Method for liquid fermentation cultivation of Agaricus bisporus strain

A technology of liquid fermentation and Agaricus bisporus, applied in botany equipment and methods, horticulture, application, etc., can solve the problems that cannot meet the cultivation needs of Agaricus bisporus, require a large amount of cultivated species, and have a long growth cycle, etc., and achieve good economy Benefits and social effects, easy vaccination, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take about 0.5cm of activated slant parent species 2 Inoculate the small pieces into the liquid culture medium, shake and cultivate the first-level shake flask strains at 25°C, and then transfer the cultured first-level shake flask liquid strains to the second-level liquid strain shake flasks for each treatment , carried out successively at all levels of culture, unless otherwise specified, all levels of shaking flask culture conditions are: 250mL Erlenmeyer flask liquid volume 100mL, inoculum size 5% (V / V), shaker speed 150r / min, 25 ℃ shaking culture 5 ~7d, similarly, the other levels of liquid strains are also cultivated in the same way. The liquid medium formula of Agaricus bisporus liquid strain is: nitrogen source, carbon source, KH 2 PO 4 3g, MgSO 4 1.5g, VB 1 10mg, water 1000mL, pH natural, sterilized at 121°C for 30min. The formula of PDA universal medium used for the slant culture of Agaricus bisporus: 200g potato, 20g sucrose, 1000mL water, natural pH,...

Embodiment 2

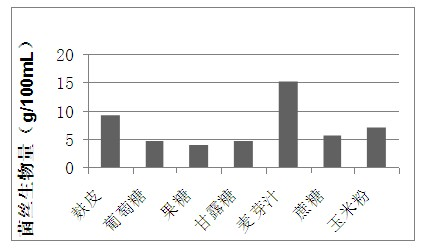

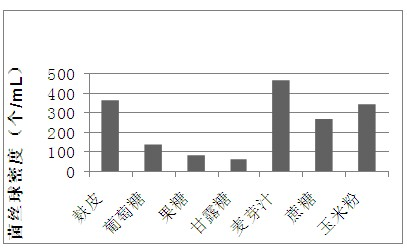

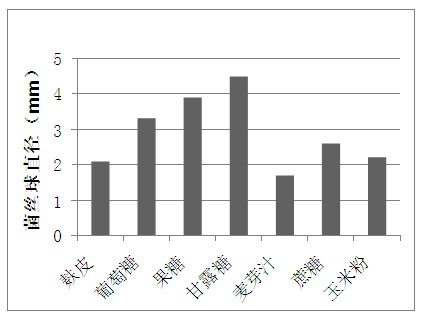

[0056] When the test tube is transferred to the liquid culture medium, it needs to obtain rich nutrients from the culture medium in time to quickly adapt to the liquid instead of the previous solid slant medium environment. Therefore, it is necessary to provide sufficient nutrients in the first-level liquid culture medium , shorten the adaptation process of mycelium growth, and obtain liquid strains that meet the standards. When the first-level liquid seeds are used as seeds to continue to expand the cultivation, the change of its growth environment needs to be considered. At this time, the impact of different carbon sources on its growth is most obvious. According to a certain amount of inoculum, the liquid seeds cultivated to the logarithmic growth phase under the optimal culture conditions of Example 1 are inoculated into the secondary liquid culture fluid, and cultivated in the secondary liquid culture fluid with different carbon sources selected. The results are as follows...

Embodiment 3

[0067] Adopt 10L full-automatic air-lift stirring fermenter tank, liquid capacity is 6L, by 5% inoculum size, under 25 ℃ of culture conditions, in liquid culture optimum medium (wheat bran 30g, corn flour 10g, potassium dihydrogen phosphate 0.5g , magnesium sulfate 1g, VB110mg / L, water 1000mL pH value 6.5) carry out liquid fermentation culture, through sampling analysis and record fermenter system monitoring data, each growth index change result of Agaricus bisporus liquid mycelium in air-lift fermenter is : Under the conditions of the fermenter, Agaricus bisporus maintained a good growth rate, and the biomass of mycelium balls increased significantly. In the early stage of fermentation, the mycelium density increased rapidly and remained at a stable value. The diameter of mycelium balls also increased to a certain extent as the fermentation process progressed, but the growth of mycelium ball diameter was still within a reasonable range. When the fermentation reached the 5th d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com