MBBR slow release carbon filler and preparation method thereof

A slow-release carbon and light calcium carbonate technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problem of increasing the hydraulic retention time of nitrification and denitrification treatment units and reducing sewage treatment. Factory automation, intelligence level, MBBR process loses the effect of sewage treatment, etc., to achieve the effect of shortening the film hanging time, strong biological adhesion, and fast film hanging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

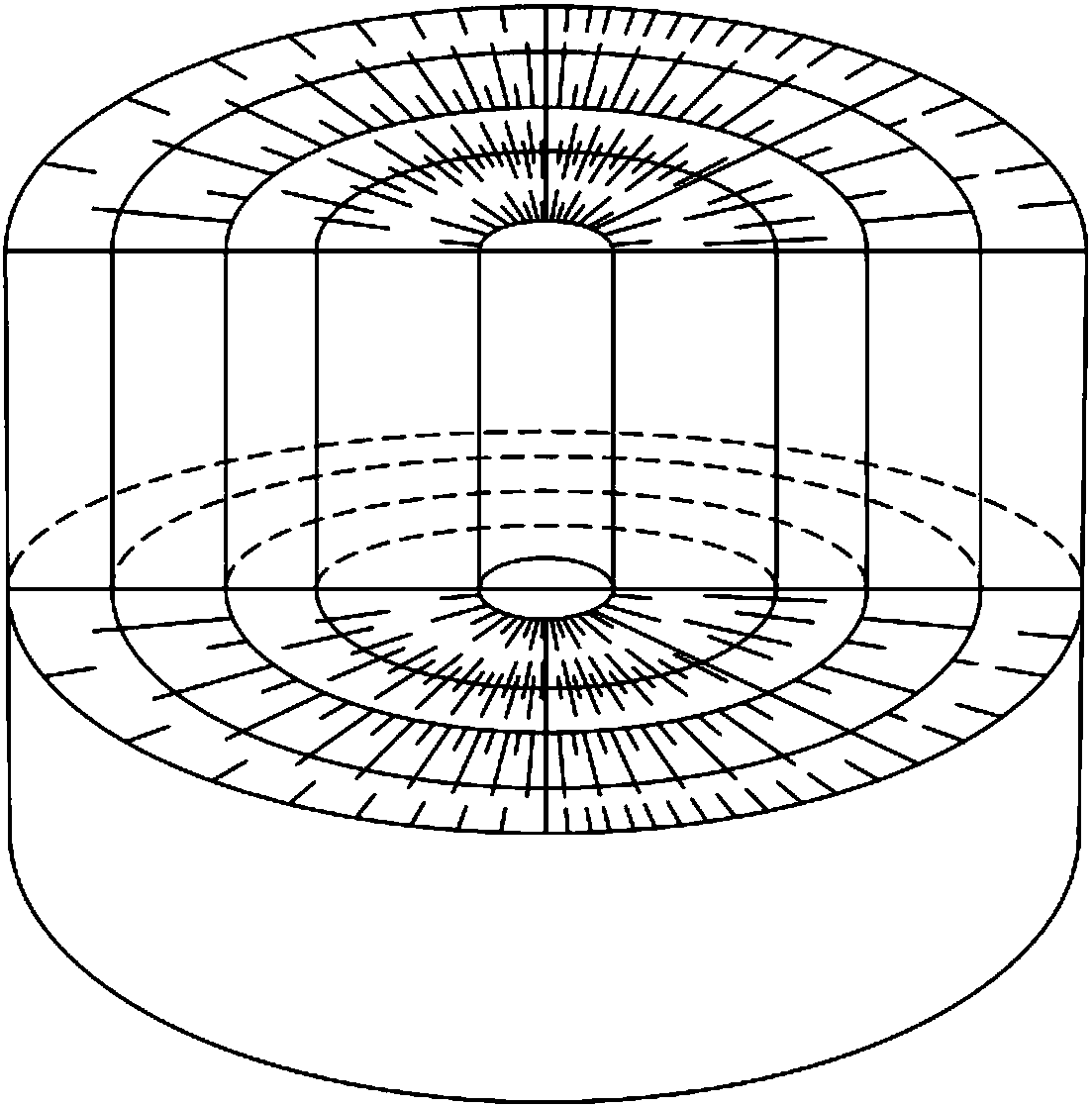

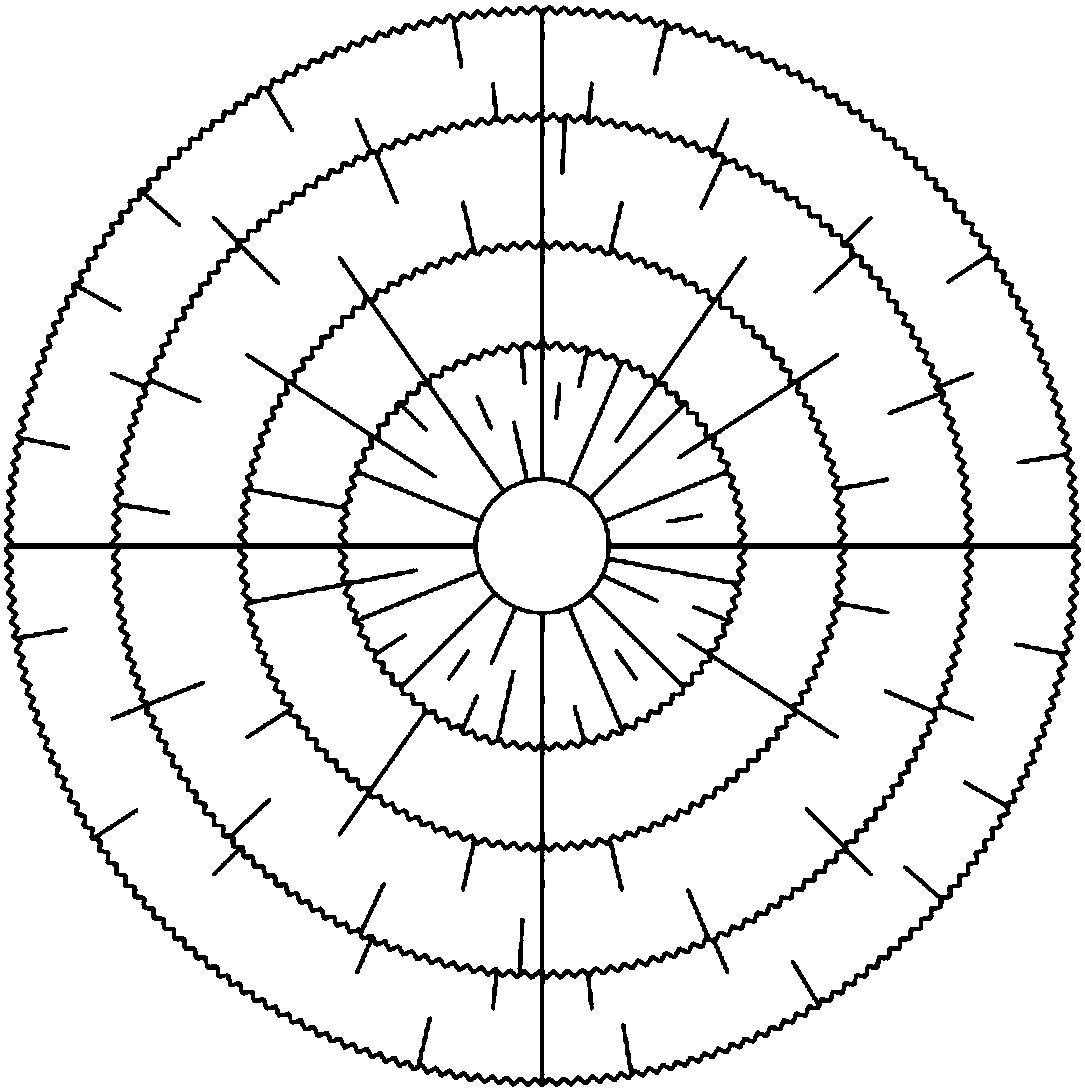

Image

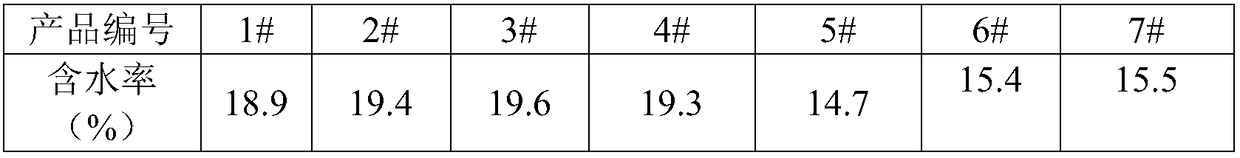

Examples

Embodiment 1

[0015] Example 1: MBBR slow-release carbon filler, calculated in parts by mass, includes 40 parts of polyhydroxyalkanoate, 30 parts of polylactic acid, 6 parts of light calcium carbonate, 15 parts of natural biomass walnut sand, and 4 parts of maleic anhydride , 0.5 parts of ferrous sulfate, 0.3 parts of magnesium chloride, 0.8 parts of composite coupling agent, 0.8 parts of white oil, 2.5 parts of polyvinyl alcohol, 1 part of stearic acid and 