Water purified process for polluted water in-situ

A water purification, in-situ technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Aging and shedding, secondary environmental pollution, etc., to achieve the effects of low preparation cost, excellent plant activity, and low operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

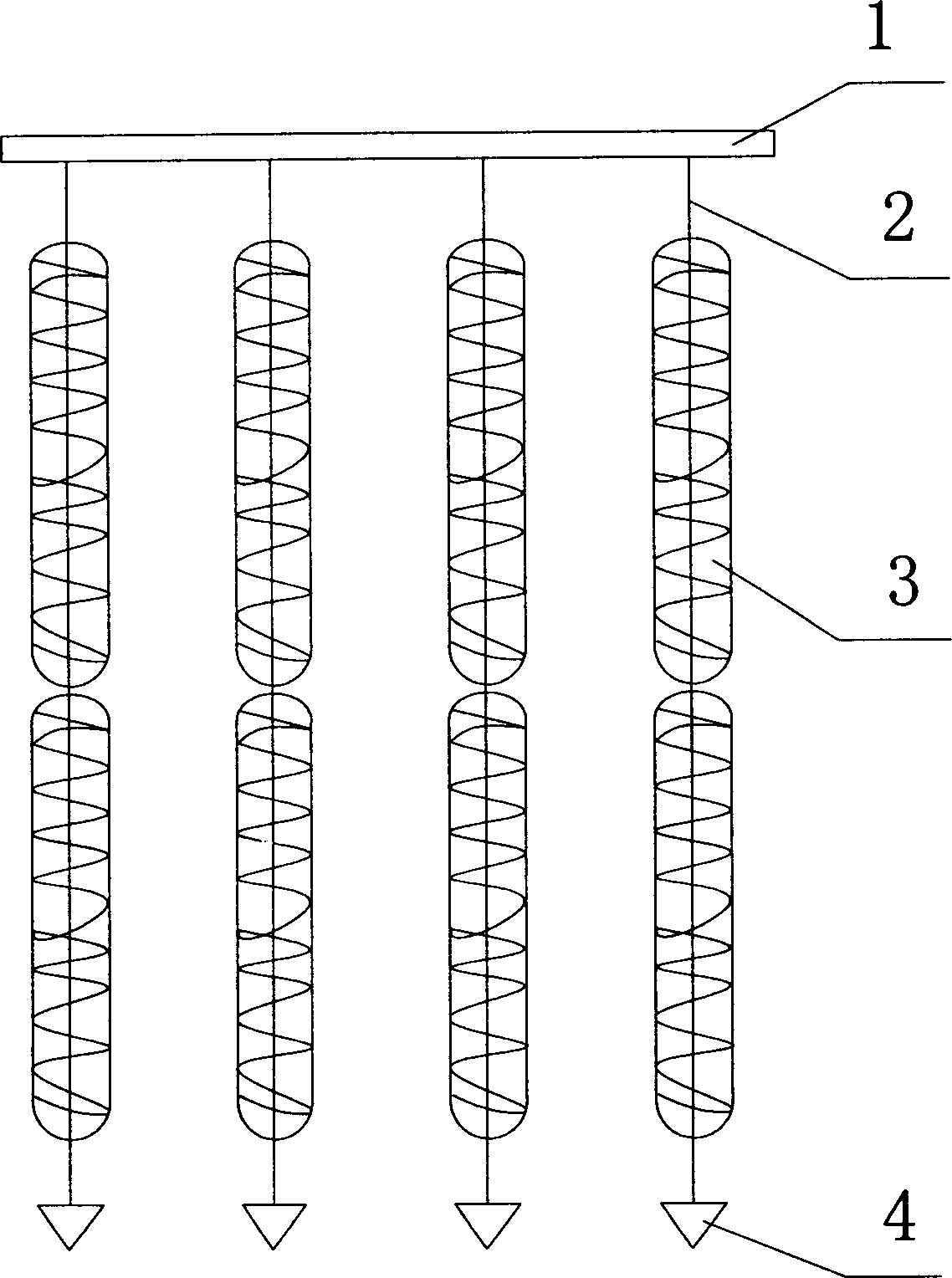

[0012] A method for in-situ water purification of polluted water, comprising the following steps: 1). Process the mature fruit or semi-ripe fruit of the natural plant loofah into a loofah; fix the loofah 3 and the rope 2, and the upper end of the rope 2 and the floating rod 1 is fixed, the lower end of the rope 2 is fixed with the pendant 4, and the floating rod is tied with 4 ropes, and each rope is strung with 2 loofahs to form a sewage in-situ purification device; 2). Put the sewage in-situ purification device into Into the in-situ water of the polluted water body, the loofah is immersed in the in-situ water of the polluted water body, and the floating rod floats on the in-situ water surface of the polluted water body; the active microbial cells in the in-situ water of the polluted water body quickly (within 2-5 days) in the loofah Active dynamic biofilm is formed on the outer surface of the biofilm, and the sewage can be purified around the dynamic biofilm. The sewage in-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com