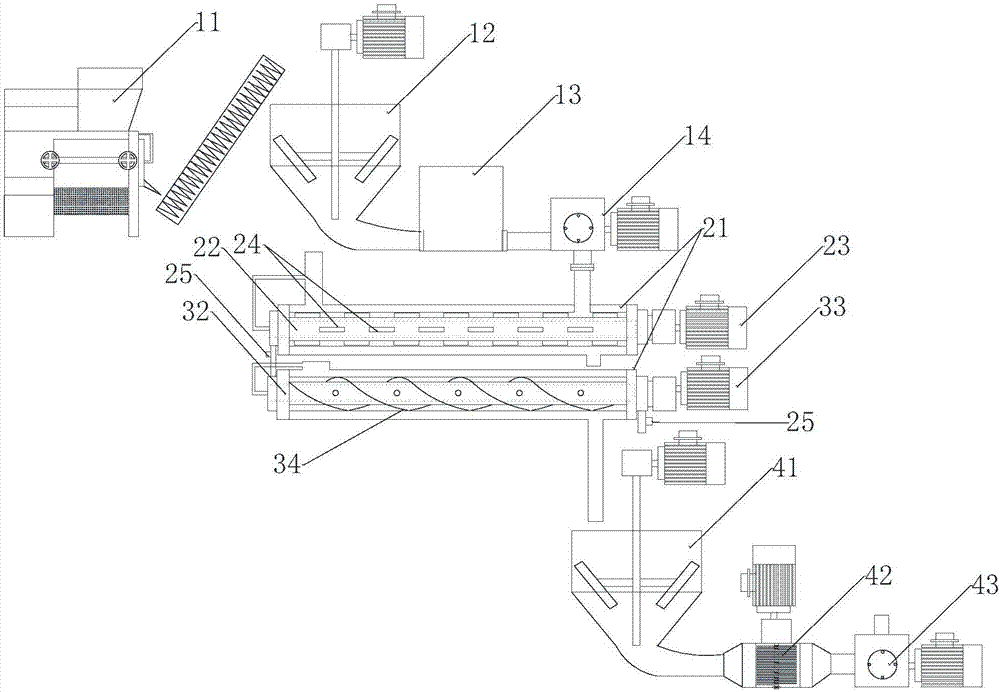

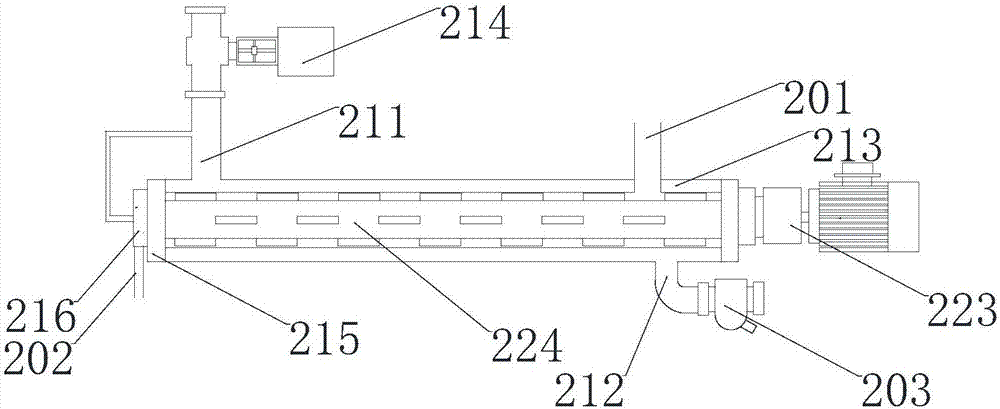

Device for quickly cooking euphausia superba

The invention relates to aquatic product processing equipment, in particular to a device for quickly cooking euphausia superb. The device comprises a feeding system, a preheating system, a coagulating system, a discharging system and a control system. The feeding system comprises a flesh separator, a regulating machine, a buffer tank and a feeding pump. The preheating system comprises a steam sleeve, a preheating spindle, a spindle motor, a scraper and a temperature sensor. The coagulating system comprises a steam sleeve, a steam direct injection spindle, a scraper motor, a screw scraper and a temperature sensor. The discharging system comprises a buffer tank, a pipeline grinder and a delivery pump. The device has advantages that by arrangement of the external heating sleeve and the steam heating spindle with a self-cleaning function and adoption of hermetical pipeline type pumping of materials, quickness and high efficiency in cooking are realized; by adoption of the device, efficiency in cooking of euphausia superb can be improved, euphausia superb cooking time is shortened, recovery of myogen in euphausia superb is improved, and yield and quality of euphausia superb powder are increased.

Owner:OCEAN UNIV OF CHINA

Low pressure herbal material blasting pulp making process

InactiveCN1384241AReduce process pressureReduce the temperaturePulping with inorganic basesPre treatmentChemical pulp

The low pressure herbal raw material blasting and pulp making process includes raw material pre-treatment of adding alkali, sodium sulfide and assistant to herbal raw material with stirring at normaltemperature to 90 deg.c high temperature and high pressure treatment of the material in a blast tank at 110-210 deg.c and 0.5-1.9 MPa for 1-15 min; and blowing to blast the material instantaneously to a receiving container. The herbal pulp thus produced has strength equivalent to that of chemical pulp and the present invention has high yield, low power consumption, low cost and high pulp whiteness.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for producing woven weftwise hollow fabric

InactiveCN102011240AAchieve the effect of weft hollowing outReduce dosageDry-cleaning apparatus for textilesSwivel-woven fabricsStop timeEngineering

The invention provides a method for producing a woven weftwise hollow fabric, which comprises the process steps of grey cloth weaving, singeing and desizing, scouring and bleaching, caustic soda mercerizing, whitening or dyeing, tentering and setting, and preshrinking in turn, and is characterized in that: a grey cloth washing step is performed between the grey cloth weaving step and the singeing and desizing step; and in the grey cloth weaving step, a certain amount of vinylon filaments are introduced according to weft flower row space when a loom moves to insert wefts. Because the certain amount of vinylon filaments are introduced according to weft lower row space when the loom moves to insert wefts in a grey cloth weaving step, a warpwise and weftwise hollow effect is well achieved without modifying the equipment; in the grey cloth washing step, the vinylon filaments are dissolved initially for reducing the processing load in the subsequent steps and reducing dye and steam consumption; and thus, production cost is reduced, the stop time of equipment for changing processes is reduced, production efficiency is improved, the fabric produced is beautiful, comfort and highly breathable.

Owner:鲁丰织染有限公司

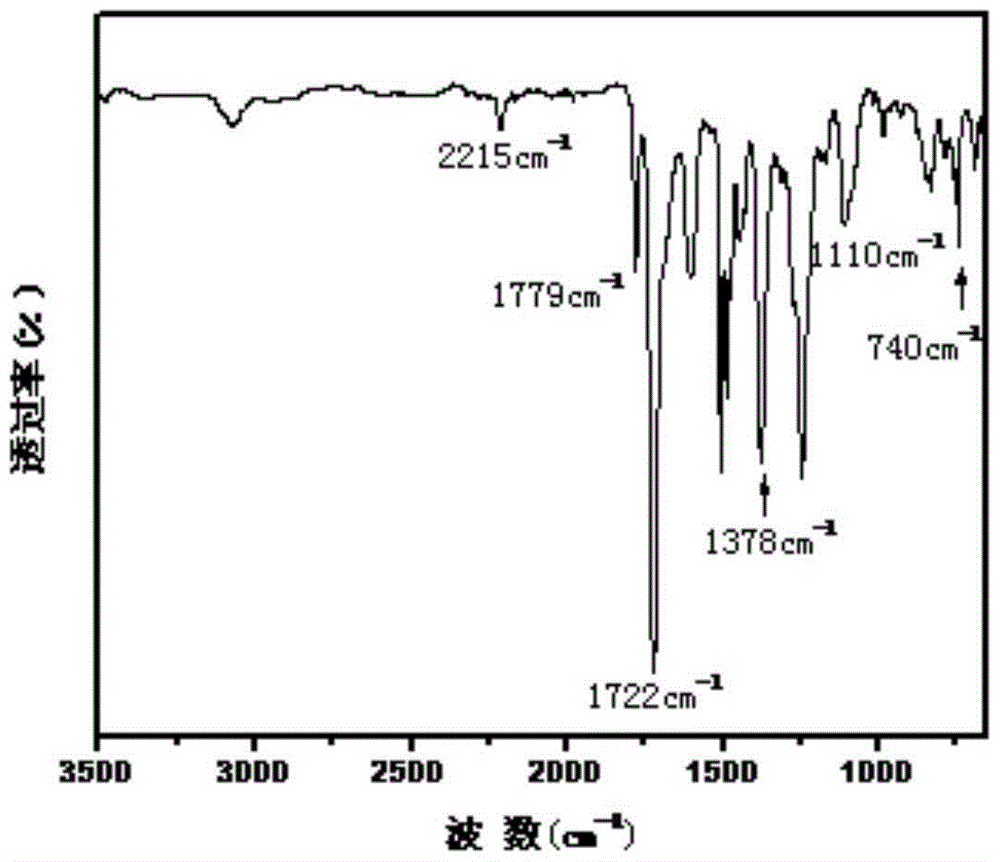

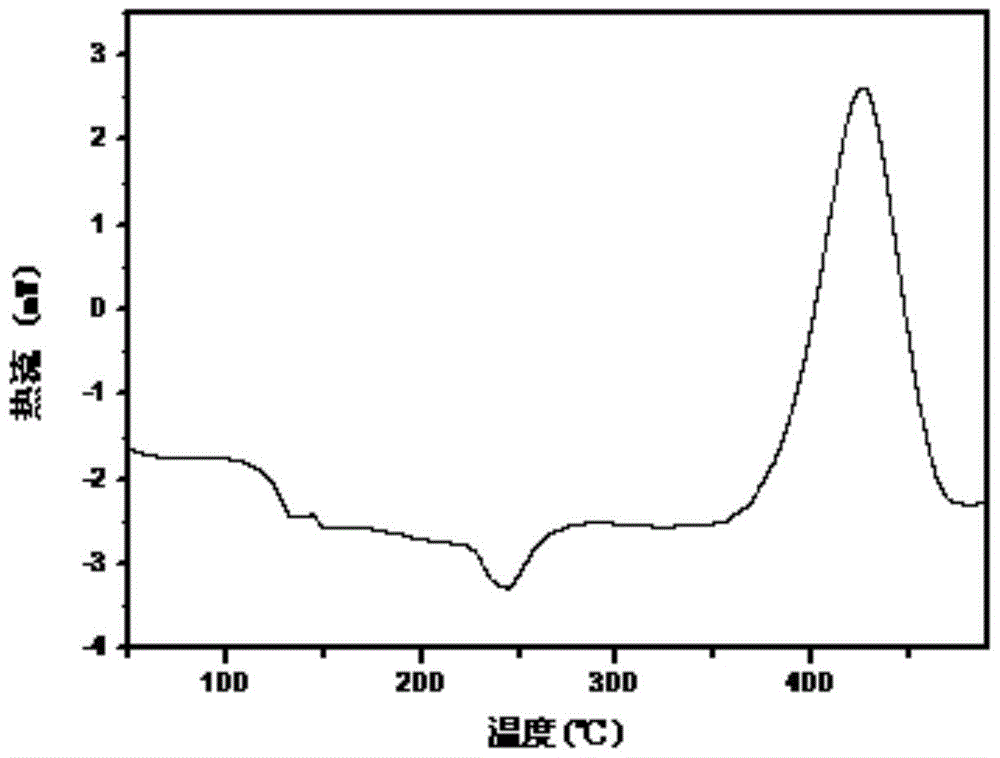

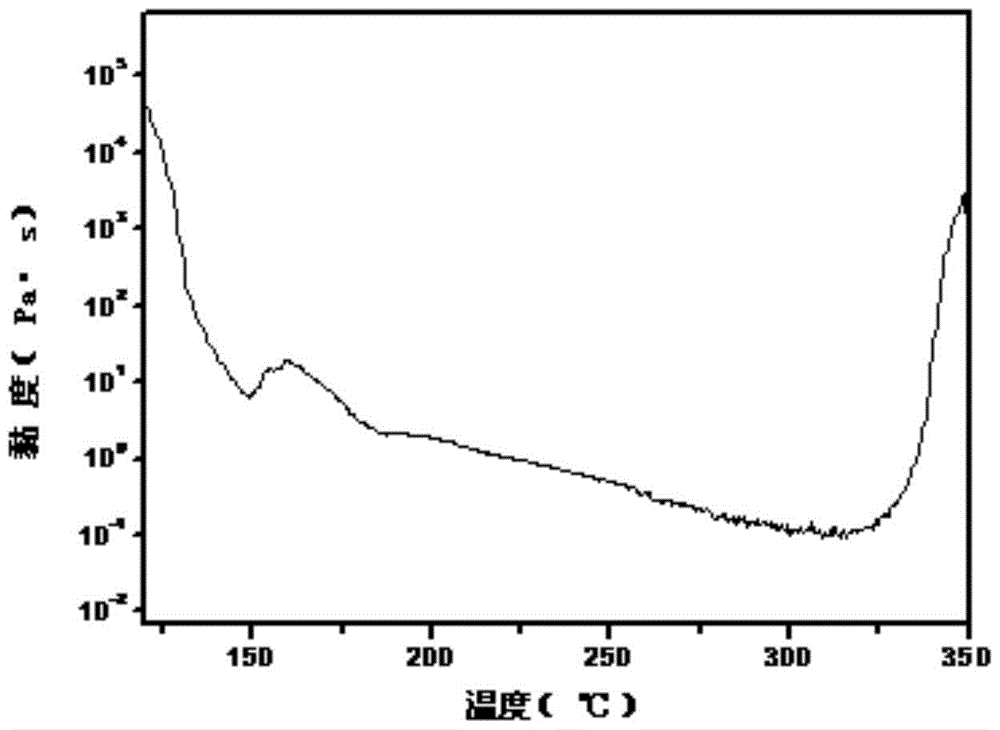

High-fluidity wide-processing-widow polyimide pre-polymer and preparation method thereof