1 part of calcium chloride are the raw materials for preparation; natural biomass material walnut sand It needs to be pulverized with an ultra-fine pulverizer in advance, and the mesh size after pulverization is greater than 320 mesh.

[0016] The preparation method of MBBR slow-release carbon filler, each component is taken by above-mentioned mass parts, comprises the steps:

[0017] 1) Dissolve the above components in 2000ml of tetrahydrofuran and ethanol mixed solution (the mixed solution is composed of 99.9% tetrahydrofuran and absol...

Embodiment 2

[0020] Embodiment 2: MBBR slow-release carbon filler, calculated in parts by mass, includes 39 parts of polyhydroxyalkanoate, 29 parts of polylactic acid, 12 parts of light calcium carbonate, 12 parts of natural biomass walnut sand, and 4 parts of maleic anhydride , 0.4 parts of ferrous sulfate, 0.25 parts of magnesium chloride, 0.65 parts of composite coupling agent, 0.6 parts of white oil, 2.5 parts of polyvinyl alcohol, 1 part of stearic acid and 1 part of calcium chloride are the raw materials for preparation; natural biomass material walnut sand It needs to be pulverized with an ultra-fine pulverizer in advance, and the mesh size after pulverization is greater than 320 mesh.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0022] Embodiment 3: MBBR slow-release carbon filler, calculated in parts by mass, includes 37 parts of polyhydroxyalkanoate, 28 parts of polylactic acid, 10 parts of light calcium carbonate, 18 parts of natural biomass walnut sand, and 3 parts of maleic anhydride , 0.3 parts of ferrous sulfate, 0.2 parts of magnesium chloride, 0.5 parts of composite coupling agent, 0.5 parts of white oil, 1.5 parts of polyvinyl alcohol, 0.5 parts of stearic acid and 0.5 parts of calcium chloride are the raw materials for preparation; natural biomass material walnut sand It needs to be pulverized with an ultra-fine pulverizer in advance, and the mesh size after pulverization is greater than 320 mesh.

[0023] The preparation method is the same as in Example 1.

[0024] Embodiment 3: MBBR slow-release carbon filler, calculated in parts by mass, includes 44 parts of polyhydroxyalkanoate, 30 parts of polylactic acid, 8 parts of light calcium carbonate, 6 parts of natural biomass walnut sand, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com