Method for biofilm culturing of filler via fermentation reactor and transferring filler to biochemical pool

A technology of reactor and biochemical pool, which is applied in the direction of aerobic and anaerobic process treatment, and can solve the constraints of the time, cycle, efficiency and stability of biochemical treatment of sewage and wastewater, and the low purity and concentration of active bacteria in bacterial liquid or powder , The film-hanging efficiency is not ideal enough to achieve the effect of saving the film-hanging time, shortening the film-hanging time, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

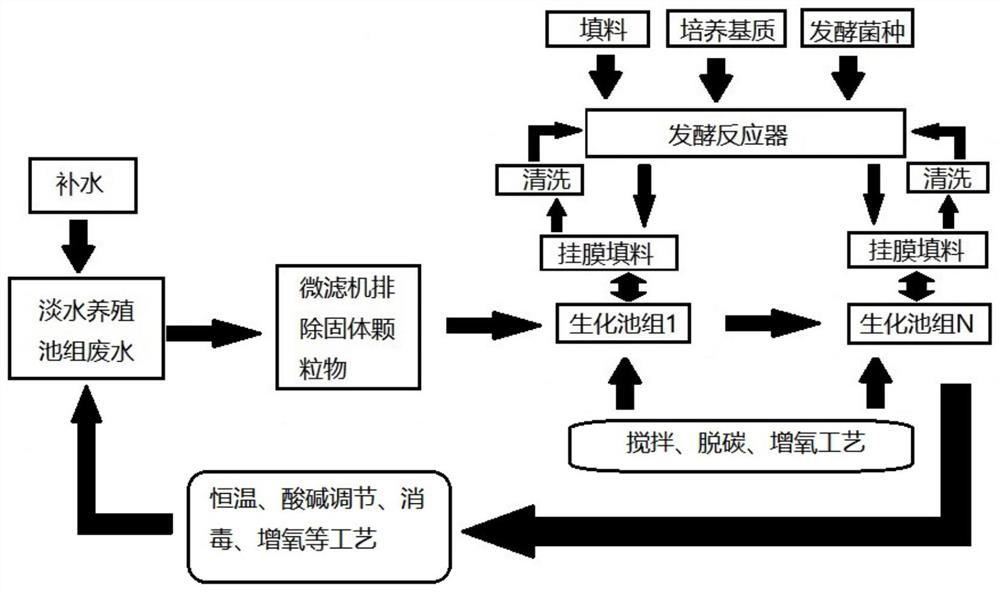

[0063] see figure 2 , figure 2 The schematic diagram of wastewater treatment and recycling of freshwater aquaculture ponds is introduced; the wastewater from aquaculture ponds first passes through the physical filtration equipment microfiltration machine to filter and remove solid particles in the water, and then enters the biochemical pond, and the film-hanging filler is directly added to the biochemical pond , the biochemical pool carries out conventional stirring, decarburization, and oxygenation processes, and the dominant bacteria on the film-coated fillers biodegrade, absorb and assimilate the harmful substances dissolved in water to farmed animals, making them harmless and bait , or mineralize into carbon dioxide, water, or become inert gas to escape the water body, and then return to the breeding pond through constant temperature, acid-base adjustment, disinfection, oxygenation and other processes for recycling.

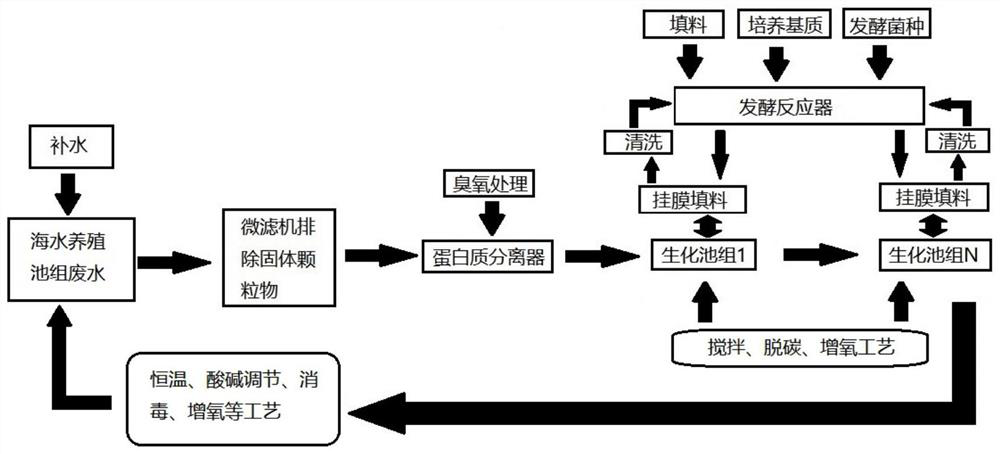

[0064] see image 3 , image 3 The schematic diagr...