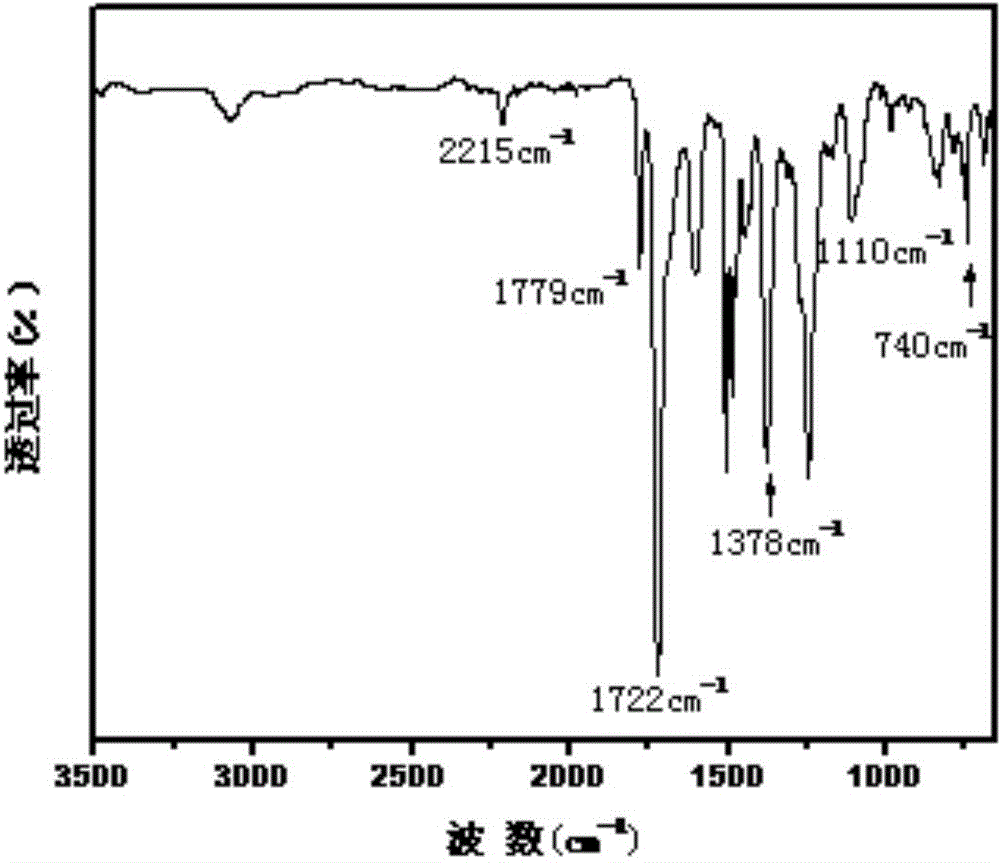

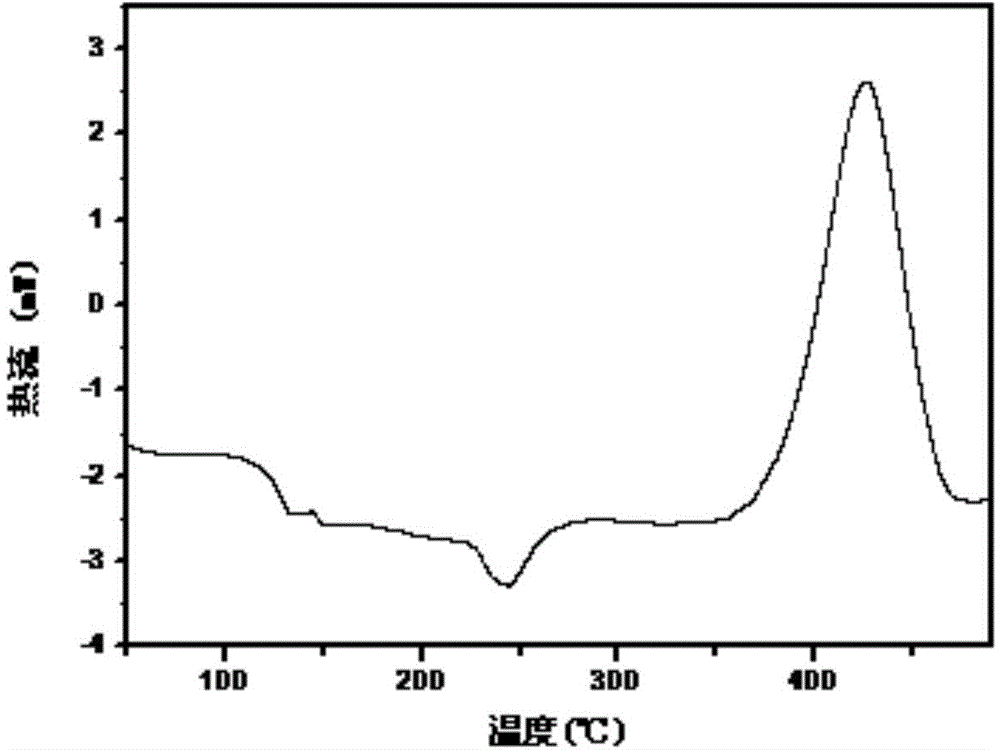

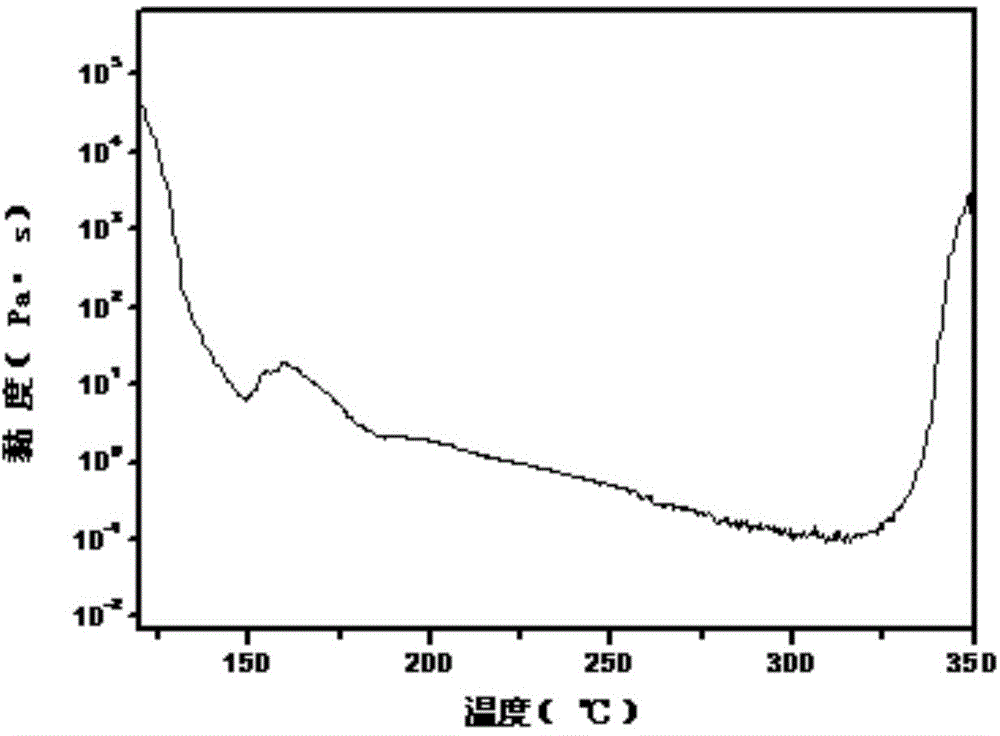

ActiveCN104530429ALower glass transition temperatureProcessing window widthOrganic chemistryDiaminodiphenyl etherAdhesive

The invention relates to a high-fluidity wide-processing-widow polyimide pre-polymer and a preparation method thereof. A structural formula is shown in the description, wherein n is 1-20 and is an integer. The preparation method comprises the steps of dissolving 3,4'-diaminodiphenyl ether 3,4'-ODA in an organic solvent under the nitrogen protection condition, adding 2,3,3',4'-tetracarboxydiphthalic ether dianhydride a-ODPA after complete dissolution, meanwhile adding the organic solvent to enable the solid content of a solution to be 10%-40%, adding an end-capping reagent during reaction at the room temperature to continue to perform reaction, dropwise adding a dehydrating agent to perform reaction, washing, drying and smashing. The pre-polymer can be formed through compression molding, is well applicable to a resin transfer forming process and has potential application value on the aspect of preparation of high-performance composite materials, high-temperature-resisting adhesives and the like.

