Preparation method of mixture of polyester and thermoplastic starch rich in starch and application thereof

A thermoplastic starch and high-starch technology, which is applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve problems such as inability to maintain solid state, decline in material mechanical properties, and weak interface interaction, etc., to achieve effective Conducive to popularization and utilization, improved hydrophobicity, and shortened film-hanging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

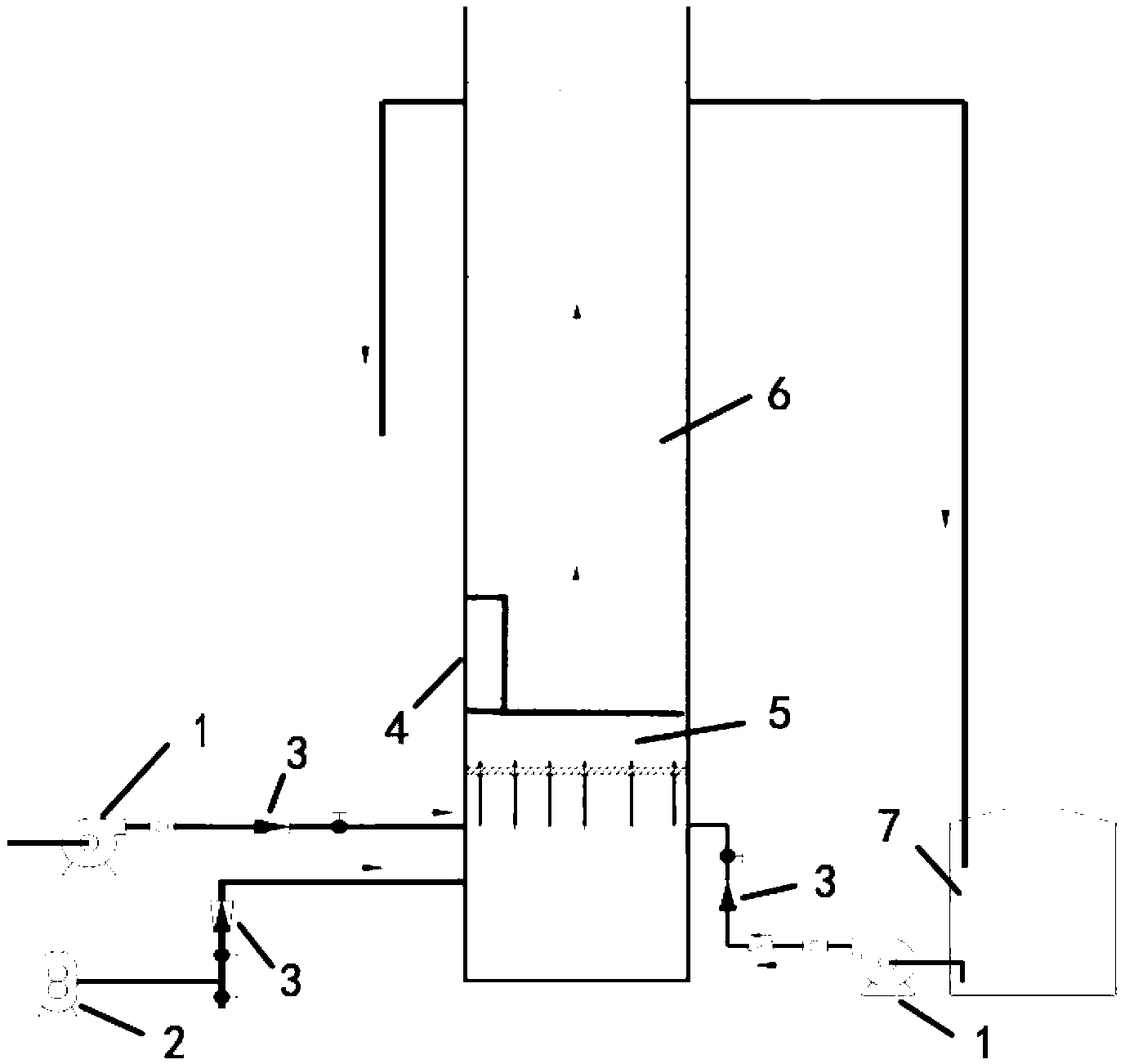

Method used

Image

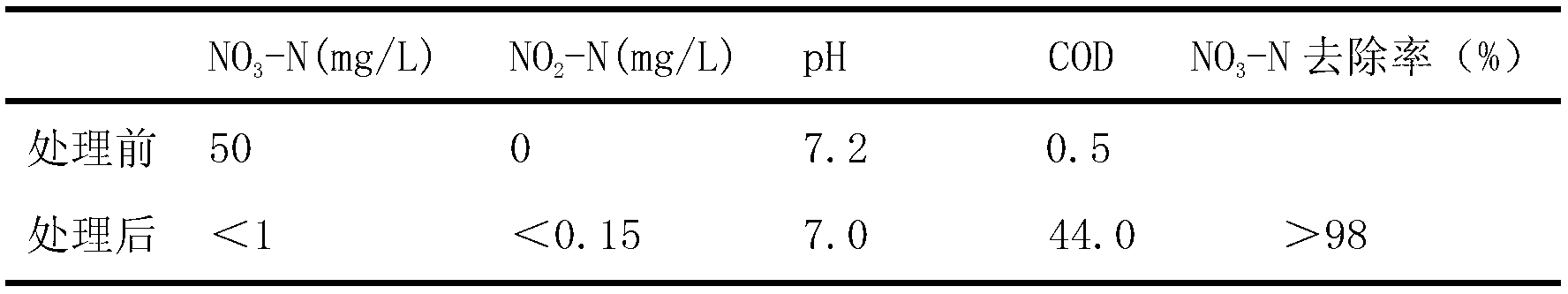

Examples

Embodiment 1

[0028] A kind of preparation method of high starch content thermoplastic starch, polyester blend, carry out according to following steps:

[0029](1) Preparation of thermoplastic starch with high starch content: add 3.3g urea, 7.7g formamide and 5g glycerol to a 100ml beaker, stir with a glass rod in a 90°C water bath until the mixture is colorless and transparent, and quickly Transfer the colorless and transparent composite plasticizer to a 250ml beaker, add 85g of cornstarch, put it in a water bath at 90°C, and stir it with an electric stirrer at the gear 2 until the starch turns waxy yellow Solid state, then, this sallow solid matter is sealed for 24 hours, so that the plasticizer is fully mixed in the starch, and after 24 hours, the sealed solid is kneaded in the internal mixer of the torque rheometer , take out the kneaded material, and crush it into granules by a high-speed pulverizer to obtain thermoplastic starch (TPS) with high starch content.

[0030] (2) Preparatio...

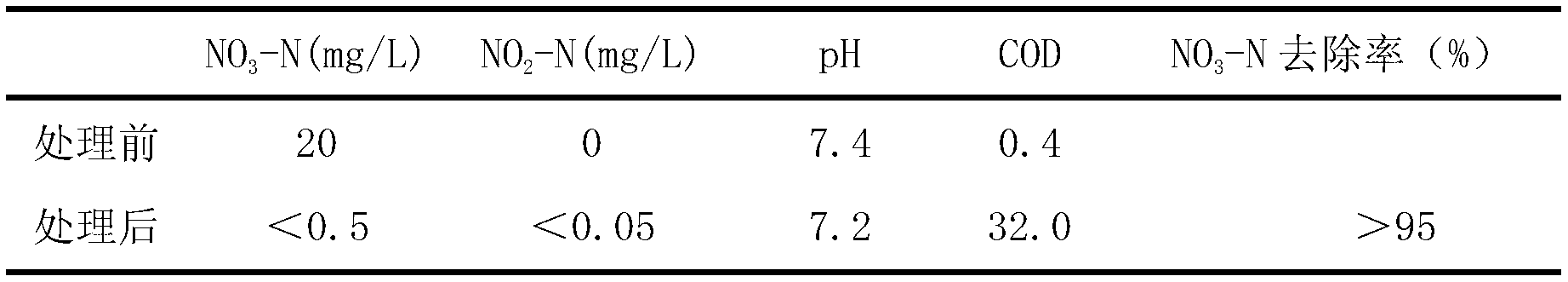

Embodiment 2

[0032] A kind of preparation method of high starch content thermoplastic starch, polyester blend, carry out according to following steps:

