Method of preparing Ti ceramic nano membrane on medical stainless steel

A technology of stainless steel and nano-membrane, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems such as insufficient wear resistance, poor adhesion between the film and the base material, and insufficient corrosion resistance , to achieve the effect of uniform and dense film and good surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

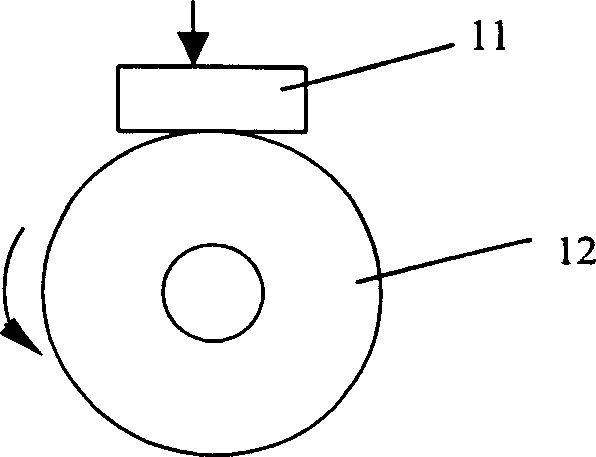

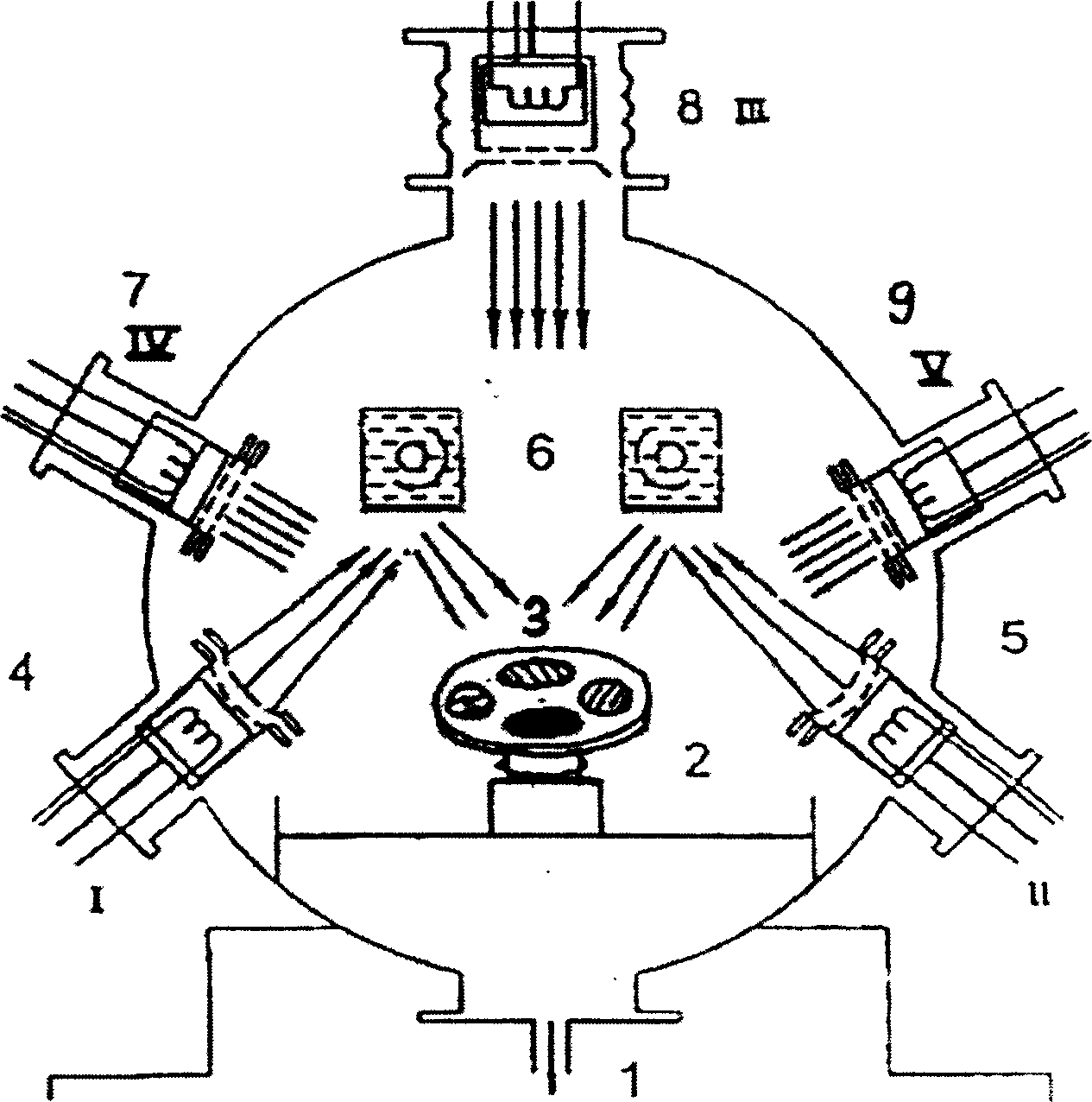

[0061] Embodiment 1: The specific steps are: before deposition, put the polished and cleaned 317L stainless steel on the water-cooled rotatable sample stage of IBAD equipment, after vacuuming, first use 1keV nitrogen ion beam to carry out sputter cleaning for 15 minutes, and then use Ar at 3keV, 80mA + While ion sputtering the Ti target, bombard it with high energy 20keV, beam current 6mA for 10 minutes, and then use low energy 50eV, beam current 10mA N + Ion beam assisted deposition, the sample stage keeps rotating during the deposition process to improve the uniformity of film formation. In the experiment, the background vacuum is better than 1×10 -3 Pa, nitrogen partial pressure is 8×10 when working -3 Pa, the film forming time is 60 minutes, and the film thickness is about 600nm.

Embodiment 2

[0062] Embodiment 2: The specific steps are: before deposition, put the polished and cleaned 317L stainless steel on the water-cooled rotatable sample stage of IBAD equipment, after vacuuming, first use 1keV nitrogen ion beam to carry out sputter cleaning for 15 minutes, and then use