Owner:DONGHUA UNIV

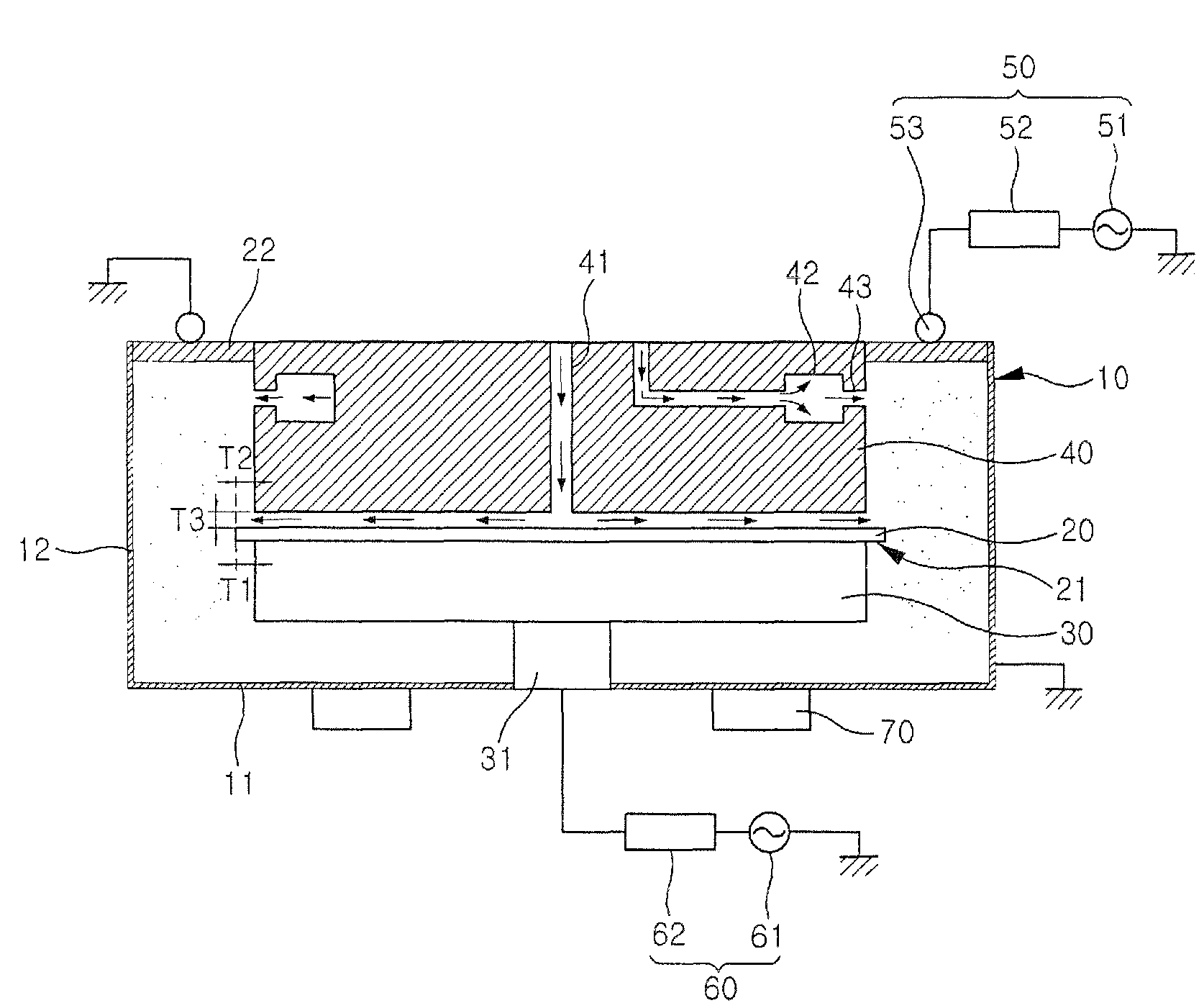

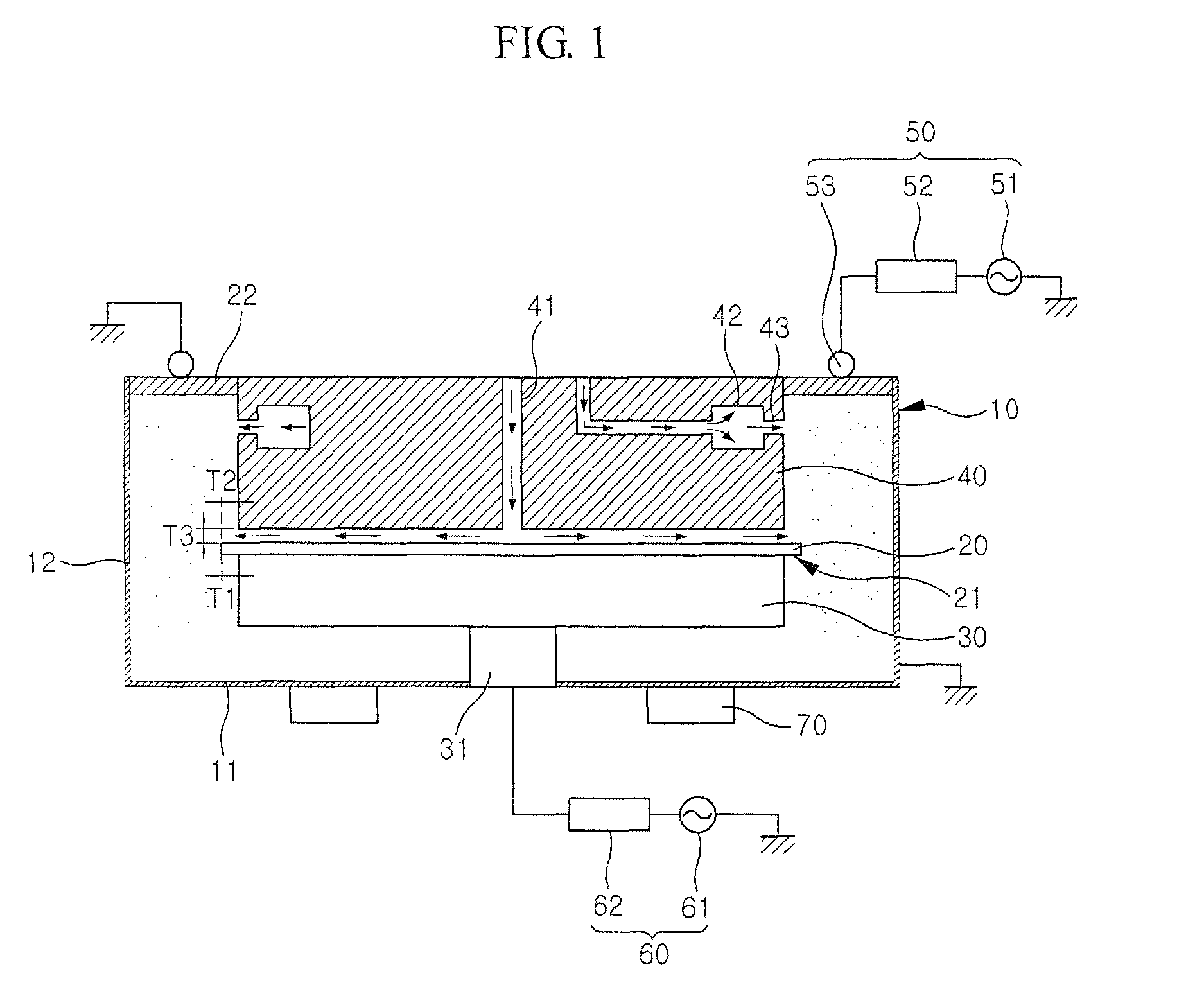

Plasma etching apparatus

InactiveUS7879187B2Limit profileHigh densityElectric discharge tubesSemiconductor/solid-state device manufacturingHigh densityEngineering

The present invention relates to a plasma etching apparatus, which comprises a chamber, a substrate support disposed inside the chamber to support a substrate, a shield disposed with a gap on the substrate such that plasma is not generated therein while allowing an edge portion of the substrate to be exposed, an antenna disposed at a position on an outer wall of the chamber to apply plasma-generating power to an area between the edge portion of the substrate and an inner wall of the chamber, and a bias-applying unit for applying bias to the substrate support. According to the present invention, the shield and the substrate support prevent plasma from being generated at other portions of a substrate except an edge portion of the substrate. Inductively coupled plasma is employed to generate plasma with high density, thereby removing a thin film and particles remained at the edge portion of the substrate. In addition, by means of the discharging of inductively coupled plasma, it is possible to improve an etching rate at the edge portion of the substrate and to adjust the profile of an etching process at a low processing pressure.

Owner:JUSUNG ENG

Anaerobic reactor for treating waste water containing emulsified liquid

InactiveCN102229447AReduce water distribution areaEven distribution of waterTreatment with anaerobic digestion processesChemical oxygen demandWater quality

The invention relates to an anaerobic reactor for treating waste water containing emulsified liquid. The height-diameter ratio of a tank body is greater than 3; an inlet water distributor is arranged at the bottom part of the tank body; the anaerobic reactor is provided with a granular sludge region which is suspended at the lower part of the tank body and a floccus sludge region which is suspended at the upper part of the granular sludge region; the surface loading of a deposit chamber of a triphase separator is not higher than 0.5m<3> / m<2>.h; and an outer circulating system is adopted. Because of the coexistence of the granular sludge region and the floccus sludge region of the anaerobic reactor, the COD (chemical oxygen demand) removal rate of the waste water containing the emulsified liquid is improved to more than 60%, the subsequent waste water processing technology pressure is reduced, the total effluent quality of a whole waste water treating system can reach the standard, and the operation cost of the whole waste water treating system is lowered.

