Honeycomb modified biological stuffing applied to water treatment and preparation method thereof

A technology of biological filler and water treatment, applied in the direction of adsorption water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Attachment growth is easier and tighter, and the effect of multiple attachment growth points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

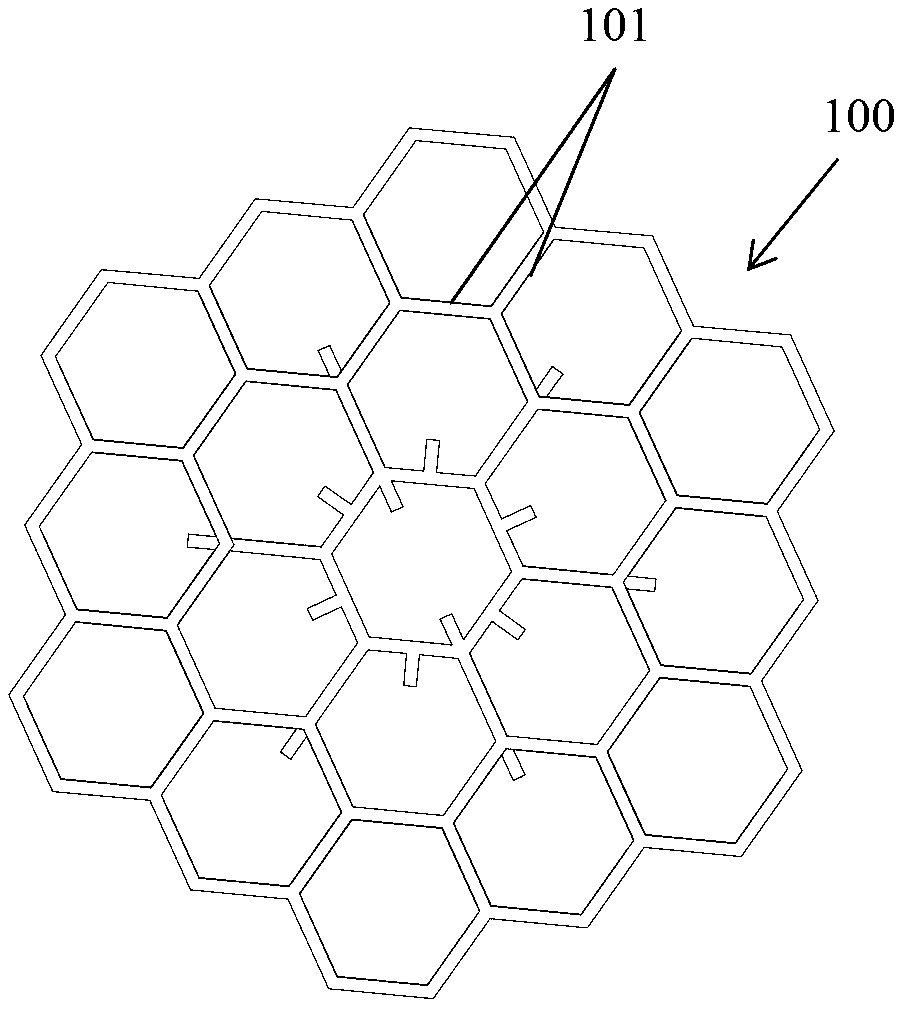

[0023] Example 1: 497.5 g of polypropylene particles and 2.5 g of activated carbon with a particle size of 0.01 mm were weighed. The polypropylene granules were moved into the extruder and molded through a filler die. The section of the filler 100 was a hexagonal honeycomb structure, and 500 pieces were cut. Then use a sandblasting machine to evenly embed and distribute activated carbon on the inner and outer surfaces 101 of the filler, thereby obtaining activated carbon modified hydrophilic filler, and the density of the prepared filler is about 0.98g / cm 3 .

[0024] The activated carbon modified hydrophilic filler and ordinary polypropylene plastic filler prepared above were respectively placed in the MBBR reaction tank under the same conditions, and a comparative test of domestic sewage treatment was carried out. The influent CODcr is 250-400mg / L, the activated sludge concentration is 10g / L, and the aeration rate is 3mg / L. After 5 days, the activated carbon modified hydrop...

Embodiment 2

[0025] Embodiment 2: Weigh 225 g of polypropylene particles and polyethylene particles each, and 50 g of activated carbon with a particle size of 0.5 mm. The polypropylene granules and polyethylene granules were moved into the extruder, shaped by a filler mold, the cross-section was a hexagonal honeycomb structure, and 500 fillers were obtained by cutting. Then use a sandblasting machine to evenly embed activated carbon on the inner and outer surfaces of the filler to obtain activated carbon modified hydrophilic filler. The density of the prepared filler is about 0.93g / cm 3 .

[0026] The experimental results of sewage treatment show that the film-hanging time of the activated carbon modified hydrophilic filler system prepared in this example is 5 days, and the CODcr removal rate is 89% after the system is stable, while the CODcr removal rate of the ordinary polypropylene plastic packing system is only 75%. .

Embodiment 3

[0027] Embodiment 3: Weigh 375g of polyethylene particles and 125g of activated carbon with a particle size of 2mm. The polyethylene pellets were moved into the extruder and shaped by a filler die with a hexagonal honeycomb structure in section, and 500 fillers were obtained by cutting. Then use a sandblasting machine to evenly embed activated carbon on the inner and outer surfaces of the filler to obtain activated carbon modified hydrophilic filler. The density of the prepared filler is about 0.86g / cm 3 .

[0028] The experimental results of sewage treatment show that the film-hanging time of the activated carbon modified hydrophilic packing system prepared in this example is 4 days, and the CODcr removal rate after 4 days has reached 90%, while the CODcr removal rate of the ordinary polyethylene plastic packing system is only 70%. %.

[0029] Hybrid

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com