Well head gas recovery and purification device and method

A purification device and wellhead gas technology, applied in gas fuel, petroleum industry, fuel, etc., can solve the problems of single function, low equipment utilization rate, large construction area, etc., and achieve simple operation, simple structure and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

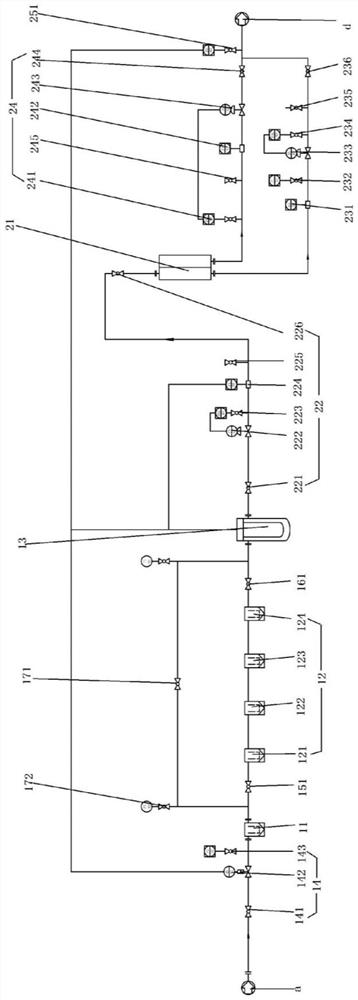

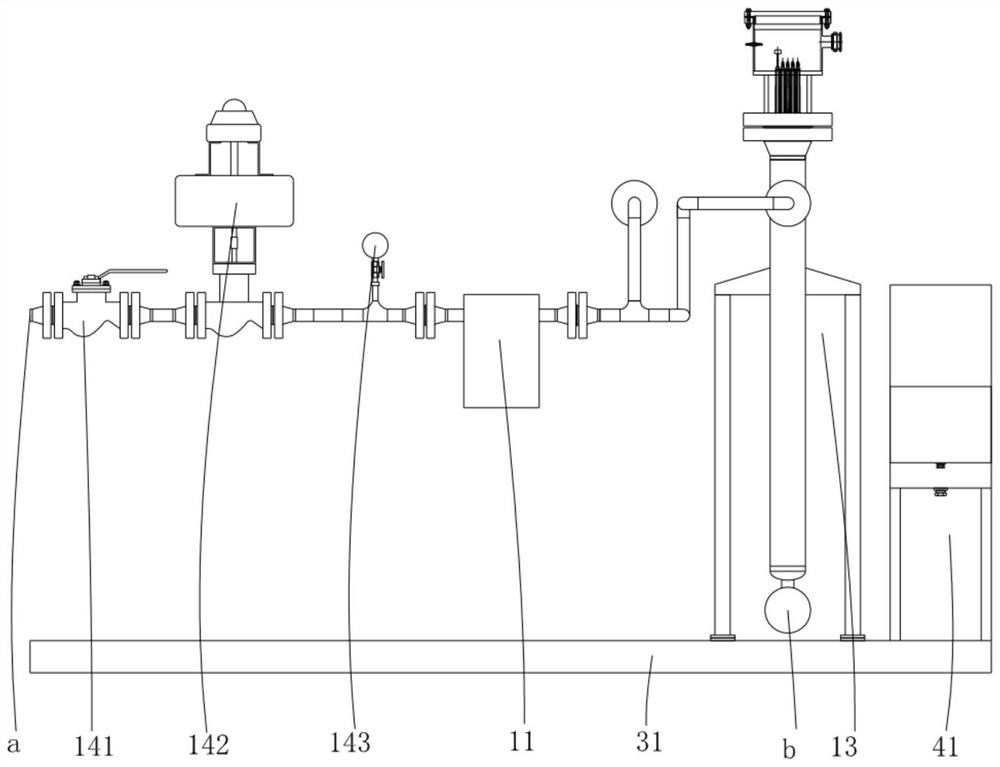

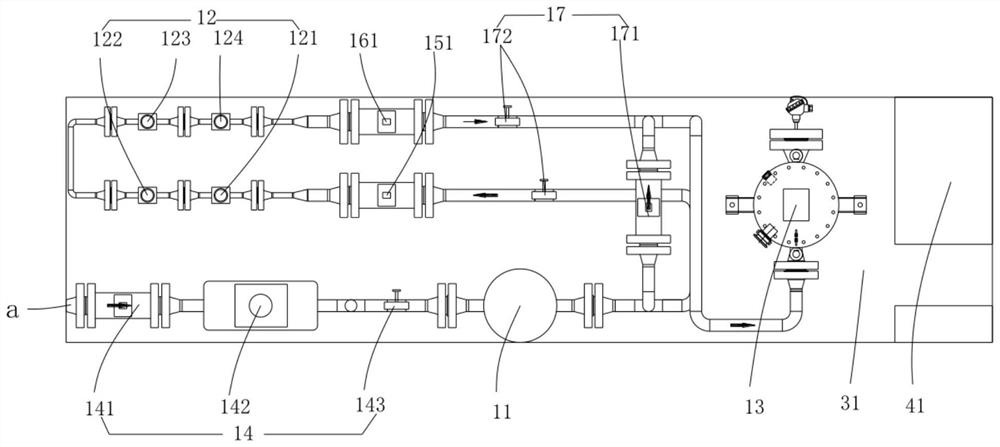

[0061] Such as Figures 1 to 5 As shown, a recovery and purification device includes a first mounting base 31, a second mounting base 32, a purification module, a separation module, a first control module 41 and a second control module 42, and the purification module and the first control module 41 are respectively set On the first mounting base 31 , the separation module and the second module are respectively disposed on the second mounting base 32 .

[0062] The first mounting seat 31 is a cuboid structure with a length of 380 cm and a width of 100 cm. The second mounting seat 32 is a cuboid structure with a length of 450 cm and a width of 90 cm.

[0063]The purification module includes a steam-water separation system 11 , a filtration system 12 and a heating system 13 . The steam-water separation system 11 includes a steam-water separator. The filter system 12 includes a first filter 121, a second filter 122, a third filter 123 and a fourth filter 144, the first filter 1...

Embodiment 2

[0081] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the first pressure valve assembly is not provided on the intake pipe 14 of this embodiment. The filtration system 12 of this embodiment is three heaters connected in series, and the filtration precision of the three filters is 1 μm, 0.01 μm, and 0.01 μm in sequence. The membrane filter of this embodiment includes a first membrane group, a second membrane group and a third membrane group, the outlet of the first membrane group is connected to the fourteenth valve 261, the outlet of the second membrane group is connected to the fifteenth valve 271, and the outlet of the second membrane group is connected to the fifteenth valve 271. The outlet of the three-membrane group is connected to the sixteenth valve 281 .

[0082] The recovery and purification device in this embodiment has three working states.

[0083] When in the first working state, the first valve 141, the second valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com