Owner:SHIYAN BISHUIYUAN ENVIRONMENTAL PROTECTION TECH CENT

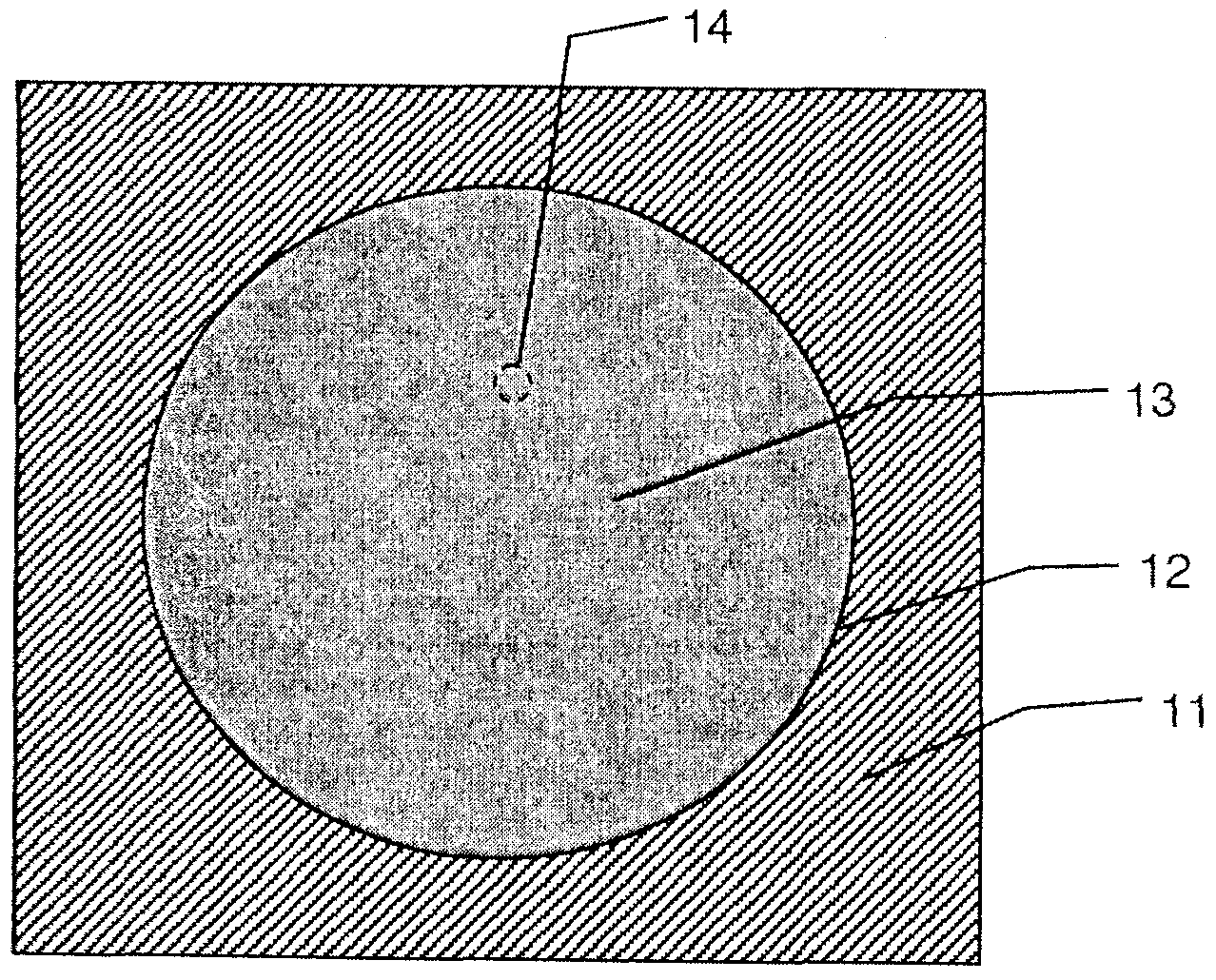

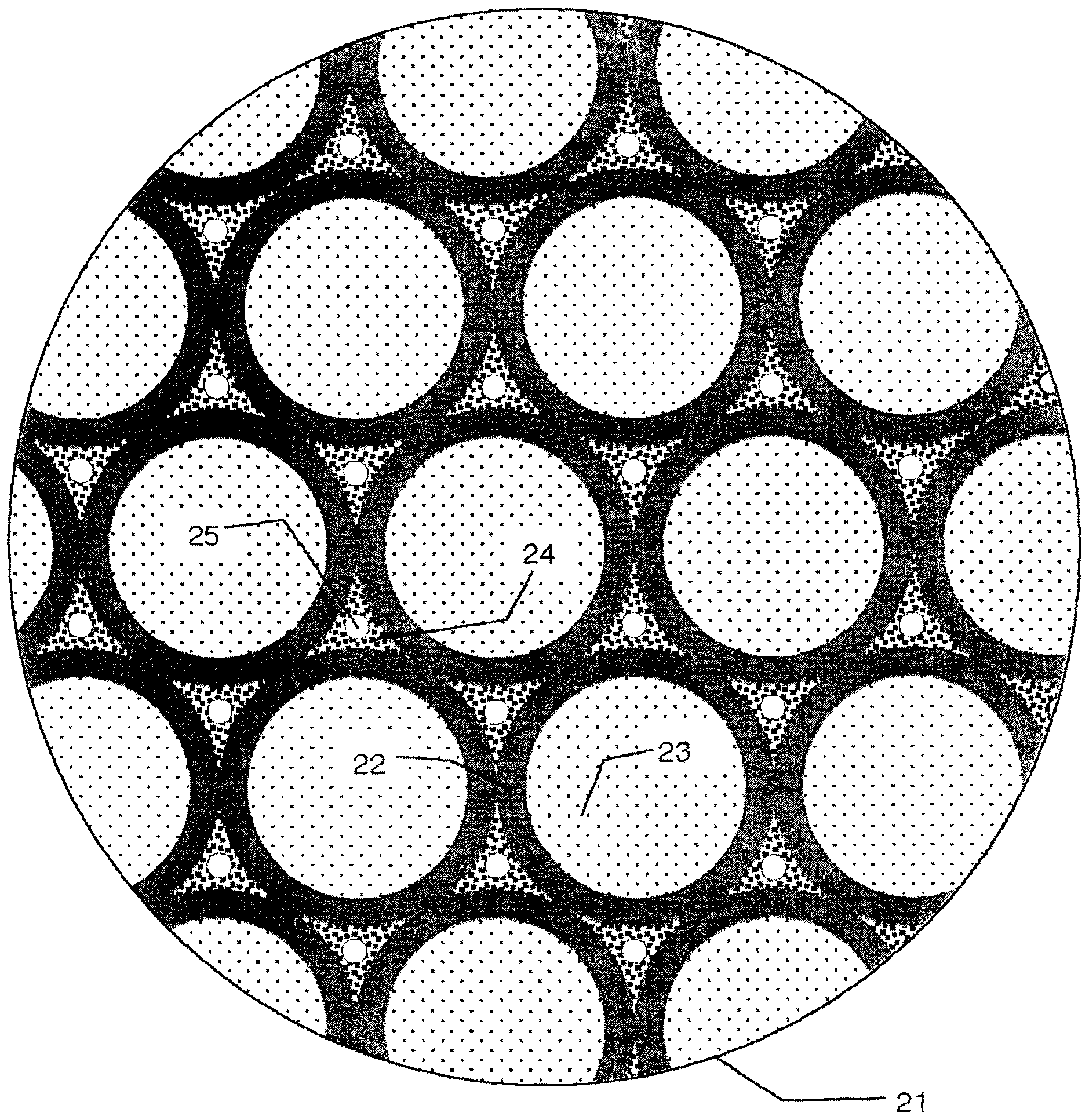

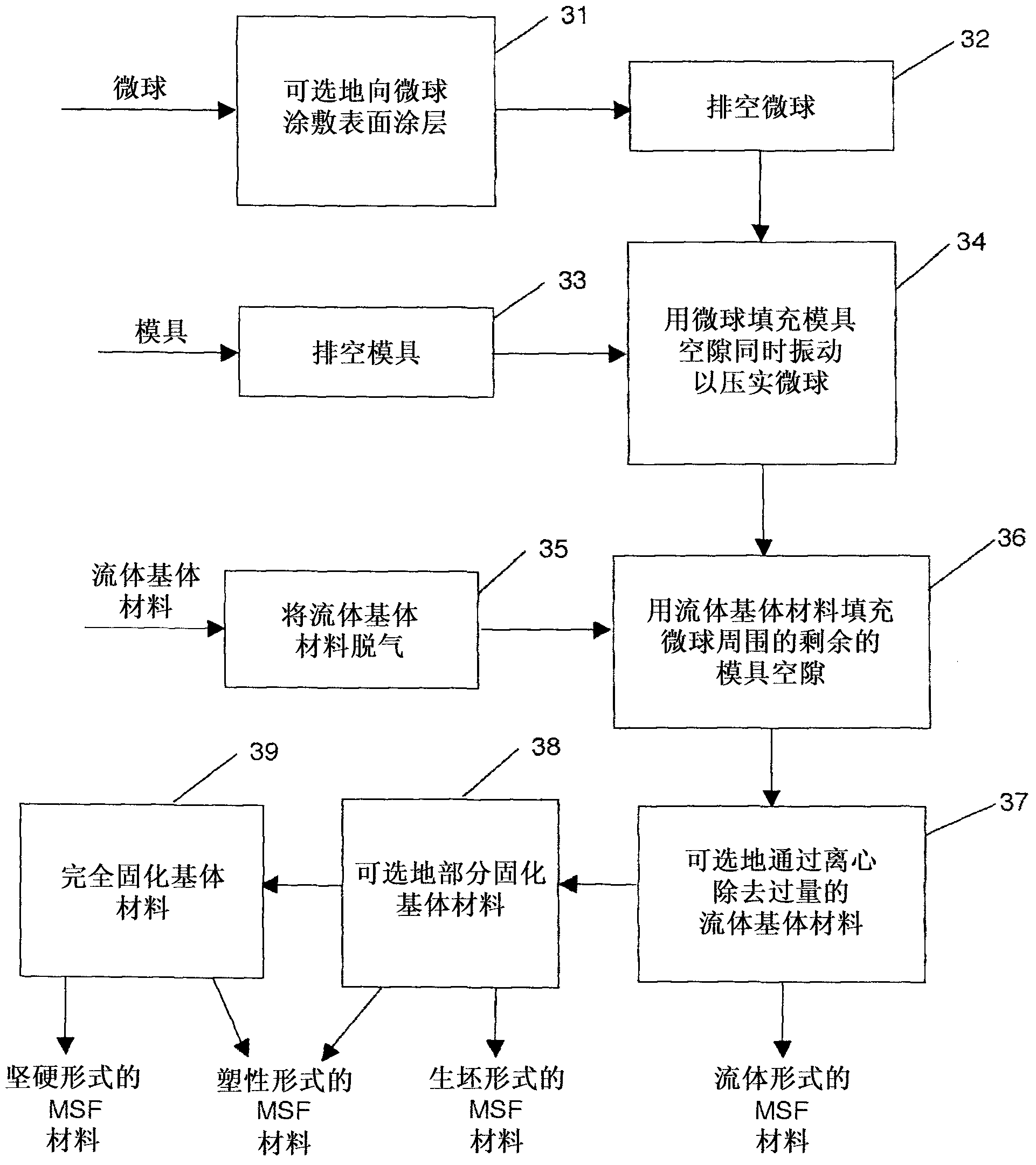

Composite materials and methods and apparatus for making same

InactiveCN103209788AReduce wearReduce replacement costsCeramic shaping apparatusThin material handlingParticulate materialCeramic materials

A composite material comprising a solid particulate material and a matrix material encapsulating the solid particulate material, wherein each dividual particle of the solid particulate material is in contact with at least one adjacent solid particle. A method comprising providing a solid particulate material, providing a mold, evacuating the solid particulate material in the mold to remove gas in the void space between the particles of the particulate material, evaluating the mold, introducing the evacuated solid particulate material into the mold, providing a fluid matrix material, and introducing the fluid matrix material into the void spaces while constraining the solid particulate material.

Owner:TORXX GROUP

Middle-or low-pressure exposion method for making pulp with broad-leaf wood

A low-and medium-pressure blasting method for pulping the broad-leaf wood includes proportioning the alkali (1-6 wt%), Na-S compound (1-16 wt%), assistant (0-1 wt%) and broad-leaf wood (rest), stirring at ordinary temp -90 deg.C for 0-24 hr, treating at 140-220 deg.C and 0.8-2.28 MPa for 3-15 min, and sudden blasting. Its advantages are high strength, output rate, whiteness, toughness and rinsability, and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH +1

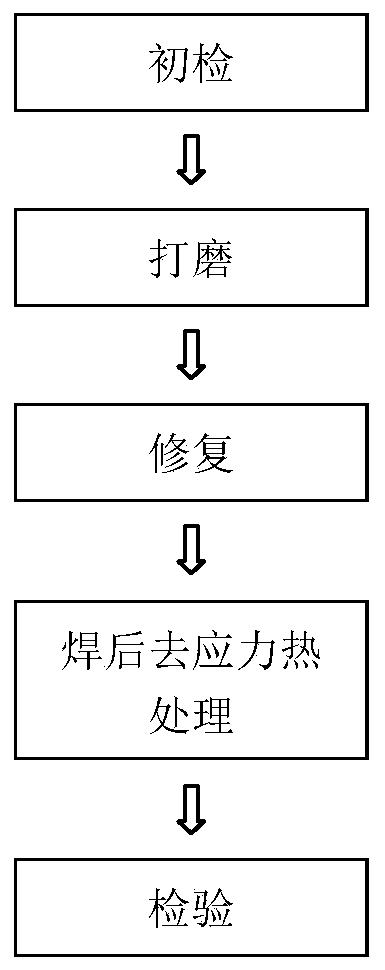

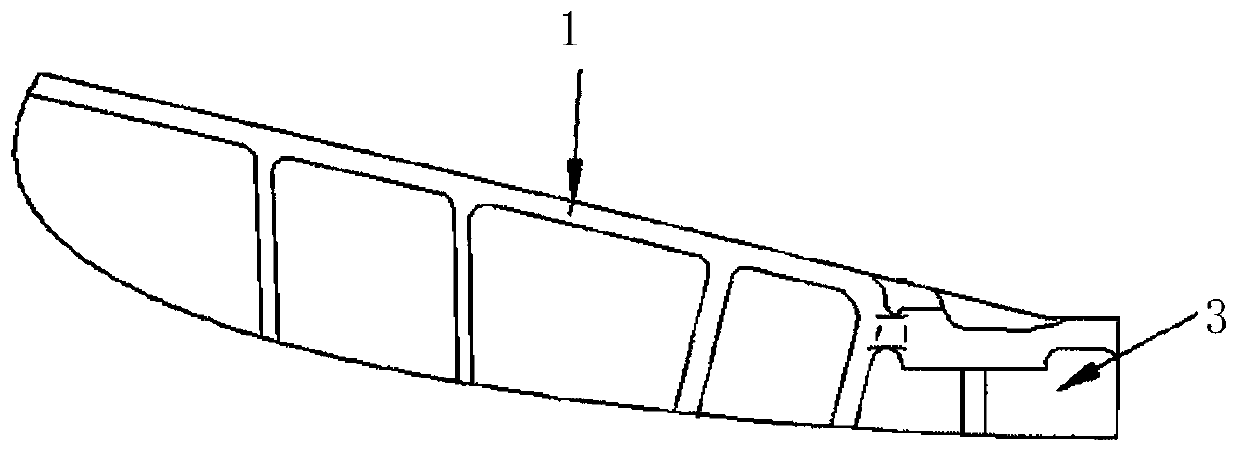

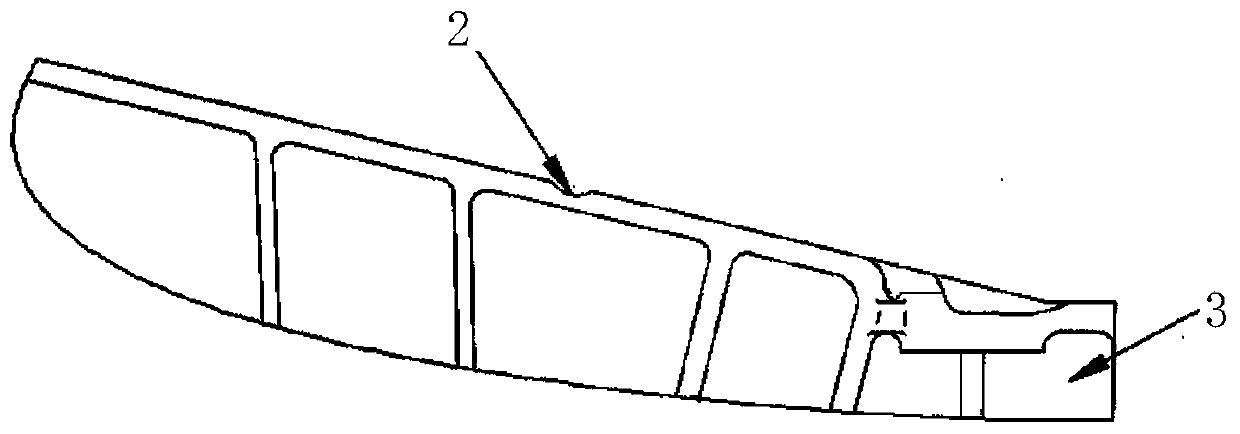

Typical part defect repairing method for tail nozzle mechanical adjusting system

ActiveCN110977322AFlexible operationProne to secondary damageAircraft componentsLaser beam welding apparatusStress reliefMachine

The invention discloses a typical part defect repairing method for a tail nozzle mechanical adjusting system, and belongs to the technical field of aero-engine K424 material part defect repairing. Thetypical part defect repairing method for the tail nozzle mechanical adjusting system comprises the following steps: S1, initial inspection is conducted, and the position, length and depth of a crackare determined; S2, grinding is conducted, specifically, the rack is ground, and an open groove is formed after the crack is ground off; S3, repairing is conducted, specifically, high-precision laserforming equipment and a high-energy precision welding repairing machine are adopted for repairing a typical part, wherein repairing specifically comprises the steps of repairing preparation, part preheating, fusion covering of the open groove and peripheral surface thereof, bonding layer grinding and welding repairing; S4, stress relief heat treatment after welding; and S5, inspecting is conducted. According to the typical part defect repairing method for the tail nozzle mechanical adjusting system, a laser fusion welding and precision pulse welding combined repairing method is adopted, so that operability is high, welding parameters are stable, the process is simple, the part repairing percent of pass is effectively increased, and the maintenance cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