[0033] (1) Preparation of thermoplastic starch with high starch content: add 3.3g urea, 7.7g formamide and 5g glycerol to a 100ml beaker, stir with a glass rod in a 90°C water bath until the mixture is colorless and transparent, and quickly Transfer the colorless and transparent composite plasticizer to a 250ml beaker, add 85g of cornstarch, put it in a water bath at 90°C, and stir it with an electric stirrer at the gear 2 until the starch turns waxy yellow Solid state, then, this sallow solid matter is sealed for 24 hours, so that the plasticizer is fully mixed in the starch, and after 24 hours, the sealed solid is kneaded in the internal mixer of the torque rheometer , take out the kneaded material, and crush it into granules by a high-speed pulverizer to obtain thermoplastic starch (TPS) with high starch content.

[0034] (2) Preparati...

Embodiment 3

[0036] A kind of preparation method of high starch content thermoplastic starch, polyester blend, carry out according to following steps:

[0037] (1) Preparation of thermoplastic starch with high starch content: add 3.3g urea, 7.7g formamide and 5g glycerol to a 100ml beaker, stir with a glass rod in a 90°C water bath until the mixture is colorless and transparent, and quickly Transfer the colorless and transparent composite plasticizer to a 250ml beaker, add 85g of cornstarch, put it in a water bath at 90°C, and stir it with an electric stirrer at the gear 2 until the starch turns waxy yellow Solid state, then, this sallow solid matter is sealed for 24 hours, so that the plasticizer is fully mixed in the starch, and after 24 hours, the sealed solid is kneaded in the internal mixer of the torque rheometer , take out the kneaded material, and crush it into granules by a high-speed pulverizer to obtain thermoplastic starch (TPS) with high starch content.

[0038] (2) Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com