Rotating cage type floating stuffing biological sewage treatment method and equipment thereof

The technology of a sewage treatment device and sewage treatment method, which is applied in the field of water treatment, can solve the problems of energy consumption, lack of leaves, and low aeration efficiency, and achieve the effects of low operating cost, uniform flow state, and accelerated shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

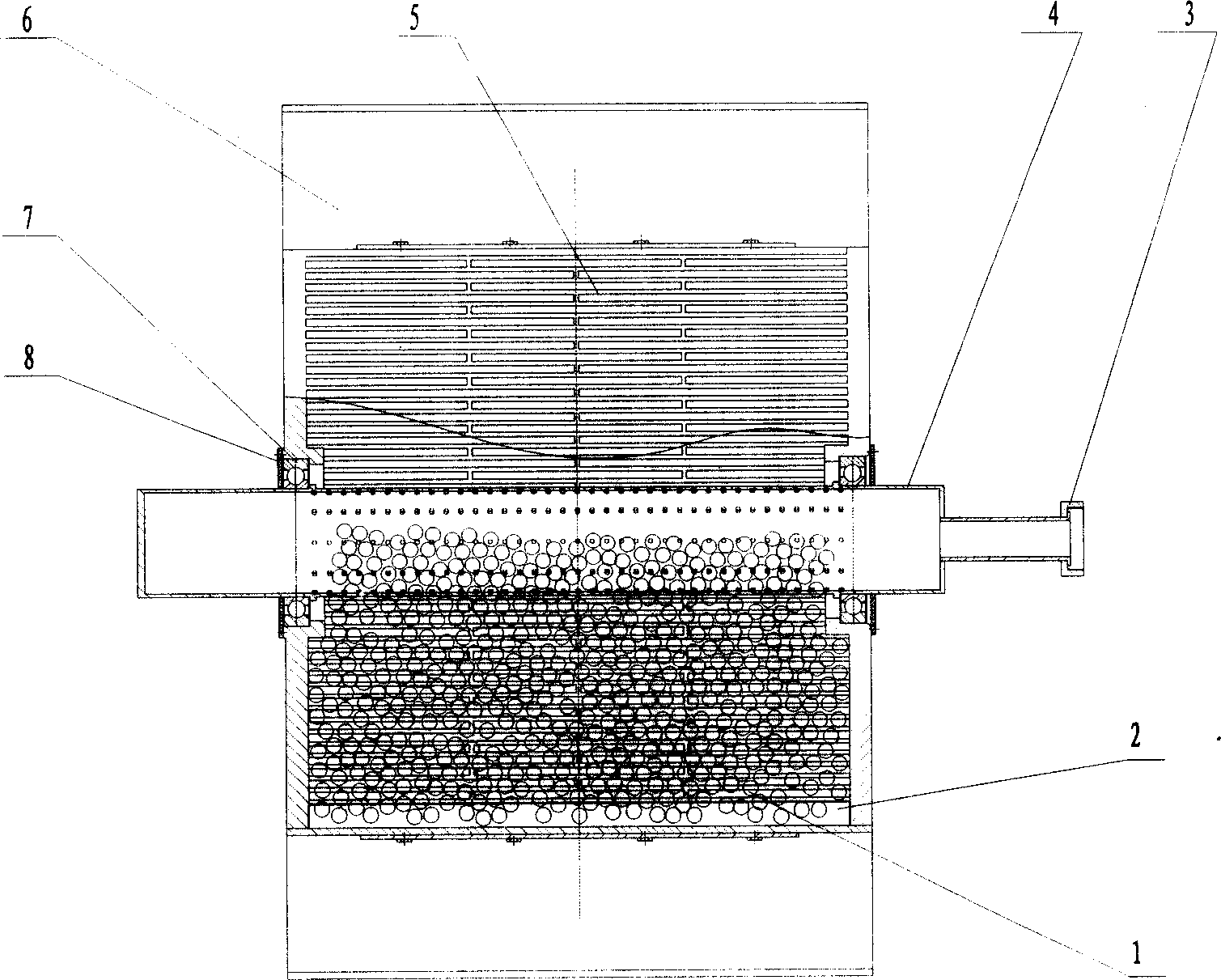

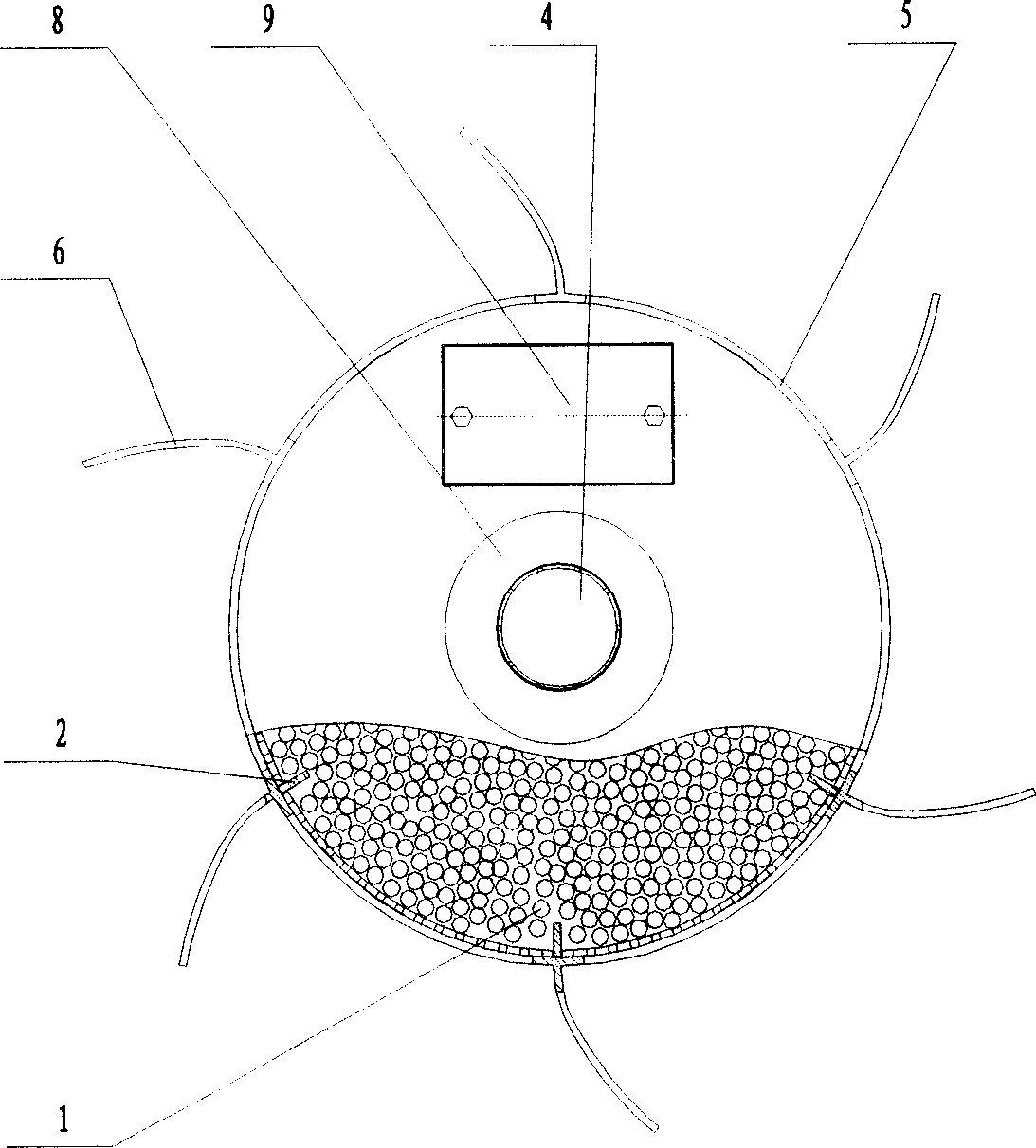

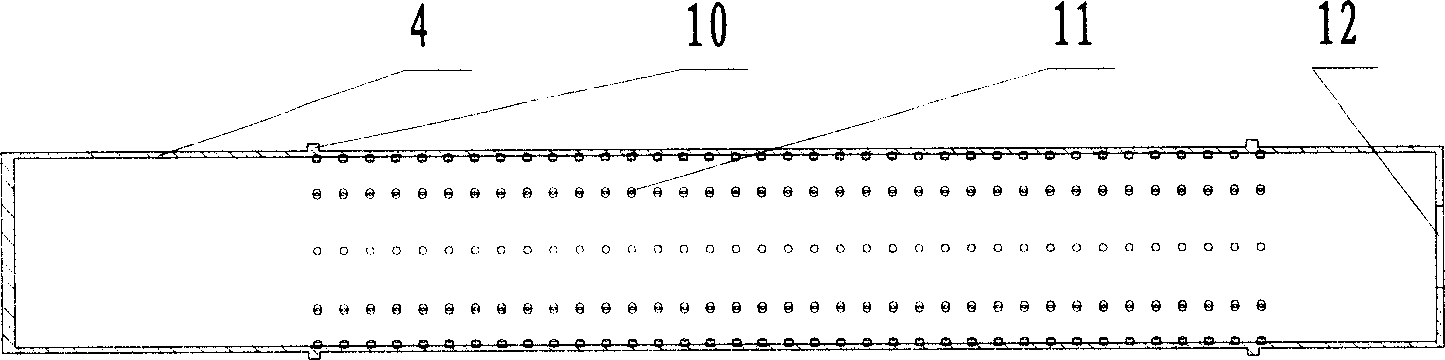

[0034] Such as figure 1 , figure 2 As shown, the rotating cage type suspended packing biological sewage treatment device consists of suspended packing 1, inner blade 2, aeration inlet pipe 3, central shaft 4, rotating cage body 5, outer blade 6, bearing 7, bearing cover plate 8, feeding window cover Plate 9 composition. Central axis 4 such as image 3 As shown, there is a shaft shoulder 10 of the axial positioning bearing on the peripheral curved surface, and there are micropores 11 with a porosity of 47%; one end of the central shaft 4 is closed, and an air inlet 12 is left at the other end. The aeration inlet pipe 3 is fixed; the central shaft 4 is connected with the rotating cage body 5 through a bearing 7, and the bearing 7 is positioned by a bearing cover plate 8 and screws. Rotating cage body 5 such as Figure 4 As shown, there is a water inlet hole 13 on its peripheral curved surface. The present embodiment is a square hole with an opening rate of 85%. There is a f...

Embodiment 2

[0037] In the present embodiment, the opening ratio of the micropores on the peripheral curved surface of the central axis 4 is 52%; the peripheral curved surface of the rotating cage body 5 is provided with water inlet holes 13, which are circular or oval holes, and the aperture ratio is 78%. . Suspended filler 1 is made of plastic suspended filler, and its filling rate is 46% of the volume of the tumbler cage. Outer blade 6 as Figure 8The V-shaped plane shown has a height of 0.35 times of the radius of the rotating cage body 5 . The inner blade 2 is a curved surface, and the height is 0.3 times of the radius of the rotating cage body 5. The inner and outer blades are integrated into one body and connected with the rotating cage body by bolts. The number of the outer blades and the inner blades is 8. All the other implementations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com