Patents

Literature

87results about How to "Shorten the film setting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

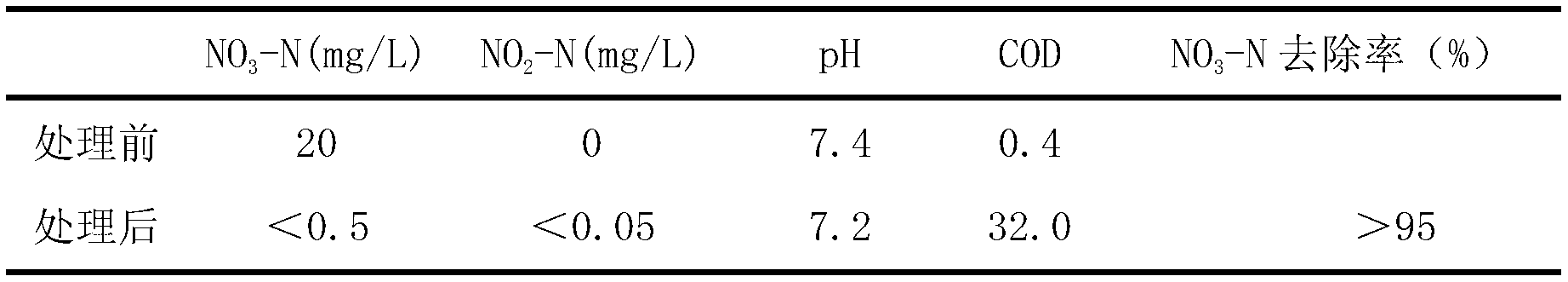

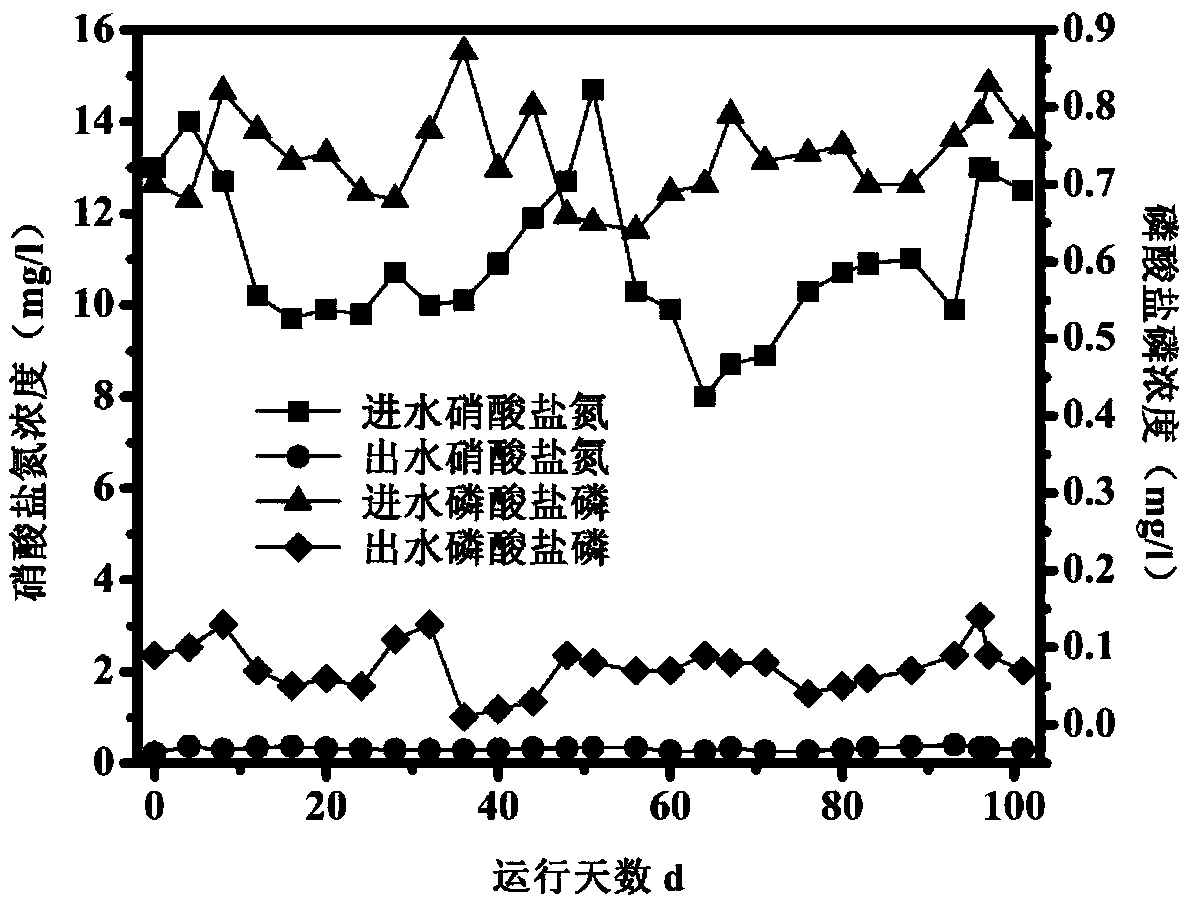

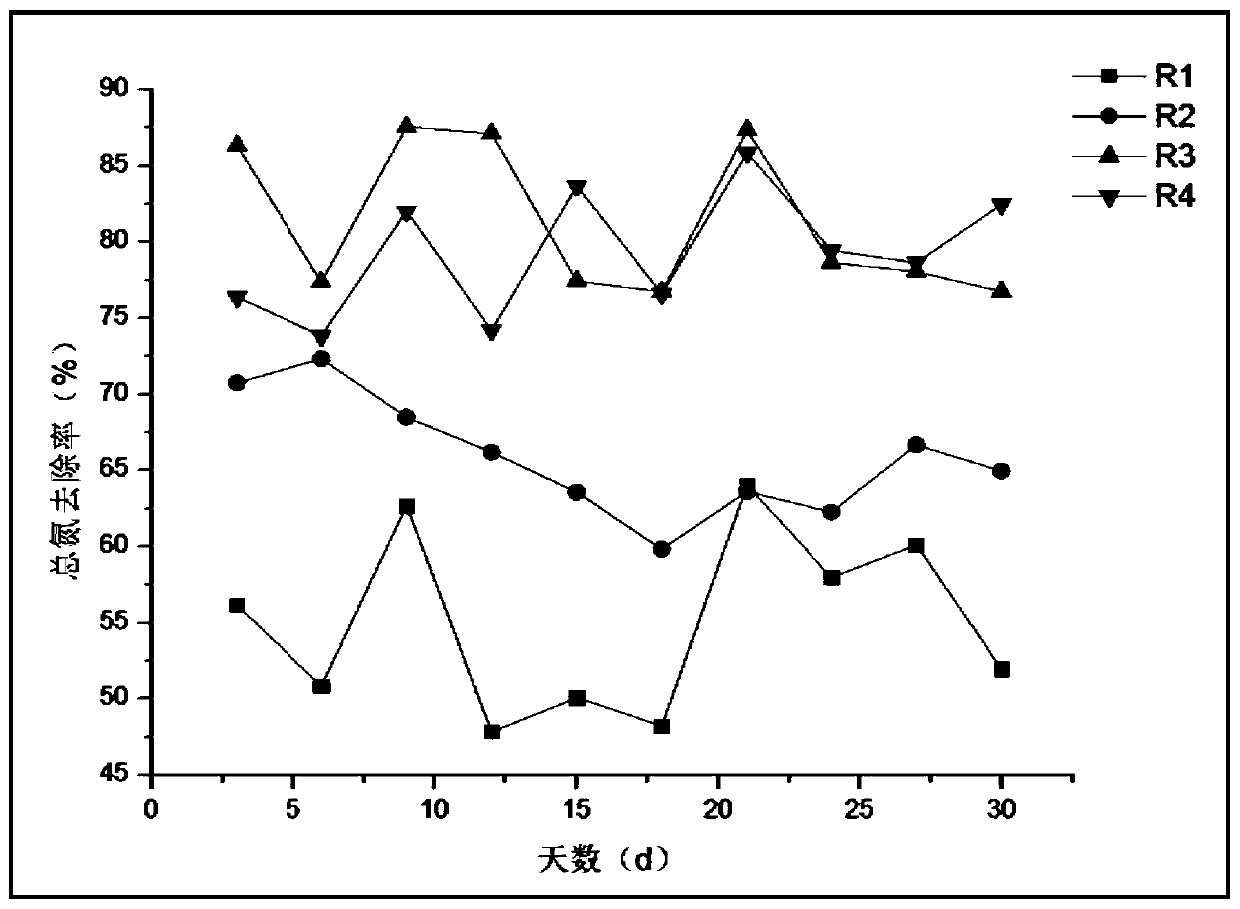

Coupling filler autotrophic denitrification biofilter and application

ActiveCN109052641ADifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiofilmSewage

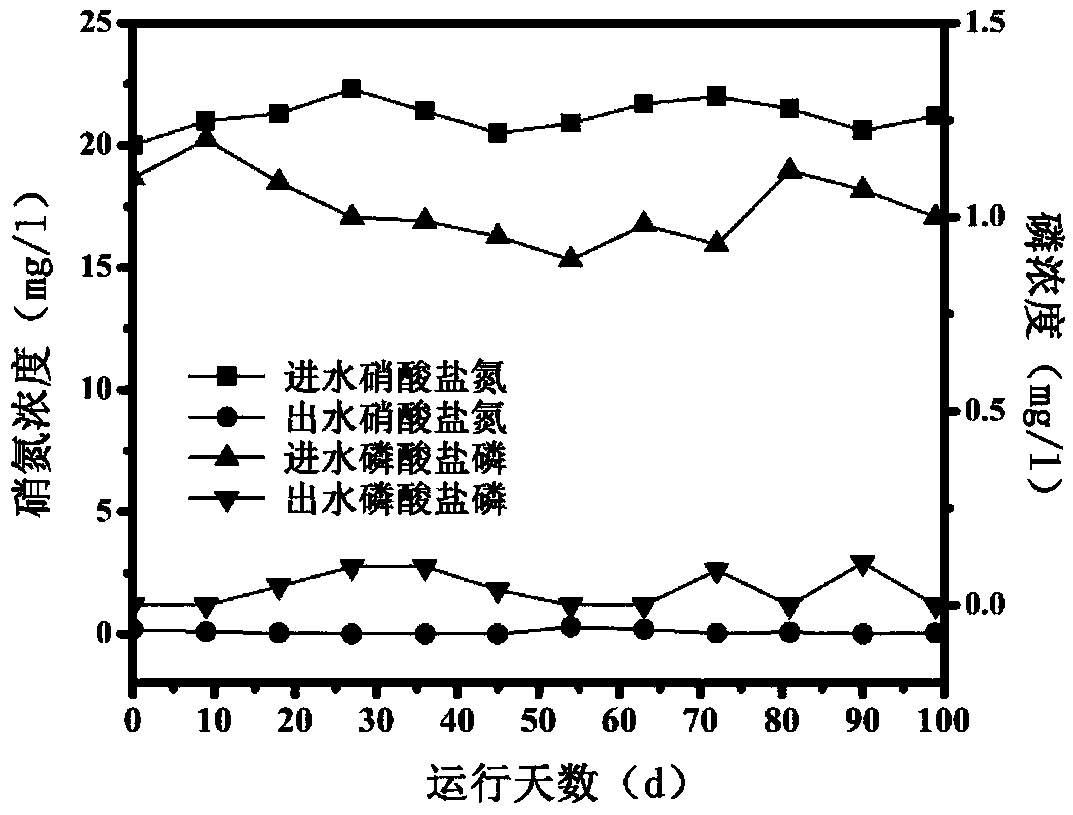

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

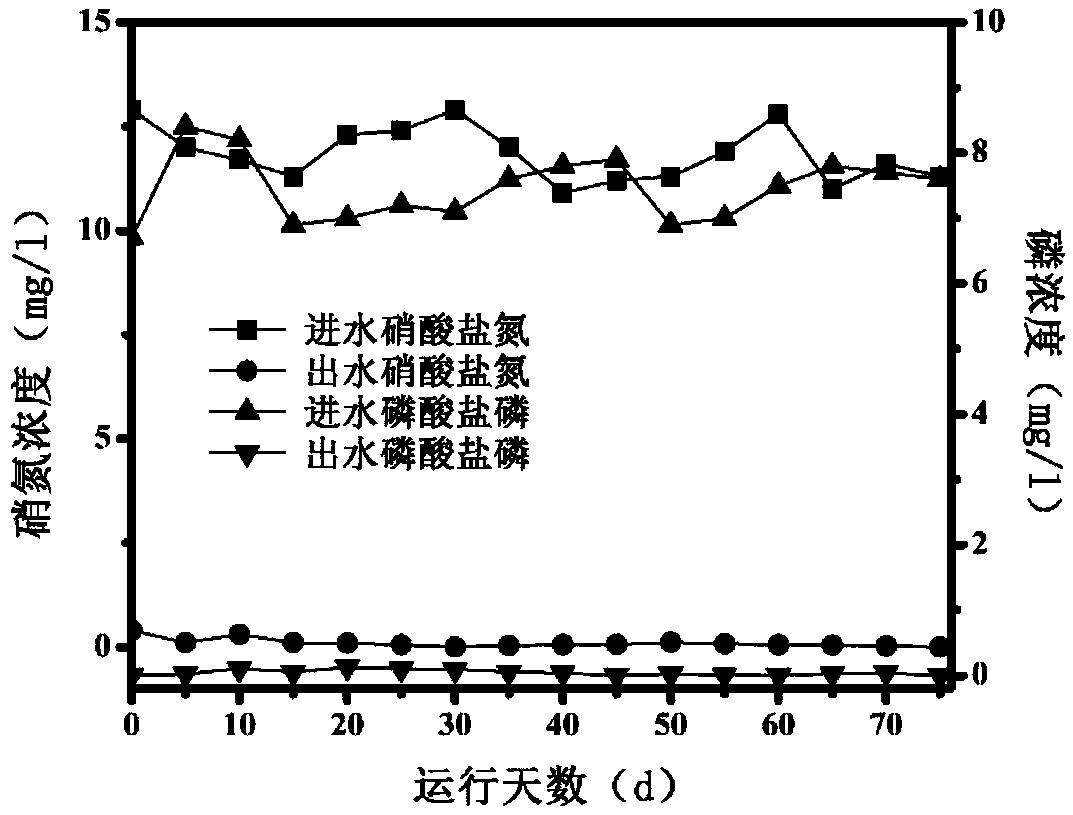

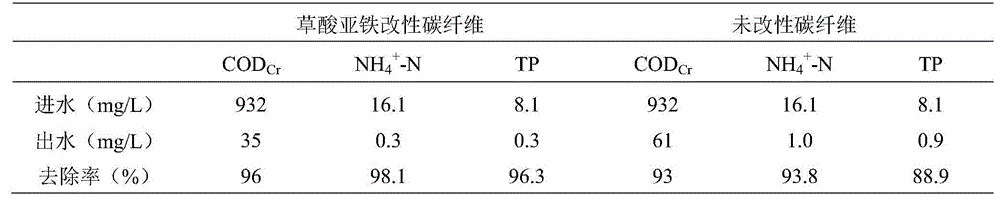

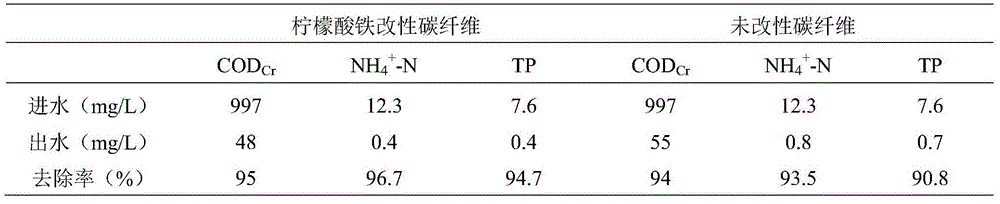

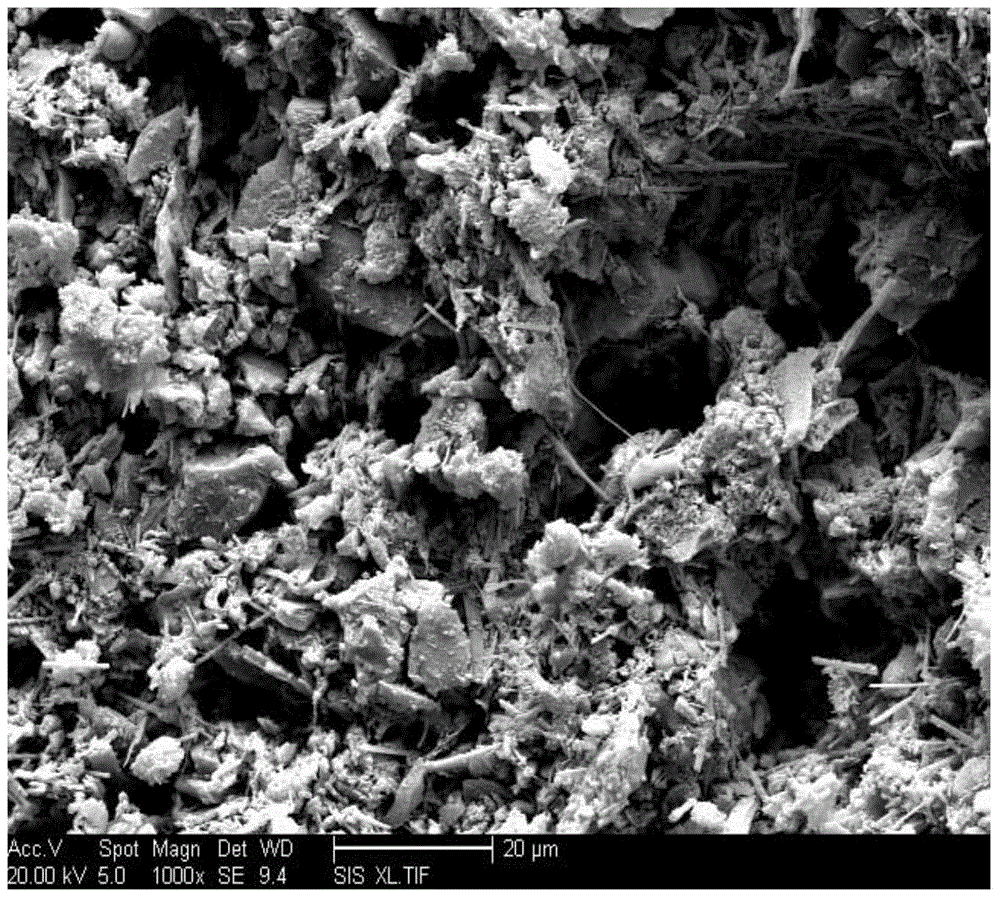

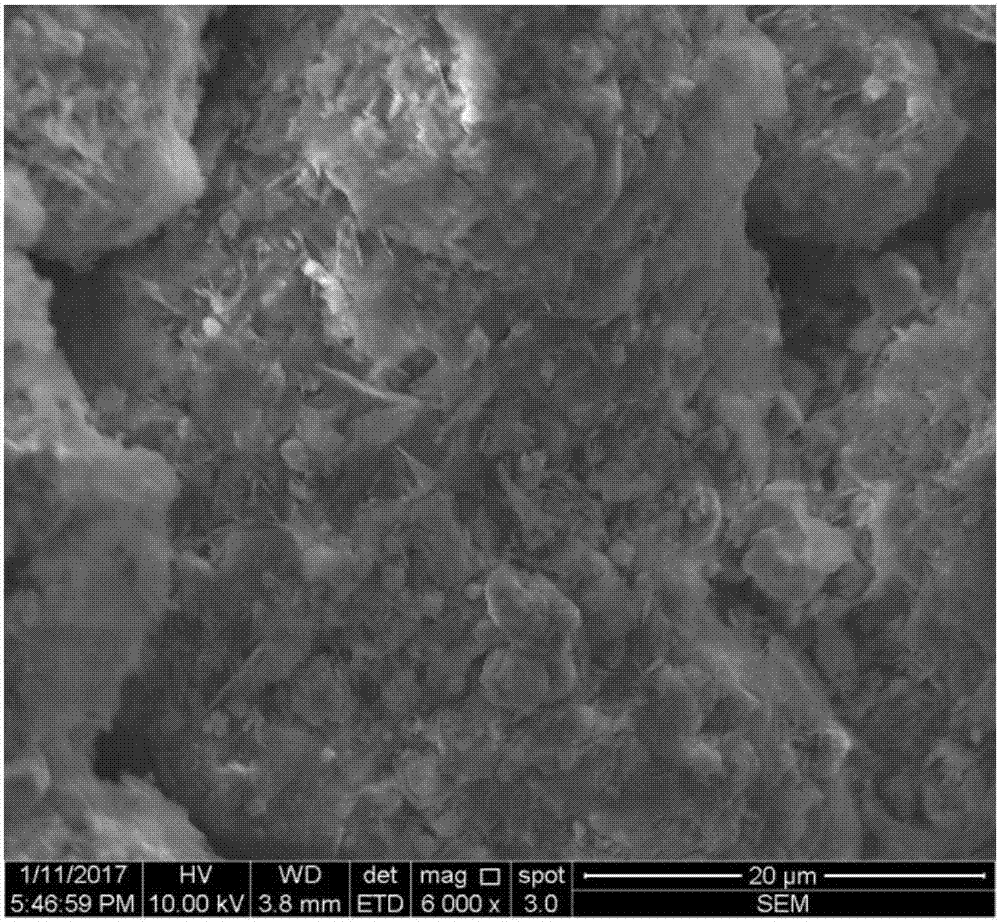

Excellent and efficient carbon fiber biofilm carrier modification method

InactiveCN104803471AGood biocompatibilityGood flexibilitySustainable biological treatmentBiological water/sewage treatmentFiberCarbon fibers