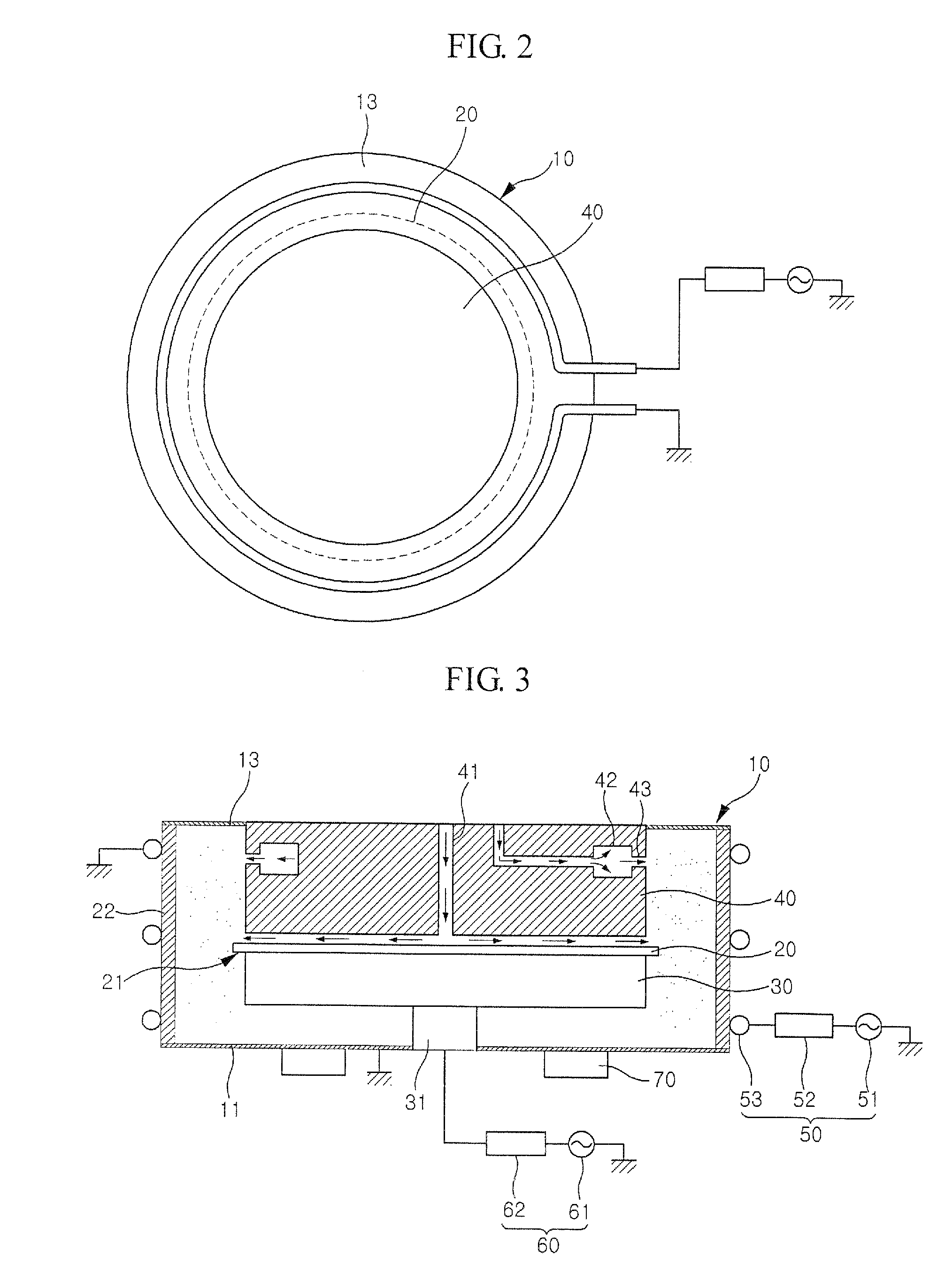

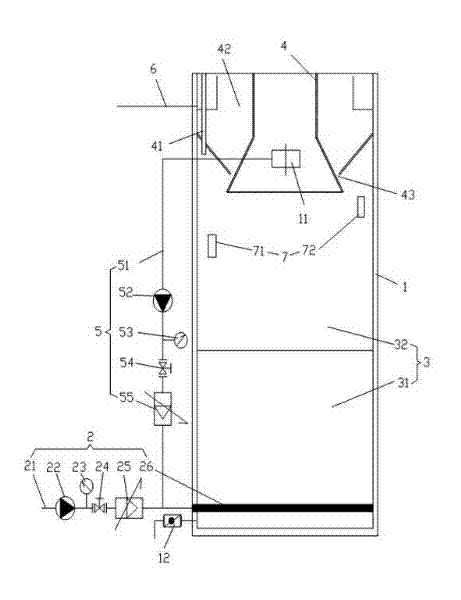

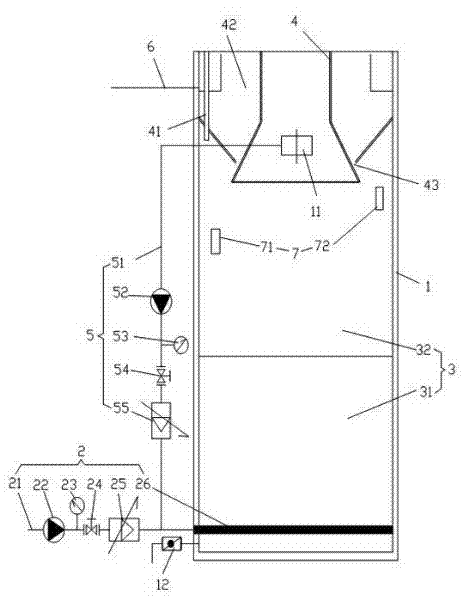

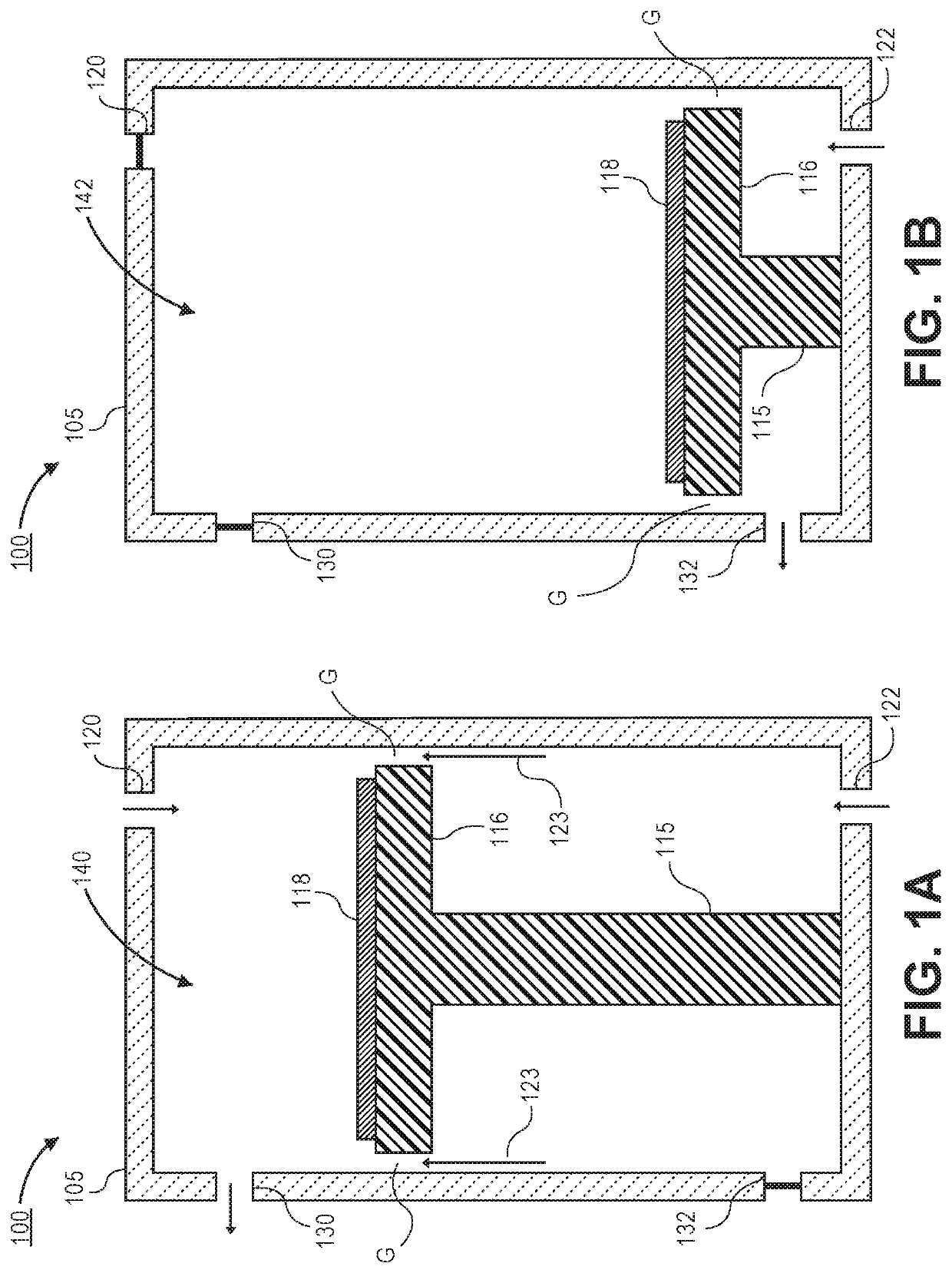

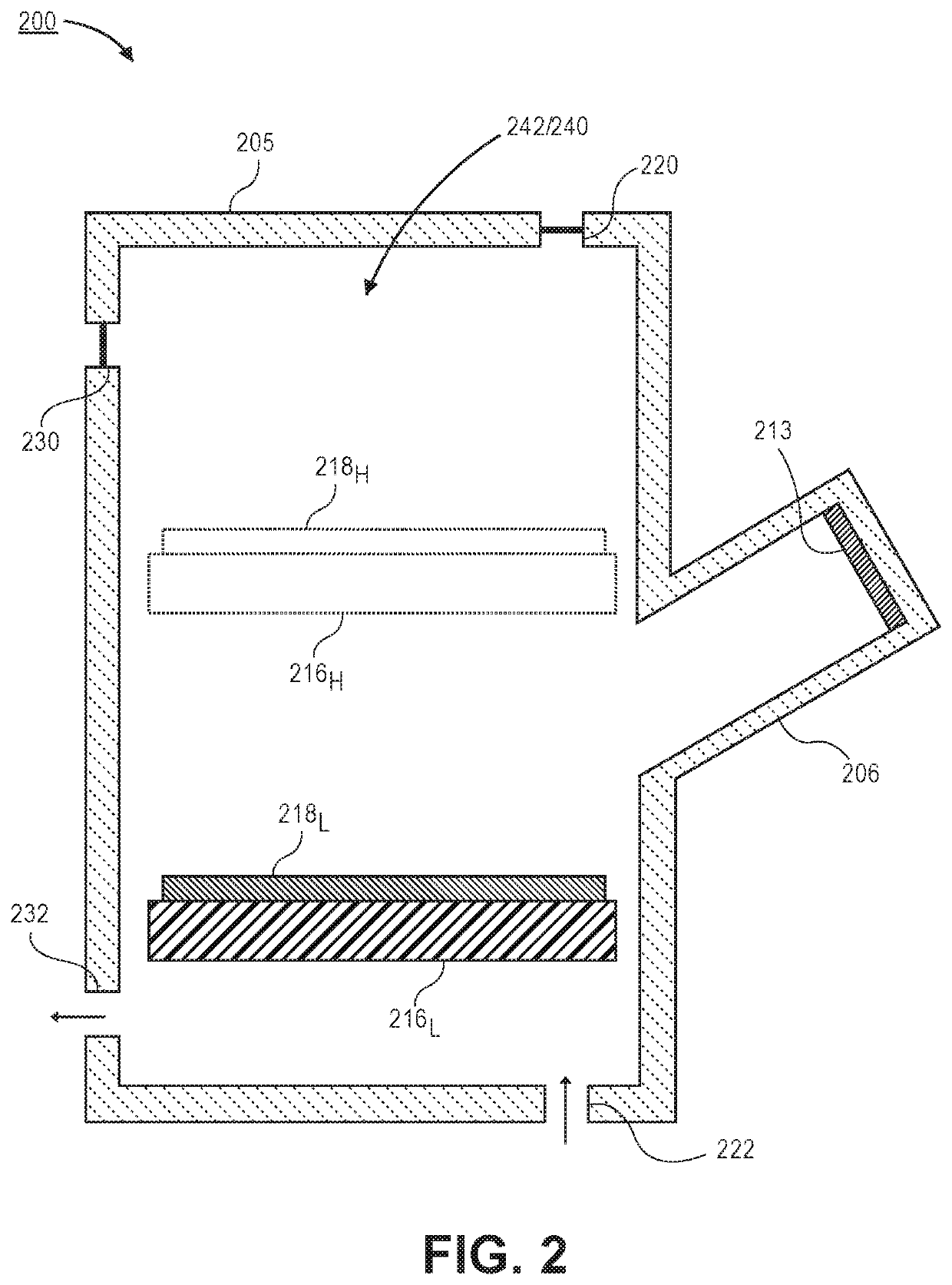

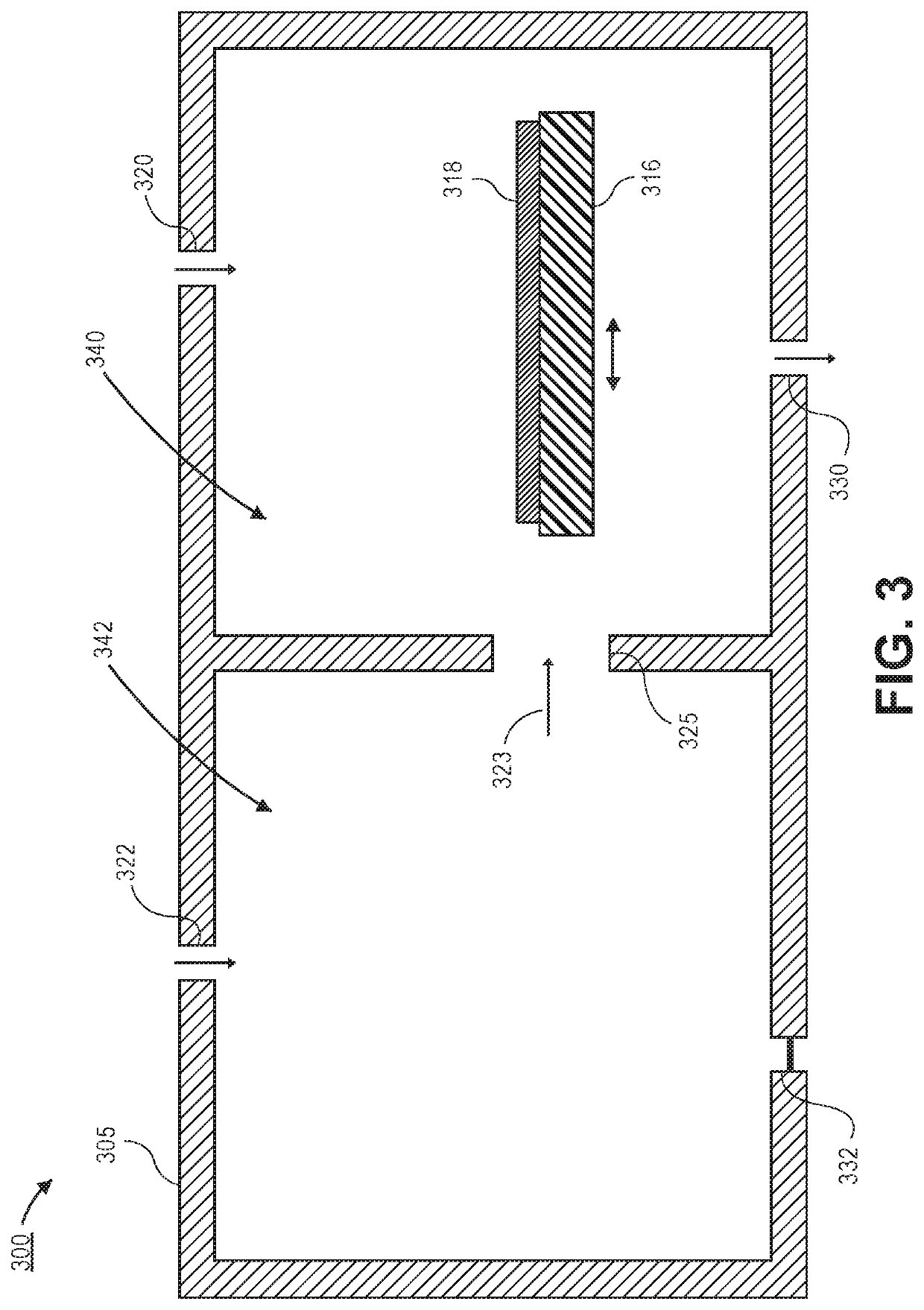

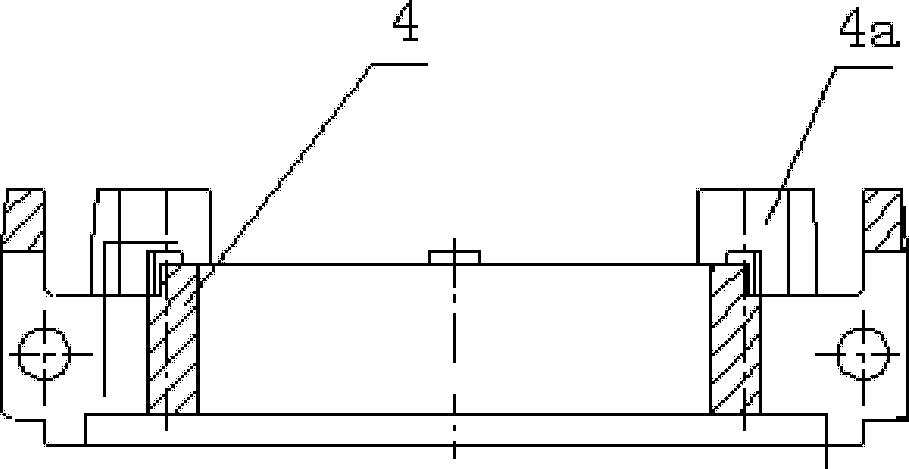

Single process volume to perform high-pressure and low-pressure processes with features to reduce cross-contamination

PendingUS20190352774A1Reduce process pressureHigh total pressure of processElectric discharge tubesVacuum evaporation coatingSingle processEngineering

Embodiments include a processing tool for processing substrates in a low processing pressure and a high processing pressure. In an embodiment, the processing tool comprises a chamber body and a pedestal in the chamber body. In an embodiment, the pedestal is displaceable, and the pedestal has a first surface and a second surface opposite the first surface. In an embodiment, the processing tool further comprises a first gas port for supplying gasses into the chamber body and a first exhaust positioned above the first surface of the pedestal. In an embodiment, the embodiment further comprises a second gas port for supplying gasses into the chamber body and a second exhaust positioned below the second surface of the pedestal.

