Preparation method of light biological filter material

A biological filter material, lightweight technology, applied in chemical instruments and methods, biological water/sewage treatment, granular microbial carrier treatment, etc., can solve the problems of high calcination temperature, poor hydrophilicity, small specific surface area, etc. High oxygen efficiency, meeting environmental emission standards, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

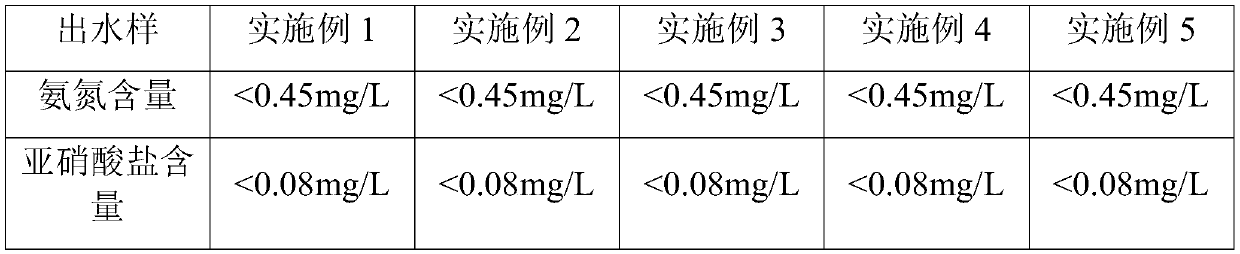

Examples

Embodiment 1

[0022] A kind of preparation method of light biological filter material, the mass parts composition of described biological filter material is as follows: 60 parts of steel slag, 12 parts of humic acid, 2 parts of ammonium carbonate, 0.6 part of binder, 10 parts of water, described preparation The method includes the following steps:

[0023] (1) Weigh steel slag, humic acid, ammonium carbonate and binder in proportion, add water and mix evenly, prepare into balls in a ball forming machine, the diameter of the spheres is 3mm, then transfer to an oven for drying, dry The temperature is 100°C, the drying time is 45min, and then it is transferred to the muffle furnace for calcination for 2.5h, the calcination temperature is 450°C, and after the calcination is finished, it is naturally cooled to room temperature to obtain a semi-finished biological filter material; the steel slag in this embodiment is The steel slag obtained after sieving, iron removal and grinding is carried out ...

Embodiment 2

[0026] A kind of preparation method of light biological filter material, the mass parts composition of described biological filter material is as follows: 65 parts of steel slag, 12 parts of humic acid, 2 parts of ammonium carbonate, 0.6 part of binder, 10 parts of water, described preparation The method includes the following steps:

[0027] (1) Weigh steel slag, humic acid, ammonium carbonate and binder in proportion, add water and mix evenly, prepare into balls in a ball forming machine, the diameter of the spheres is 5mm, then transfer to an oven for drying, and dry The temperature is 110°C, the drying time is 50min, and then it is transferred to the muffle furnace for calcination for 2.5h, the calcination temperature is 450°C, and after the calcination is completed, it is naturally cooled to room temperature to obtain a semi-finished biological filter material; the steel slag in this embodiment is The steel slag obtained after sieving, iron removal and grinding is carried...

Embodiment 3

[0030] A kind of preparation method of light biological filter material, the mass parts composition of described biological filter material is as follows: 70 parts of steel slag, 15 parts of humic acid, 5 parts of ammonium carbonate, 0.7 part of binder, 20 parts of water, described preparation The method includes the following steps:

[0031] (1) Weigh steel slag, humic acid, ammonium carbonate and binder in proportion, add water and mix evenly, prepare into balls in a ball forming machine, the diameter of the spheres is 6mm, and then transfer them to an oven for drying. The temperature is 110°C, the drying time is 50min, and then it is transferred to a muffle furnace for calcination for 2.8h, the calcination temperature is 500°C, and after the calcination is completed, it is naturally cooled to room temperature to obtain a semi-finished biological filter material; the steel slag in this embodiment is The steel slag obtained after sieving, iron removal and grinding is carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com