The invention discloses an excellent and efficient carbon fiber biofilm carrier modification method and aims to improve water treatment performance of carbon fibers used as biofilm carrier materials. A basic raw material is the carbon fibers; the modification method mainly comprises steps as follows: firstly, acid oxidation treatment is performed on the carbon fibers, so that surfaces of the carbon fibers are ensured to have sufficient functional groups for preparation for iron carrying; then an organic iron solution is used as a modifying agent, surface modification is performed on the carbon fibers with a liquid phase impregnation method, and an organic-iron-modified carbon fiber biofilm carrier material with the surface containing the iron element is prepared. The preparation method is simple and easy to implement, prepared organic-iron-modified carbon fibers can keep original excellent performance of the carbon fibers, the surface roughness and the hydrophilicity are significantly improved, the film colonization cycle is short, the microbial activity is improved, time required for water treatment is short, removal rates of COD, ammonia nitrogen and total phosphorus are obviously increased, the outgoing water quality is good in stability, and the reuse rate is higher.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

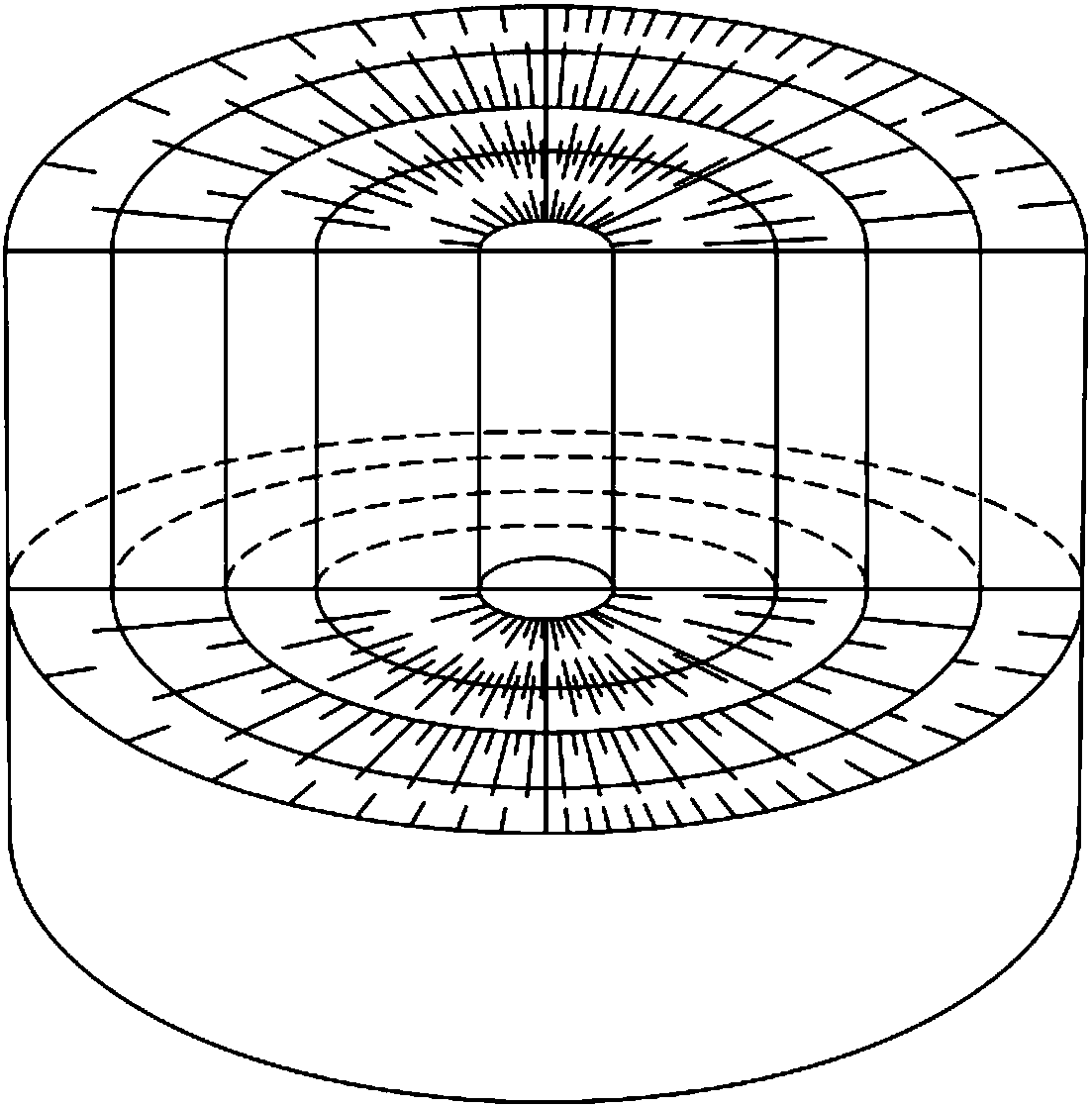

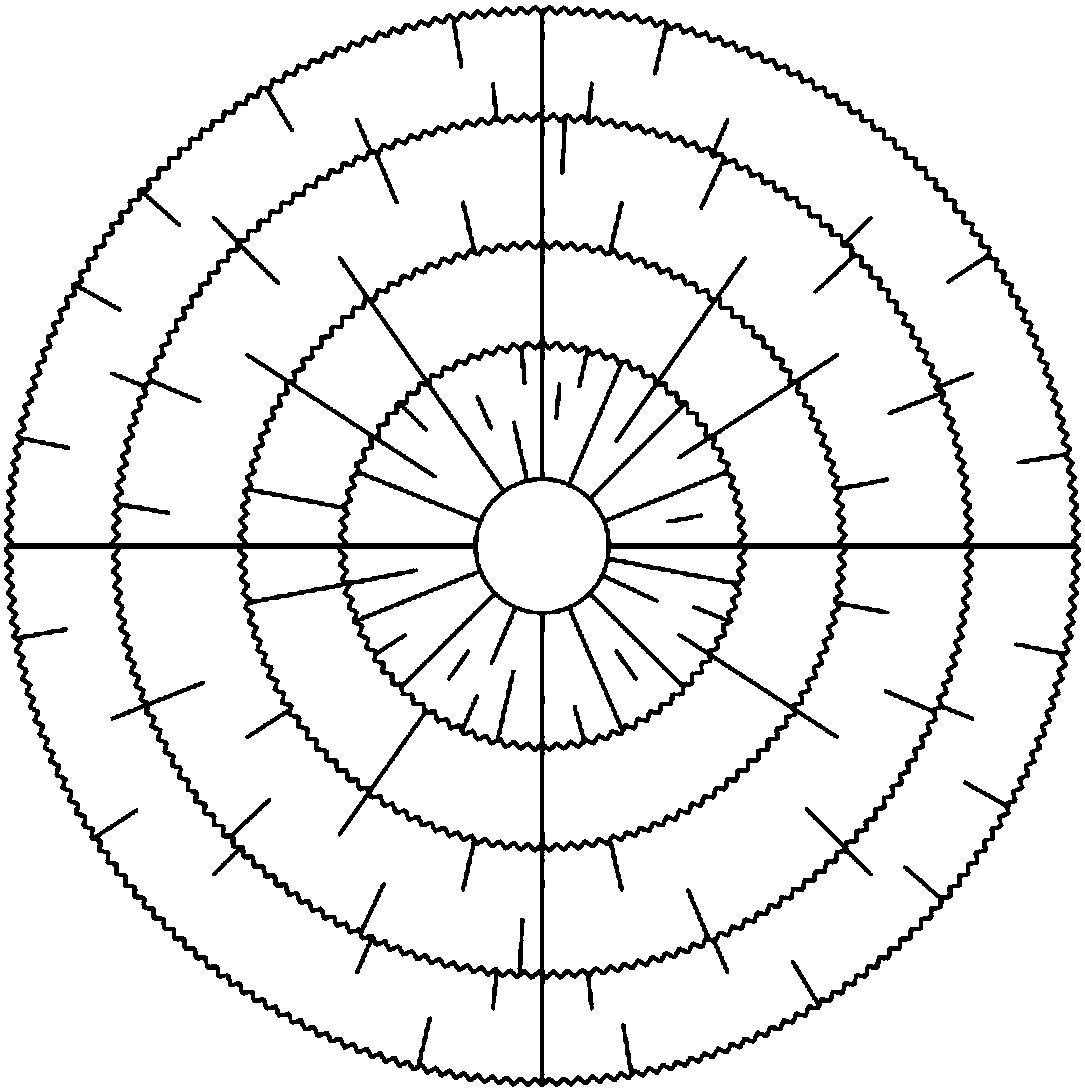

Rotating cage type floating stuffing biological sewage treatment method and equipment thereof

InactiveCN1654359APromote sheddingEasy to handleSustainable biological treatmentBiological water/sewage treatmentDecompositionPollutant

The present invention relates to water treating technology, and is especially one kind of rotary cage type biological suspended stuffing sewage treating method and apparatus. The apparatus includes central shaft, rotary cage, inner and outer vanes, suspended stuffing, bearing and bearing cover plate. The central shaft is connected to the rotary cage to form rotating pair, the bearing is located with the bearing cover plate and screws, the suspended stuffing is filled into the rotary cage, and the inner and outer vanes are screwed to peripheral wall of the rotary cage. The inflowing sewage drives the outer vanes to rotate the rotary cage and mixes with the suspended stuffing and central aerating airflow, the inner vanes of the rotary cage form homogeneous gas, liquid and solid fluid to make sewage well contact with biological membrane on the stuffing and aerating airflow for biodegradation and airflow oxidation decomposition of organic pollutant and purification of sewage.