Owner:APPLIED MATERIALS INC

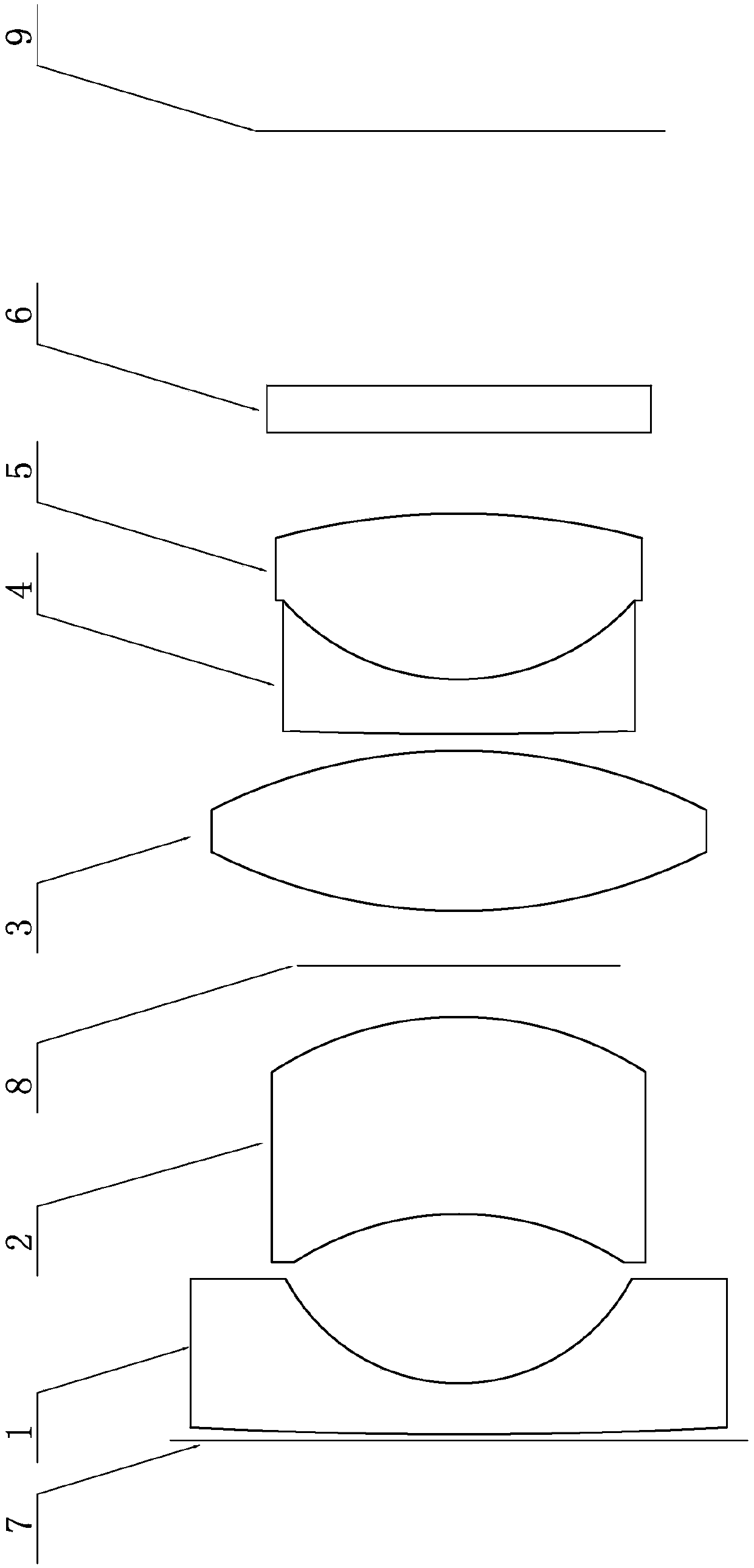

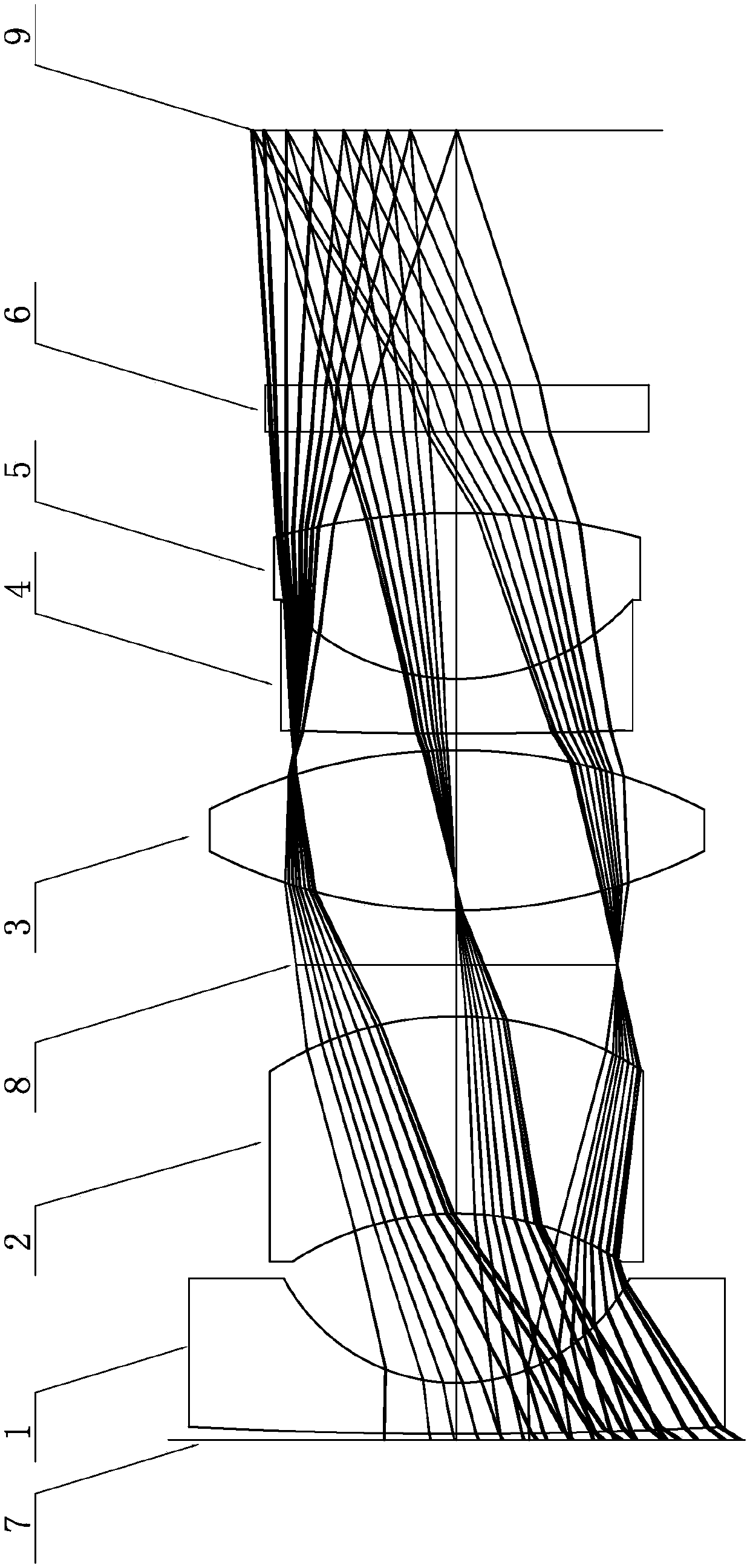

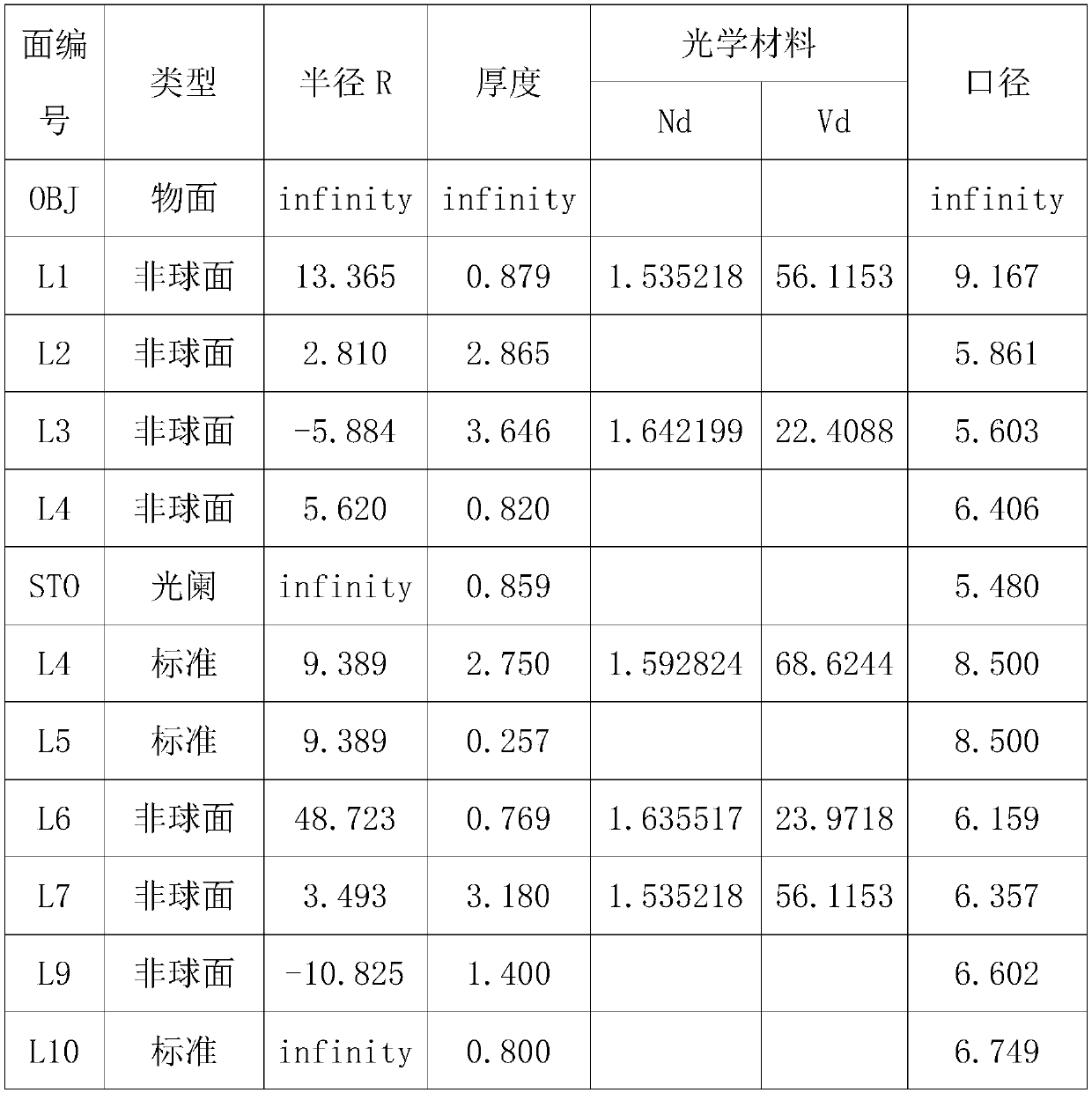

Large-aperture low-cost optical imaging system

The invention discloses a low-cost optical imaging system with a large aperture, which is sequentially provided with a first lens, a second lens, a diaphragm, a third lens, an aspheric double-glued lens and an optical filter from the object side to the image surface; the aspheric surface The doublet lens comprises a fourth lens and a fifth lens cemented together, the first lens and the fourth lens are all negative focal length lenses, the second lens, the third lens, and the fifth lens are all positive focal length lenses, the first lens, the second lens The second lens, the fourth lens and the fifth lens are all aspherical lenses, the third lens is a spherical lens; the focal length of the first lens is f1, the focal length of the second lens is f2, the focal length of the third lens is f3, and the fourth lens The focal length of the fifth lens is f4, and the focal length of the fifth lens is f5, where f1, f2, f3, f4, and f5 satisfy: f1<‑3, f4<‑60, f5>30,0.05 <f1 f4<5,‑5<f1 f5<5,f2 f3>2. The aperture of the optical imaging system of the present invention reaches more than Fno1.6, and the relative illuminance reaches more than 70%, which can effectively control the aperture and thickness of the lens and reduce the tolerance sensitivity of the system.< / f1>

Owner:UNION OPTECH

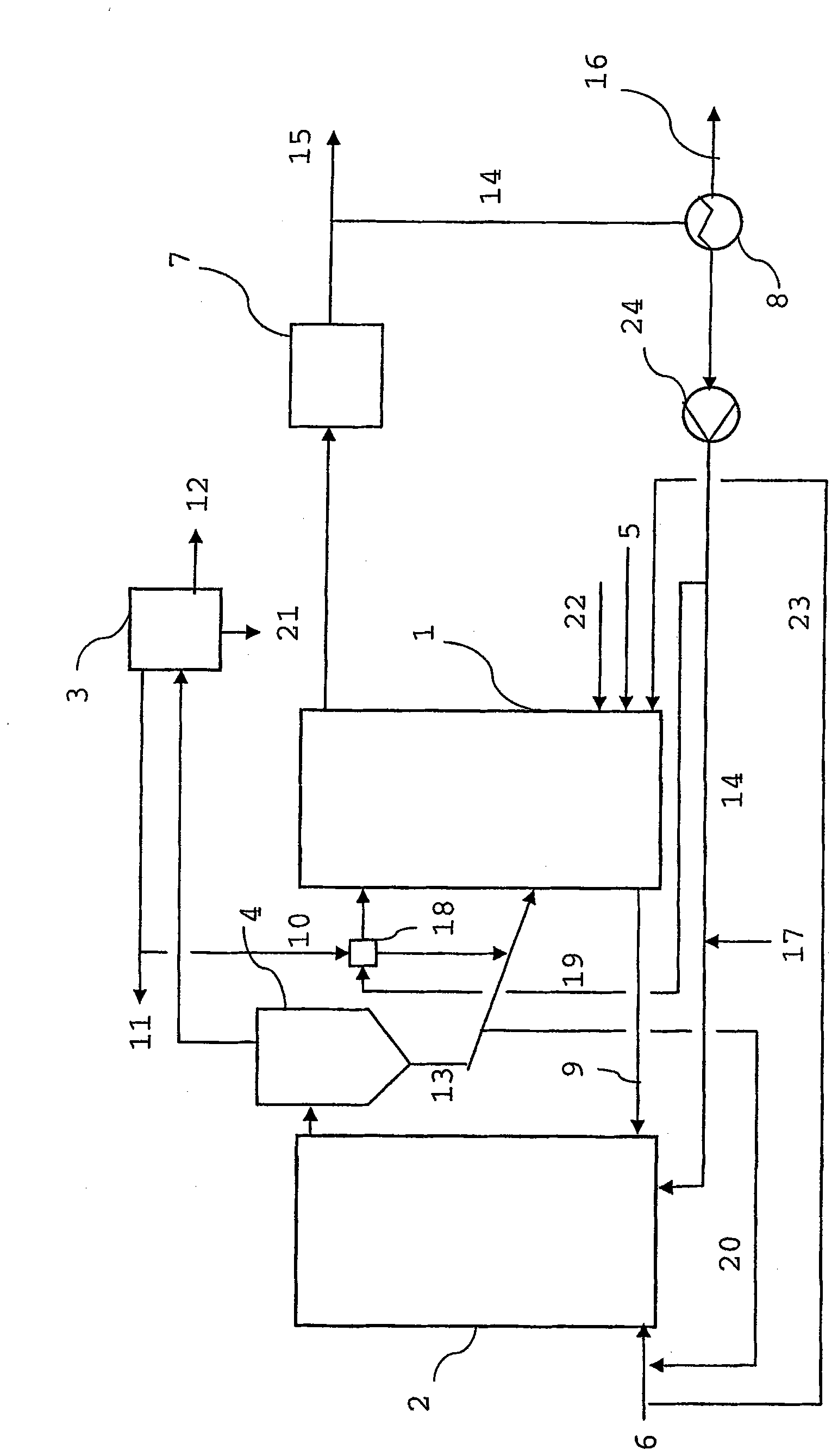

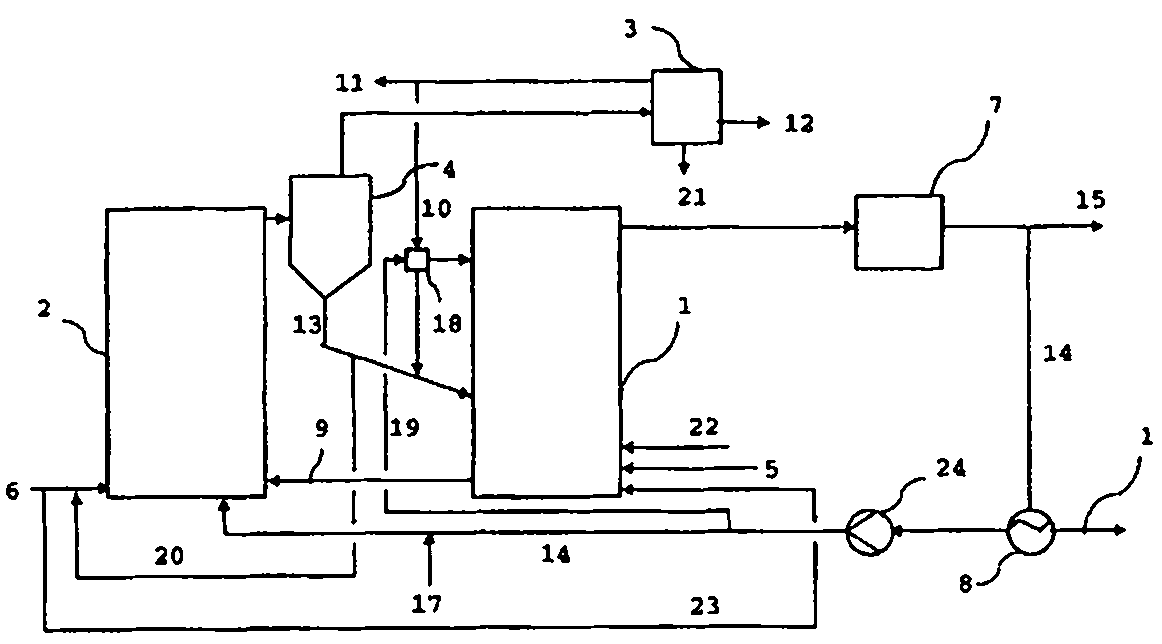

Apparatus for producing a pyrolysis product

InactiveCN101896577AReduce coke contentImprove securityProductsReagentsCombustionProcess engineering

The invention relates to an apparatus for producing a pyrolysis product, the apparatus comprising a pyrolysis reactor (2) for forming pyrolysis product fractions from raw material by fast pyrolysis, a condensing device (3) for condensing gaseous pyrolysis product fractions to mainly liquid pyrolysis product fractions, a combustion boiler (1) arranged in conjunction with the pyrolysis reactor for forming energy fractions, and feeding devices (5, 6, 22) for feeding raw materials to the pyrolysis reactor and the combustion boiler. According to the invention, the apparatus comprises a separating device (4) arranged substantially in conjunction with the pyrolysis reactor for separating other fractions (13) from the gaseous pyrolysis product fractions after the pyrolysis and means (13) for conducting other fractions than the gaseous pyrolysis product fractions from the separator (4) to the combustion boiler (1).

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

A kind of polyimide prepolymer with high fluidity and wide processing window and preparation method thereof

ActiveCN104530429BLower glass transition temperatureProcessing window widthOrganic chemistryDiaminodiphenyl etherAdhesive

Owner:DONGHUA UNIV

Low pressure blast pulping method in palm fiber

