Self-oxygenation biological filter bed for sewage treatment

A biological filter bed and sewage treatment technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as the need for strong aeration, wetland surface soil compaction, and difficulties , to achieve the effects of improving sewage treatment efficiency, high nitrogen and phosphorus removal efficiency, and strong seasonal adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

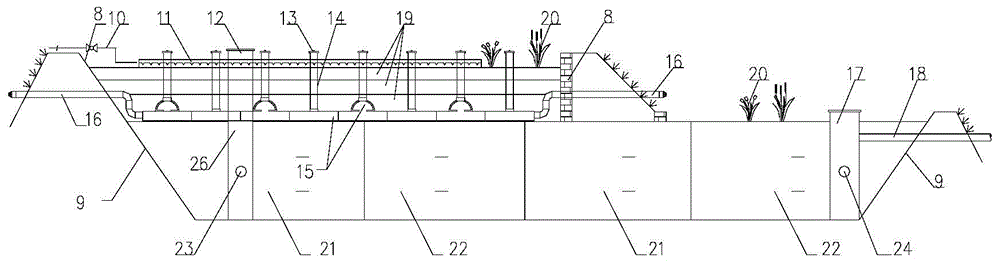

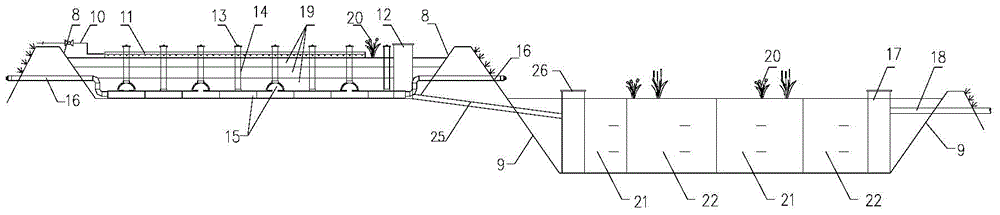

[0089] The present invention will be further described below in conjunction with the accompanying drawings.

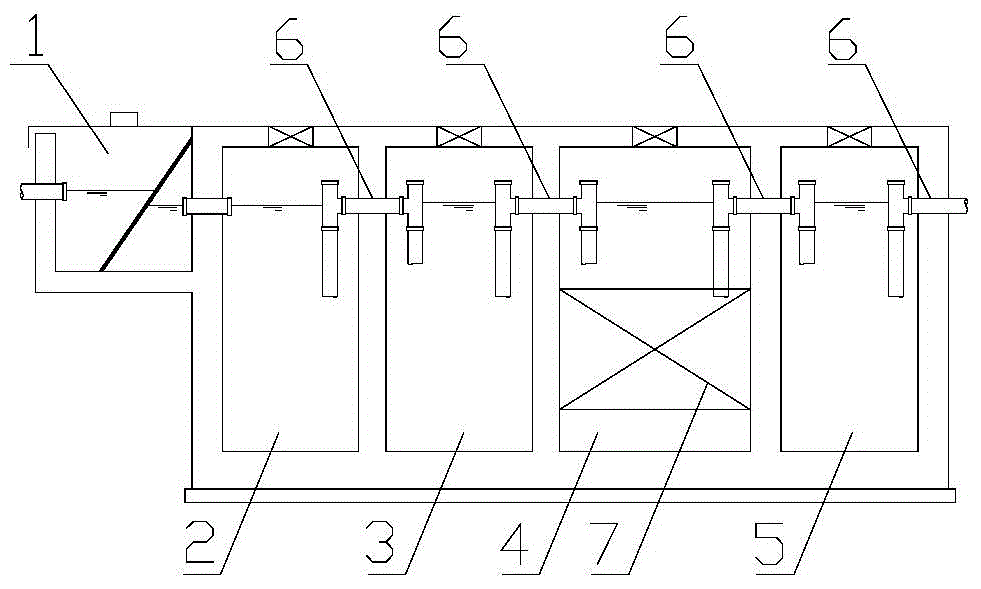

[0090] as attached Figure 1-7 As shown, the present invention mainly consists of an anaerobic water collection pretreatment system, an automatic aerobic aerobic biological filter bed system and an anaerobic underflow ecological phosphorus fixation system.

[0091] In the anaerobic water collection pretreatment system: grid well 1, filter sediment tank 2, oil separation adjustment tank 3, anaerobic hydrolysis tank 4, and water outlet tank 5 are connected in sequence, and the oil separation and scum removal device 6 is used to remove the scum in the tank body liquid The locations are connected, and the oil separation and descum removal device extends 0.5 to 1.5 meters below the liquid surface. The diameter of the oil separation and descum removal device 6 is Φ75 to 200 mm, and an anaerobic filter material layer 7 is set in the anaerobic hydrolysis tank 4 .

[0092] Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com