Owner:SOUTH CHINA UNIV OF TECH

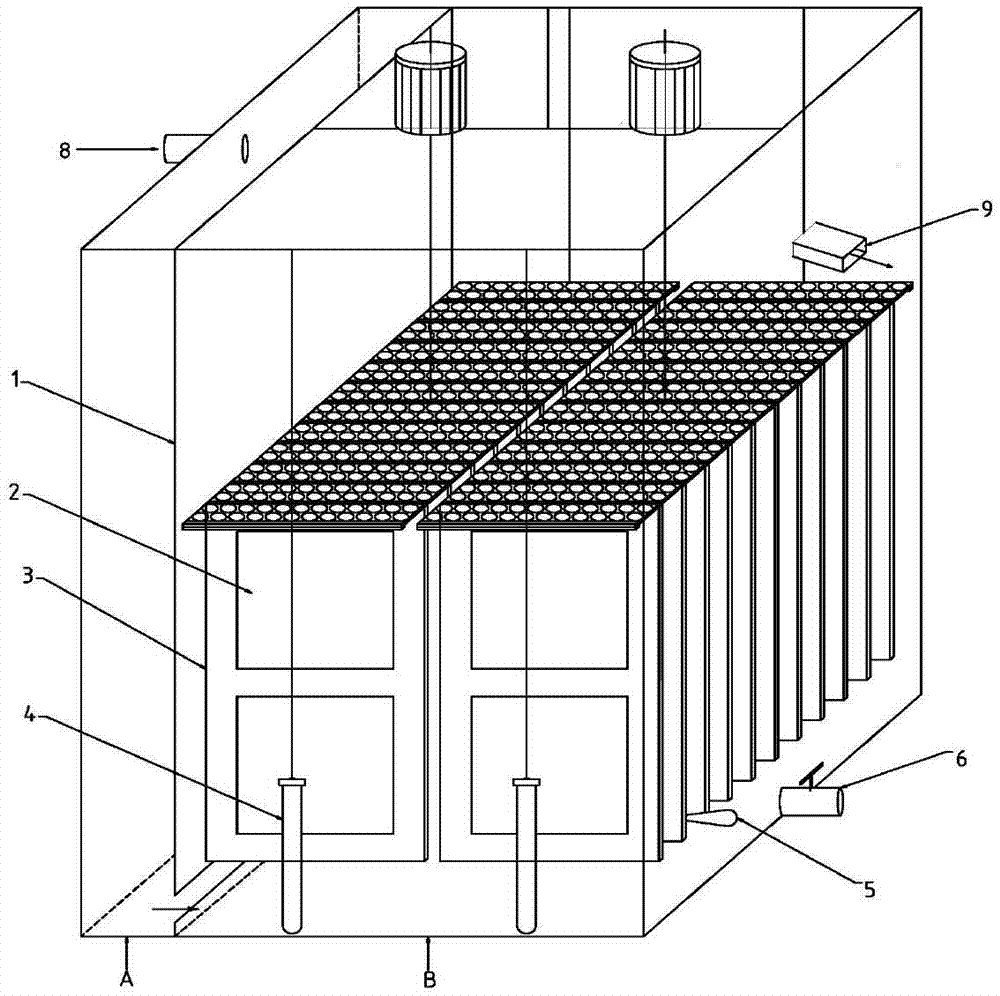

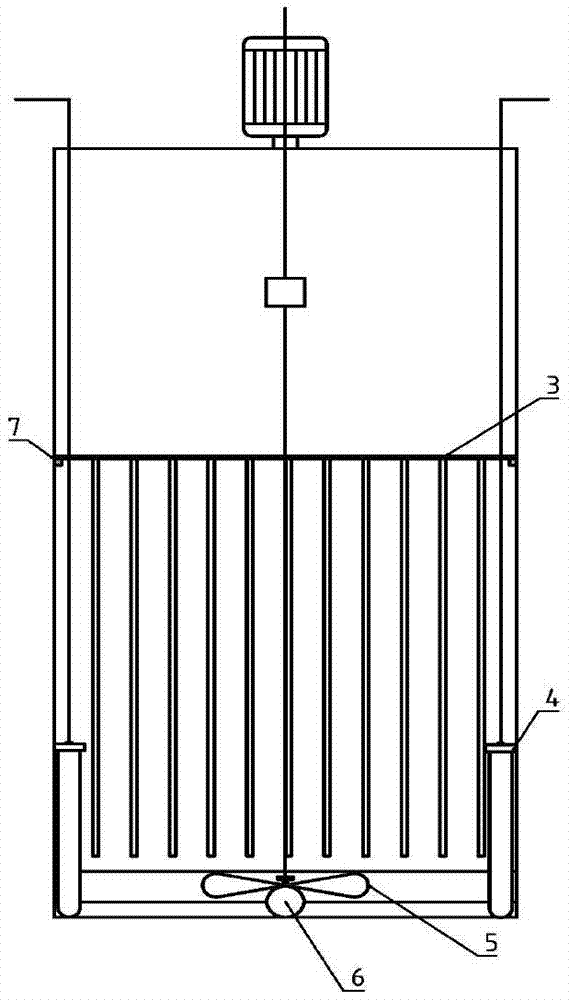

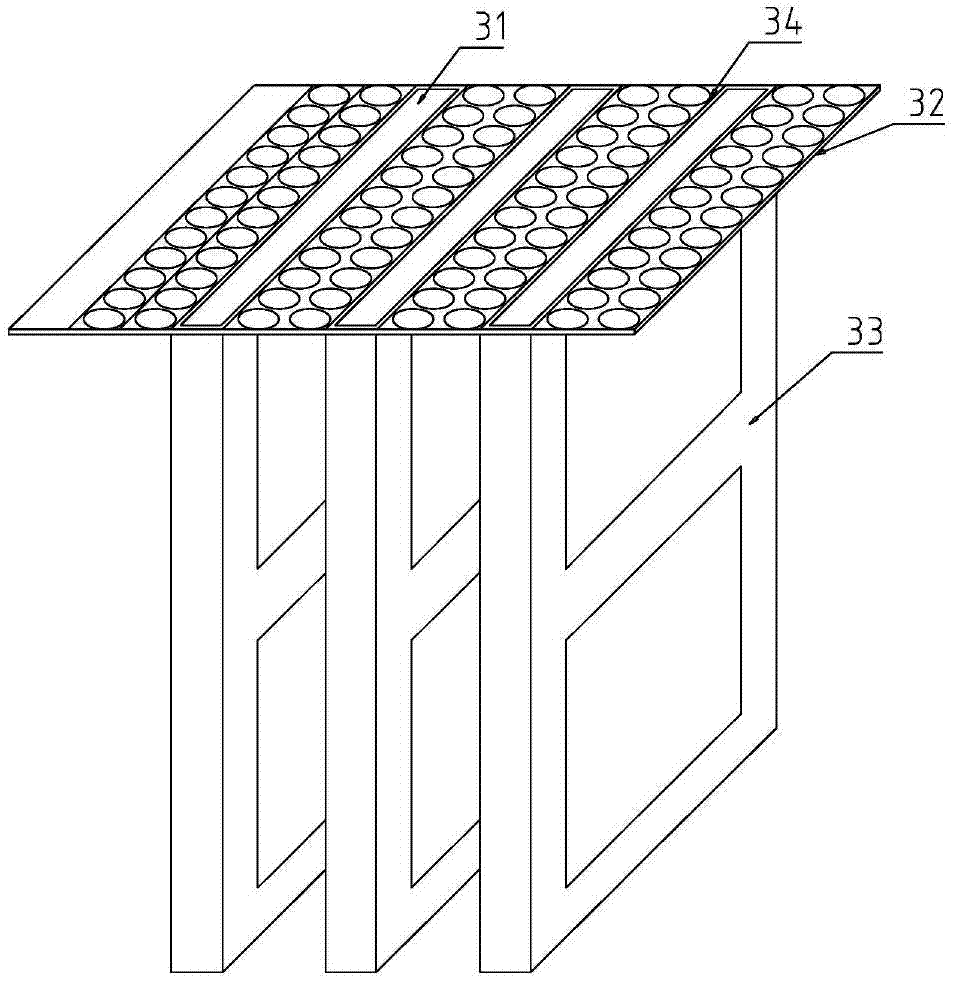

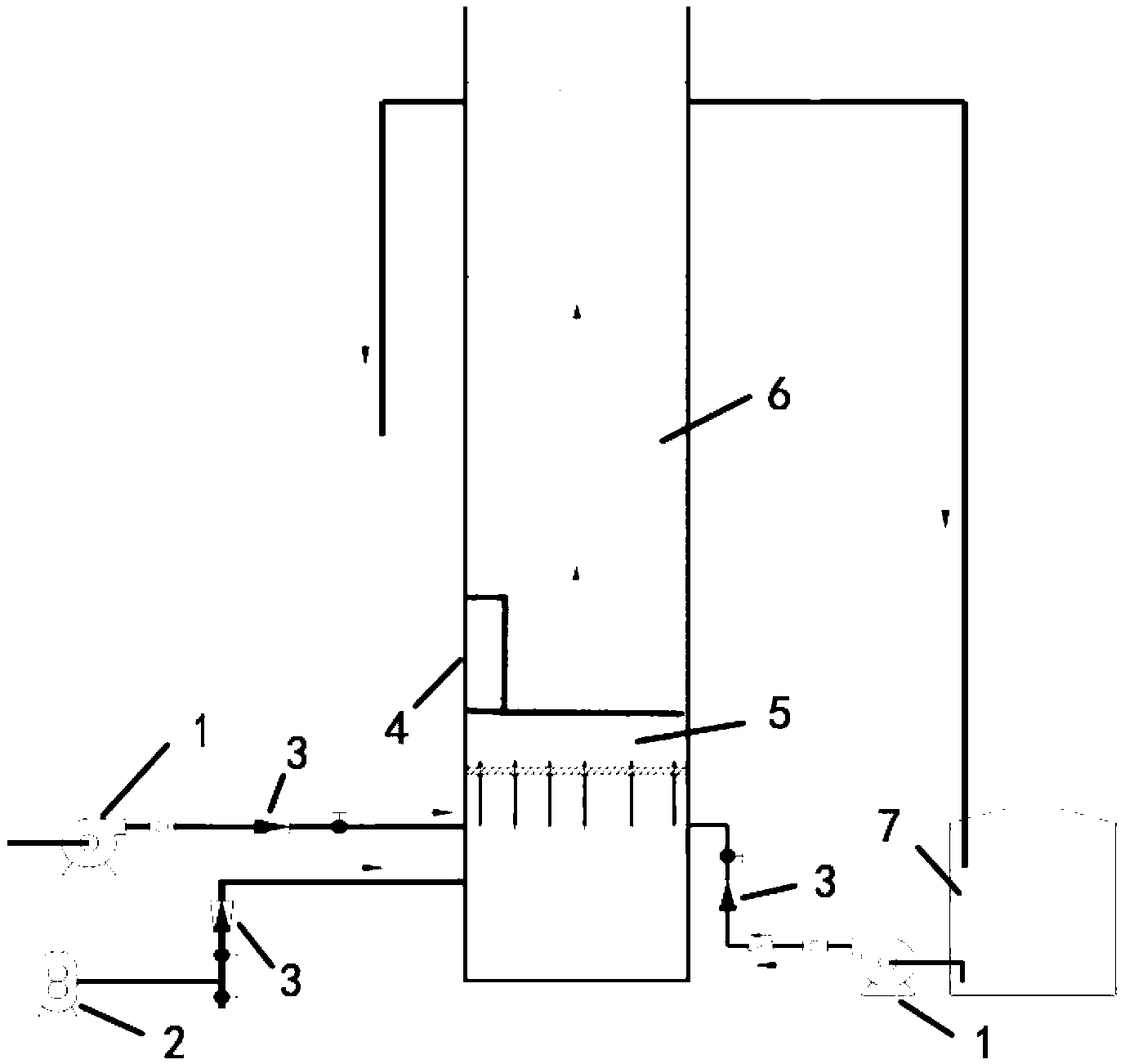

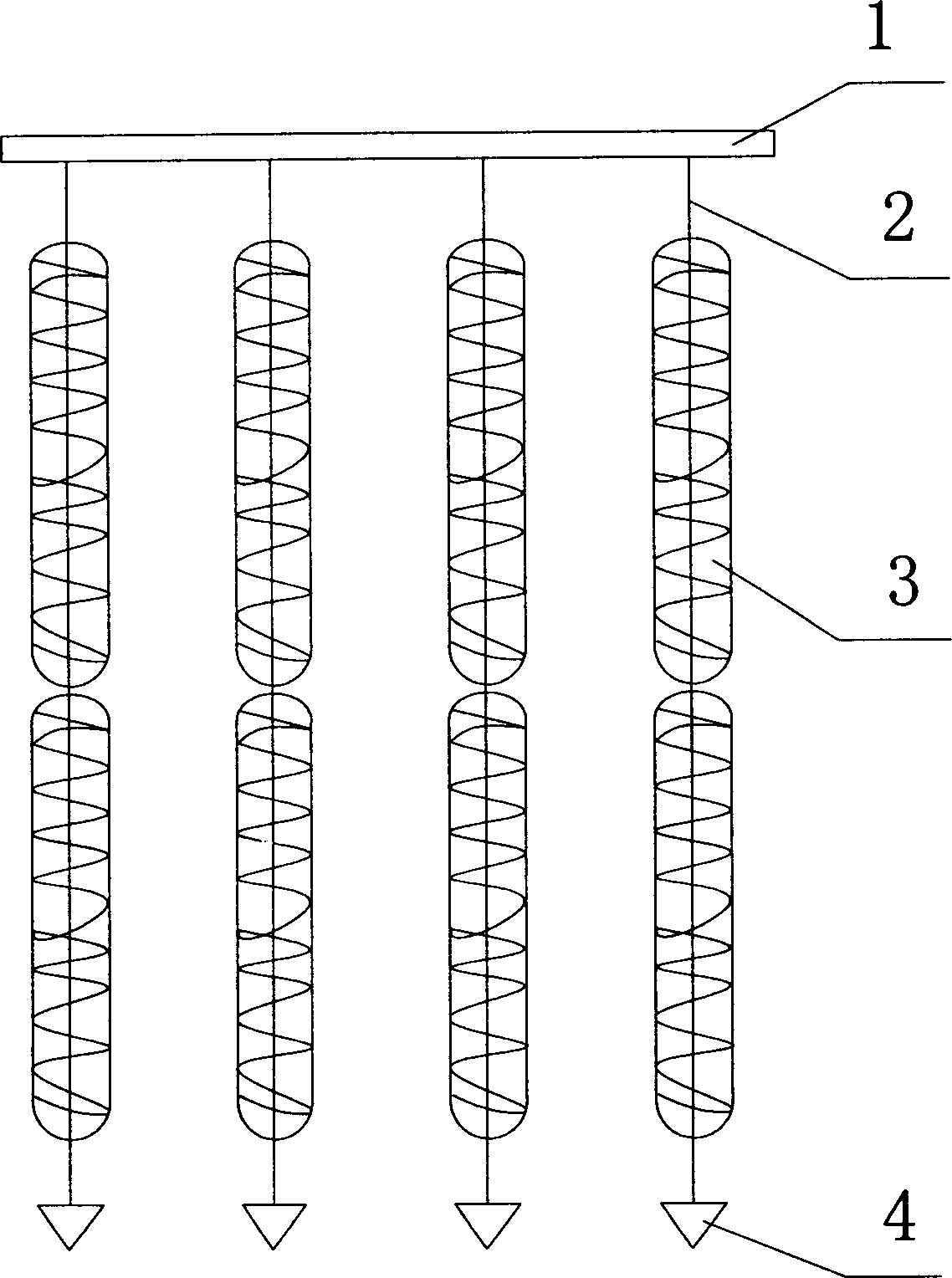

Up-flow solid carbon source biofilm carrier denitrification bioreactor

ActiveCN103172172AGood biodegradabilitySimple system structureTreatment with anaerobic digestion processesChemistryFixed frame

Owner:CHONGQING UNIV

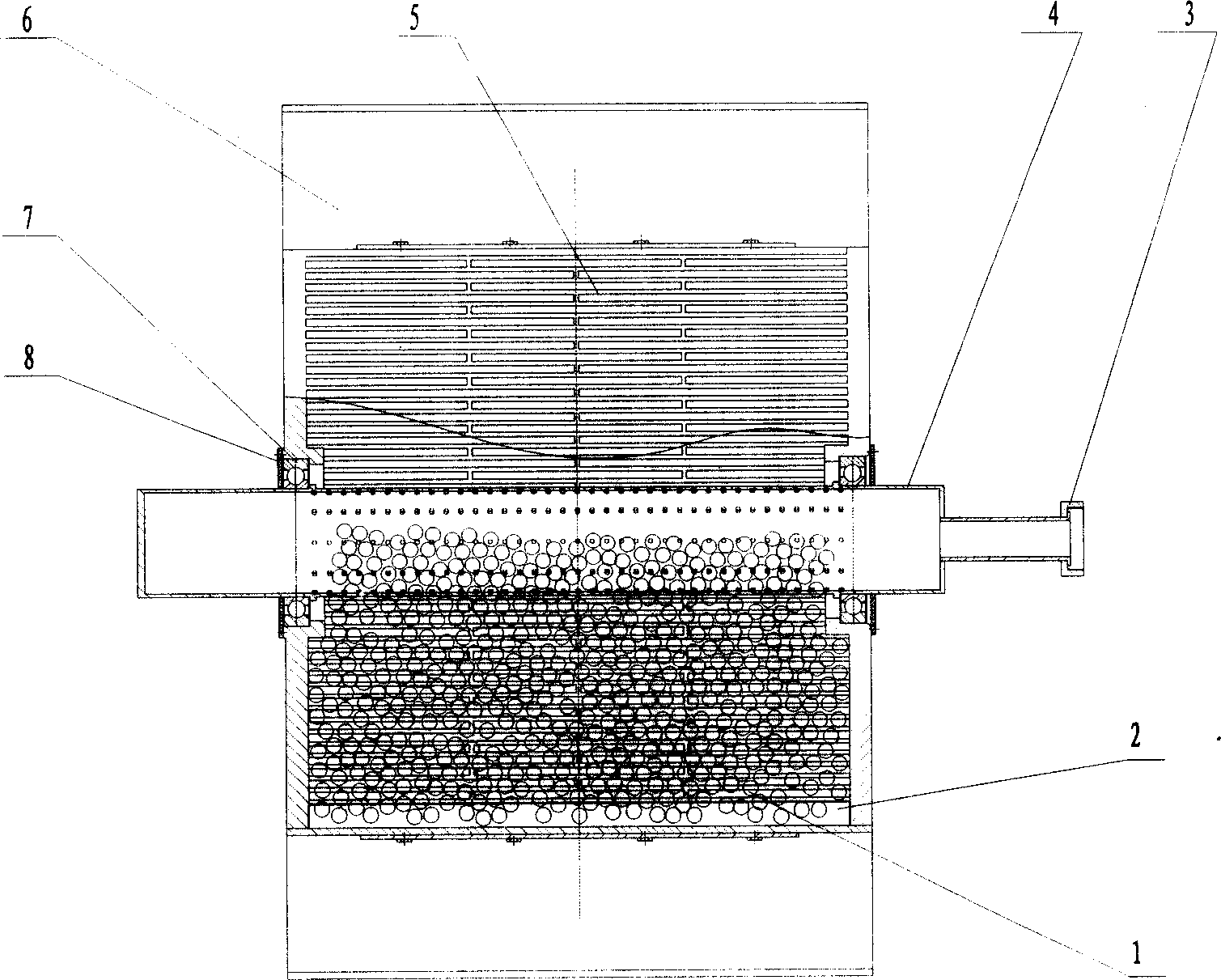

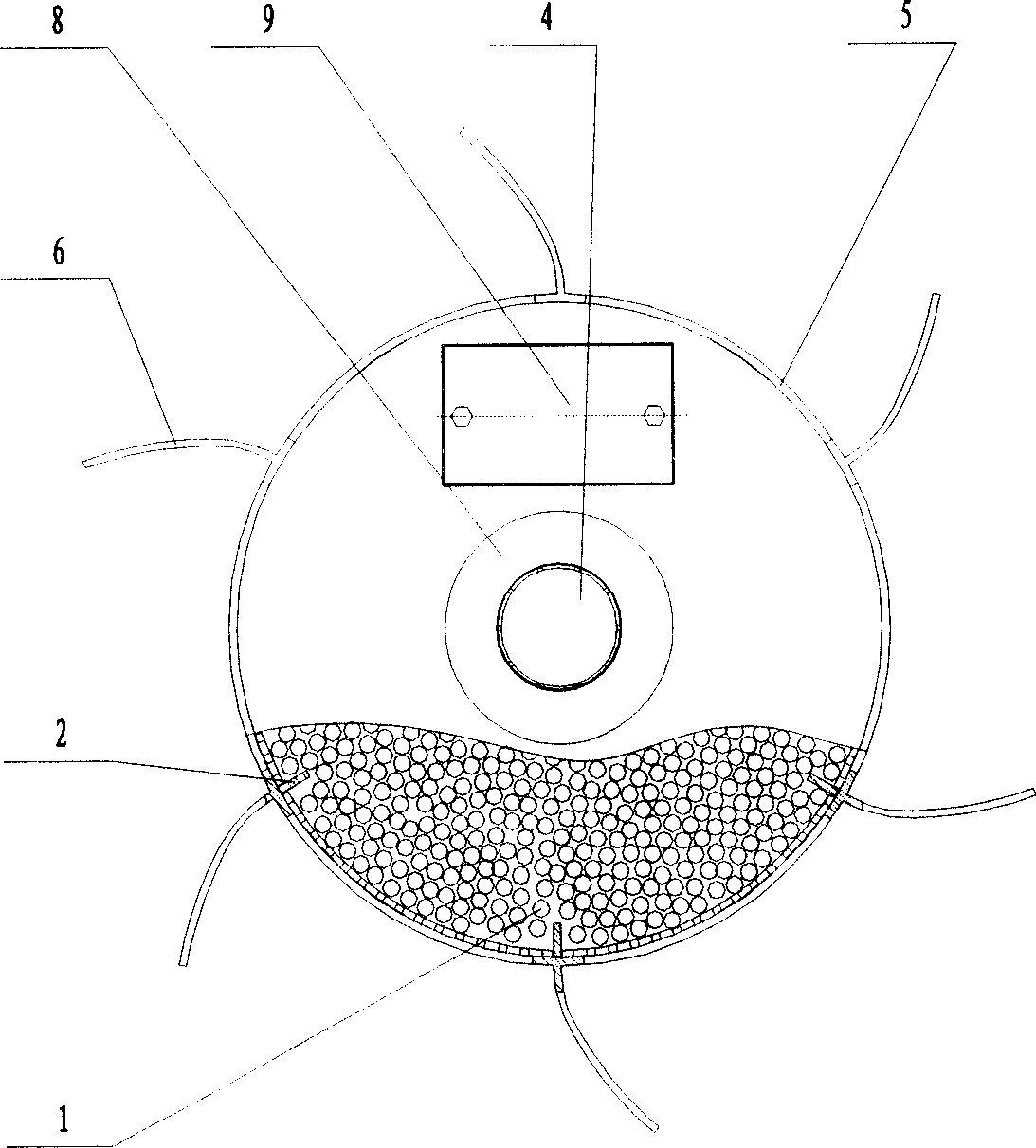

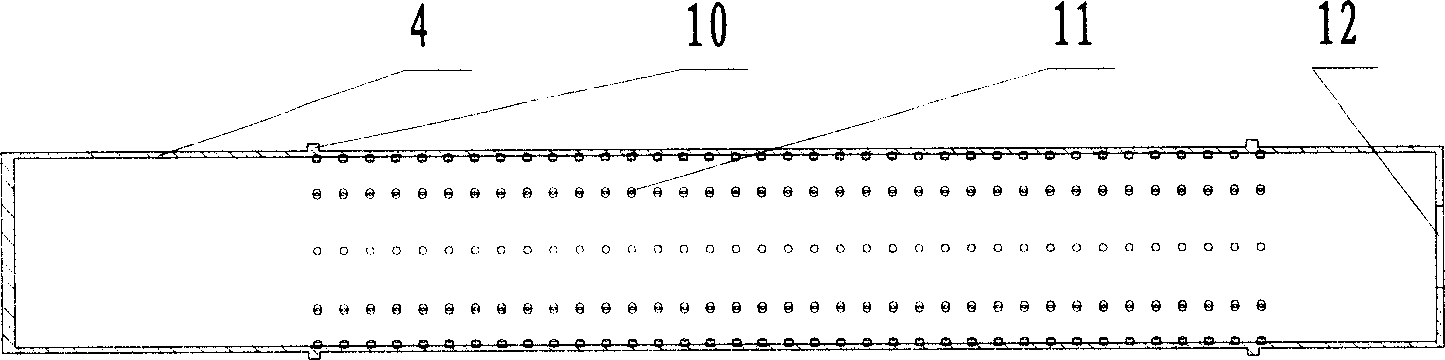

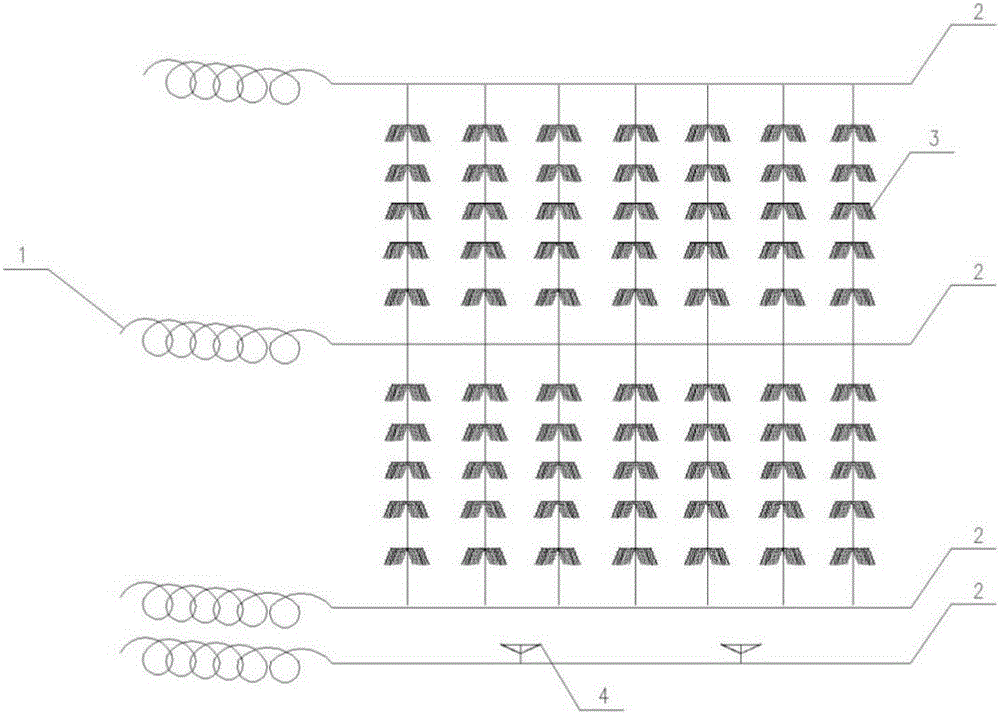

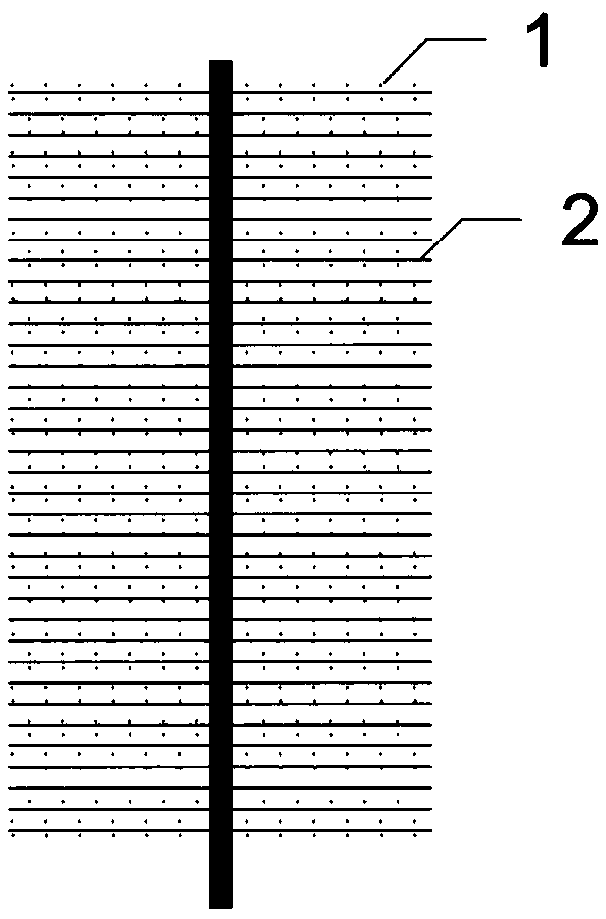

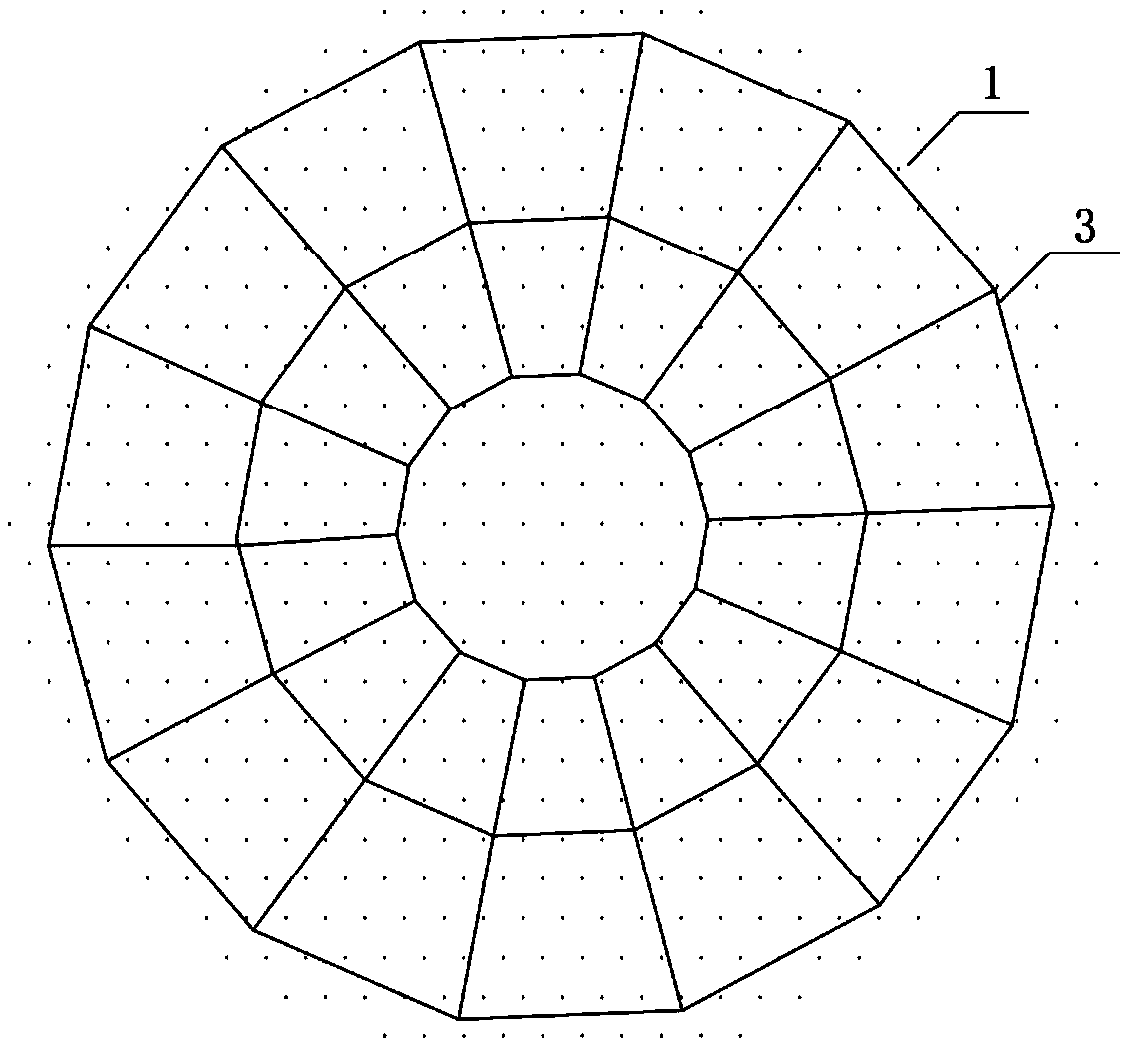

Layered ecological floating bed for intensifying natural biofilm suspension membrane and construction method

InactiveCN107698029AIncrease surface areaHas water purification effectSustainable biological treatmentBiological water/sewage treatmentGrowth plantBiofilm

The invention relates to a layered ecological floating bed for intensifying a natural biofilm suspension membrane and a construction method. The vertical floating bed is formed by four layers which are a plant growth area, a combined packing area (1), a flotage area (2) and a suspension packing area from top to bottom. The combined packing area and the flotage area form a floating bed frame (4); anatural biofilm suspension membrane is arranged in the floating bed frame; the flotage area is filled with aquaculture floating balls (3); in the suspension packing area, a vertical elastic packing (6), a combined packing (7), a biological rope and a nanometer material are suspended on a packing suspension rope (5). According to the layered ecological floating bed for intensifying the natural biofilm suspension membrane and the construction method provided by the invention, a biofilm technology is combined with the ecological floating bed, and an improved characteristic of the vertical layered ecological floating bed structure and a matrix-adding function are fully utilized, so that the depth of the floating bed provided by the invention in water is greatly lager than the depth of a traditional ecological floating bed in water, and the floating bed provided by the invention also has a water body purification function in a deeper water body. The layered ecological floating bed for intensifying the natural biofilm suspension membrane provided by the invention is applicable to eutrophication restoration of water bodies such as rivers, lakes and aquaculture ponds.

