Quick starting method of step-by-step biofilm culturing of river biofilm restoration system

A biofilm system and river restoration technology, which is applied in the field of rapid start-up of gradual film formation of river restoration biofilm systems, can solve problems such as affecting ecological safety and human health, and water bodies are black and odorous, and can shorten the time for film formation, The effect of improving activity and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

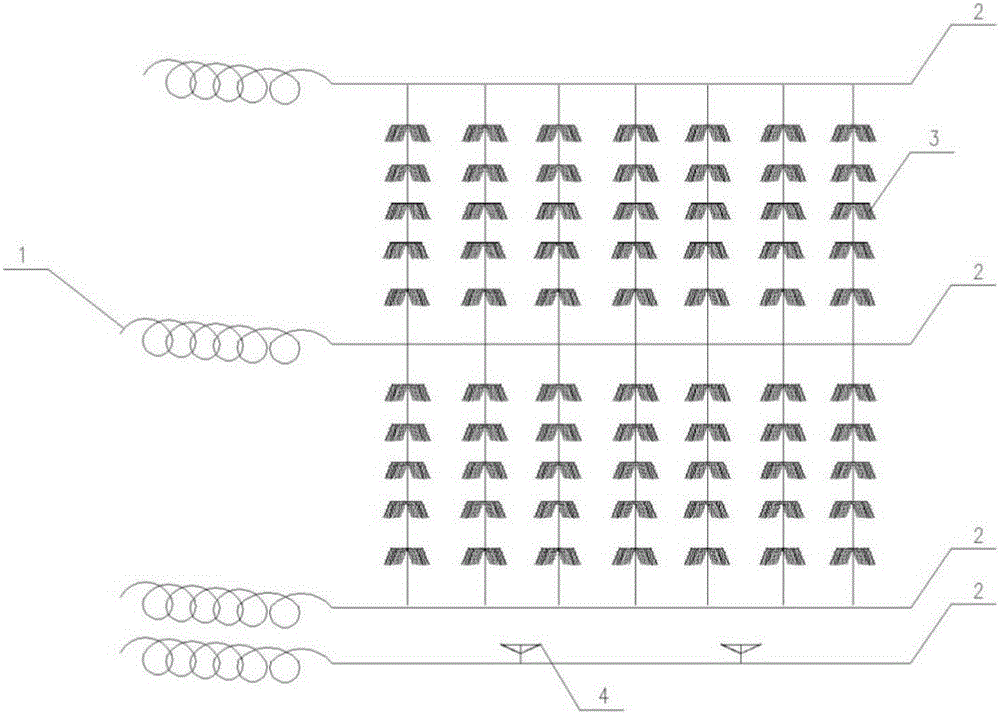

[0037] 5-7 strings of Φ150×80mm=(80) elastic composite fillers are arranged in a 35L river channel simulated biofilm reactor, each string of fillers is composed of 3-5 pieces in series, with a diameter of 16-18cm and a specific surface area of 350m 2 / m 3 . In addition, two aerators are evenly arranged at the bottom of the river simulated biofilm reactor.

[0038] A Preloading of biofilm: Fill and hang the filler arranged above in a 50L SBR reactor, take activated sludge as inoculation sludge, the sludge concentration is about 4000-5000mg / L, and use 4000mL biochemical Better sewage or laboratory simulated sewage (27.5g sucrose per liter of water, 2.5g KH 2 PO 4 , yeast extract 0.3g, K 2 HPO 4 1.3g, NH 4 Cl 7.3g, NaHCO 3 33g), add water to 30-40L to form a culture solution, mix and aerate for 5 days, and replace the culture solution every other day.

[0039] B. Low-pollution water domestication: fill 35L of low-pollution water into the simulated biofilm reactor in the...

Embodiment 2

[0051] A. Preloading of biofilms. Suspend the filler in the SBR reactor, take the activated sludge as the inoculation sludge, the sludge concentration is about 4000-5000mg / L, and use 4000mL of biodegradable sewage or laboratory simulated sewage (per liter of water Contains 27.5g sucrose, 2.5g KH 2 PO 4 , yeast extract 0.3g, K2HPO 4 1.3g, NH4Cl 7.3g, NaHCO 3 33g), add water to 30-40L, mix and aerate for 5 days, replace the culture medium every other day, before replacing the culture medium, first settle the sludge for 30 minutes, drain the supernatant, and then re-inject the culture medium.

[0052] Acclimatization of low-pollution water in B river course. Take low-pollution water from natural rivers into the SBR reactor, aerate for 23 hours at an aeration rate of 40L / min, stop aeration for 30 minutes, open the drain valve to drain the supernatant, open the water inlet valve to introduce a new river After the low-pollution water reaches the original water level, the aera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com