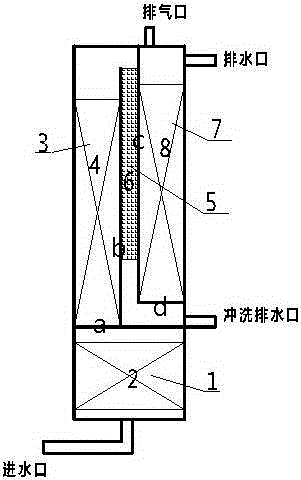

Short-distance nitrification/denitrification biomembrane nitrogen-removal reactor and rapid membrane forming method

A short-range nitrification and reactor technology, applied in the field of sewage biological treatment, can solve problems such as insufficient residence time, short flow of sewage, incomplete reaction, etc., to achieve enhanced oxidation decomposition and nitrogen conversion and removal, slow down blockage, and enhance treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The sewage to be treated is nitrogenous sewage from a sewage treatment plant, the concentration of ammonia nitrogen is 300mg / L, the concentration of total nitrogen is 500mg / L, the concentration of COD is 400mg / L, and B / C=0.5. Control the pH value of the sewage to 7.0, the treatment temperature is 25°C, add glucose and potassium dihydrogen phosphate to adjust the BOD in the wastewater 5 :N:P=100:5:1.

[0037] (1) Fill the corresponding fillers in the two reaction zones A and O, so that the volume of the fillers accounts for 3 / 4 of the volume of each reaction zone, and spread the activated sludge to three places according to the sludge concentration of 5g / L. In the packing of two reaction zones; Palladium-copper supported activated carbon catalyst particles are loaded into the transition zone, the upper surface of the catalyst particles is flush with the upper surface of the vertical plate b, and the catalyst volume accounts for about 3 / 5 of the transition zone volume.

...

Embodiment 2

[0042] The sewage to be treated is nitrogenous sewage from a sewage treatment plant, the concentration of ammonia nitrogen is 300mg / L, the concentration of total nitrogen is 500mg / L, the concentration of COD is 400mg / L, and B / C=0.5. Control the pH value of the sewage to 8.0, the treatment temperature is 35°C, add glucose and potassium dihydrogen phosphate to adjust the BOD in the wastewater 5 :N:P=100:5:1.

[0043] (1) Fill the corresponding fillers in the two reaction zones A and O, so that the volume of the fillers accounts for 3 / 5 of the volume of each reaction zone, and spread the activated sludge into three parts according to the sludge concentration of 10g / L. Palladium-copper supported activated carbon catalyst particles are loaded into the transition zone, the upper surface of the catalyst particles is flush with the upper surface of the vertical plate b, and the catalyst volume accounts for 3 / 4 of the transition zone volume.

[0044] (2) Inject nitrogen-containing sew...

Embodiment 3

[0048] The sewage to be treated is nitrogenous sewage from a sewage treatment plant, the concentration of ammonia nitrogen is 300mg / L, the concentration of total nitrogen is 500mg / L, the concentration of COD is 400mg / L, and B / C=0.5. Control the pH value of the sewage to 7.5, the treatment temperature is 30°C, add glucose and potassium dihydrogen phosphate to adjust the BOD in the wastewater 5 :N:P=100:5:1.

[0049] (1) Fill the corresponding fillers in the two reaction zones A and O, so that the volume of the fillers accounts for 3 / 5 of the volume of each reaction zone, and spread the activated sludge into three parts according to the sludge concentration of 7g / L. Palladium-copper supported activated carbon catalyst particles are loaded into the transition zone, the upper surface of the catalyst particles is flush with the upper surface of the vertical plate b, and the catalyst volume accounts for 3 / 4 of the transition zone volume.

[0050](2) Inject nitrogen-containing sewag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com