Owner:JIANGXI ACADEMY OF SCI

Preparation method of mixture of polyester and thermoplastic starch rich in starch and application thereof

ActiveCN103194050AImprove the mixing effectStrong mechanical propertiesWater contaminantsBiological water/sewage treatmentSolid carbonThermoplastic

The invention discloses a preparation method of a mixture of polyester and thermoplastic starch rich in starch and an application thereof, belonging to the technical field of environment protection. According to the method, the polyester and the thermoplastic starch rich in starch are taken as the raw materials, and addition agents such as aluminic acid ester coupling reagent and the like are added, thermoplastic starch / polyester blending material is prepared through banburying by a torque rheometer, and then a product is prepared through smashing, extrusion and pelleting. The thermoplastic starch base mixture rich in starch can be used as both a carbon source and a biofilm carrier for denitrification in the water treatment deep denitrification technology, so that the defect that the carbon source dosage is not easy to control in a conventional denitrification technology is overcome, the defects that the microorganism is difficult to form a membrane, the cost is high and the staring time is long when only biodegradable polymer is taken as a solid carbon source are overcome, and the thermoplastic starch base mixture rich in starch has strong adaptability to both water dissolved oxygen concentration and pH.

Owner:CHONGQING UNIV

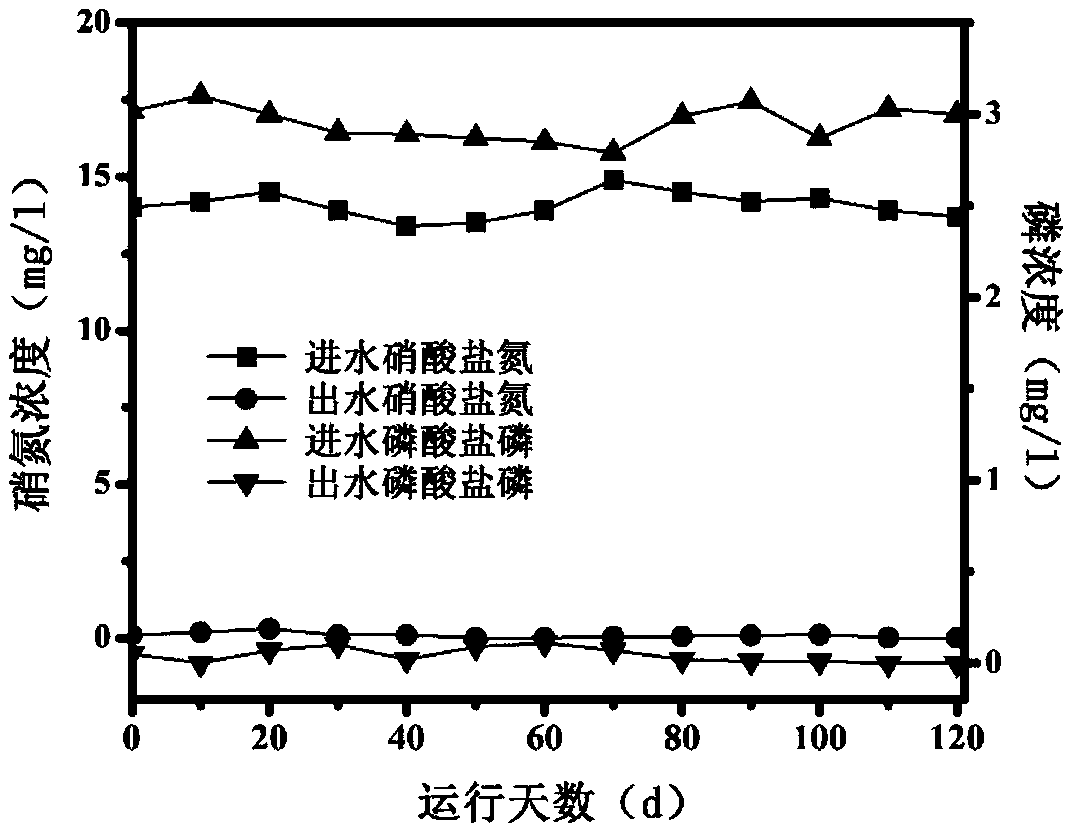

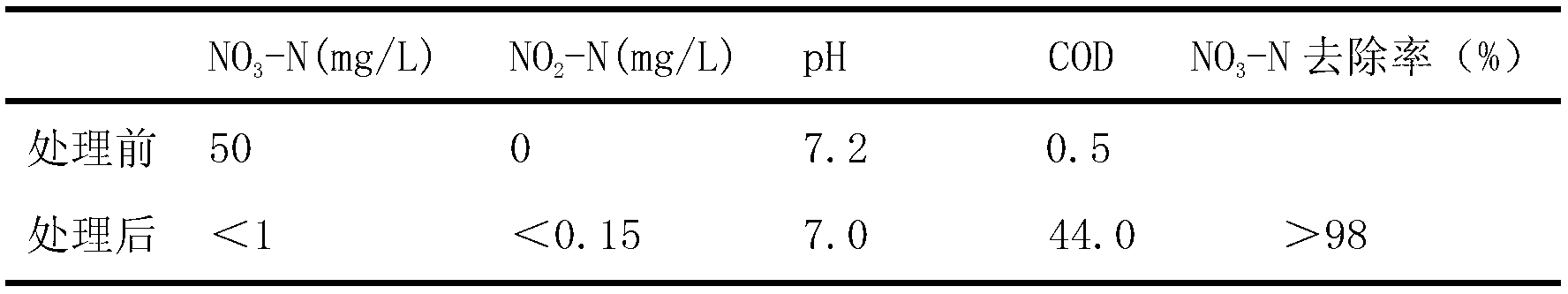

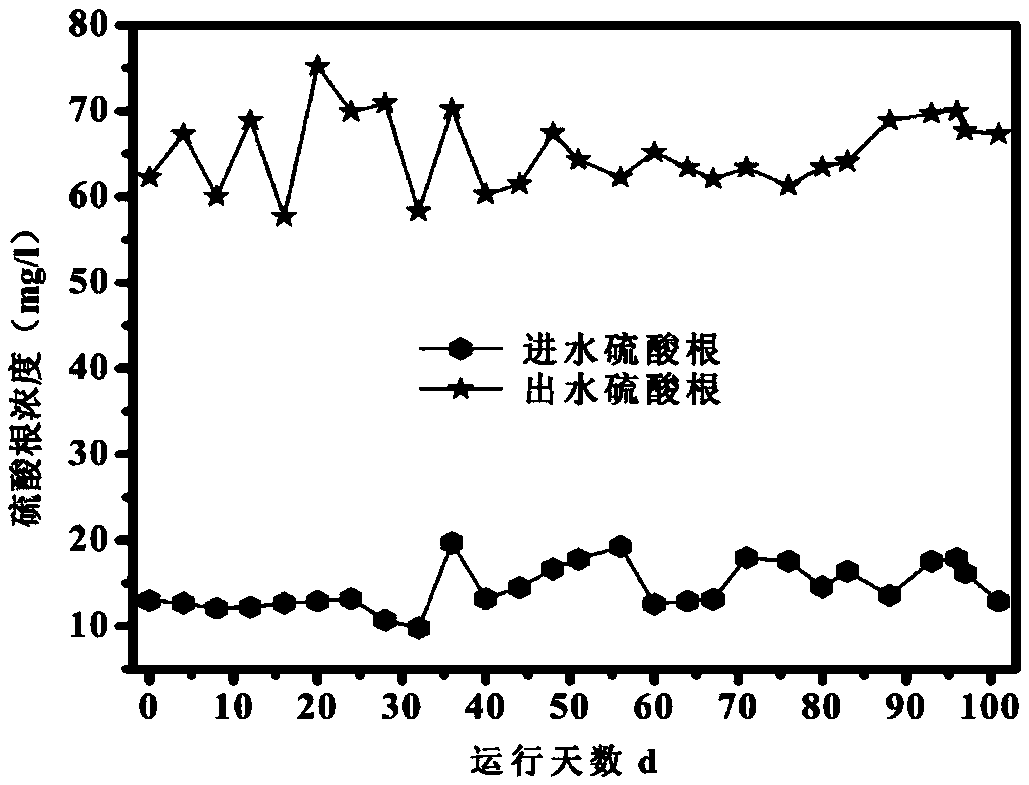

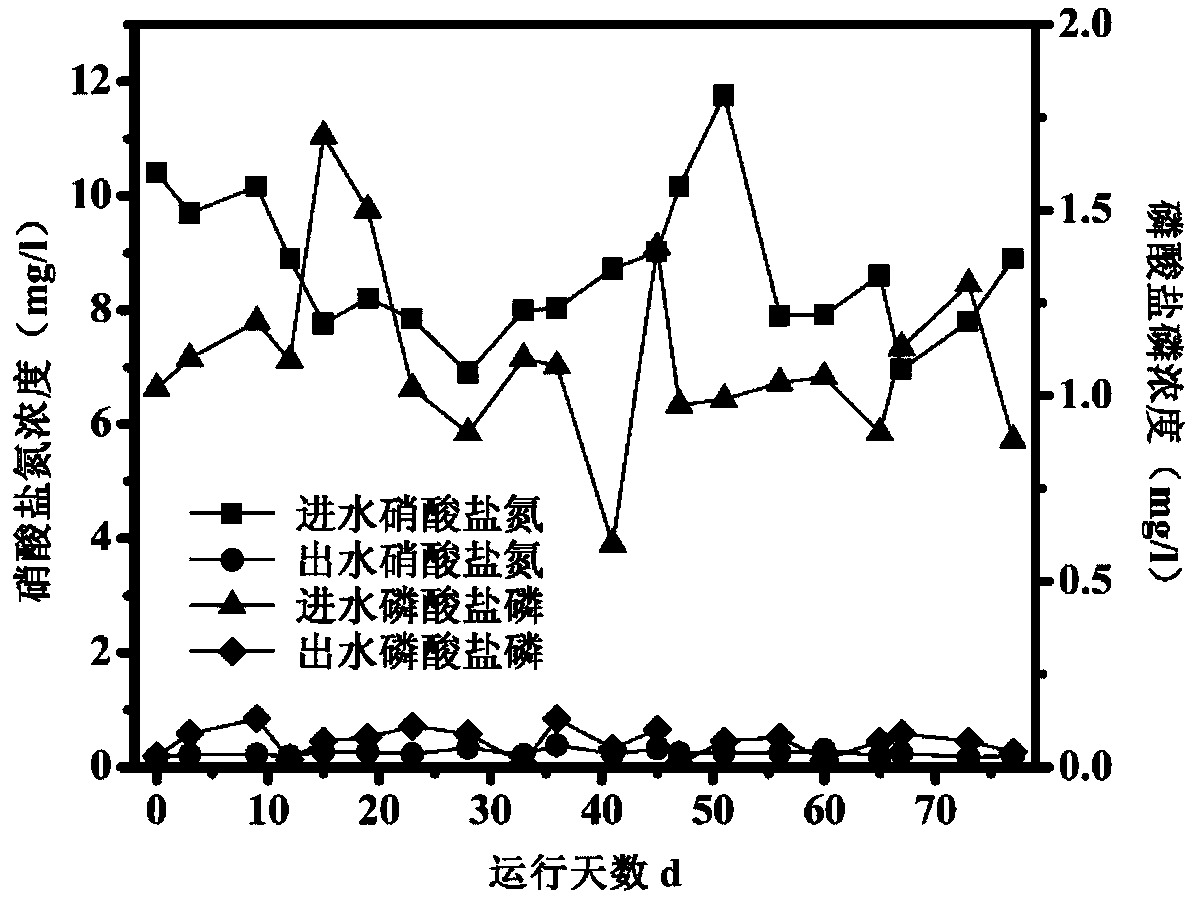

Method for synchronously removing nitrogen and phosphorus in mixed nutritional biofilter based on pyrite

InactiveCN109292972AReduce usageLow running costWater treatment compoundsWater contaminantsCarbonate mineralsDenitrification

The invention discloses a method for synchronously removing nitrogen and phosphorus in a mixed nutritional biofilter based on pyrite, and belongs to the technical field of sewage treatment. A reactoris filled with the pyrite or pyrite and inorganic carbonate minerals which are uniformly mixed, sludge containing autotrophic denitrification bacteria is inoculated into the reactor to realize biofilmformation, sewage to be treated is led into the reactor, the carbon nitrogen ratio of the sewage is controlled by adding an organic carbon source, a reaction system forms the mixed nutritional biofilter, and nitrogen and phosphorus are removed from the sewage in the mixed nutritional biofilter. The biofilter is simple and easy, and hydraulic retention time of only 0.3-1.5 hours is needed when thebiofilter is used for treating the sewage containing nitrogen and phosphorus, so that requirements can be met, nitrogen and phosphorus removing effects are excellent, and the biofilter is low in costand suitable for engineering application. Besides, compared with a traditional sulfur autotrophic denitrification biofilter, the biofilter has the advantage that the concentration of effluent sulfateradicals is greatly reduced.

Owner:NANJING UNIV

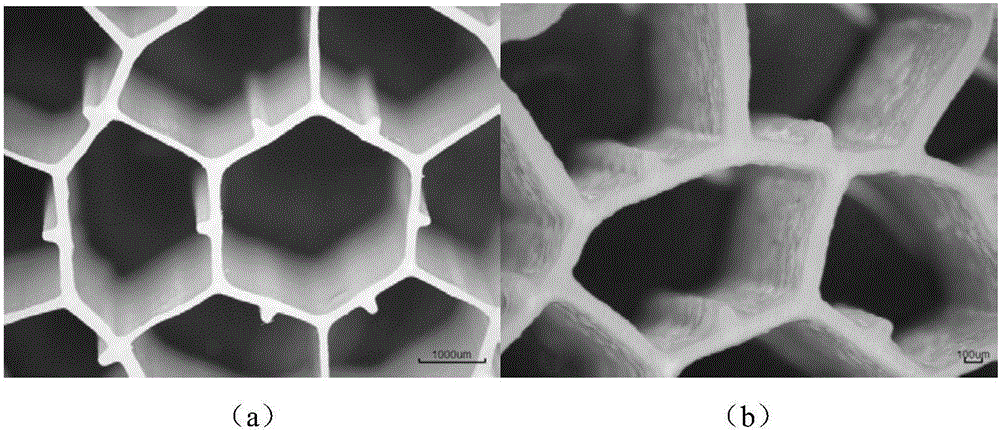

Novel non-sintered biological stuffing rapid in biofilm formation and preparation method thereof

InactiveCN103951044ALarge specific surface areaHigh porositySustainable biological treatmentBiological water/sewage treatmentSolid componentPolyvinyl alcohol

The invention provides novel non-sintered biological stuffing rapid in biofilm formation and a preparation method thereof, relating to biological stuffing and preparation methods thereof and solving the technical problems that the existing biological stuffing has long biofilm formation time and poor effluent quality in water treatment processes and preparation processes are high in energy consumption and pollute the environment. The biological stuffing is prepared from sepiolite, medical stone, cement, polyvinyl alcohol, sodium alginate, hydrogen peroxide, ferric chloride, manganese sulfate, cobalt chloride and agar. The method comprises the following steps: I. heating and dissolving polyvinyl alcohol and sodium alginate, adding hydrogen peroxide after cooling, and mixing the components uniformly, thus obtaining a liquid mixture; II. mixing the liquid mixture with other solid components, granulating the mixture, putting the granules at normal temperature, drying and sieving the granules, curing the granules at high pressure and low temperature, steam-curing the granules at constant temperature, and cooling the granules at normal temperature, thus obtaining the biological stuffing. Compared with the common ceramsite, the biological stuffing has short biofilm formation time, good effluent quality and coarse surface and is beneficial for microorganism growth. The biological stuffing is applied to the fields of environmental applied materials and sewage treatment.

Owner:HARBIN UNIV OF SCI & TECH

Preparation method of biofilm carrier

ActiveCN107252680AGood biocompatibilityGood compatibilityOther chemical processesWater treatment compoundsBiocompatibility TestingPhospholipid

The invention relates to a preparation method of a biofilm carrier and belongs to the technical field of water treatment. The preparation method includes: using diatomite as a template, and forming a layer of chelated coating adsorption calcium ions on the surface of the template through dopamine; burning white phosphorus to generate phosphorus pentoxide to react with alcohol to generate phospholipid; under action of ammonia water, and hydrolyzing phospholipid, wherein hydroxyl on a hydrolysis product are slowly combined with the calcium ions to generate crystal nuclei which grow gradually to finally obtain a carrier crude product with hydroxyl calcium phosphate on the surface. Hydroxyl calcium phosphate is high in biocompatibility, so that the problem that conventional biofilm carriers are low in compatibility with microorganisms is solved; saponin and organic carboxylic acid in biological fermentation liquid increase number of hydrophilic groups on the surface of the carrier under action of the microorganisms, improve wettability of the surface of the carrier and increase probability that sewage contacts with the carrier; nutritional substances provide both a nutritional source and more adhesion sites, so that adhesion difficulty of the microorganisms is lowered, film forming time is shortened, and the biofilm carrier has wide application prospect.

