Coal chemical industry concentrated salt wastewater regeneration and recycling treatment method and system for implementing method

A treatment method, coal chemical technology, applied in the direction of energy wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as patent publications that have not yet been found, reduce scale and operating costs, and reduce the amount of high-concentration brine , to ensure the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

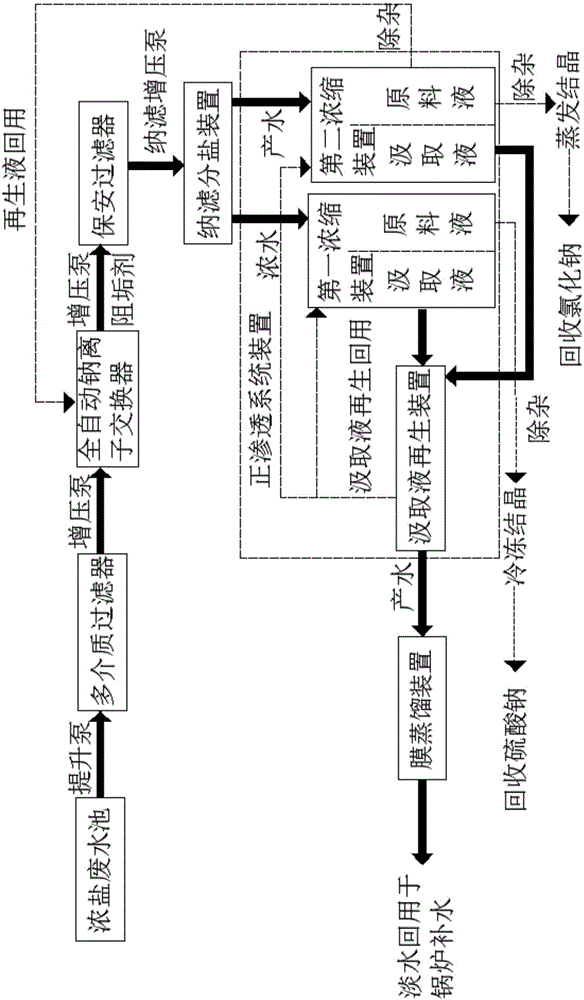

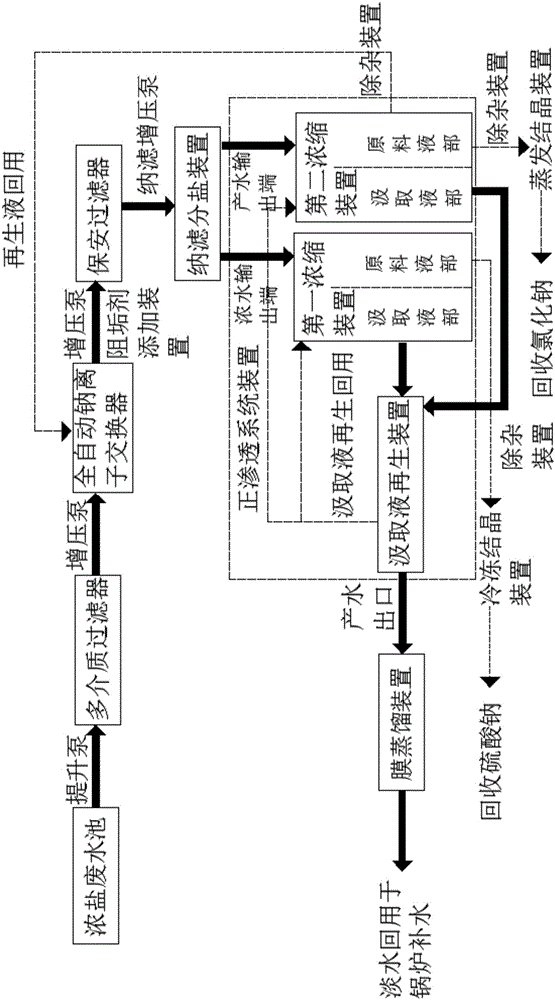

[0045] A kind of regeneration and reuse treatment method of concentrated salt waste water of coal chemical industry, the steps are as follows (the process flow diagram can be as follows: figure 1 shown):

[0046] (1) The concentrated salt wastewater produced by coal chemical industry is pressurized by a lift pump, and then passed through a multi-media filter to remove suspended solids. The specific operation requires that the inlet water is at room temperature and the inlet pressure is 0.1-0.6MPa, and then processed by an automatic sodium ion exchanger. , so that the hardness of the wastewater is lower than 0.03mmol / L, add 3-6ppm scale inhibitor to the outlet pipe of the automatic sodium ion exchanger, after passing through the security filter, and then pressurized by the nanofiltration booster pump to enter the nanofiltration separator The salt device intercepts high-value salts (mainly sodium sulfate) and small molecular organics, separates concentrated water (mainly sodium ...

Embodiment 2

[0061] A kind of regeneration and reuse treatment method of concentrated salt waste water of coal chemical industry, steps are all the same as embodiment 1 unless otherwise specified, and the difference is as follows:

[0062] (1) Multi-media filter

[0063]Concentrated salt wastewater (TDS: 10000mg / L, COD: 200mg / L, total hardness: 4mmol / L) produced after biochemical treatment and desalination of coal chemical production wastewater or clean water desalination enters the multi-media filter, and the inlet pressure is 0.1 MPa, to remove residual suspended matter (to protect the subsequent sodium ion exchanger), pressurize the effluent to 0.2MPa and send it to the fully automatic sodium ion filter;

[0064] (2) Fully automatic sodium ion exchanger

[0065] The fully automatic sodium ion exchanger adopts strong acid cation exchange resin, the inlet water is at room temperature and the pressure is 0.2MPa, so that the total hardness of the outlet water is 0.020mmol / L;

[0066] (3) ...

Embodiment 3

[0071] A method for regeneration and reuse of concentrated salt wastewater from coal chemical industry, the steps are the same as in Example 1 unless otherwise specified, the differences are as follows:

[0072] (1) Multi-media filter

[0073] Concentrated salt wastewater (TDS: 15000mg / L, COD: 250mg / L, total hardness: 6mmol / L) produced by biochemical treatment and desalination of coal chemical production wastewater or clean water desalination enters the multi-media filter, and the inlet pressure is 0.2 MPa, to remove residual suspended matter (to protect the subsequent sodium ion exchanger), pressurize the effluent to 0.3MPa and send it to the fully automatic sodium ion filter;

[0074] (2) Fully automatic sodium ion exchanger

[0075] The fully automatic sodium ion exchanger adopts strong acid cation exchange resin, the inlet water is at room temperature and the pressure is 0.3MPa, so that the total hardness of the outlet water is 0.025mmol / L;

[0076] (3) Nanofiltration sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com