InactiveCN100500987CSignificant changes in microstructureHigh yieldPulping with inorganic basesCardboardDry weight

This invention discloses a low blasting pulp making method in palm fibre. It includes material pretreatment, that is alkali, and sodium-sulfur compound and water are added into palm fibre materials. The bone dry weight percentage is that alkali 0-10%, sodium-sulfur compound 0-16% and water that can make liquid ratio to 0.5-3, then they are placed for 0-24 hours after uniformly blended. Then the materials after pretreatment are low pressure proposed and discharged. The advantages are low cost, low temperature, and low damage to fiber. The waste water after pulp making can be used as fertilizer for crop irrigation, low pollution high gain ratio. It can be used to make high strength card board, corrugated board, writing paper, manifold paper and other culture using paper.

Owner:SOUTH CHINA UNIV OF TECH

High purity cyclic peptide compound and preparation method and application thereof

ActiveCN102627688BHigh purityLess impuritiesAntimycoticsPeptide preparation methodsChemical structureCyclic peptide

The invention discloses a high-purity cyclic peptide compound, the chemical structure of which is shown in formula I, wherein R represents H or a cation capable of forming a pharmaceutically acceptable salt, and the purity is greater than or equal to 99.0%. The preparation method and application of the high-purity cyclolipopeptide compound are also disclosed.

Owner:SHANGHAI TECHWELL BIOPHARMACEUTICALS CO LTD

Processing method of water conveying hole of mold base template

InactiveCN109550990AReduce process pressureShorten the timeBoring/drilling machinesEngineeringProcessing cost

The invention provides a processing method of a water conveying hole of a mold base template. The processing method comprises the following steps that S1, a short gun drill is mounted at a spindle ofa horizontal processing center, and the short gun drill is used for drilling a first section hole with first depth in the to-be-processed mold base template; and S2, a long gun drill is mounted at a spindle of a gun drill, and the long gun drill is used for drilling inwards in the axial direction of the first section hole and drilling a second section hole with second depth, and the first sectionhole communicates with the second section hole to form the water conveying hole. According to the processing method of the water conveying hole of the mold base template, the first section hole is continuously processed after a flying ring hole and a frame of the mold base template are processed, and therefore the required processing depth of the long gun drill is reduced, the time of processing the second section hole of the long gun drill is shortened correspondingly, the time required by processing is shortened, processing pressure of the long gun drill is reduced, processing efficiency isimproved, and the processing cost is reduced.