Ar at 3keV, 80mA + While ion sputtering the Ti target, bombard it with high energy 10KeV, beam current 6mA for 15 minutes, and then use low energy 250eV, beam current 20mA N + Ion beam assisted deposition, the sample stage keeps rotating during the deposition process to improve the uniformity of film formation. In the experiment, the background vacuum is better than 1×10 -3 Pa, nitrogen partial pressure is 8×10 when working -3 Pa, the film forming time is 120 minutes, and the film thickness is about 900nm.

Embodiment 3

[0063] Embodiment 3: The specific steps are: before deposition, put the polished and cleaned 317L stainless steel on the water-cooled rotatable sample stage of IBAD equipment, after vacuuming, first use 1keV nitrogen ion beam to carry out sputter cleaning for 15 minutes, and then use Ar at 3keV, 80mA + While ion sputtering the Ti target, first bombard it with high energy 40KeV, beam current 6mA for 20 minutes, and then use low energy 350eV, beam current 30mA N + Ion beam assisted deposition, the sample stage keeps rotating during the deposition process to improve the uniformity of film formation. In the experiment, the background vacuum is better than 1×10 -3 Pa, nitrogen partial pressure is 8×10 when working -3 Pa, the film forming time is 180 minutes, and the film thickness is about 1200nm.

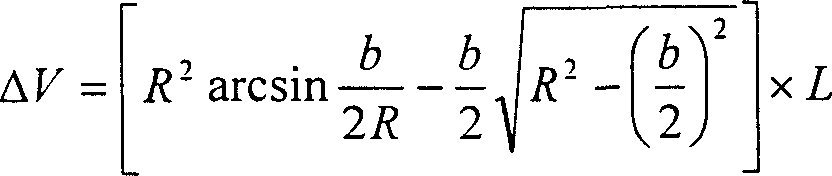

[0064] The process of preparing TiN thin film is: using Ar + While sputtering Ti target with ions, high-energy and low-energy N + The ion beam is used for bombardment, and the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com