Embodiment 2

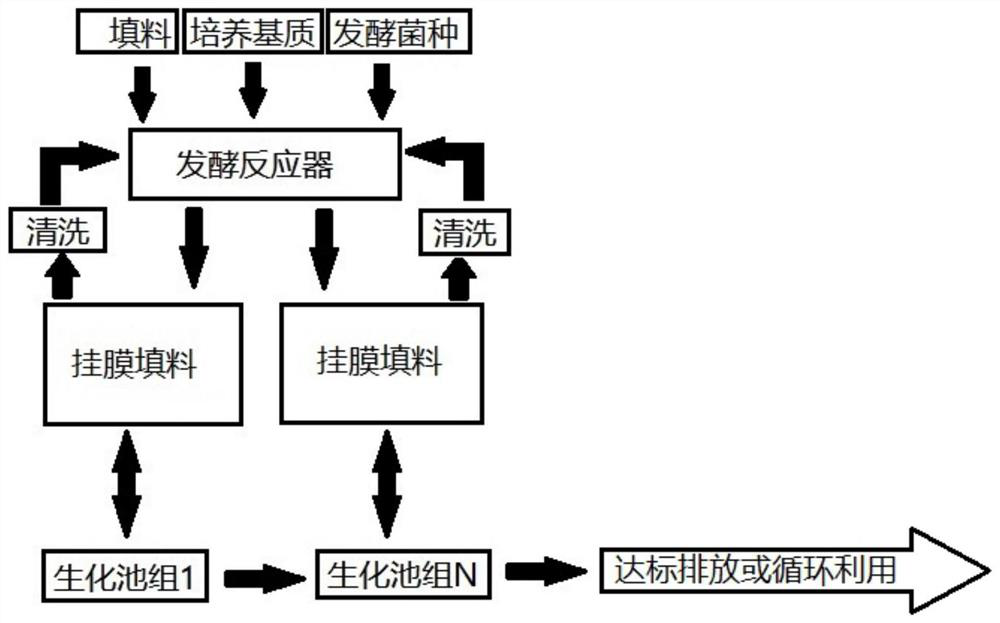

[0068] see Figure 4 , Figure 4 Introduces the schematic diagram of wastewater treatment and discharge or reclaimed water reuse; sewage and wastewater enter the biochemical pool group after the pre-treatment process, and the film-coated filler is directly added to the biochemical pool, and the biochemical pool undergoes conventional stirring and decarbonization , Oxygenation process, the dominant bacteria on the film-hanging filler biodegrade, absorb and assimilate the harmful substances dissolved in water to farmed animals, making them harmless, baitized, or mineralized into carbon dioxide, water, or It becomes an inert gas and escapes from the water body, and then after disinfection and other post-processing processes, it is discharged up to the standard, or the reclaimed water is reused.

[0069] Maintain water quality monitoring and sampling testing of biochemical pools at all levels, understand and track changes in water quality, and optimize targeted treatment to conti...

Embodiment 3

[0071] see Figure 5 , Figure 5 Introduced the schematic diagram of fish and vegetable symbiotic water treatment; the wastewater from the aquatic animal breeding pool group enters the biochemical pool group, and the film-coated filler is directly added to the biochemical pool. The dominant bacteria on the membrane filler biodegrade, absorb and assimilate the organic matter and ammonia nitrogen in the water, etc., making them harmless, especially nitrifying ammonia nitrogen into nitrate nitrogen that is most suitable for plants to absorb, and further disinfecting the plants Cultivation, the water quality after the three-dimensional plant cultivation is returned to the aquatic animal breeding pool group, so as to realize the double harvest of fish and vegetables and recycling.

[0072] Maintain water quality monitoring and sampling testing of biochemical pools at all levels, understand and track changes in water quality, and optimize targeted treatment to continuously improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com