Owner:HEYUAN LUNG KEE METAL PRODS

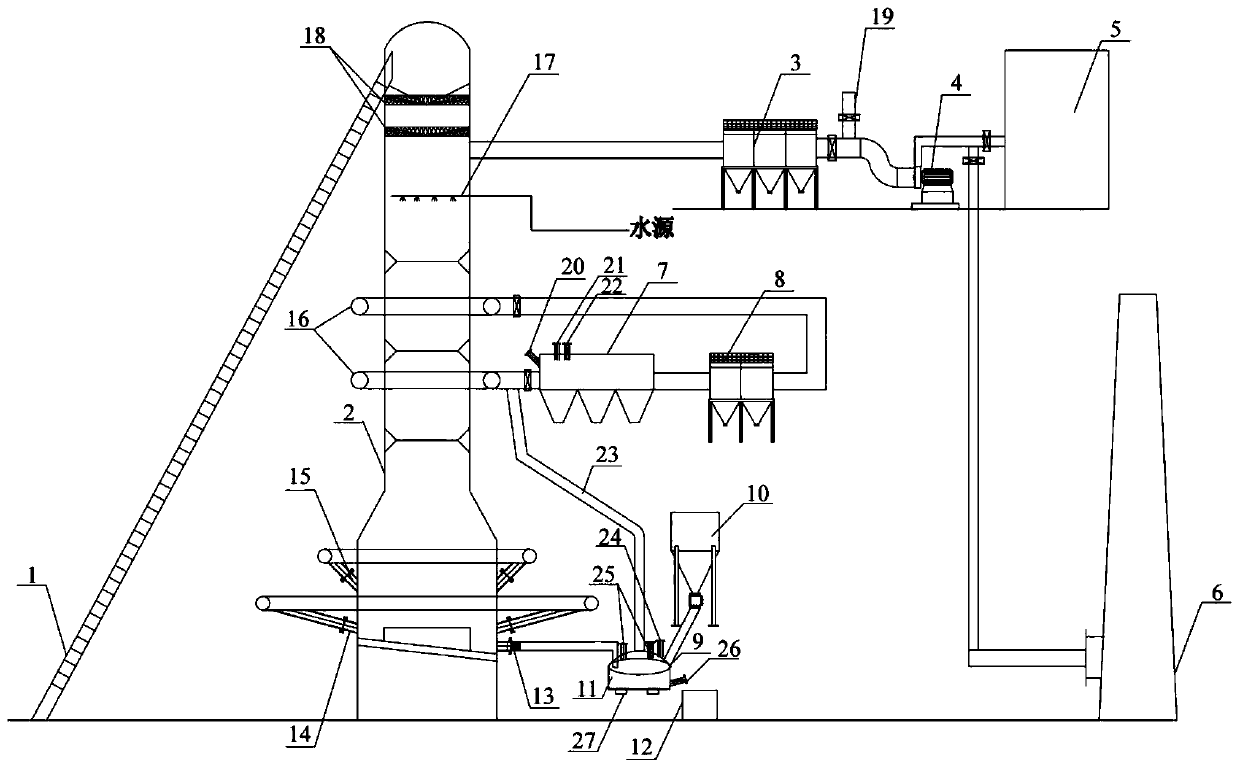

Self-generating gas circulation tail-gas-emission-free scrap steel smelting system and steelmaking method

ActiveCN111485060ANo consumptionNo generationChemical industryExhaust gas handlingSteelmakingElectric arc furnace

The invention discloses a self-generating gas circulation tail-gas-emission-free steel scrap smelting system and a steelmaking method, and belongs to the technical field of metallurgy. The system involves a feeding system, a shaft furnace, a dust remover, a variable-frequency induced draft fan, a gas holder, a chimney, a coal gasification furnace, a cyclone dust remover, a liftable heat preservation cover, a material bin, a fine adjustment tundish and a steel ladle. The system utilizes high-temperature flue gas of the shaft furnace to inject coal to generate gas, gas self-circulation all-ironand steel scrap smelting is realized, and zero emission of flue gas in a smelting link can be realized, so that the effect of reasonable cyclic utilization of energy flow is achieved; meanwhile, the energy flow is more reasonable, and the heat consumption in the gas generation process is reduced, so that waste water treatment equipment and cost in the gas generation process are avoided; the energy-saving and emission-reducing effects are remarkable, the energy consumption in the smelting link is only about 25% of that of a traditional electric arc furnace, and the whole manufacturing cost is reduced by 180-260 yuan per ton of steel compared with the electric arc furnace; and the all-steel-scrap smelting process is a green smelting process integrating energy conservation, low carbon, environmental protection and low cost.

Owner:SHENYANG DONGDASHANHUI ENVIRONMENTAL TECH CO LTD

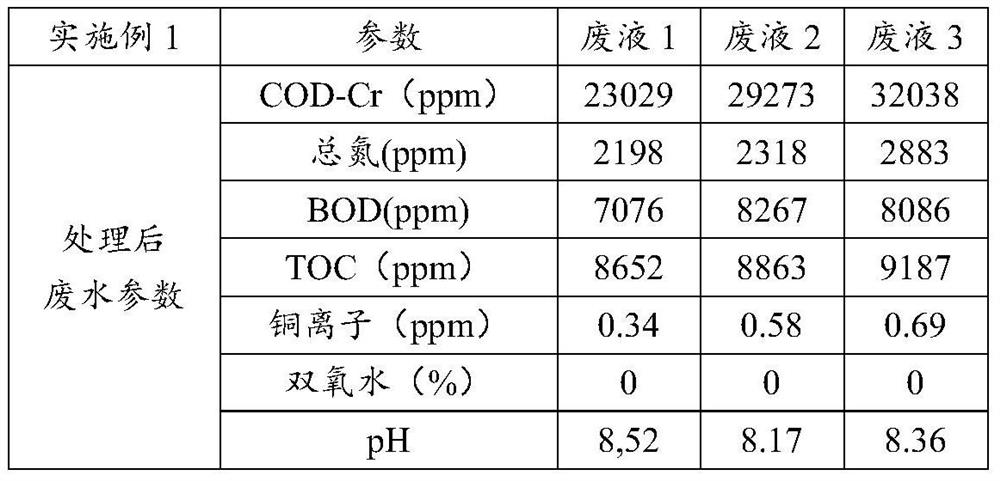

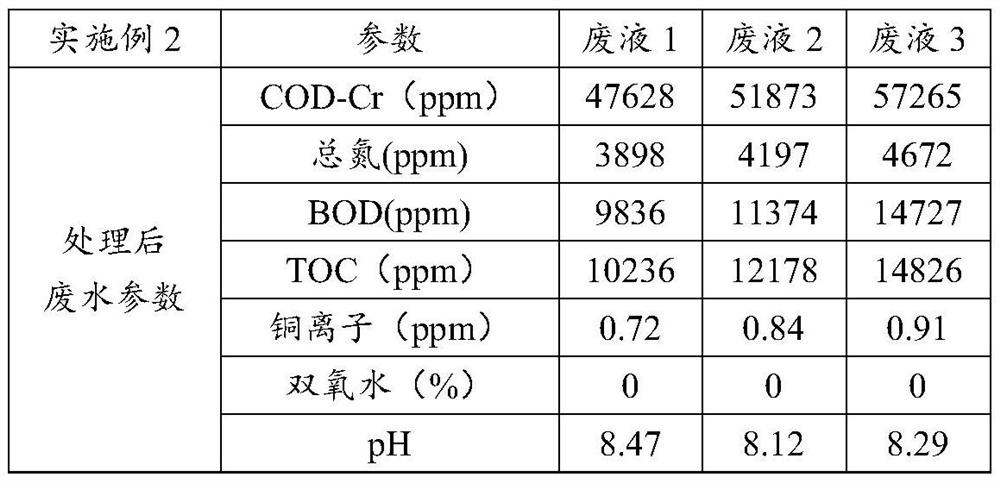

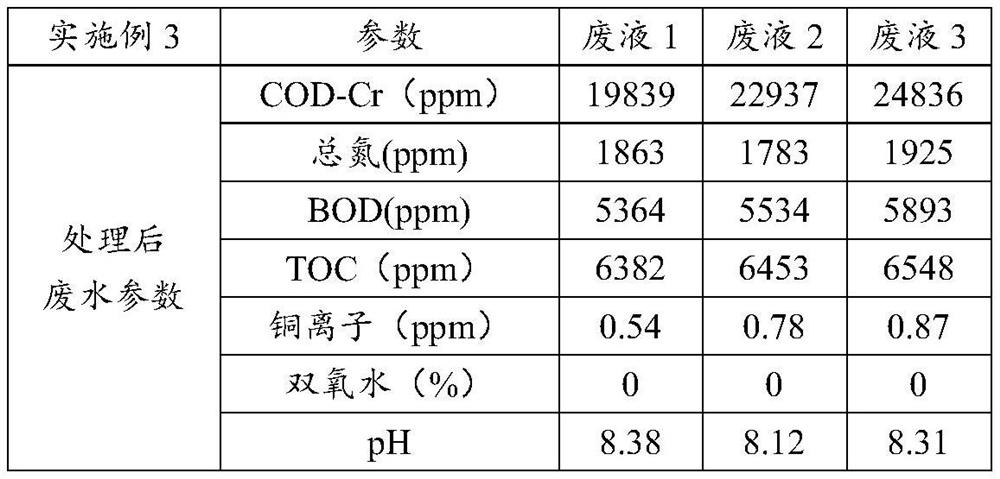

Composition for removing copper ions in waste liquid and application thereof

PendingCN114835284AReduce process pressureImprove removal efficiencyWater treatment compoundsWater contaminantsEnvironmental chemistryEtching

The invention relates to the field of C02F9 / 04 of IPC classification, in particular to a composition for removing copper ions in waste liquid and application of the composition. The composition comprises the following raw materials in percentage by mass based on the total mass of the waste liquid: 0.5-5% of a ferrous ion source, 0.1-10% of alkaline hydroxide, 0.2-4% of a sulfur ion source and 0.1-3% of a settling agent. The composition prepared by the invention has a good copper ion removal effect, can synergistically remove hydrogen peroxide and most organic matters in the waste liquid at the same time, is suitable for being popularized in the field of etching, and has a wide development prospect.

Owner:江苏和达电子科技有限公司

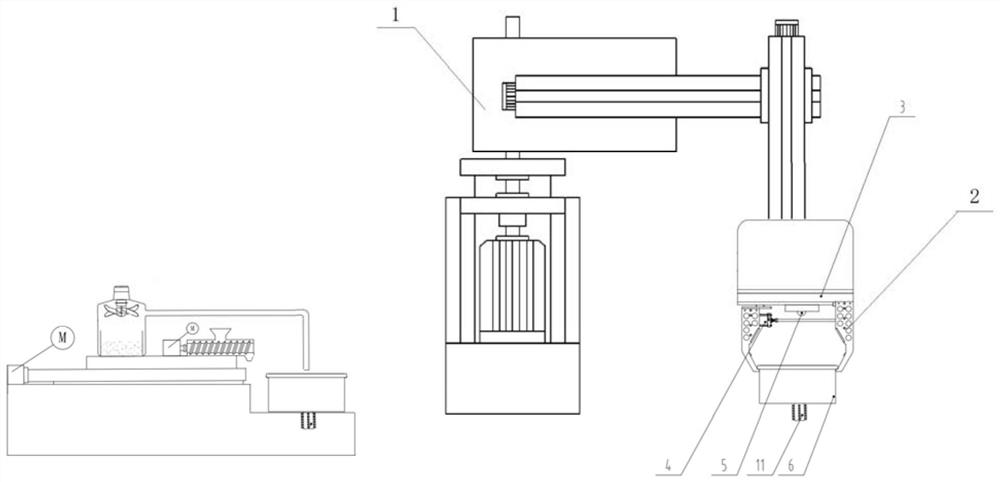

Liquid metal grinding disc self-repairing device with automatic grasping function

ActiveCN111451937BAchieve preparationFast formingLapping machinesAbrasive surface conditioning devicesLiquid stateLiquid metal

The invention discloses a liquid metal grinding disc self-repairing device with automatic grabbing function, which includes a three-degree-of-freedom drive device, a rotating platform, a mechanical gripper, a gripper cylinder, a camera, a grinding disc, a processing station and a self-repairing device. Station, the three-degree-of-freedom driving device is set between the processing station and the self-repairing station. Connect the mechanical gripper and drive the opening and closing of the mechanical gripper. The camera is set at the rotating end of the rotating platform connected to the mechanical gripper; the invention injects the mixture of liquid metal and abrasive grains into the In the grinding tool, the liquid metal is slowly solidified into a solid through the cooling module to realize the production of the grinding disc. Due to the low melting point of liquid metal, the grinding and polishing plate is formed quickly, and the self-leveling technology can achieve extremely high surface flatness.

Owner:ZHEJIANG UNIV OF TECH

Bundled bullet release device with primary and secondary structure

ActiveCN102494563BFast and reliable releaseSimple structureAmmunition projectilesProjectilesCircular discButt joint

The invention provides a bundled bullet release device with a primary and secondary structure. The bullet release device comprises a bundling mechanism which is connected among a primary body, bullets and a tail wing seat and a release mechanism, wherein the release mechanism is arranged at a cylindrical opening of a head cap of the primary body; the periphery of a ring gear wherein the release mechanism is connected with the head cap is provided with a plurality of pairs of shaft seats; an axis of each shaft seat is parallel to a tangent line of the ring gear; a radial turning block opening is formed in the ring gear between each pair of shaft seats; an axial turning block opening is formed at a position corresponding to the head cap; one turning block is arranged on each pair of shaft seats through a rotating shaft; a positioning notch and a boss for hooking a bundling rope are formed on the turning block, a rope hooking side of the boss is reverse to a positioning surface of the positioning notch, and the rope hooking side and the positioning surface of the positioning notch are formed in two quadrants which are not adjacent to each other; a disc-shaped limiting plate is positioned on the rear side of the ring gear and is correspondingly attached to the positioning surface with the positioning notch on the turning block; a middle part of the disc-shaped limiting plate extends out of one side of the head cap to form a necking section and a fixing ring table; the fixing ring table is connected with an internal thread of the ring gear; an exploder is arranged in the necking section; a cylindrical section of the head cap is in butt joint with the bullets through a jack; one end of the bundling rope is fixed on a rear connecting ring; and a lantern ring at the other end of the bundling rope is sleeved on the boss of the turning block.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com