Method for bonding between electrical devices using ultrasonic vibration

A technology of electrical devices and ultrasonic waves, which is applied in the field of bonding between electrical devices, can solve problems such as difficult ACF bonding processes, and achieve the effect of reducing processing pressure and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below.

[0035] In the present invention, an electrical device to be bonded means a device used in an electrical product such as a semiconductor chip or a substrate, and bonding between an electrical device means between a semiconductor chip and a substrate, a semiconductor chip and a An electrical connection between semiconductor chips or between a substrate and a substrate.

[0036] The type of such semiconductor chips is not particularly limited, and may include, for example, display driver circuit ICs, image sensor ICs, memory ICs, non-memory ICs, ultra-high frequency or RF ICs, semiconductor ICs with silicon as a main component, and compound semiconductor ICs.

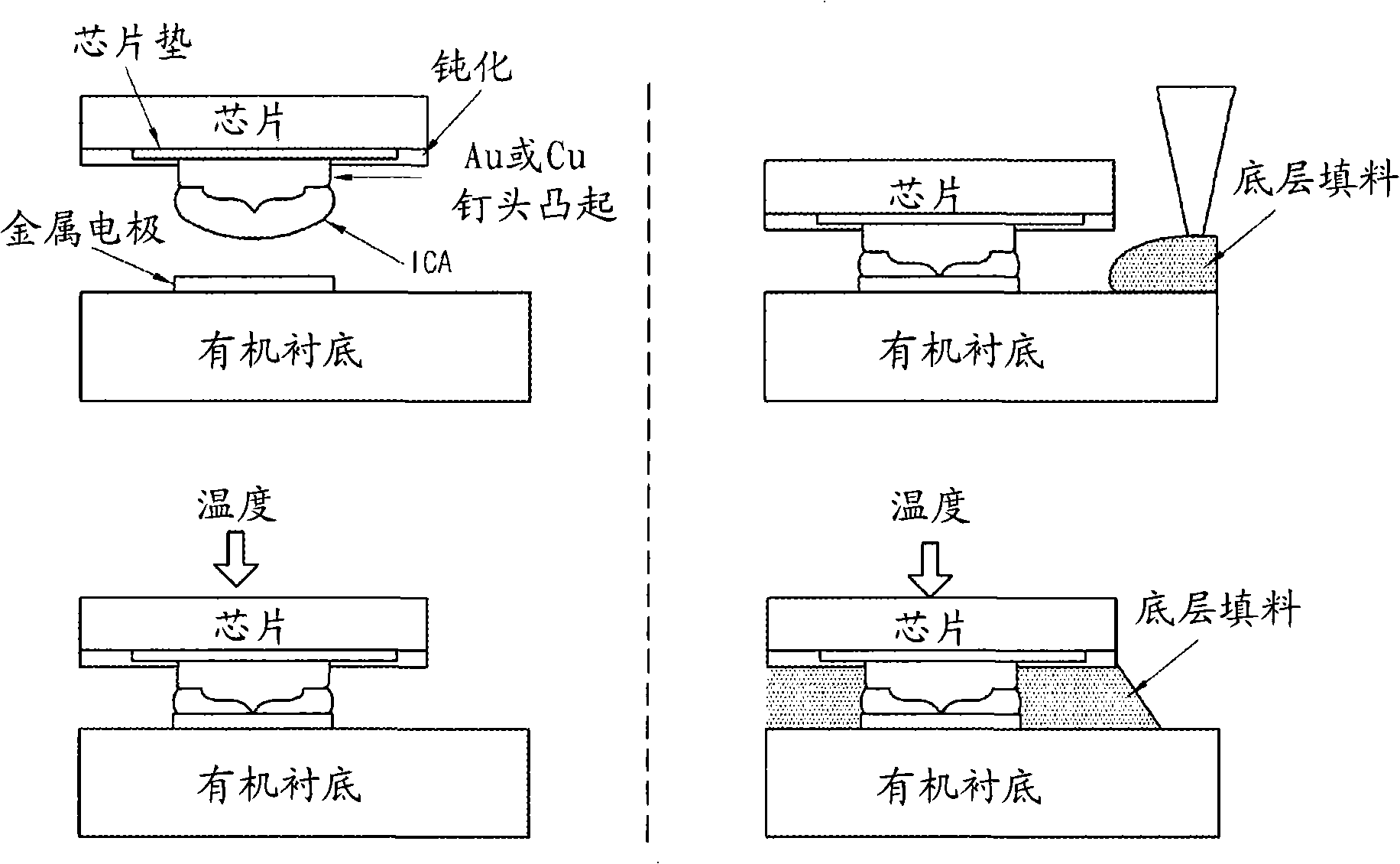

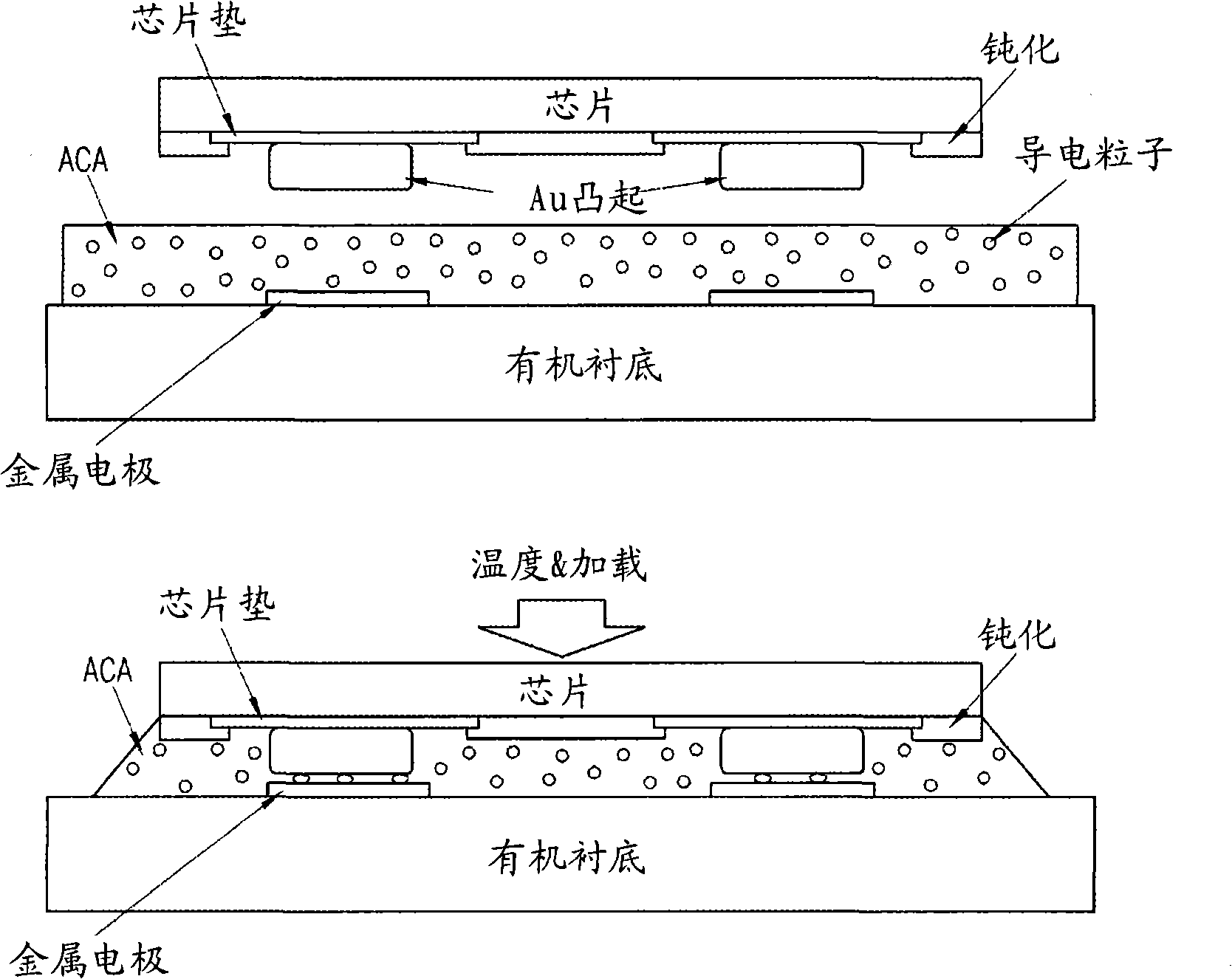

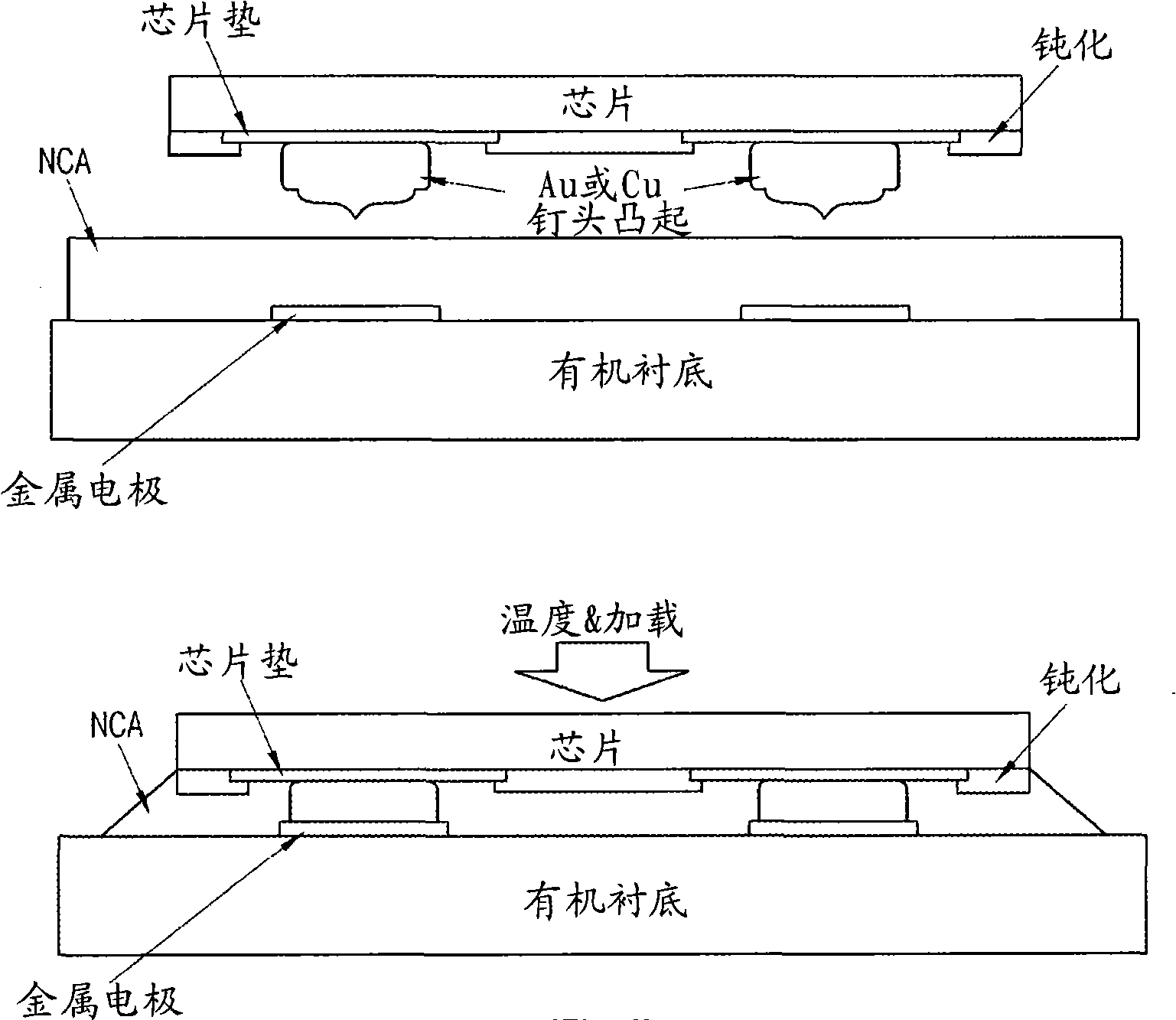

[0037] In electrodes on the bonding area (or input / output pads), the semiconductor chip may have no non-solder bumps or may have bumps selected from, for example, gold stud bumps, copper stud bumps, gold plated bumps, copper plated One of bumps, electroless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com