Owner:神美科技有限公司

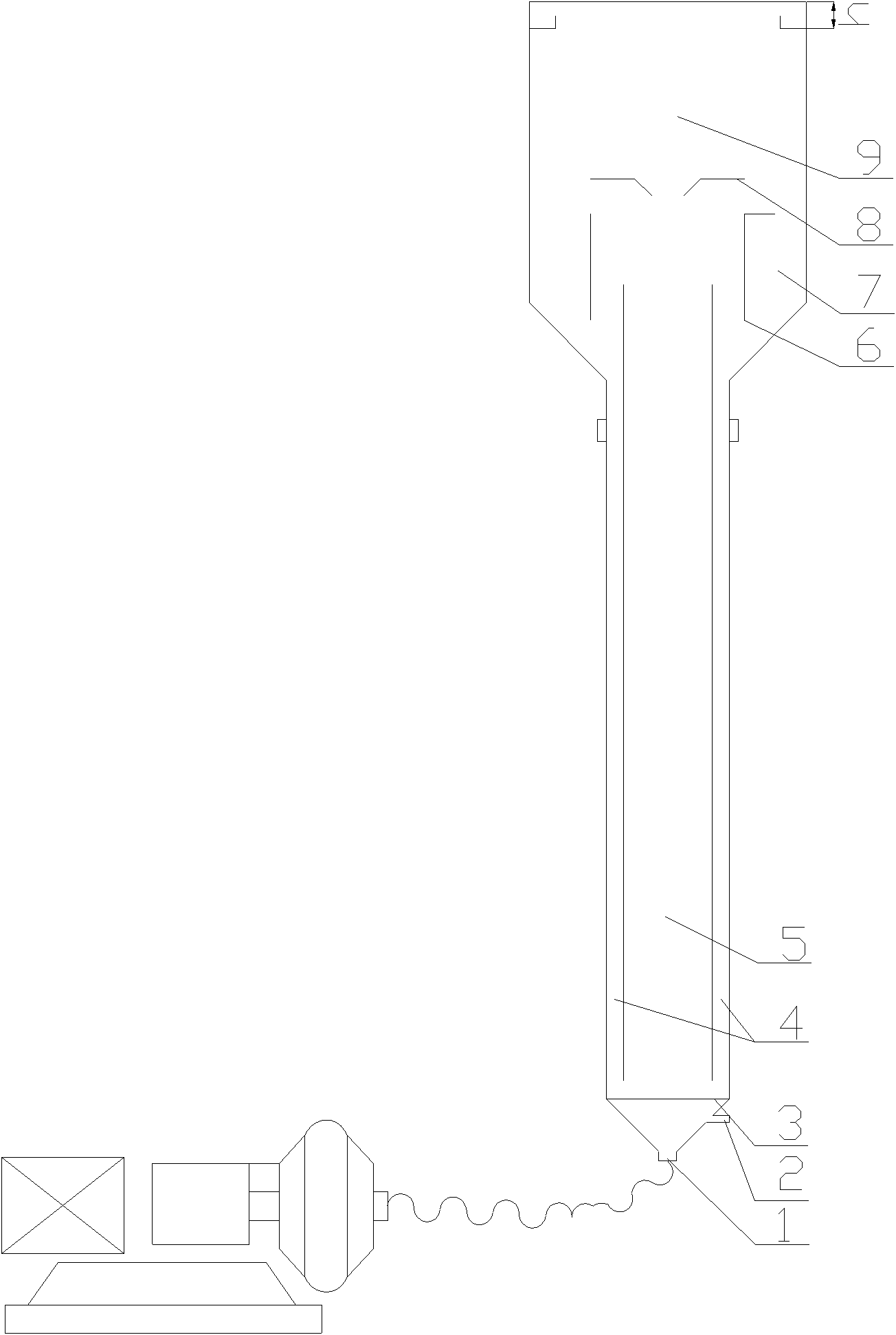

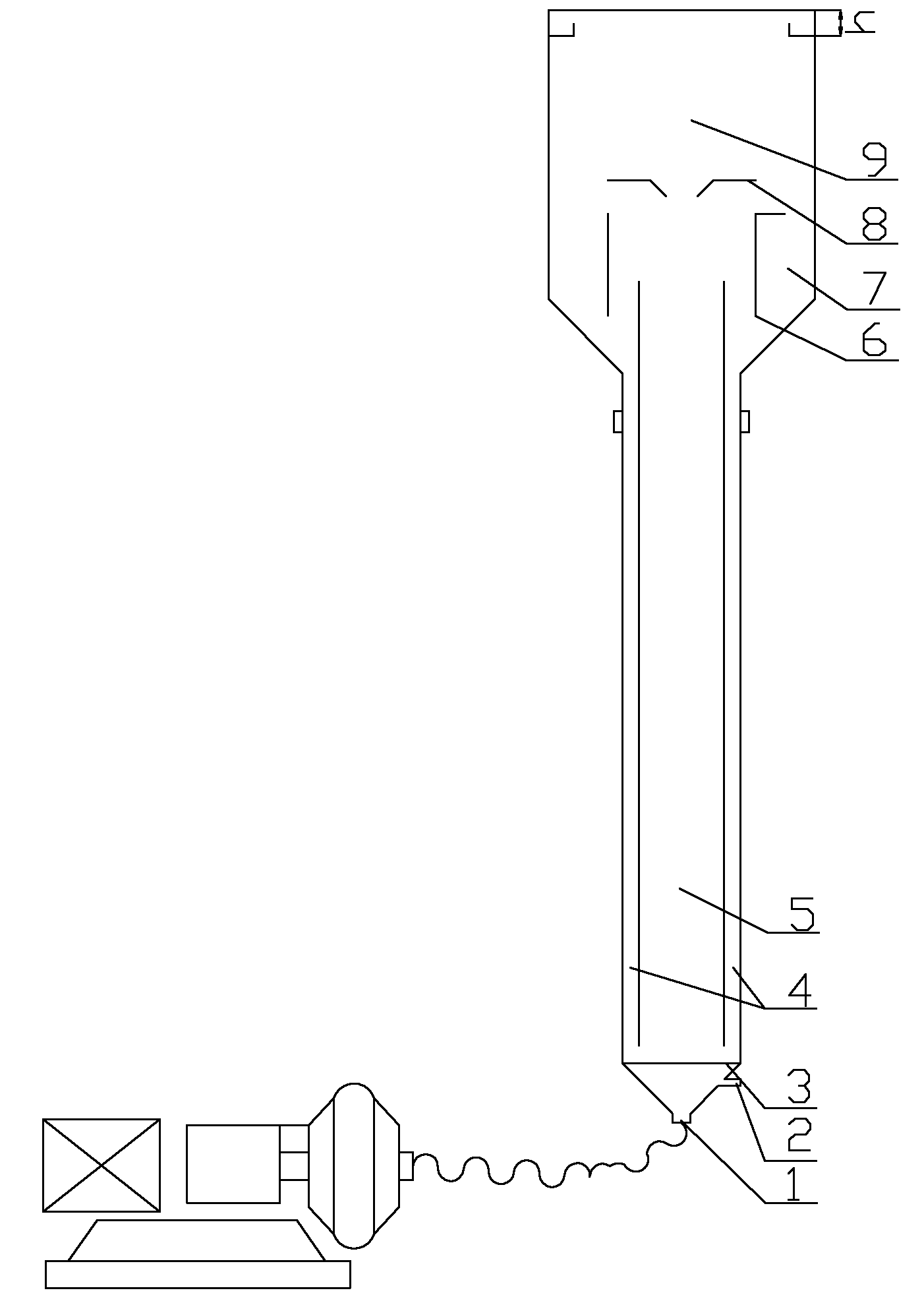

Method and equipment for treating antibiotic mycelium residues

ActiveCN104593433AImprove processing efficiencyImprove processing speedGas production bioreactorsWaste based fuelBiogasChemistry

The invention provides a method and equipment for treating antibiotic mycelium residues. According to the method, the antibiotic mycelium residues and water are prepared into a mycelium residue suspension which is subjected to anaerobic fermentation treatment. The invention also provides the equipment for treating the antibiotic mycelium residues, and the equipment comprises a residue water generating device, an anaerobic fermentation device, a gas-liquid separation device positioned above the anaerobic fermentation device, a biogas collection device positioned above the gas-liquid separation device and a riser pipe for communicating the gas-liquid separation device and the anaerobic fermentation device. By using the method and equipment for treating the antibiotic mycelium residues, the mycelium residue suspension obtained after the mixing of the antibiotic mycelium residues and the water is subjected to anaerobic fermentation treatment, so that the inhibition of harmful substances of anaerobic fermentation antibiotics and the like in the conventional antibiotic mycelium residues is overcome, the amount of preponderant bacteria is kept to the utmost extent, the efficiency of anaerobic fermentation is improved, and the method and the equipment have the advantages of small floor area, simple operation, low cost and the like.

Owner:ZHENGZHOU UNIV +1

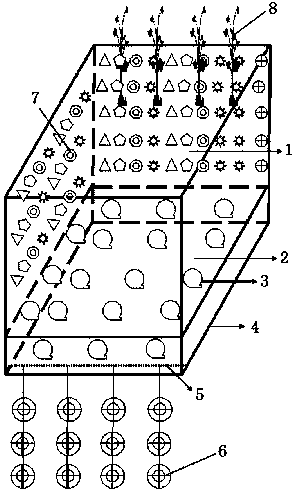

Quick starting method of step-by-step biofilm culturing of river biofilm restoration system

ActiveCN106379992AShorten the film setting timeHigh activityWater resource protectionWater treatment parameter controlBiologySewage

The invention provides a quick starting method of step-by-step biofilm culturing of a river biofilm restoration system. The method comprises the following steps: A, hanging a filling material in an SBR reactor, taking activated sludge as inoculation sludge, injecting simulation sewage good in biodegradability into the SBR reactor to form a culture solution, performing uniform mixing and aeration for 5 days, and changing the simulation sewage once every other day; B, taking the filling material from the SBR reactor and putting the filling material in a river simulation biofilm reactor, the bottom of which is uniformly provided with aerators, wherein the river simulation biofilm reactor is operated in an intermittent aeration manner and discharges the supernatant during an aeration-stopping period, and filling the river simulation biofilm reactor with new low-pollution water, and performing repeated operation for 2-3 days in an intermittent aeration manner; and C, taking river deposit out, removing the upper overlaying water, removing animal and plant impurities through screening, laying the river deposit at the bottom of the river simulation biofilm reactor, and performing sealed aeration for 3-5 days. Quick starting of biofilm culturing is achieved, the obtained biofilm enriches functional microorganisms, and the river biofilm restoration system can be stably operated.

Owner:HUATIAN ENG & TECH CORP MCC

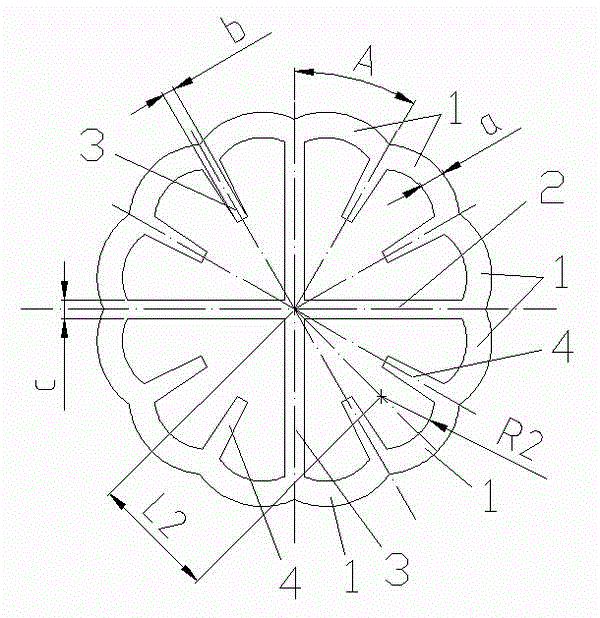

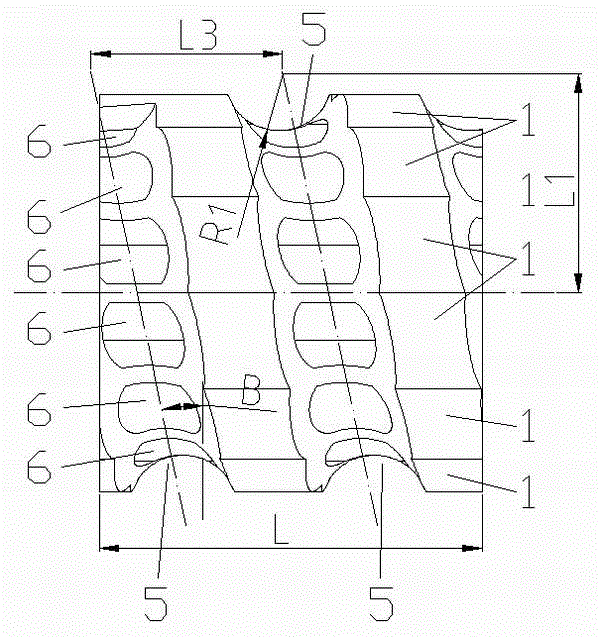

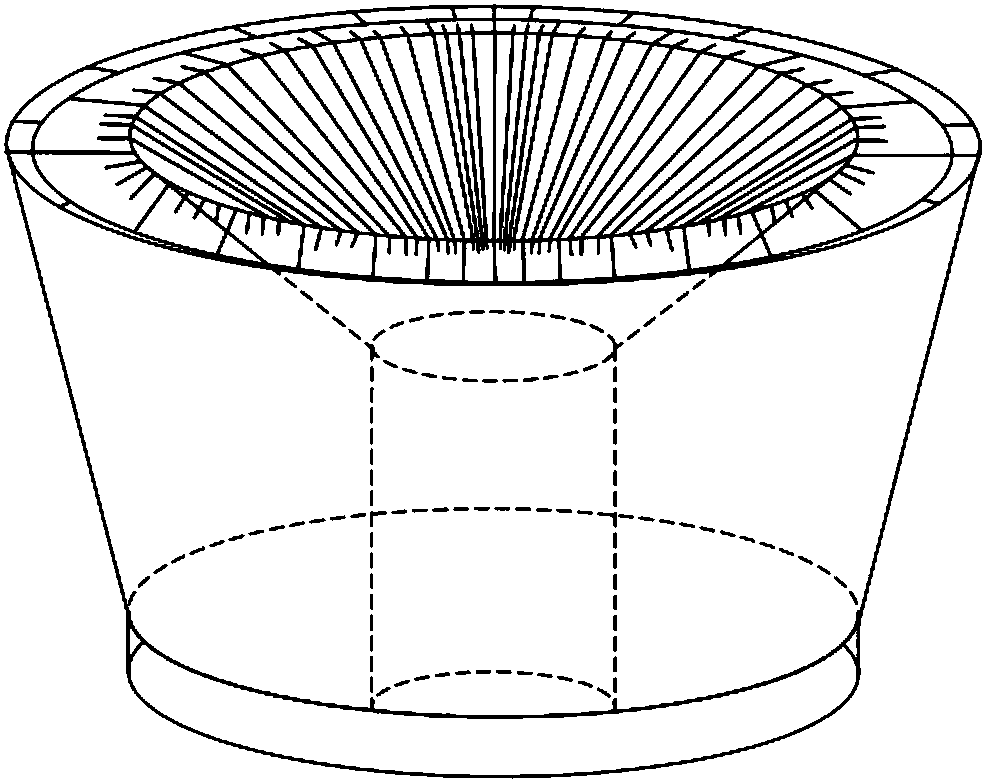

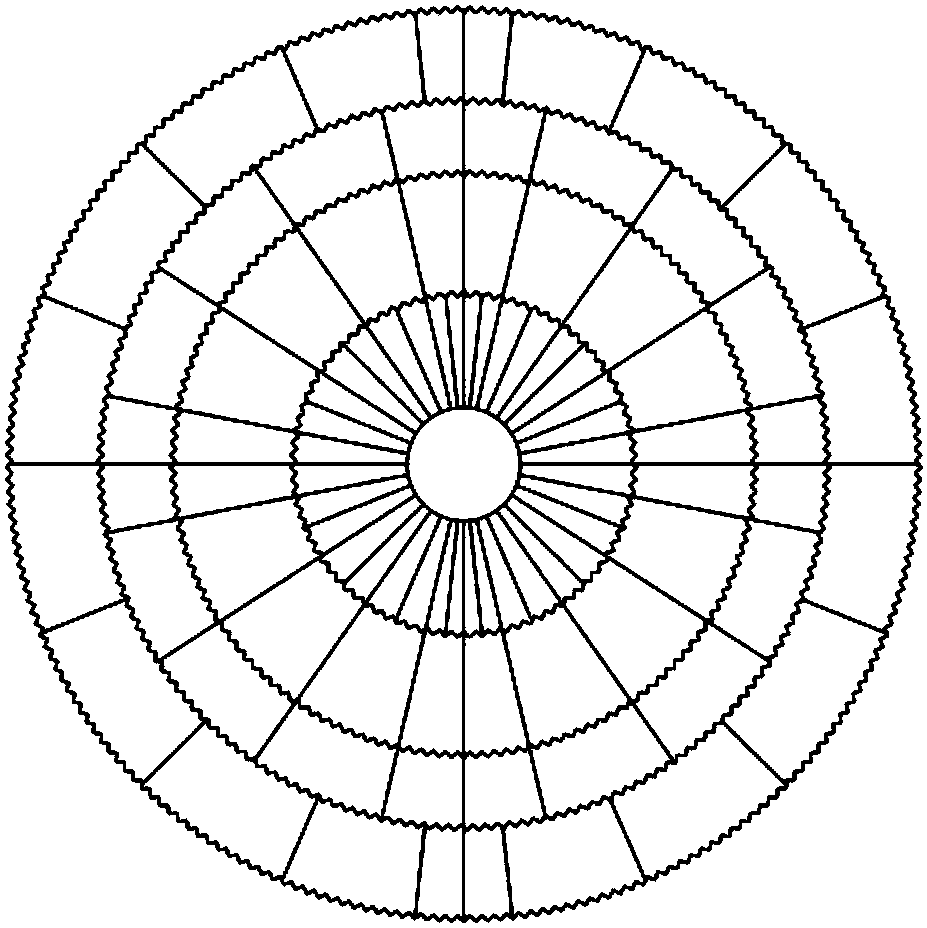

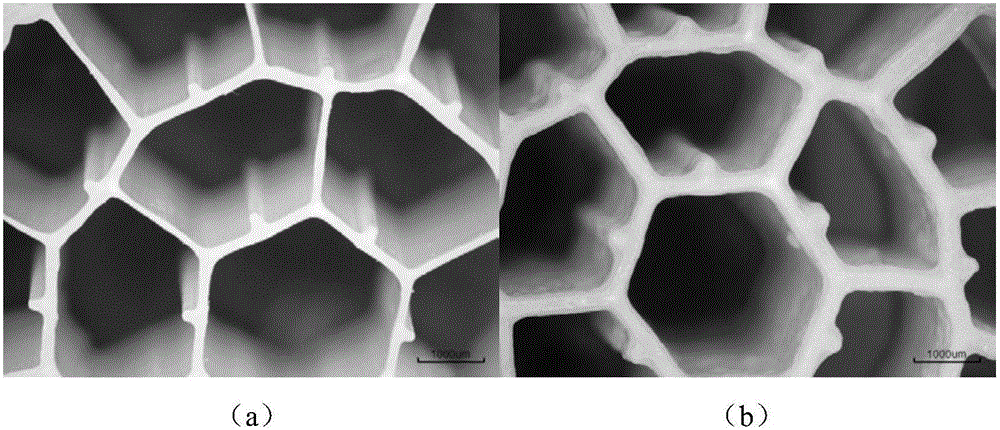

Multi-phase flow dynamic membrane microbial carrier filler

InactiveCN104787874AGood flexibilitySolve the problem of not being able to aggressively tumbling fluidizeSustainable biological treatmentBiological water/sewage treatmentPliabilityEngineering

The invention discloses multi-phase flow dynamic membrane microbial carrier filler and belongs to the technical field of environmental protection and water treatment. The carrier filler with high-density polyethylene as a main material and calcium carbonate and starch as auxiliary materials adopts a thin-wall tubular structure, wherein reinforcing ribs forming 90-degree angles mutually and a plurality of inner rib plates are arranged in the thin-wall tubular structure, and spiral grooves are formed in the outer wall of the thin-wall tubular structure. The carrier filler solves the problem of incapability of positive rolling fluidization under the actions of hydraulic power, stirring, aeration and the like of conventional biological filler and makes up the defects of poor attaching force due to the smooth surface, poor hydrophobicity, small specific surface area and the like of the conventional filler. The filler with uniform small holes in the outer wall is in a suspended state in water and can vertically roll in a tank under the action of external force to have a sufficient contact reaction with the water; the carrier filler has a rough surface and is suitable for microbial membrane hanging; the filler has high flexibility, is suitable for a high-strength fluidization reaction and is made of a hydrophilic material, and the membrane hanging time is greatly shortened.

