Treatment process for cooperating magnetic sludge carbon carrier with sewage upgrading and capacity expansion

A treatment process and technology of sludge charcoal, applied in water/sludge/sewage treatment, sludge treatment, magnetic field/electric field water/sewage treatment, etc. Water quality, saving operating costs, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

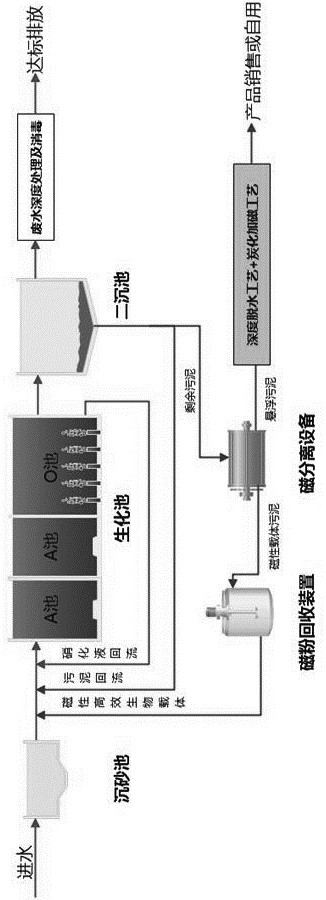

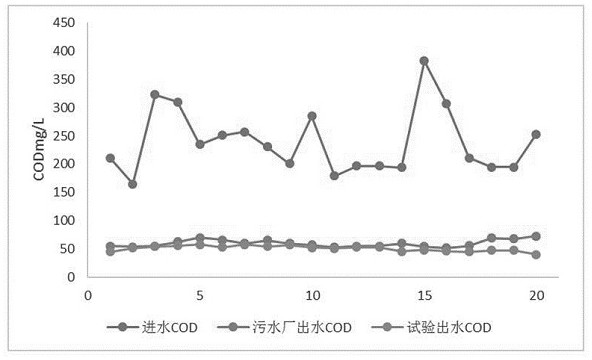

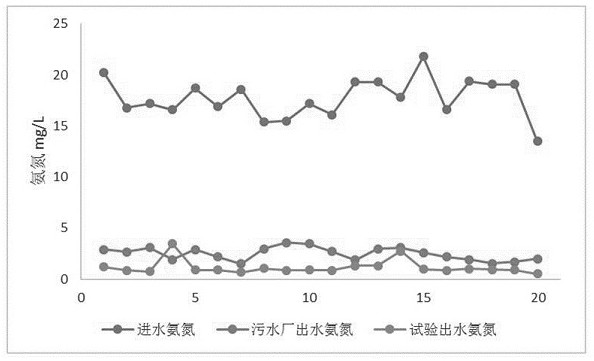

[0066] A municipal sewage treatment plant wastewater biochemical treatment magnetic sludge carbon carrier test, the details are as follows:

[0067] The primary sewage treatment process is mainly coarse screen + fine screen + cyclone grit chamber + primary sedimentation tank. The effluent from the primary sedimentation tank is pumped to the front end of the biochemical treatment pilot test, with a flow rate of 400L / h.

[0068] The magnetic sludge charcoal carrier is produced by sludge charcoal processing, sieved with 200 mesh, mixed with water in a mixing tank to prepare a mixed solution with a concentration of 4.0%, and then transported to the front end of the biochemical treatment pilot water by a screw pump. Wastewater inflow: The dosage of magnetic sludge carbon carrier is 40:1.

[0069] The sludge concentration of the biochemical treatment pilot system is 6000mg / L, and microorganisms attach and adsorb to the sludge charcoal carrier to form composite carrier particles, in...

Embodiment 2

[0074] The deep dehydration test of biological leaching of excess sludge in a municipal sewage treatment plant, the details are as follows:

[0075] The residual sludge concentration of the sewage treatment plant adopts radial flow continuous gravity concentration, and the remaining sludge of the secondary settling tank is discharged into the concentration tank, and the sludge is gravity concentrated to a moisture content of about 97% without adding concentration agents. The sludge in the thickening tank is taken for sludge bioleaching conditioning, including the steps of sludge domestication, sludge inoculation, and sludge cultivation, which are the same as the specific implementation disclosed in CN201410010263.0.

[0076] After the sludge enters the leaching conditioning tank, it is necessary to add special leaching microbial nutrients according to the amount, the dosage is 8% of the absolute dry sludge, 24 hours of continuous aeration culture, and the conditioning time is 3...

Embodiment 3

[0082] A municipal sewage treatment plant sludge carbonization test to prepare magnetic sludge carbon carrier test, the details are as follows:

[0083] In Example 2, the air-dried sludge particles and the mixture are proportioned and transported to the carbonization furnace for carbonization. During the pyrolysis and carbonization process, the temperature is kept constant at 500-650°C, and the carbonization chamber is in an oxygen-free or anoxic state.

[0084] The sludge charcoal obtained after pyrolysis and carbonization is cooled and sieved to obtain magnetic sludge charcoal products.

[0085] The internal specific surface area of the magnetic sludge carbon carrier is 55m2 / g, and the density is controlled to be 0.9g / m3.

[0086] To sum up, the magnetic sludge carbon carrier cooperates with the treatment process of sewage standard expansion and expansion, which has strong implementability, and can realize the internal circulation standard expansion and expansion of sewage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com