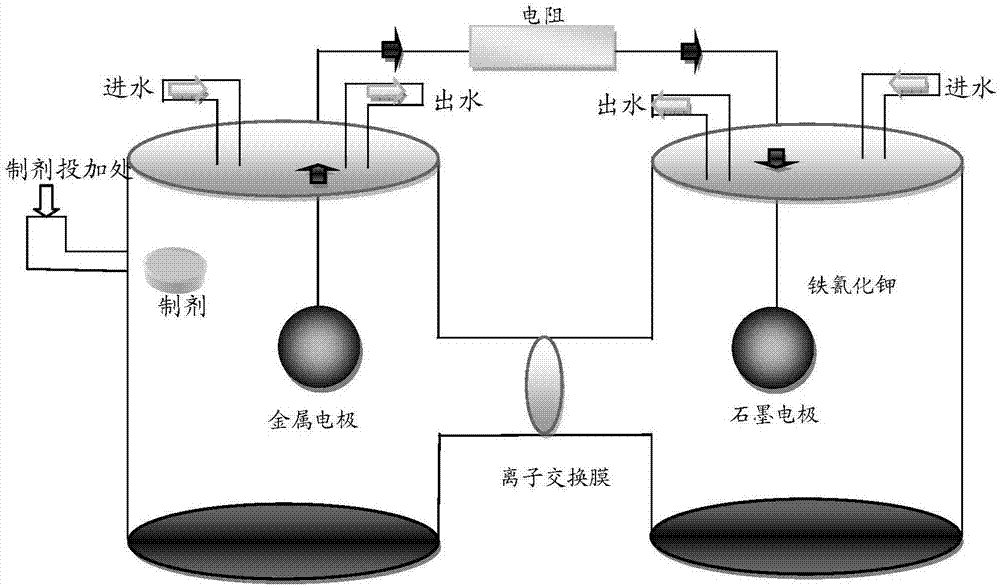

Preparation and application for accelerating Gram-negative current-producing bacteria anode bio-film efficiency in microbial fuel cell

A gram-negative, fuel cell technology, used in biochemical fuel cells, biological water/sewage treatment, electrochemical-biocombination treatment, etc. The effect of low cost of use, shortened film hanging time, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

