Conductive water treatment filler

A water treatment, conductive technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. Easy to process, simple to use, and the effect of reducing the concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

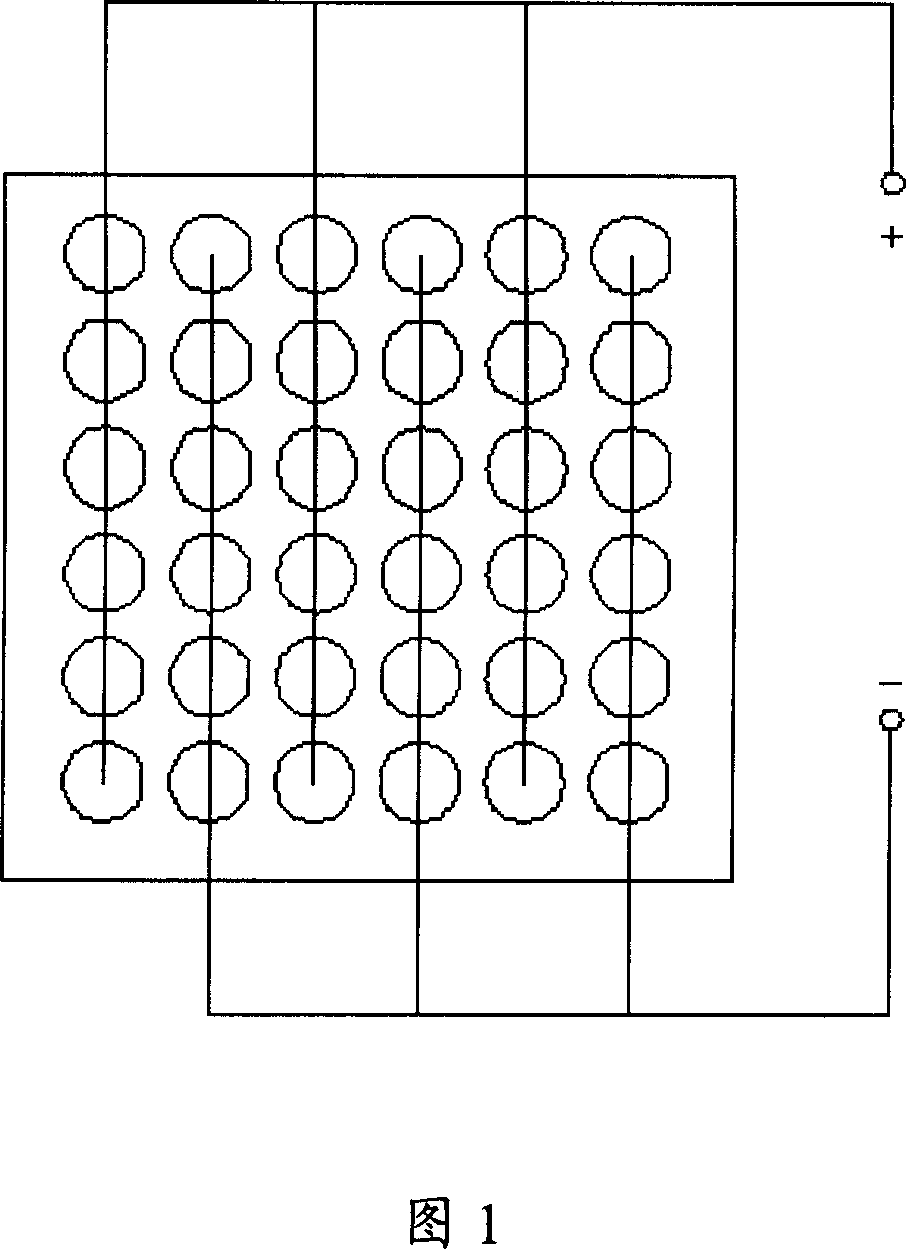

[0036] Example 1: Preparation of conductive water treatment filler

[0037] Main raw materials: commercially available φ15cm elastic packing (Shanghai Petrochemical Waters Environmental Protection Factory), water-based polyacrylate coating (Tianjin Qunhui Sealing Material Factory)

[0038]Conductive coating formula: graphite powder 2kg, water 5kg, water-based polyacrylate coating 5kg, sodium dodecylsulfonate 0.5kg

[0039] Mix the above formula materials evenly, impregnate the surface of the elastic filler, and dry at 80 degrees for 2 hours to get the finished product.

