Device for quickly cooking euphausia superba

An Antarctic krill, rapid technology, applied in food science and other directions, can solve the problems of long time, heat exchange efficiency, reduction of cooking liquid temperature, dissolution of water-soluble protein, etc., to improve yield and quality, fast and efficient cooking, and reduce cooking. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

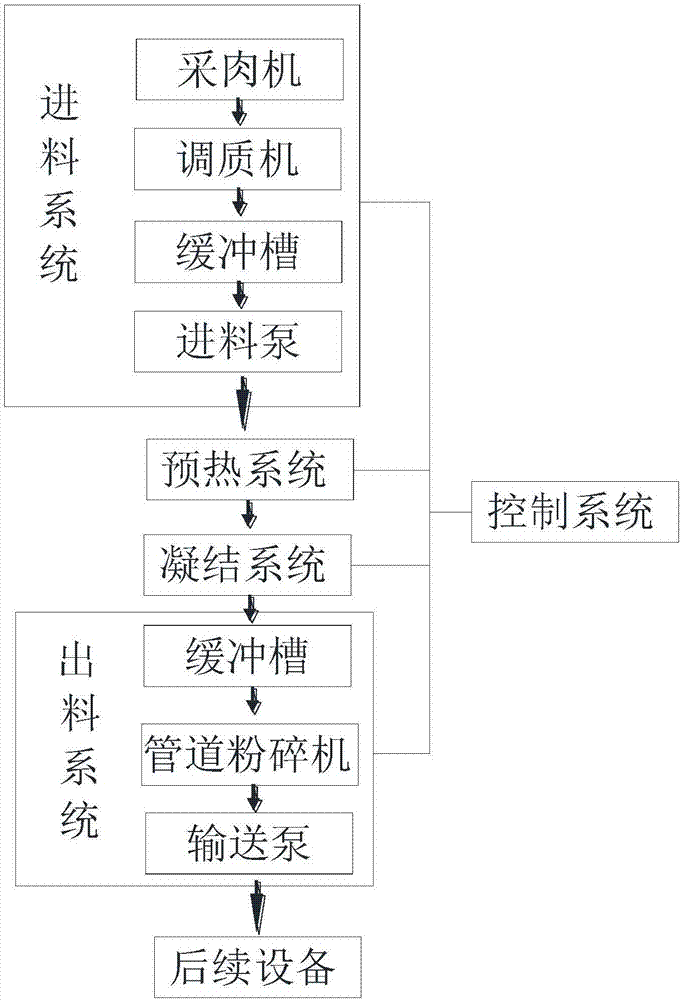

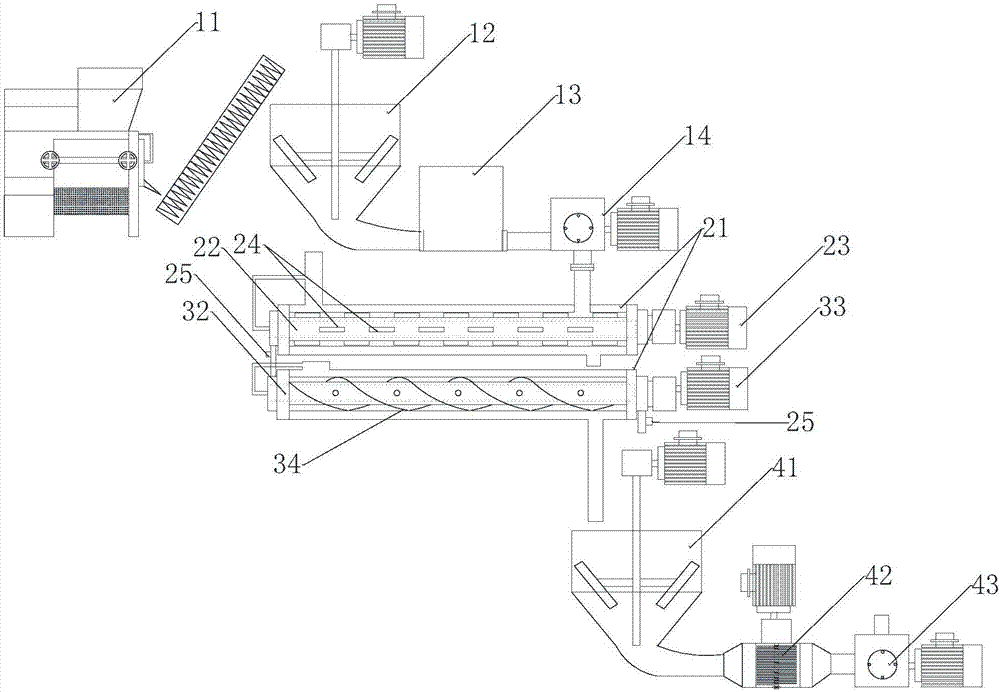

[0044] A device for rapid cooking of Antarctic krill, including a feeding system, a preheating system, a coagulation system, a discharging system and a control system;

[0045] The feed system includes a meat harvester 11, a conditioning machine 12, a buffer tank 13 and a feed pump 14;

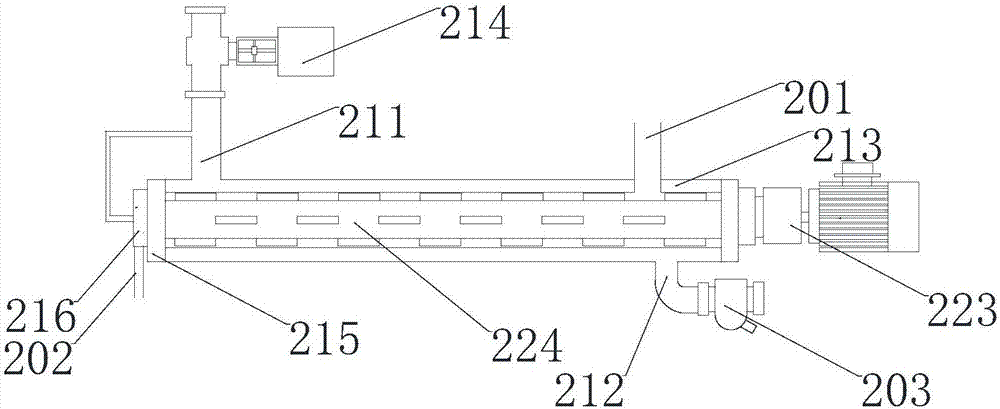

[0046] The preheating system includes a steam sleeve 21, a preheating spindle 22, a spindle motor 23, a scraper 24 and a temperature sensor 25;

[0047] The condensation system includes a steam sleeve 21, a direct steam injection main shaft 32, a scraper motor 33, a spiral scraper 34 and a temperature sensor 25;

[0048] The discharge system includes a discharge buffer tank 41, a pipeline pulverizer 42 and a delivery pump 43;

[0049] Both the preheating system and the condensing system are provided with a material inlet 201 and a material outlet 202, and the material outlet 202 of the preheating system is connected with the material inlet 201 of the condensing system through a pipeline;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com