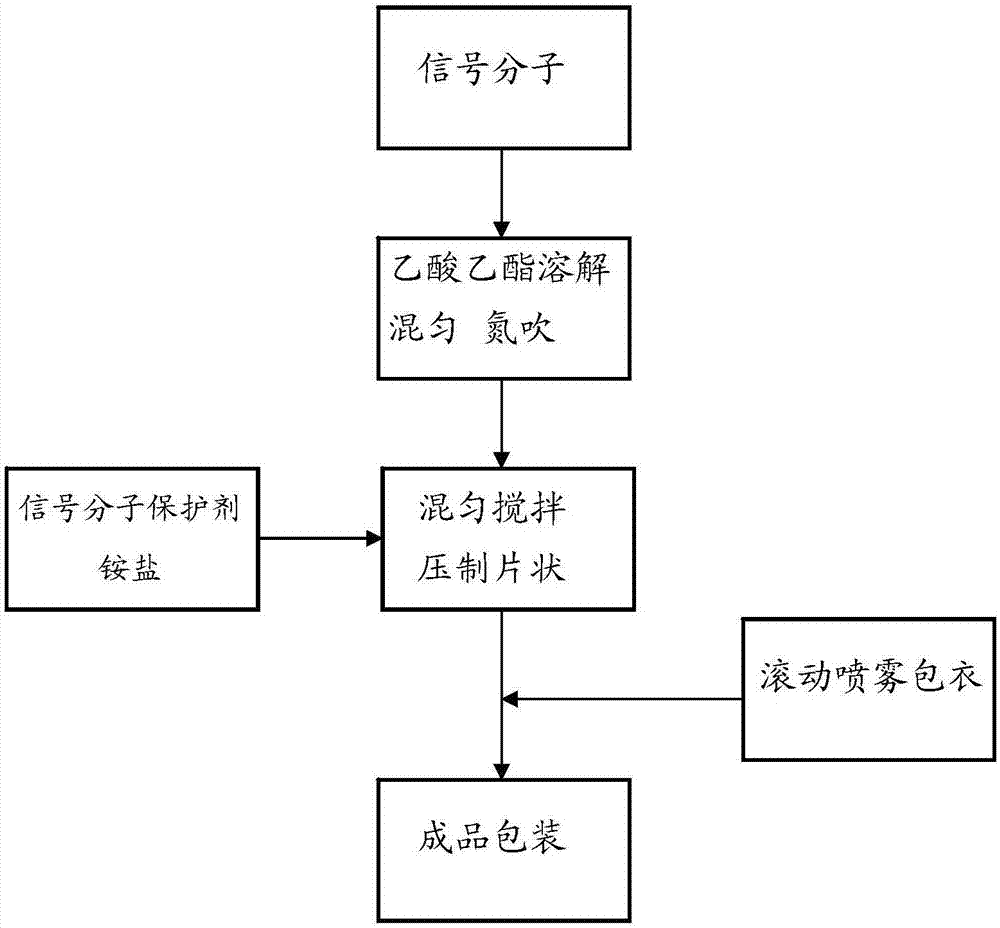

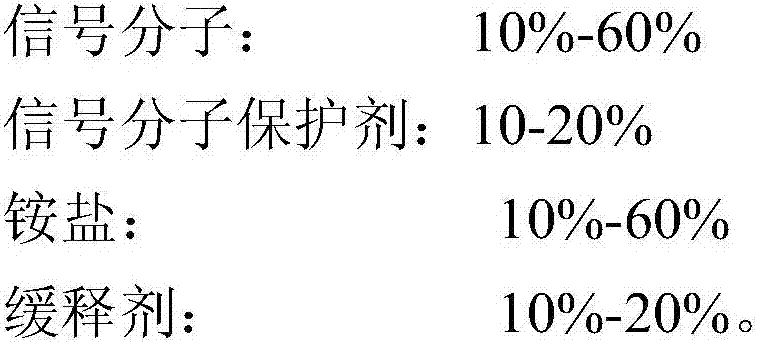

[0107] (1) Preparation of preparation: Weigh all the components required by various signal molecules according to the mass percentage of the components (C4-HSL10%, C6-HSL10%, C8-HSL 10%, C10-HSL10%, C12-HSL10% , 3-oxo-6-HSL10%, 3-oxo-C8-HSL10%, 3-oxo-C10-HSL10%, 3-oxo-C12-HSL10%, pC-HSL10%), dissolved in ethyl acetate and mixed well , and then blow off by nitrogen, drop into ammonium chloride and dimethyl sulfoxide weighed in component mass percentage and stir evenly (signal molecule 50%, ammonium chloride 30%, dimethyl sulfoxide 10%, signal molecule, Ammonium chloride and dimethyl sulfoxide are pressed into tablet preparations, tablet specifications: diameter is 2cm, thickness 5mm. Coating liquid is configured, and each component weighs ethyl cellulose 60%, phthalate Diethyl formate 30%, PEG600010%. Utilize rolling spray coating technology, in preparation outsourcing with coating film. Finished product (preparation flow process such as figure 2 shown).

[0108] (2) Microbi...

Embodiment 2

[0117] (1) Preparation of preparation: Weigh all the components required by various signal molecules according to the mass percentage of the components (C4-HSL10%, C6-HSL10%, C8-HSL 10%, C10-HSL10%, C12-HSL10% , 3-oxo-6-HSL10%, 3-oxo-C8-HSL10%, 3-oxo-C10-HSL10%, 3-oxo-C12-HSL10%, pC-HSL10%), dissolved in ethyl acetate and mixed well , then blow off by nitrogen, drop into ammonium chloride and dimethyl sulfoxide weighed in component mass percentage and stir evenly (signal molecule 50%, ammonium chloride 30%, dimethyl sulfoxide 10%, coating solution 10% %), the signal molecule, ammonium chloride and dimethyl sulfoxide were compressed into a tablet preparation, the tablet specification: diameter 2cm, thickness 5mm. A coating liquid is prepared, and each component is weighed by mass percentage of 60% of ethyl cellulose, 30% of diethyl phthalate, and 10% of PEG6000. Utilize the rolling spray coating technology to coat the preparation with a coating film. After passing the inspect...

Embodiment 3

[0127] (1) Preparation of preparation: Weigh all the components required by various signal molecules according to the mass percentage of the components (C4-HSL10%, C6-HSL10%, C8-HSL 10%, C10-HSL10%, C12-HSL10% , 3-oxo-6-HSL10%, 3-oxo-C8-HSL10%, 3-oxo-C10-HSL10%, 3-oxo-C12-HSL10%, pC-HSL10%), dissolved in ethyl acetate and mixed well , then blow off by nitrogen, drop into ammonium chloride and dimethyl sulfoxide weighed in component mass percentage and stir evenly (30% of signal molecule, 50% of ammonium chloride, 10% of dimethyl sulfoxide, coating solution 10% %), the signal molecule, ammonium chloride and dimethyl sulfoxide were compressed into a tablet preparation, the tablet specification: diameter 2cm, thickness 5mm. A coating liquid is prepared, and each component is weighed by mass percentage of 60% of ethyl cellulose, 30% of diethyl phthalate, and 10% of PEG6000. Utilize the rolling spray coating technology to coat the preparation with a coating film. After passing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com