Food flour-coating device capable of recycling coating flour

A technology of breading and food, which is applied in the field of food breading devices, can solve the problems of increasing production costs, inability to recycle breading materials, and waste of breading materials, so as to save production costs, improve the quality of breading, and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

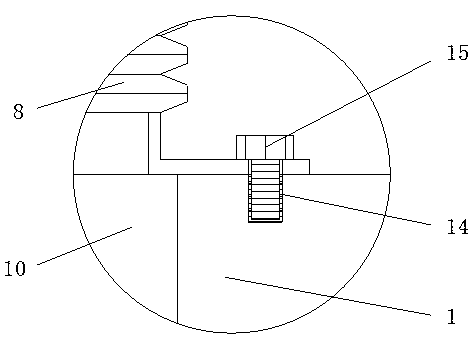

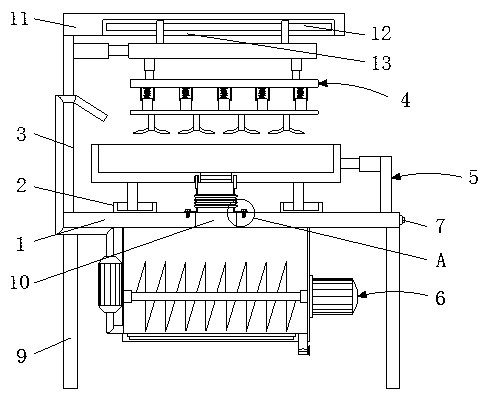

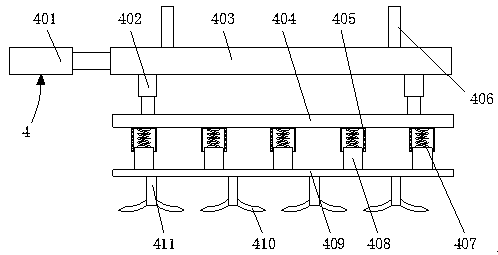

[0024] see Figure 1-8, a food coating device that can recycle powder coating materials, including a support 1, support legs 9 are fixedly connected around the bottom of the support 1, the bottom of the support legs 9 is fixedly connected with a moving mechanism, and the moving mechanism is installed with The support of the walking wheel is installed on the bottom of the support leg 9, and its movement method is: people push the support 1 with their hands, so that the walking wheel moves, and finally drives the support 1 to move, and the middle end of the right side of the support 1 A controller 7 is fixedly connected, and the two terminals of the controller 7 are connected with a power plug through wires, and the outer surface of the controller 7 is fixedly connected with a motor switch 71, a fan switch 72, a kneading switch 73, and a shaking switch in sequence from front to back. 74. Telescopic control buttons 75 and temperature adjustment knobs 76. The left end of the inner...

Embodiment 2

[0026] see Figure 1-8 , a food coating device that can recycle powder coating materials, including a support 1, support legs 9 are fixedly connected around the bottom of the support 1, the bottom of the support legs 9 is fixedly connected with a moving mechanism, and the moving mechanism includes The traveling wheel at the bottom of the support leg 9 and the driving machine installed at the bottom left end of the support 1 move in the following way: the driving machine is activated by the driving machine switch, and the output shaft of the driving machine drives the walking wheel at the left front end of the bottom of the supporting seat 1 through a belt Walking with the walking wheel located at the left rear end of the bottom of the support 1, so as to realize the mobile demand of the support 1, the middle end on the right side of the support 1 is fixedly connected with the controller 7, and the two terminals of the controller 7 are connected by wires. A power plug, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com