Embodiment 2

[0040] Example 2: Preparation of conductive water treatment filler

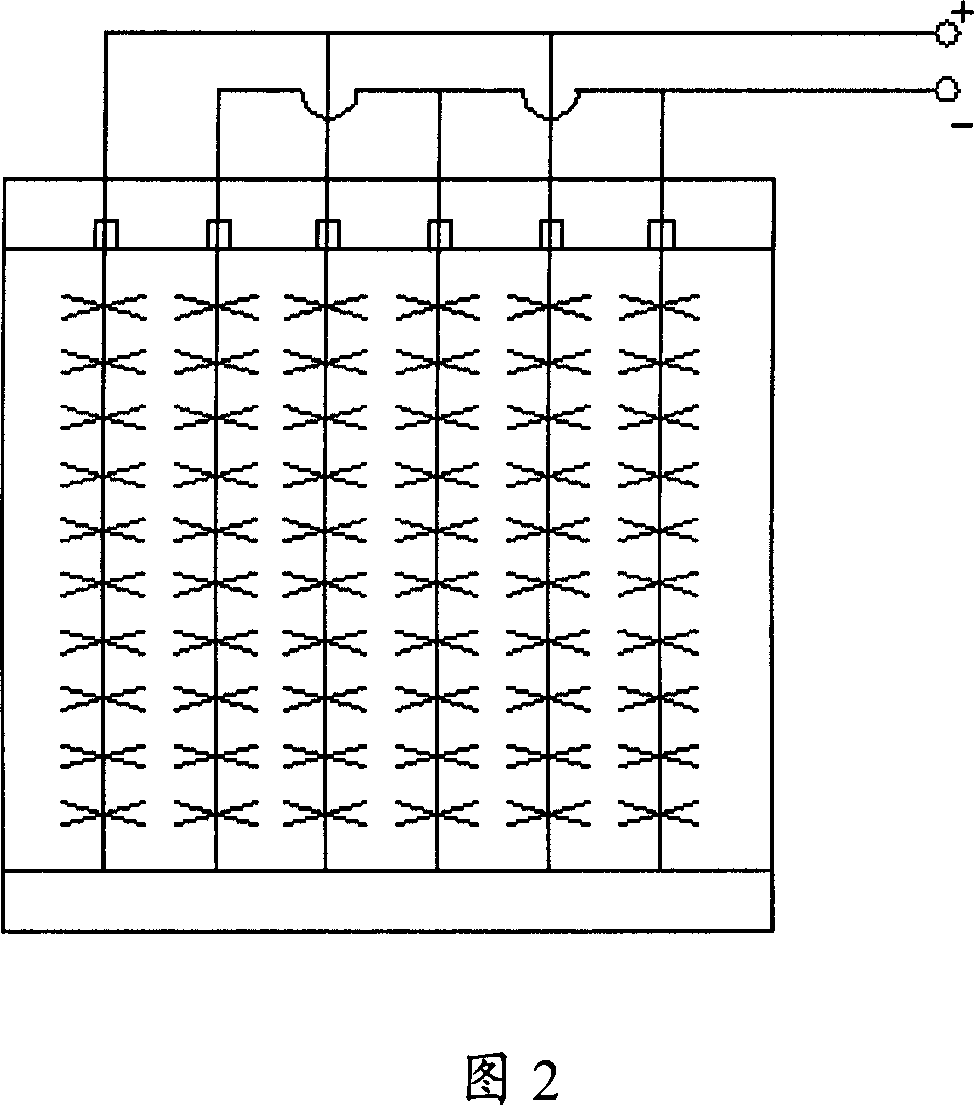

[0041] Main raw materials: stepped ring plastic packing produced by Jiangxi Quanxing Chemical Packing Co., Ltd., water-based polyurethane coating produced by Wenzhou Huanyu Company

[0042] Conductive coating formula: graphite powder 1kg, carbon fiber short filament 1kg, water 3kg, water-based polyurethane coating 5kg, sodium dodecylsulfonate 0.5kg

[0043] Mix the above formula materials evenly, spray on the surface of the chemical filler, and dry at 80 degrees for 2 hours to get the finished product.

