Method and equipment for treating antibiotic mycelium residues

A technology of antibiotic bacteria residue and treatment method, which is applied to gas production bioreactors, waste fuels, fermentation, etc., and can solve the problems of high toxicity to the ecological environment, difficult separation of sludge, and increased reactor load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

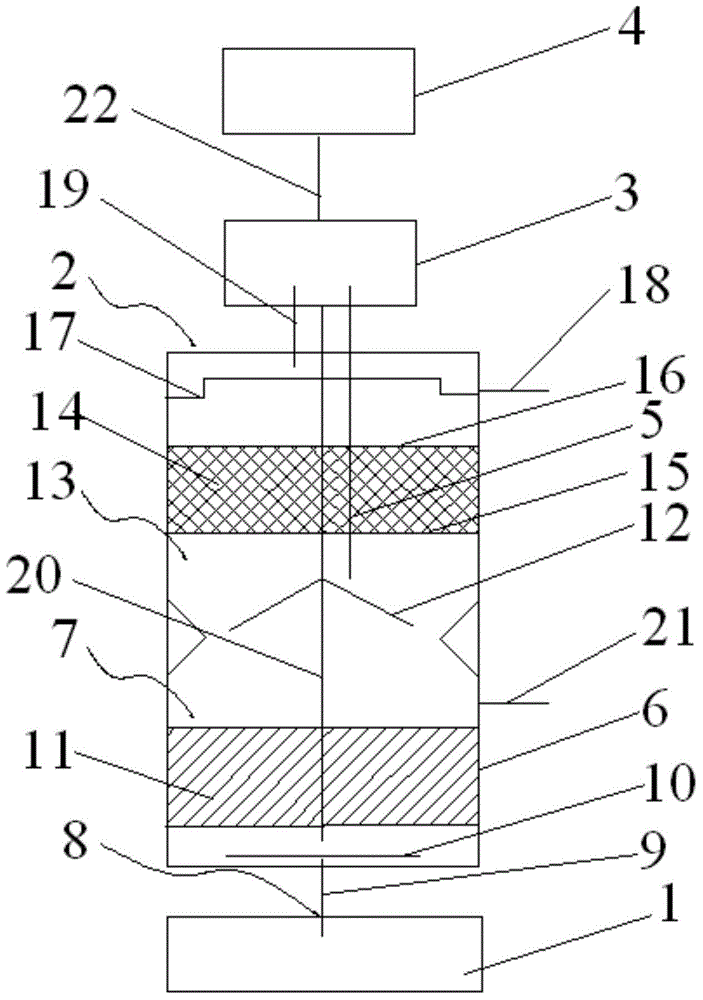

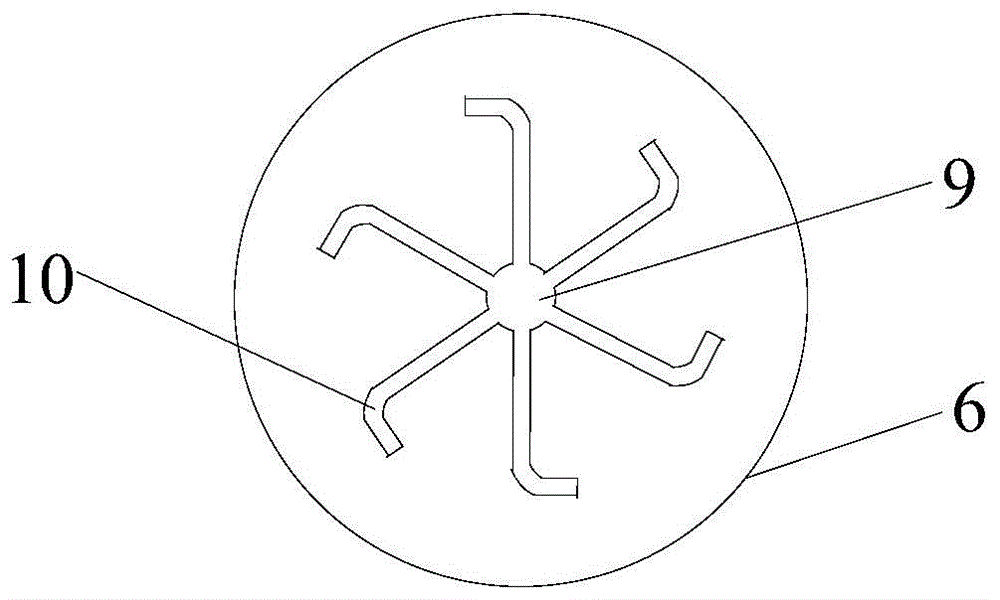

[0118] Take by weighing 0.75kg gentamicin bacterium slag and join in the slag water generating device 1, then pass into water in the slag water generating device 1, start the stirrer, it is stirred, after it is fully mixed, stop stirring, prepare The chemical oxygen demand (COD) of the gentamicin slag suspension with a solid content of 6% is 21455 mg / L.

[0119] The configured gentamicin slag suspension is distributed into the anaerobic fermentation device 2 through the water distribution device 8, wherein the concentration of the anaerobic granular sludge in the anaerobic fermentation tank is 7.14kg VSS m -3 , the fermentation temperature is 34°C, and the volume exchange rate of the reactor is 15%.

[0120] The gentamicin residue is anaerobically fermented in the anaerobic fermentation device to generate biogas, and the biogas enters the gas-liquid separation device 3 through the gas collecting pipe 19 and the riser pipe 5, and enters the biogas collection device 4 after bein...

Embodiment 2

[0123] Take by weighing 0.87kg gentamicin bacterium slag and join in the slag water generating device 1, then pass into water in the slag water generating device 1, start the stirrer, it is stirred, after it is fully mixed, stop stirring, prepare The chemical oxygen demand (COD) of the gentamicin slag suspension with a solid content of 7% is 22080 mg / L.

[0124] The configured gentamicin slag suspension is distributed into the anaerobic fermentation device 2 through the water distribution device 8, wherein the concentration of the anaerobic granular sludge in the anaerobic fermentation tank is 7.0kg VSS m -3 , the fermentation temperature is 33°C, and the volume exchange rate of the reactor is 18%.

[0125] The gentamicin residue is anaerobically fermented in the anaerobic fermentation device to generate biogas, and the biogas enters the gas-liquid separation device 3 through the gas collecting pipe 19 and the riser pipe 5, and enters the biogas collection device 4 after being...

Embodiment 3

[0128] Take by weighing 0.8kg gentamicin bacterium slag and join in the slag water generating device 1, then pass into water in the slag water generating device 1, start the stirrer, it is stirred, after it is fully mixed, stop stirring, prepare The gentamicin slag suspension with a solid content of 6.5% has a chemical oxygen demand (COD) of 21705 mg / L.

[0129] The configured gentamicin slag suspension is distributed into the anaerobic fermentation device 2 through the water distribution device 8, wherein the concentration of the anaerobic granular sludge in the anaerobic fermentation tank is 7.40kg VSS m -3 , the fermentation temperature is 35°C, and the volume exchange rate of the reactor is 12%.

[0130] The gentamicin residue is anaerobically fermented in the anaerobic fermentation device to generate biogas, and the biogas enters the gas-liquid separation device 3 through the gas collecting pipe 19 and the riser pipe 5, and enters the biogas collection device 4 after bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com