Owner:大连爱特流体控制有限公司

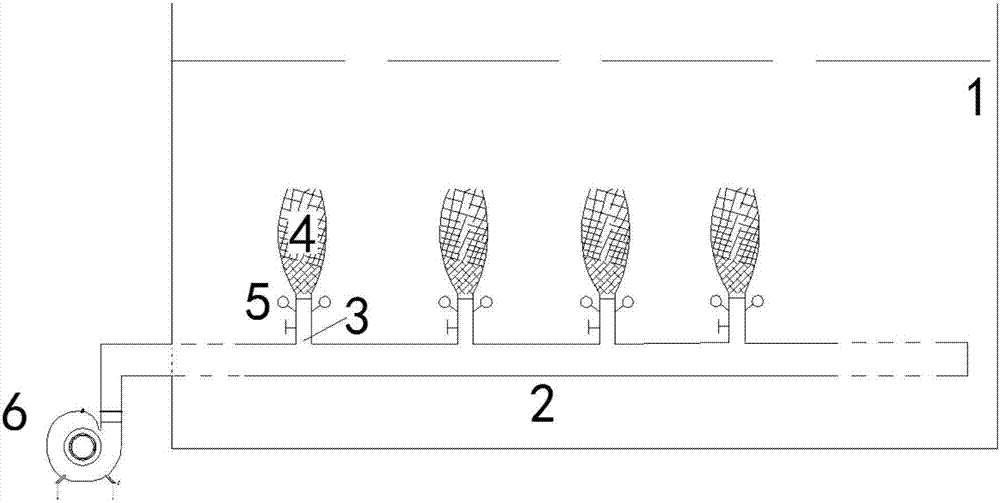

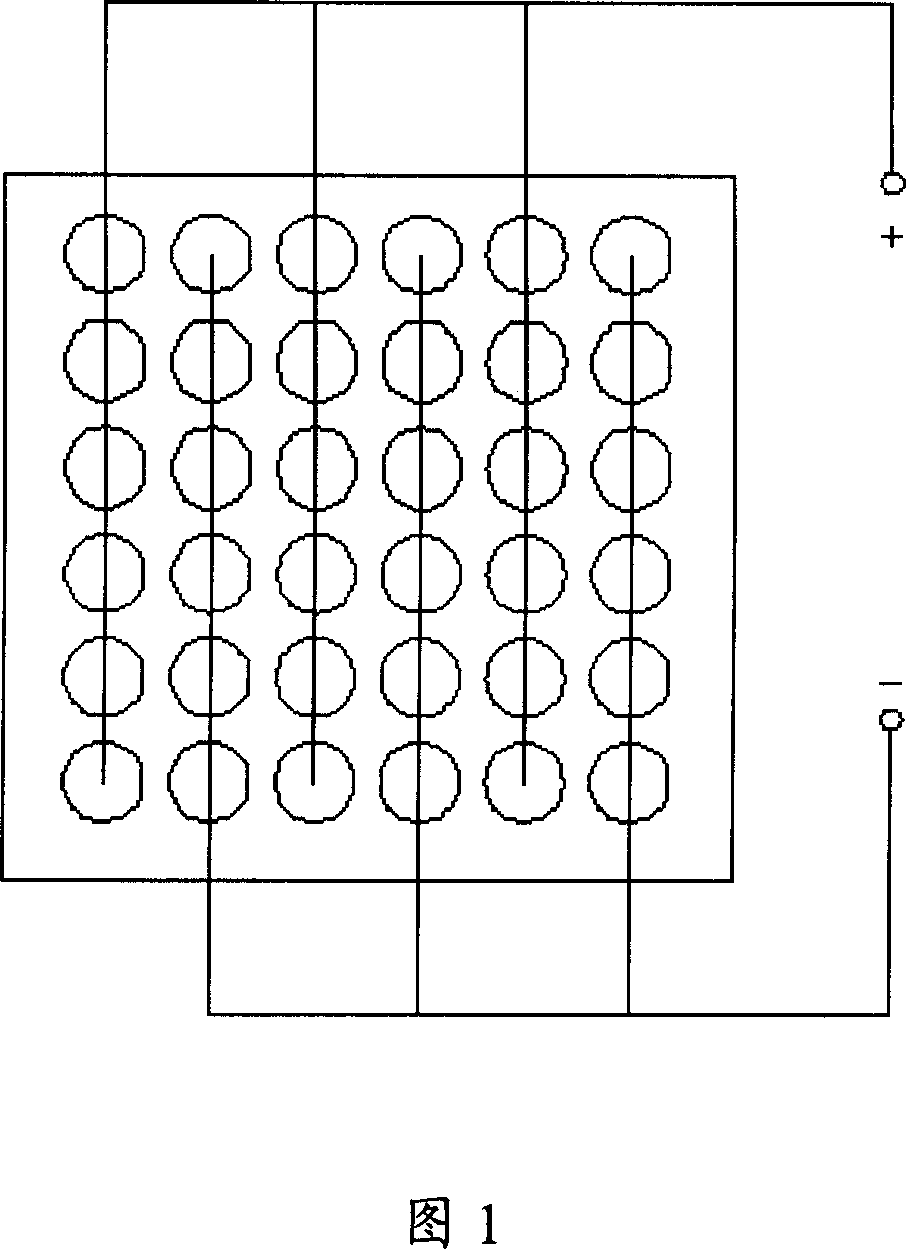

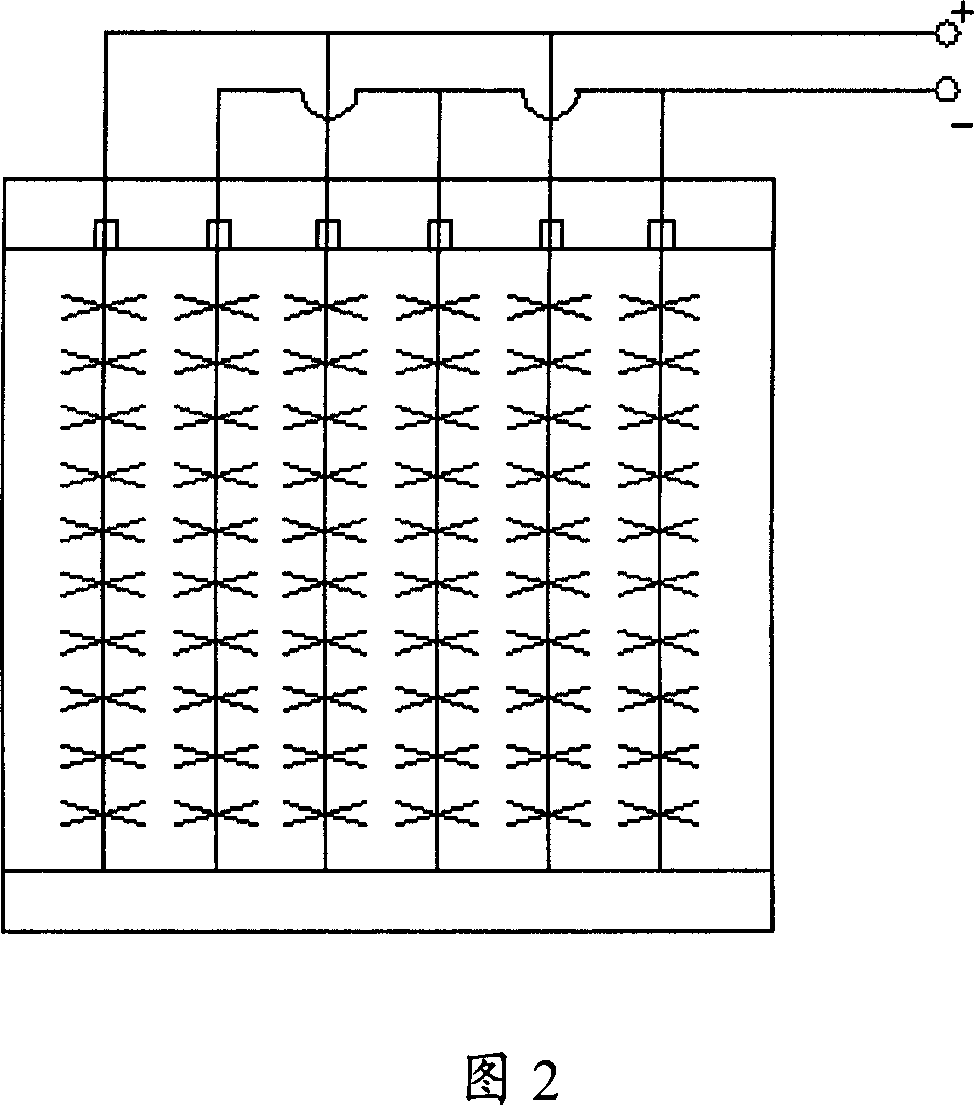

Biological membrane reactor

ActiveCN107055752AIncrease specific gravity and activityShorten the film setting timeTreatment using aerobic processesSustainable biological treatmentSpecific gravityMembrane configuration

The invention belongs to the field of water treatment and particularly relates to a biological membrane reactor. The biological membrane reactor comprises a sewage reaction tank, an aeration pipe and biological membrane filler; the aeration pipe is arranged in the sewage reaction tank and provided with a plurality of air outlet positions, and the biological membrane filler is filled in the sewage reaction tank and connected with the air outlet positions. By connection of the biological membrane filler with the aeration pipe, internal aeration of the biological membrane filler can be realized so as to make the interior of a biological membrane in an aerobic state, activity and proportion of aerobic microorganisms on the biological membrane can be increased beneficially, membrane forming time of sewage microorganisms on the surface of the filler is further shortened, and sewage degradation efficiency is improved. According to experiments, compared with a traditional biological membrane reactor under same conditions, the biological membrane reactor has advantages that membrane forming time is shortened by 17 days, biological membrane thickness is increased by 10.42% after maturity, effluent TN is smaller than 10mg / L, COD is smaller than 50mg / L, and BOD is smaller than 10mg / L.

Owner:GUANGDONG UNIV OF TECH

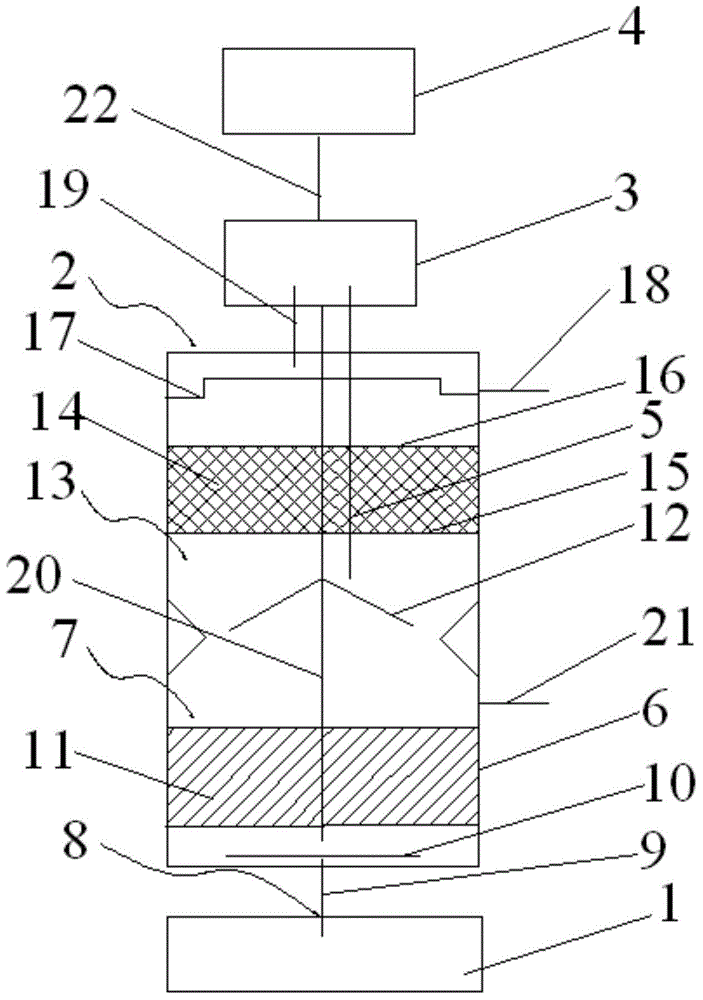

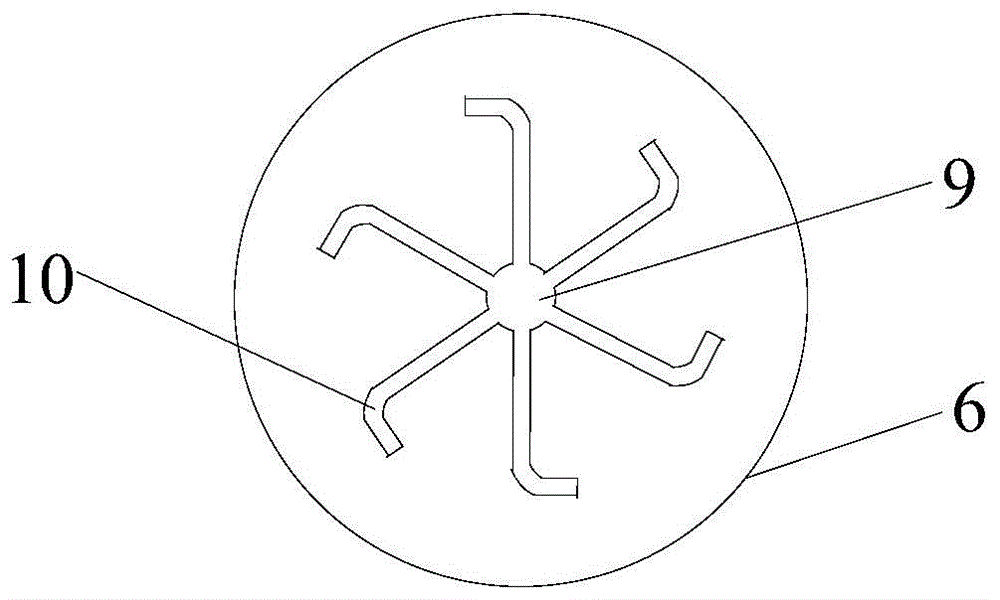

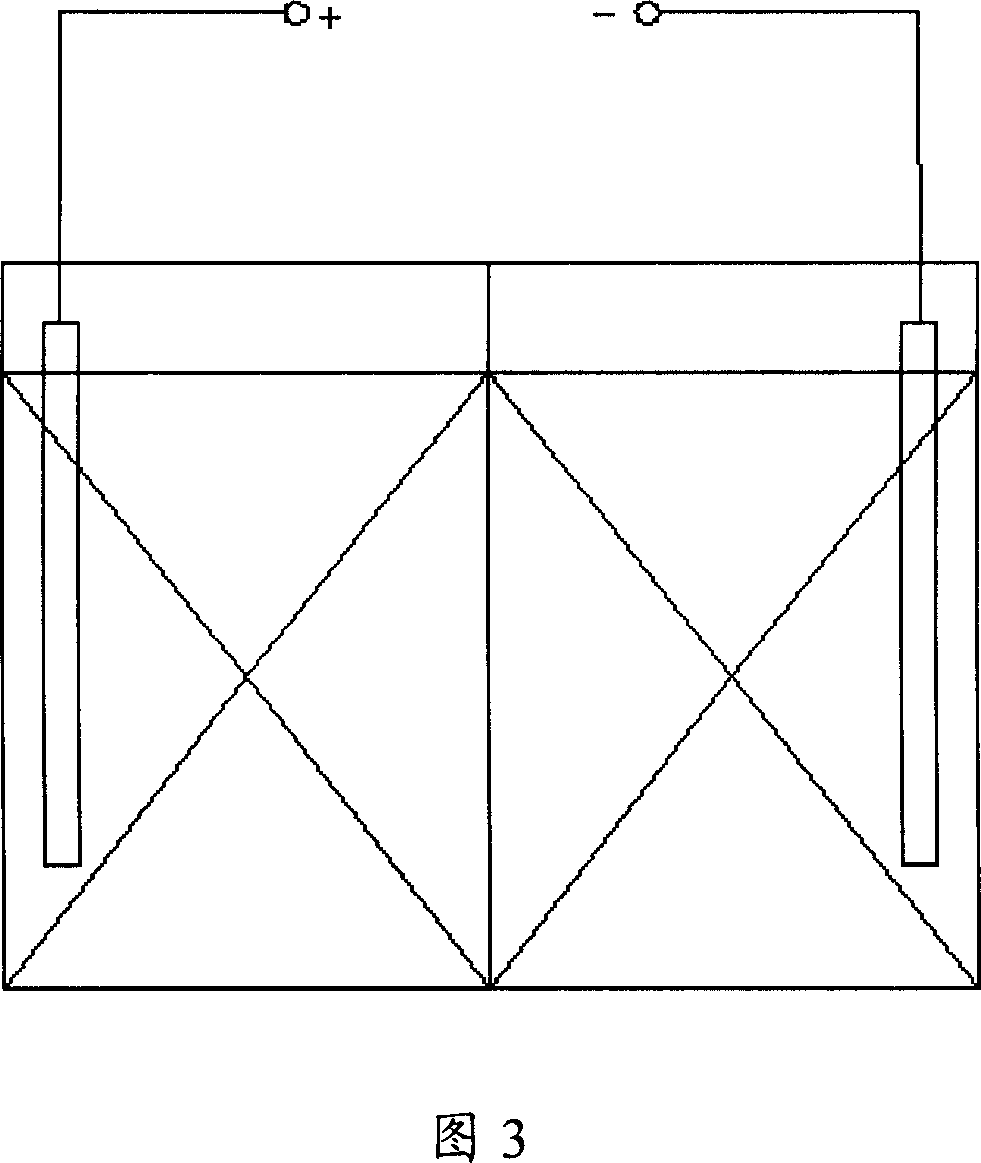

Three-phase biological fluidized bed

InactiveCN101781016AShorten the film setting timeResistant to hydraulic loadsTreatment using aerobic processesSustainable biological treatmentEngineeringThree-phase

The invention discloses a three-phase biological fluidized bed, which comprises a draft tube, a three-phase separator, a baffle, clapboards, a water inlet, a gas inlet and a plate-type gas distributor. The three-phase separator and the baffle are arranged on the upper part of the draft tube. The three-phase separator and the top of the draft tube form a gas-liquid separation area. A solid-liquid separation area is formed between the baffle and the inner wall of the draft tube. The baffle is arranged in the middle part of the draft tube. A down-flow area is formed between the clapboards and the inner wall of the draft tube. An up-flow area is formed between the clapboards. The plate-type gas distributor, the water inlet and the gas inlet are arranged on the bottom of the draft tube sequentially from top to bottom. The fluidized bed has a certain capacity of resisting impact of hydraulic loading and water quality loading and has rapider recovery rate. The amount of TSS is larger in the effluent of the fluidized bed. After the effluent is processed by a sedimentation tank, each index is basically normal. The final processing effect of the whole system is that the COD removal rate is about 75 percent, the SS removal rate is about 50 percent and the chroma removal rate is about 50 percent, so the expected effect is reached.

Owner:SHAANXI UNIV OF SCI & TECH

Rapid biofilm forming method of biofilm reactor

ActiveCN111348751AShorten the film setting timeImprove stabilityWater treatment parameter controlWater treatment compoundsBiotechnologyActivated sludge

The invention relates to a rapid biofilm forming method of a biofilm reactor. The method comprises the following steps: inoculating aerobic activated sludge into a reactor loading a biological filler,carrying out biofilm forming culture by using industrial sewage under aerobic conditions, and adding an organic carbon source and humus in the culturing process; and when the concentration of the effluent sludge is basically stable and unchanged, inoculating anaerobic activated sludge into the reactor, transferring into an anaerobic condition, carrying out biofilm forming culture, and adding sugar alcohol compounds and humus in the culturing process. According to the method, the anaerobic bacteria can be rapidly proliferated in the reactor, the biofilm forming speed is high, the starting period is short, the biofilm is not prone to falling off, and it is guaranteed that the biofilm reactor stably achieves the deep denitrification effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

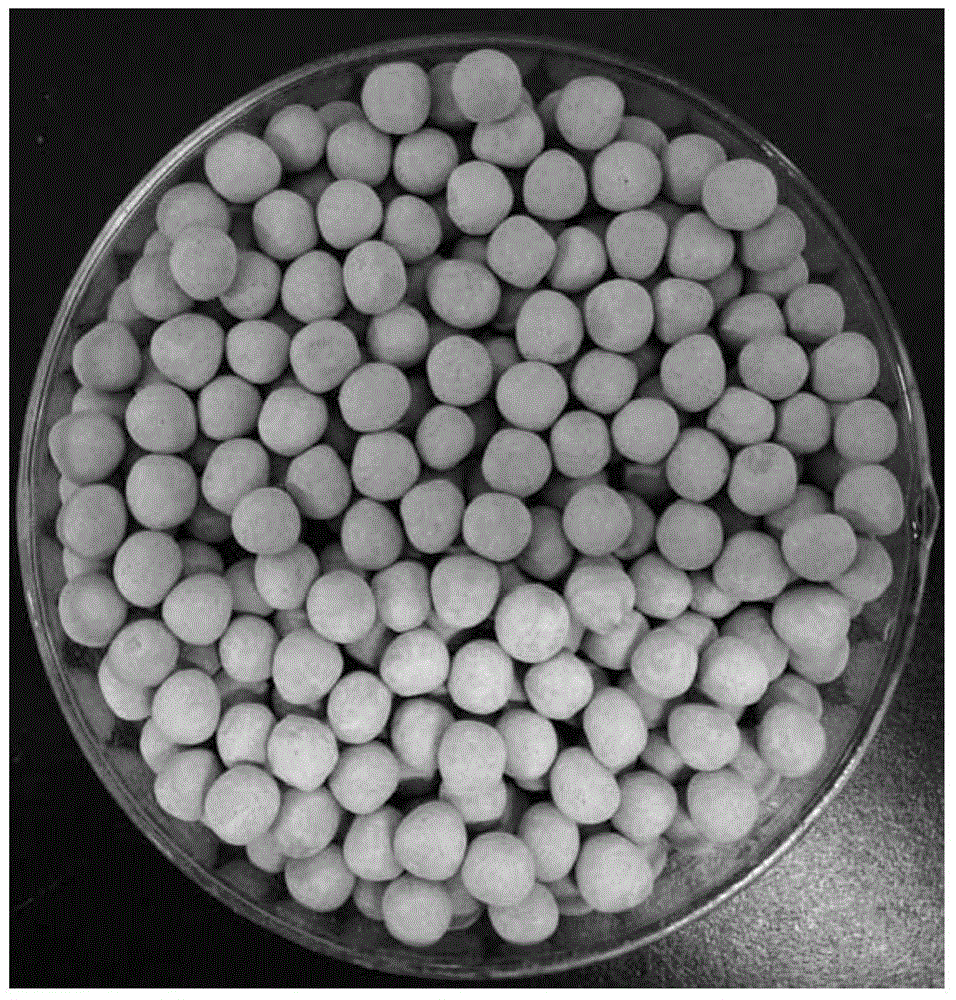

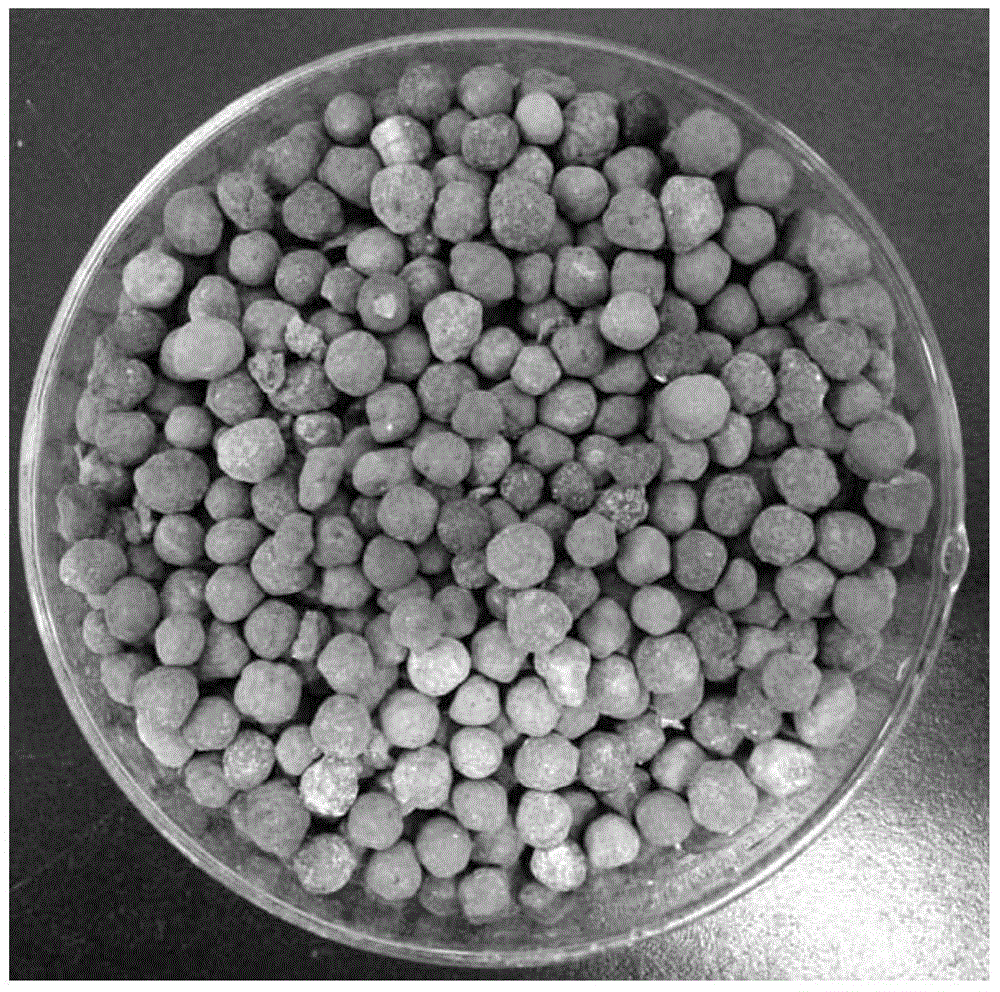

Preparation and application of sulfur-based autotrophic and heterotrophic denitrification nitrogen removal biological filler

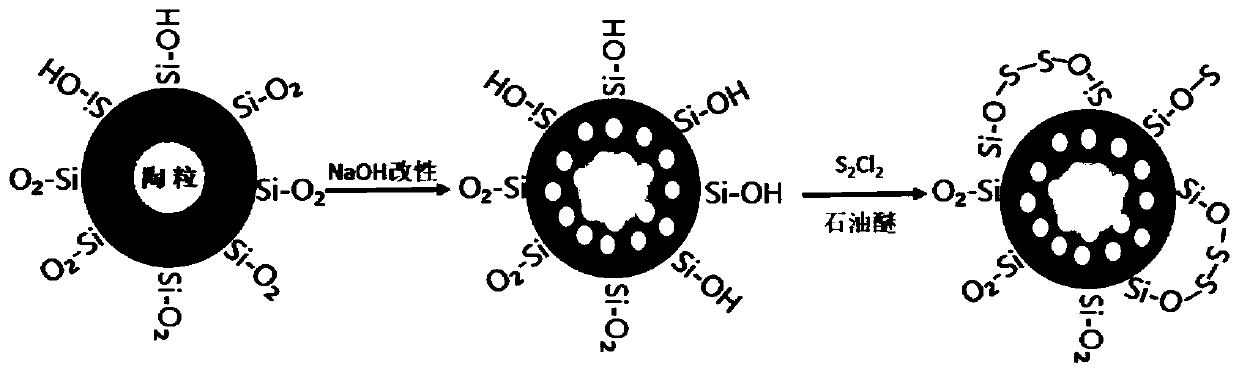

ActiveCN110467276AConducive to loadPromote dissolutionWater treatment parameter controlTreatment with anaerobic digestion processesMicroorganismNitrogen removal

The invention discloses preparation and application of a sulfur-based autotrophic and heterotrophic denitrification nitrogen removal biological filler. According to the invention, the number of micropores and silicon hydroxyl groups on the surface of ceramsite is increased through alkali etching; then the surface of the alkali-modified ceramsite is activated by utilizing high-activity disulfur dichloride; and the disulfur dichloride can be chemically bonded with hydroxyl functional groups on the surface of the ceramsite, so sulfur is loaded onto the surface of the ceramsite to form Si-O-S andcross-linking is performed so as to form a stable net-shaped structure. The sulfur-based autotrophic and heterotrophic denitrification nitrogen removal biological filler provided by the invention canrealize coupling of sulfur-based autotrophic and heterotrophic denitrification, is beneficial for the attached growth of microorganisms, reduces the addition of carbon sources, improves population richness, further increases nitrogen removal efficiency and stabilizes effluent quality.