Embodiment 3

[0044] Example 3: Preparation of conductive water treatment filler

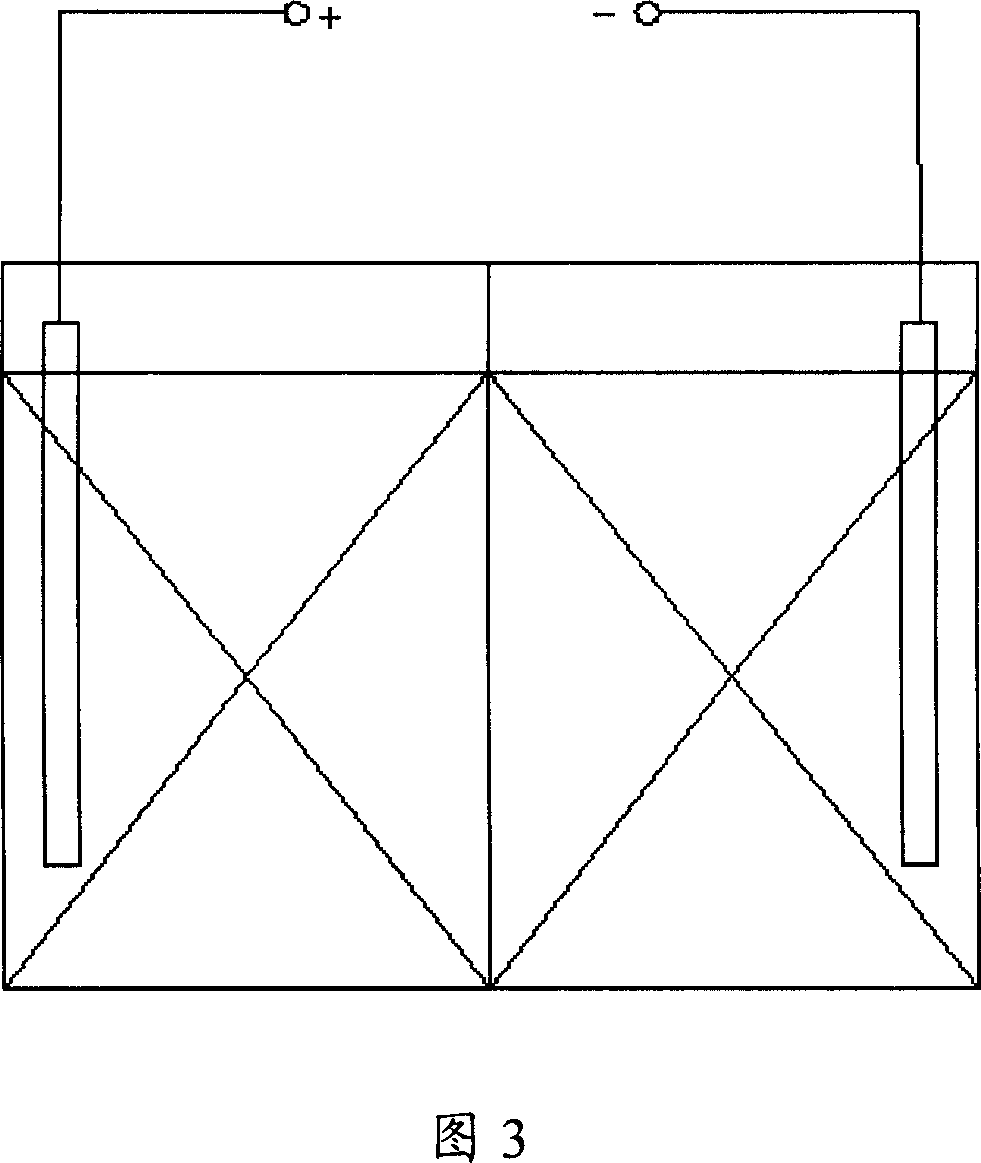

[0045] Main raw materials: φ15cm elastic filler produced by Shanghai Petrochemical Waters Environmental Protection Plant, polyethylene formal acetaldehyde coating produced by Shanghai Shunqiang Biotechnology Co., Ltd.

[0046] Conductive coating formula: acetylene carbon black 1kg, polyethylene formal coating 3kg, dimethylformamide 6kg

[0047] Mix the above formula materials evenly, brush on the surface of the elastic filler, dry at 80°C for 1 hour, then heat up to 110°C and heat cure for 2 hours to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com