Self-generating gas circulation tail-gas-emission-free scrap steel smelting system and steelmaking method

A tail gas emission and gas technology, applied in the metallurgical field, can solve the problems of high energy consumption, energy waste, and small furnace volume in the electric arc furnace smelting process, and achieve the effects of avoiding low-efficiency conversion, avoiding air pollution, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

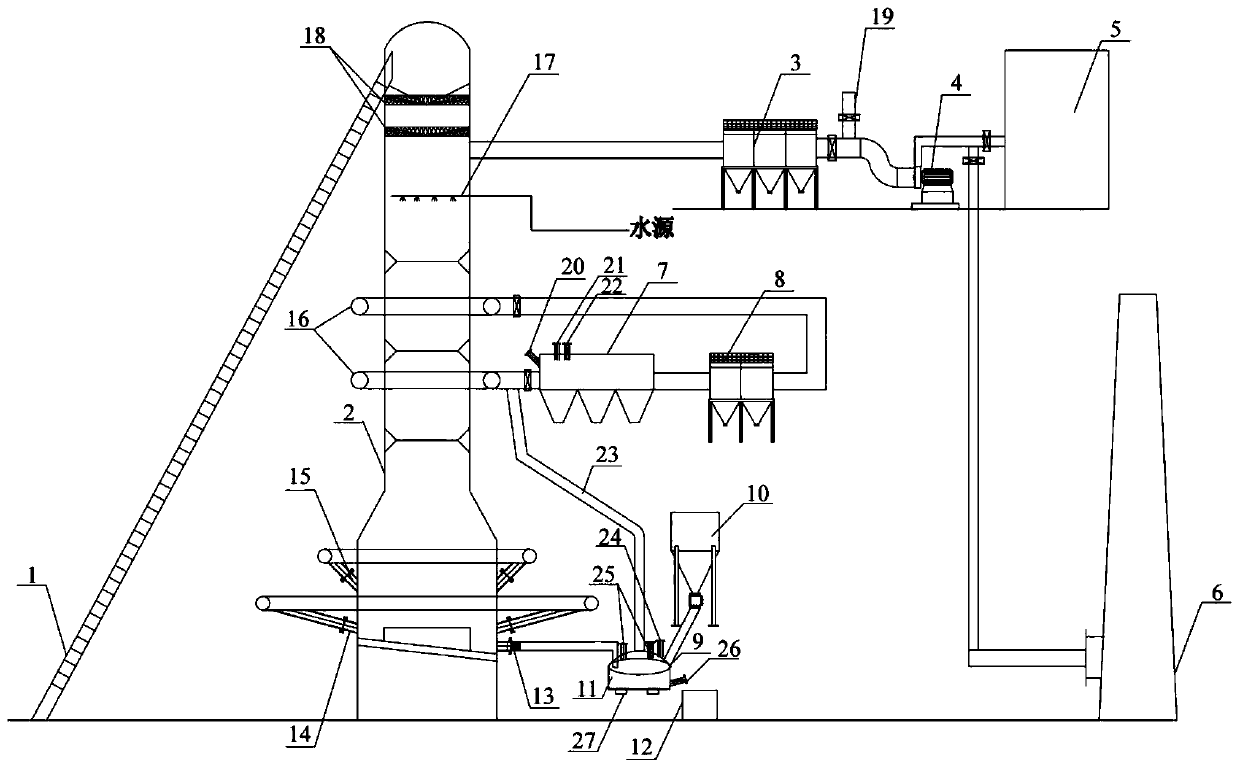

[0054] Such as figure 1 As shown, a scrap steel smelting system with self-generating gas circulation without tail gas emission, including feeding system 1, shaft furnace 2, dust collector 3, frequency conversion induced draft fan 4, gas cabinet 5, chimney 6, coal gasifier 7, cyclone dust removal 8, liftable heat preservation cover 9, silo 10, fine-tuning tundish 11 and steel ladle 12;

[0055] The bottom side wall of the shaft furnace 2 is provided with a tap hole 13, the lower part of the melting section of the shaft furnace 2 is provided with a molten steel heating oxygen burner 14, and the upper part of the melting section of the shaft furnace 2 is provided with a main oxygen burner 15. An annular flue 16 is installed at the temperature of 1200-1700°C in the transition section, a cooling spray system 17 is installed in the preheating section of the shaft furnace 2, and a sealed feeding system 18 is installed on the top of the shaft furnace 2;

[0056] The coal gasification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com