Owner:NANJING UNIV

Conductive water treatment filler

InactiveCN1966425AFavorable for attachment growthPromote growthSustainable biological treatmentBiological water/sewage treatmentNitrosoCompound (substance)

There's provided an electric-conductible water-treatment filling on which there's electric-conductible paint. The filling can be elastic filling, combined filling, soft filling, semi-soft filling or chemical engineering filling; the mentioned electric-conductible paint is latex with carbon powder as the main electric-conducting material. The beneficial effects of the invention include the following aspects: (1) short membrane-form time, it only needs 3-14d to form good microbial film; (2) it can degrade the organics quickly: the degrading rate of aromatic hydrocarbon is faster than rate of the optimized obligate degrading bacteria; the nitro and nitroso can be anti-nitrated with no need to add carbon source so that it decreases the density of organics in discharged sewage which is helpful to improve the water quality; (3) it's convenient and easier to get electric-conductible fillings through smearing.

Owner:ZHEJIANG UNIV OF TECH

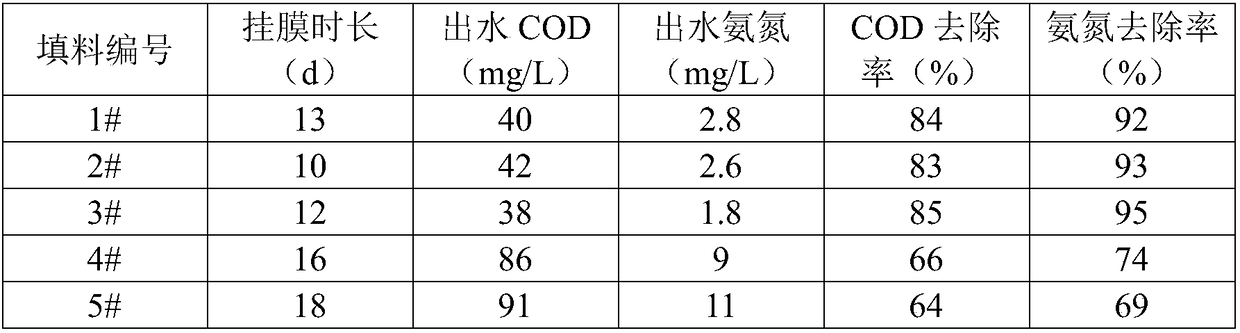

MBBR slow release carbon filler and preparation method thereof

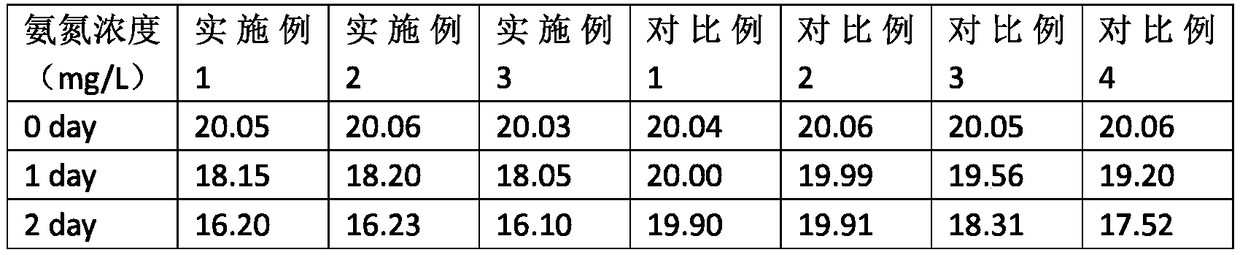

InactiveCN108529758AImprove hydrophilic abilityBiological affinityWater contaminantsBiological water/sewage treatmentSewageAmmonia nitrogen

The invention discloses an MBBR slow release carbon filler and a preparation method thereof. The product provided by the invention has the advantages of fast biofilm formation speed, strong biologicaladhesion, difficult falling and high treatment efficiency, and is especially used for treatment of domestic sewage and industrial wastewater with high BOD5 content. The biological filler provided bythe invention has strong hydrophilicity and biological affinity, and the filler itself contains a slow-release carbon source, can provide the carbon source needed for biological metabolism, and the porous walnut sand material is beneficial to microbial growth, shortening of the biofilm formation time and improvement of the microbial treatment efficiency. With an ammonia nitrogen removal rate of greater than 92% and COD removal efficiency all exceeding 83%, compared with the existing filler, the MBBR slow release carbon filler provided by the invention can better treat biodegradable sewage.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Preparation method of immobilized microbial filler

InactiveCN109455824AShorten the film setting timeQuick purificationWater contaminantsBiological water/sewage treatmentChemistrySodium alginate

The invention discloses a preparation method of immobilized microbial filler, and belongs to the technical field of sewage treatment. The preparation method comprises the following steps: first, sodium alginate and polyvinyl alcohol are dissolved in water to prepare a sodium alginate-polyvinyl alcohol solution; then a microbial bacteria solution and zeolite are mixed evenly and then added into thesodium alginate-polyvinyl alcohol solution, full stirring and even mixing are conducted, and thus a sodium alginate-polyvinyl alcohol mixed solution containing microorganisms is obtained; and then biological filler is soaked in a mixed solution containing the microorganisms to enable the surface of the filler to be evenly covered with the mixed solution containing the microorganisms, and then thefiller is taken out, finally soaked in a boric acid-calcium chloride aqueous solution for 12-24 h, washed by normal saline and air-dried, and thus the microbial filler is obtained. The preparation method is easy to operate, the problem that the natural biofilm culturing time of the biological filler in a water body is long is effectively solved, and the degradation efficiency of the biological filler to pollutants is improved.

Owner:上海同瑞环保科技有限公司

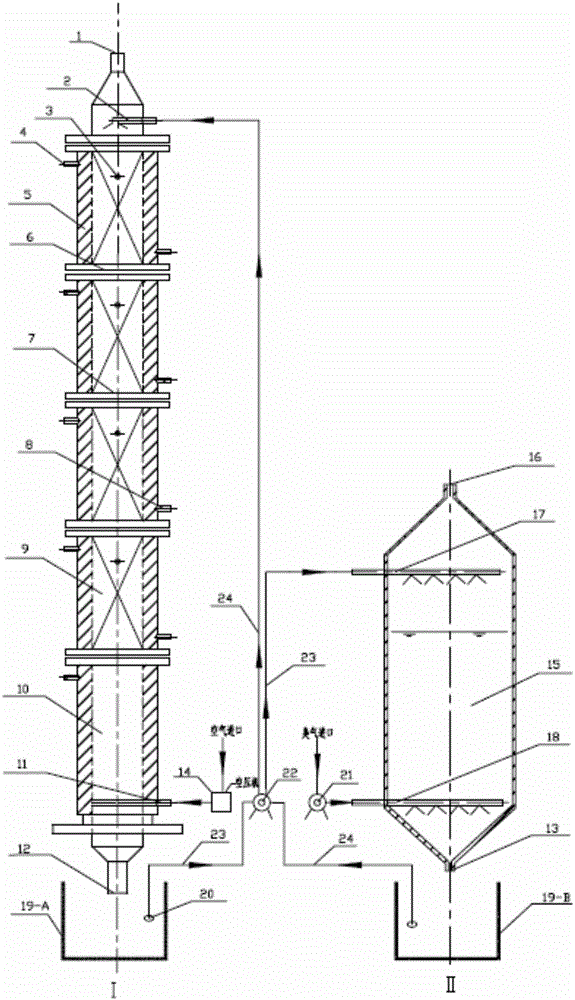

Biological desulfurizing and deodorizing trickling-filtration tower device and biological desulfurizing and deodorizing method

InactiveCN106268291AImpact resistantImpact resistance achievedDispersed particle separationAir quality improvementCushioningFiltration

The invention discloses a biological desulfurizing and deodorizing trickling-filtration tower device and a biological desulfurizing and deodorizing method for odor. The biological desulfurizing and deodorizing trickling-filtration tower device comprises a biological oxidizing tower, a chemical-absorption desulfurizing and deodorizing tower and a circular spraying device, wherein the biological oxidizing tower is formed by connecting a plurality of biological oxidizing units containing fillers and an odor-inflow cushioning area; a biological trickling filter is arranged at the top part of the tower, and an air inlet is arranged at the odor-inflow cushioning area; the chemical-absorption desulfurizing and deodorizing tower contains chemical absorbing liquid, an odor inlet is arranged at the bottom part of the chemical-absorption desulfurizing and deodorizing tower, and a rich-liquid inlet is arranged above the liquid level; the circular spraying device comprises a poor-liquid collecting groove, a rich-liquid collecting groove and a circulating pump; the rich-liquid collecting groove is used for collecting spraying liquid discharged from the biological oxidizing tower and conveying the spraying liquid to the rich-liquid inlet by the circulating pump; and the poor-liquid collecting groove is used for collecting chemical absorbing liquid discharged from the chemical-absorption desulfurizing and deodorizing tower and conveying the chemical absorbing liquid to the biological trickling filter. The invention also discloses a biological desulfurizing and deodorizing method utilizing the biological desulfurizing and deodorizing trickling-filtration tower device.

Owner:NANJING UNIV OF TECH

Self-oxygenation microorganism degradation filler and preparation method thereof

ActiveCN108504058AImprove processing efficiencyReduce surface tensionSustainable biological treatmentBiological water/sewage treatmentBiocompatibility TestingBiofouling

The invention discloses self-oxygenation microorganism degradation filler and a preparation method thereof. A product disclosed by the invention has a rapid film formation speed, strong biological adhesiveness, uneasiness of falling off and high treatment efficiency and is especially used for treating domestic sewage and industrial wastewater with relatively high BOD5 (Biochemical Oxygen Demand 5)content; the product disclosed by the invention has extremely strong hydrophilicity and biocompatibility; the filler contains an oxygen-carrying material and surface tension between air bubbles and awater surface can be reduced; oxygen can be dissolved into sewage and the growth of microorganisms is facilitated; the film formation time is shortened and the microorganism treatment efficiency is improved. The ammonia nitrogen removal rate is higher than 90 percent and the removal efficiency of COD (Chemical Oxygen Demand) exceeds 80 percent; compared with existing filler, the sewage with relatively high BOD5 content can be treated better.

Owner:安徽绿源高分子材料科技有限公司

Method for improving biofilm forming efficiency of packing in water treatment reactor

ActiveCN108892235AHigh film-hanging efficiencyNot easy to fall offWater treatment compoundsSustainable biological treatmentActivated sludgeBiochemical engineering

The invention discloses a method for improving the biofilm forming efficiency of packing in a water treatment reactor. The method comprises the following implementation steps that activated sludge isinoculated in the reactor, the reactor is operated in a sequencing batch, the hydraulic retention time is 4 h, and according to each rotary group, water is fed for 5 min, aeration is performed for 108-111 min, standing settling is performed for 2-5 min, and water is drained for 2 min, wherein organic loads of water feeding are 6-12 g / (L d), and the air flow rate is 1.6-2.4 cm / s; when the reactor is operated at the second to fourth days, aerobic granular sludge containing a large number of film forming microorganisms is formed inside the reactor, and the packing is put into the reactor; 2-5 d after the packing enters the reactor, film forming is completed. Compared with other film forming methods, the film forming method has the advantages that no high-cost special microorganisms or substrate needs to be added, and the film forming cost is low; meanwhile, the operation cost is lowered, the film forming time of the packing is shortened to 2-5 d, and the film forming efficiency of a biofilm method is greatly improved.

Owner:NANJING JIANGDAO INST OF ENVIRONMENT RES CO LTD

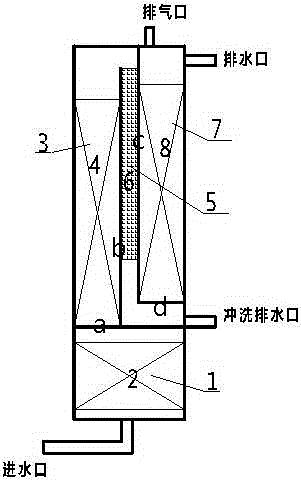

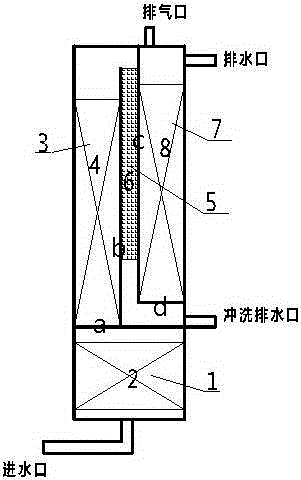

A short-distance nitrification-denitrification biomembrane denitrogenation method for nitrogen containing sewage

ActiveCN106554122APromote formationImprove denitrification effectWater contaminantsMultistage water/sewage treatmentActivated carbonShortest distance

A short-distance nitrification-denitrification biomembrane denitrogenation method for nitrogen containing sewage is disclosed. A biomembrane reactor having the following structure is adopted, wherein a cross plate a, a vertical plate b, a vertical plate c and a cross plate d are disposed in the reactor, the cross plate a separates the reactor into an upper part and a lower part, the lower part is a hydrolysis acidifying zone and the upper part is an A / O zone; the A / O zone is divided into three parts which are an aerobic zone O, a transition zone and an anaerobic zone A in order through the vertical plate b and the vertical plate c, the lower end of the vertical plate b is hermetically connected to the cross plate a, a water opening is between the upper end of the vertical plate b and the top of the reactor, the upper end of the vertical plate c is hermetically connected to the top of the reactor, a water opening is between the lower end of the vertical plate c and the cross plate a, the left end of the cross plate d is hermetically connected to the bottom of the vertical plate c, the right end of the cross plate d is hermetically connected to the wall of the reactor, and the transition zone is filled with palladium-copper loaded activated carbon catalyst particles. During sewage treatment, water is fed from the bottom of the reactor, passes through the hydrolysis acidifying zone, the aerobic zone, the transition zone and the anaerobic zone in order and discharged from the upper part. Biomembranes in each zone of the reactor are cultured separately, biomembranes with specific performance can be formed, film hanging is rapid and denitrogenation effects are good.

Owner:CHINA PETROLEUM & CHEM CORP +1

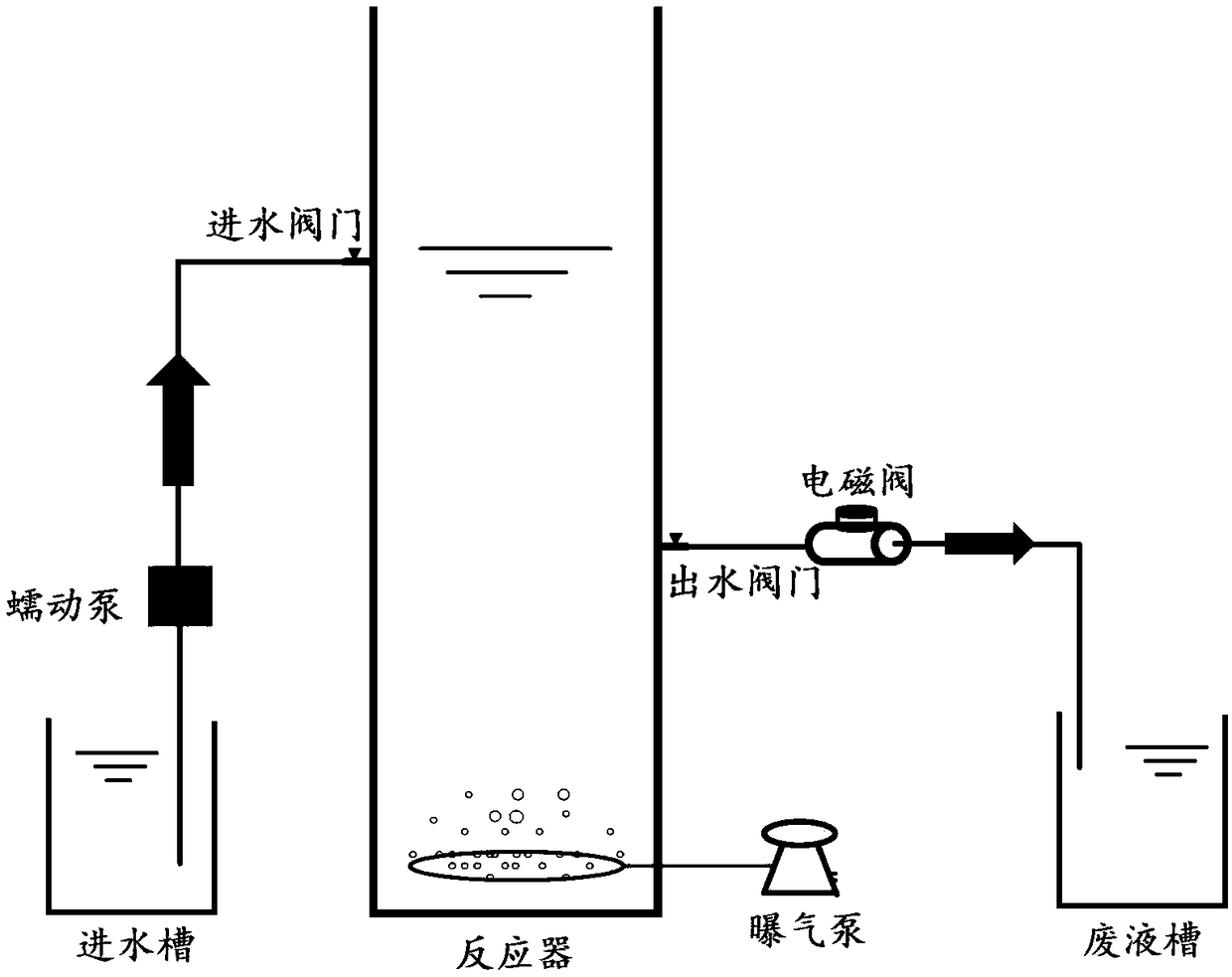

Method and device for improving wastewater treatment biological film forming efficiency

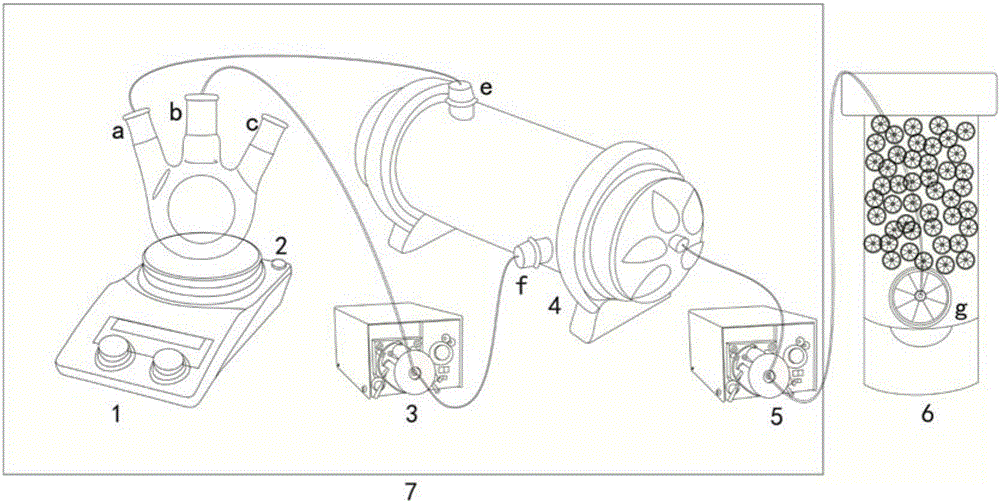

ActiveCN106495313ALow film-hanging efficiencyIncrease costBiological water/sewage treatmentHomoserinePeristaltic pump

The invention belongs to the technical field of wastewater treatment and discloses a method and a device for improving wastewater treatment biological film forming efficiency, aiming to solve the problems of low film forming efficiency, high cost and low applicability in the prior art. The device comprises a magnetic stirrer, a three-neck flask is arranged on the magnetic stirrer, a bacterial solution is fed into an ultrafiltration cross-flow filter device from a lower sample inlet of the ultrafiltration cross-flow filter device through a bacterial solution feeding port and a first peristaltic pump pipeline, and a sample outlet of the ultrafiltration cross-flow filter device is connected with an excretion feeding head of a reactor through a second peristaltic pump. The method and the device have the advantages that different quick film forming means are selected according to the content of homoserine lipid materials under same conditions, high film forming efficiency, low cost and high applicability are realized, effective film forming is realized to the greatest extent, integral film forming time is shortened, and the risk of adopting a packing process is minimized.

Owner:NANJING UNIV

Short-distance nitrification/denitrification biomembrane nitrogen-removal reactor and rapid membrane forming method

ActiveCN106554080AGood denitrification effectEnhanced oxidative decomposition and conversion removal of nitrogenTreatment with aerobic and anaerobic processesActive carbonEngineering

The invention discloses a short-distance nitrification / denitrification biomembrane nitrogen-removal reactor and a rapid membrane forming method. According to the invention, a transverse plate a, a vertical plate b, a vertical plate c and a transverse plate d are arranged in the reactor, the reactor is transversely divided into an upper part and a lower part by the transverse plate a , the lower part is a first anaerobic zone, the upper part is vertically divided into three parts by the vertical plate b and the vertical plate c, which are an aerobic zone, a transition zone and a second anaerobic zone; the lower end of the vertical plate b is connected with the transverse plate a, a water passing port is kept at the top of the upper end and the reactor, the upper end of the vertical plate c and the top of the reactor are connected in a sealing mode, the water passing port is kept at the lower end and the transverse plate a, the left end of the transverse plate d and the bottom of the vertical plate c are connected in the sealing mode; the right end and the wall of the reactor are connected in the sealing mode; and the transition zone is filled with palladium-copper supported active carbon catalyst particles. While the membrane is formed, water is introduced from bottom, the sewage passes through the first anaerobic zone, the aerobic zone, the transition zone and the second anaerobic zone in order, then is discharged from the upper part of the reactor, biomembranes at each area in the reactor are subjected to partitioning culture, the biomembrane having specific performance can be better formed, the membrane forming speed is rapid, and the nitrogen removal effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

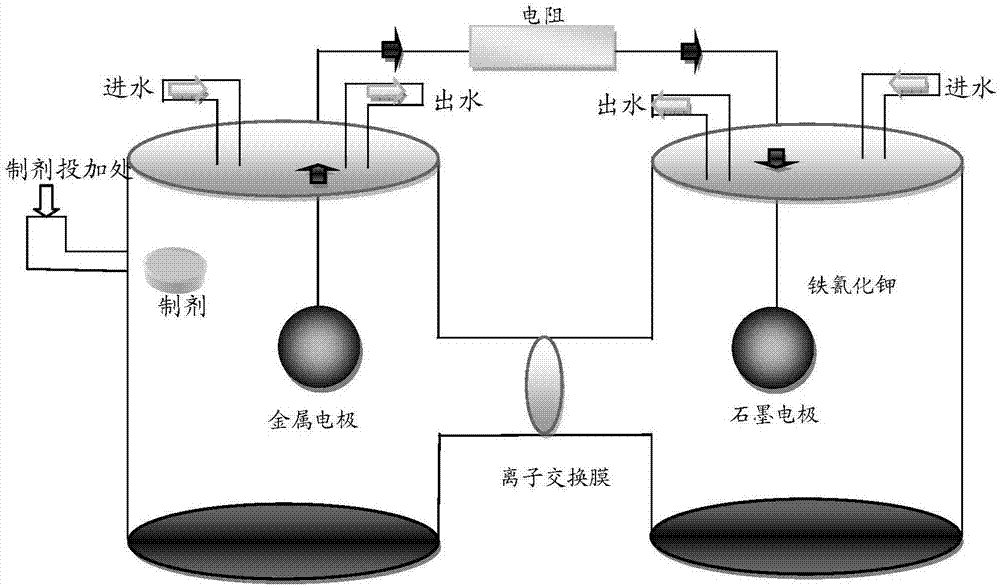

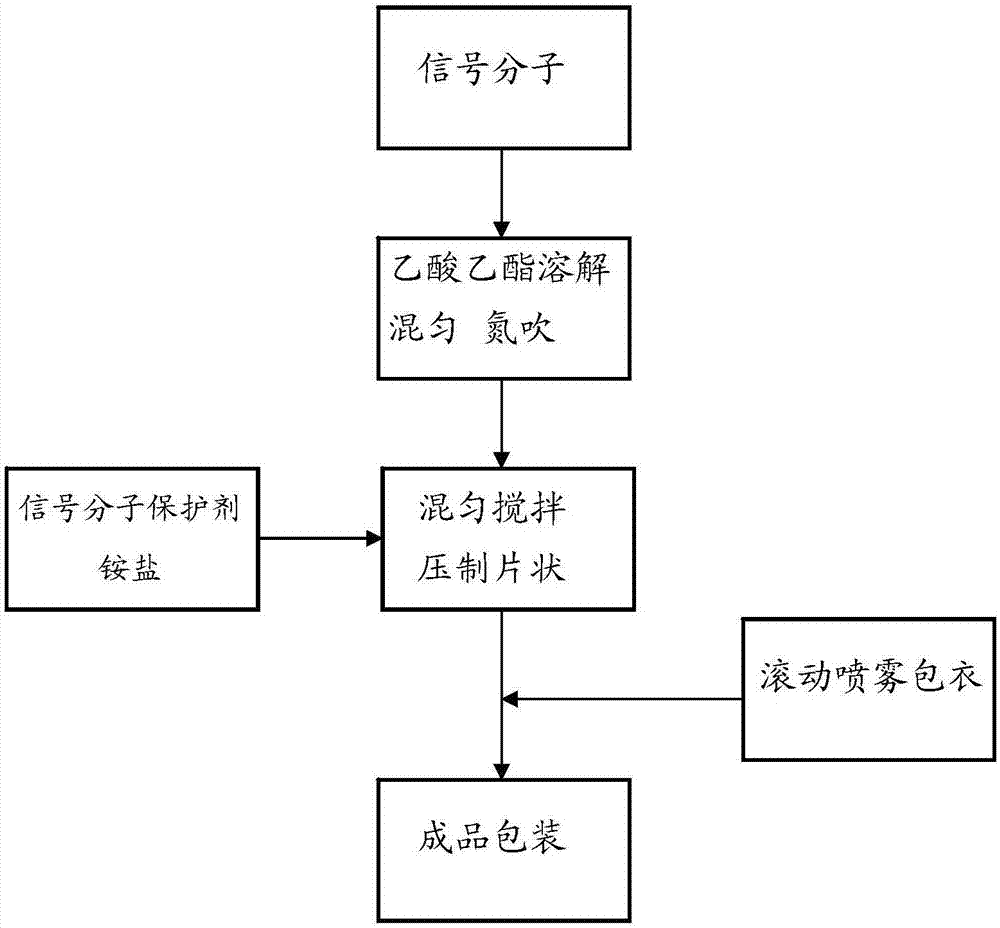

Preparation and application for accelerating Gram-negative current-producing bacteria anode bio-film efficiency in microbial fuel cell

ActiveCN107285477APromote growth rateFast growthTreatment by combined electrochemical biological processesWater treatment compoundsBiofilm growthSignalling molecules

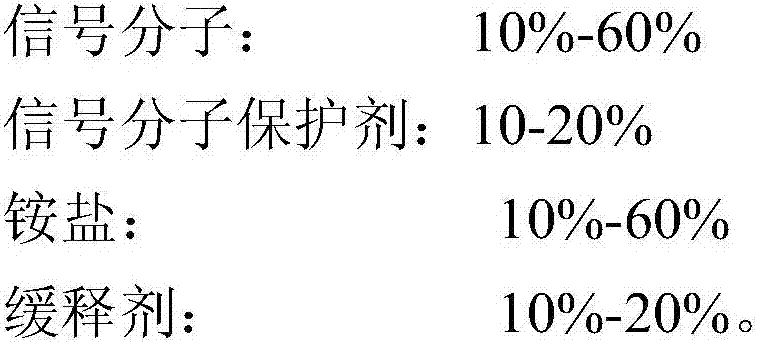

The invention discloses preparation and application for accelerating Gram-negative current-producing bacteria anode bio-film efficiency in a microbial fuel cell. The anode bio-film is prepared from the following components in percentage by mass: 10-60% of a signal molecule, 10-60% of an ammonium salt, 10-20% of a signal molecule protective agent and 10-20% of a sustained-release agent. The preparation method comprises the following steps: feeding to-be-treated wastewater into an anode chamber of the microbial fuel cell, sequentially adding the preparation capable of accelerating the Gram-negative current-producing bacteria anode bio-film efficiency and inoculating Gram-negative current-producing bacteria synchronously or according to any sequence. The preparation disclosed by the invention is capable of improving the bio-film growth speed and shortening the forming time of the bio-film, has the characteristics of low cost and wide applicability and lays a foundation for expanded engineering application of the microbial fuel cell.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

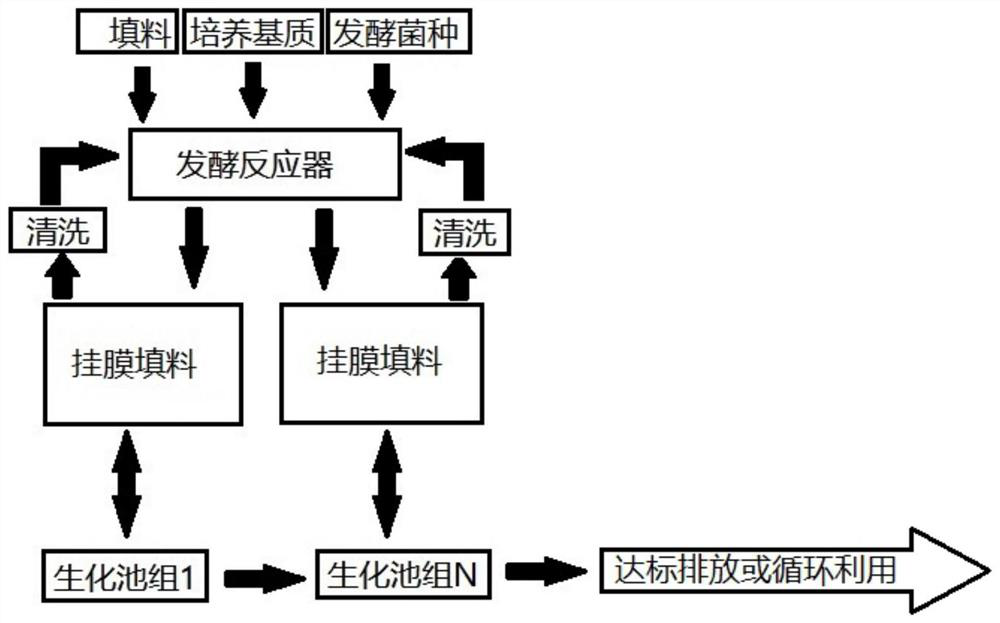

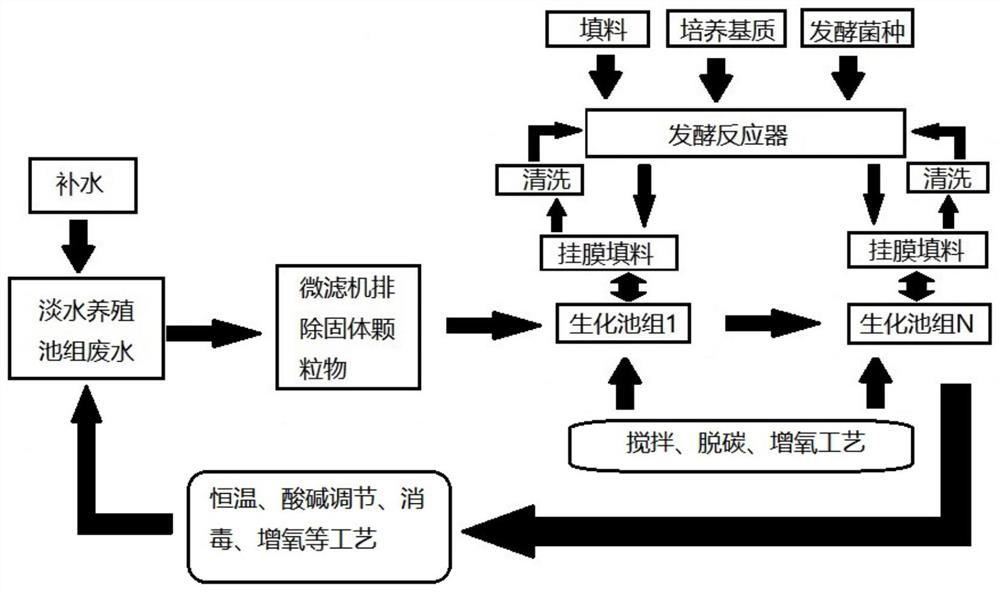

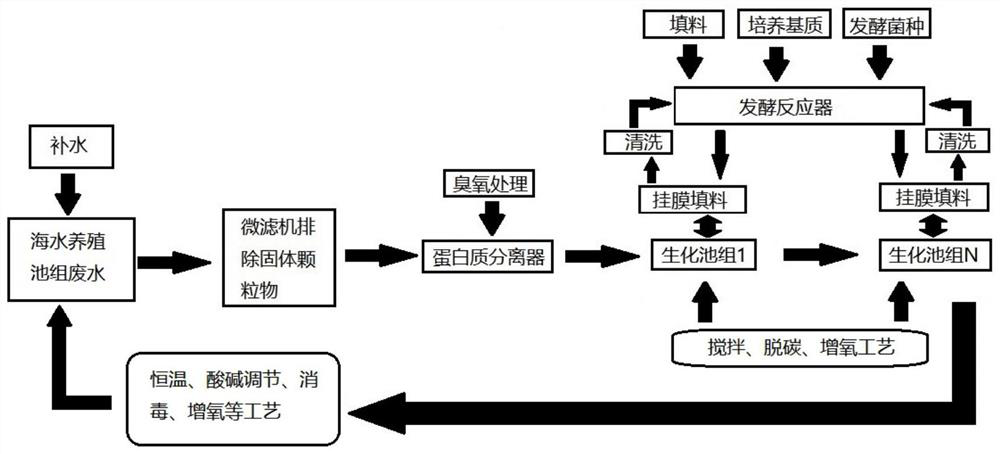

Method for biofilm culturing of filler via fermentation reactor and transferring filler to biochemical pool

PendingCN111717999AShorten the film setting timeHigh purity densityTreatment with aerobic and anaerobic processesBiotechnologyBiofilm

The invention provides a method for biofilm culturing of a filler via a fermentation reactor and transferring the filler to a biochemical pool. The method comprises the following steps: putting a soaked and flushed filler and clean water into a fermentation reactor together, carrying out disinfection and inactivation treatment, adding a culture medium matched with a fermentation strain into the fermentation reactor, carrying out premixing and homogenizing treatment, adding the fermentation strain into the fermentation reactor, and continuing to operate the fermentation reactor until a biofilmgrows on the surface of the filler; putting the biofilm-cultured filler into a working biochemical pool; detecting whether the water quality in the biochemical pool reaches a standard or not at set intervals; and, fishing out the ineffective filler in the working biochemical pool, cleaning the filler, and putting the filler into the fermentation reactor in the step S3 again for fermentation again.According to the invention, since the filler and mother liquor which have successfully undergone biofilm culturing are directly fed into the biochemical pool to serve as a working filler and workingflora of the biochemical pool, so the biochemical pool directly enters an ideal working state, the long biofilm culturing time of the biochemical pool is saved, and a biochemical process is kept stable and continuously improved.

Owner:SHANDONG YUANTU ENVIRONMENTAL TECH CO LTD

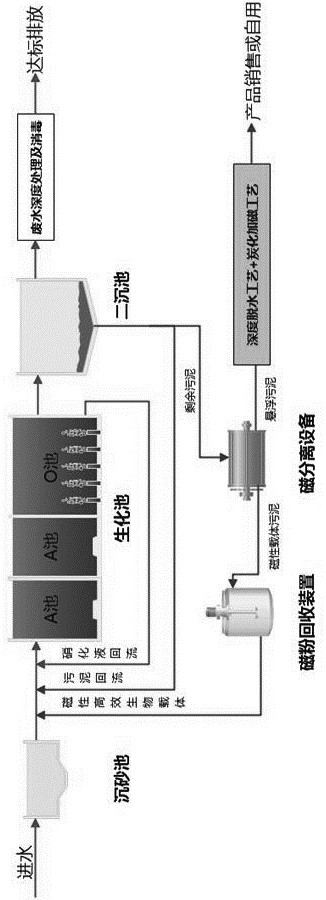

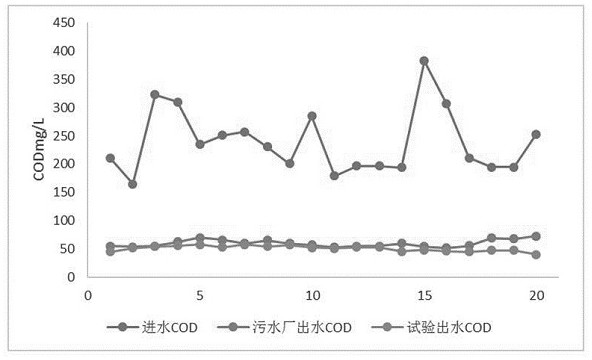

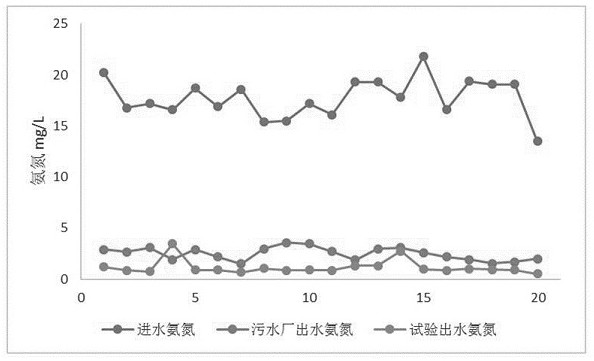

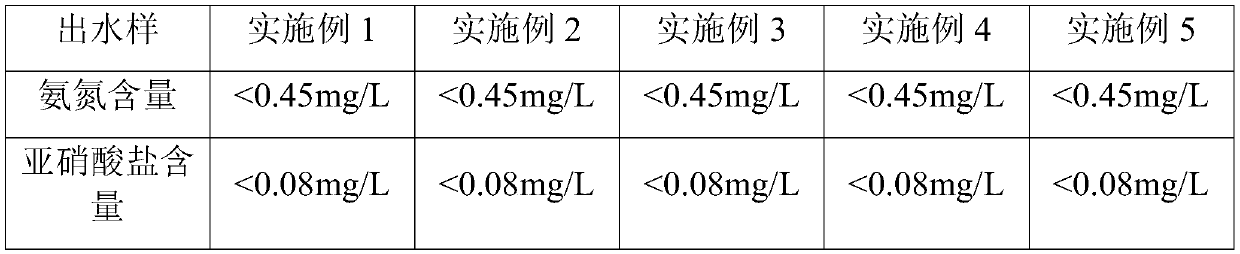

Treatment process for cooperating magnetic sludge carbon carrier with sewage upgrading and capacity expansion

ActiveCN113003857AIncrease concentrationImprove removal efficiencyTreatment involving filtrationTreatment with aerobic and anaerobic processesActivated sludgeSewage

Owner:ZHEJIANG ZONE KING ENVIRONMENTAL SCI&TECH CO LTD

Preparation method of light biological filter material

ActiveCN111018094AHigh strengthRich in holesCeramic materials productionTreatment with microorganism supports/carriersMicrobial inoculationBiofilm

The invention relates to the technical field of filter materials, and in particular, relates to a preparation method of a light biological filter material. The biological filter material is prepared from the following components in parts by mass: 60-80 parts of steel slag, 12-18 parts of humic acid, 2-8 parts of ammonium carbonate, 0.6-0.8 part of an adhesive and 10-30 parts of water. The preparation method comprises the following steps: (1) weighing steel slag, humic acid, ammonium carbonate and the adhesive in proportion, adding water, uniformly mixing, preparing into balls in a ball formingmill, transferring into a drying oven, drying, calcining, and cooling to obtain a semi-finished product; (2) soaking the biological filter material semi-finished product obtained in the step (1) in anutrient solution for 30-45 min, and carrying out microbial inoculation for 5-7 d, to obtain the biofilm-culturing biological filter material. According to the prepared light biological filter material, the sewage treatment efficiency per unit volume is improved by 7-8 times compared with that of a conventional filter material, the environment-friendly emission standard can be met, the oxygenating efficiency is high, energy consumption is reduced, and the problem that the treatment efficiency is reduced due to the fact that the material surface is not uniform after an existing filter materialruns for a period of time is solved.

Owner:NANJING GONGCHENG RES INST OF ENERGY CONSERVATION & NEW MATERIALS TECH CO LTD

Water purified process for polluted water in-situ

InactiveCN1792887ALow cost of preparationExcellent PhytoactivityBiological water/sewage treatmentSewageWater quality

An in-situ cleaning method for the polluted water system includes such steps as providing luffa, tying them to floating rods via strings, tying a weight to said floating rod, arranging them in the water to make the luffa be suspended in water, and treating for 6-9 days.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com