Method for improving biofilm forming efficiency of packing in water treatment reactor

A technology of reactor and membrane efficiency, applied in chemical instruments and methods, special compound water treatment, biological water/sewage treatment, etc. The effect of reducing operating costs and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

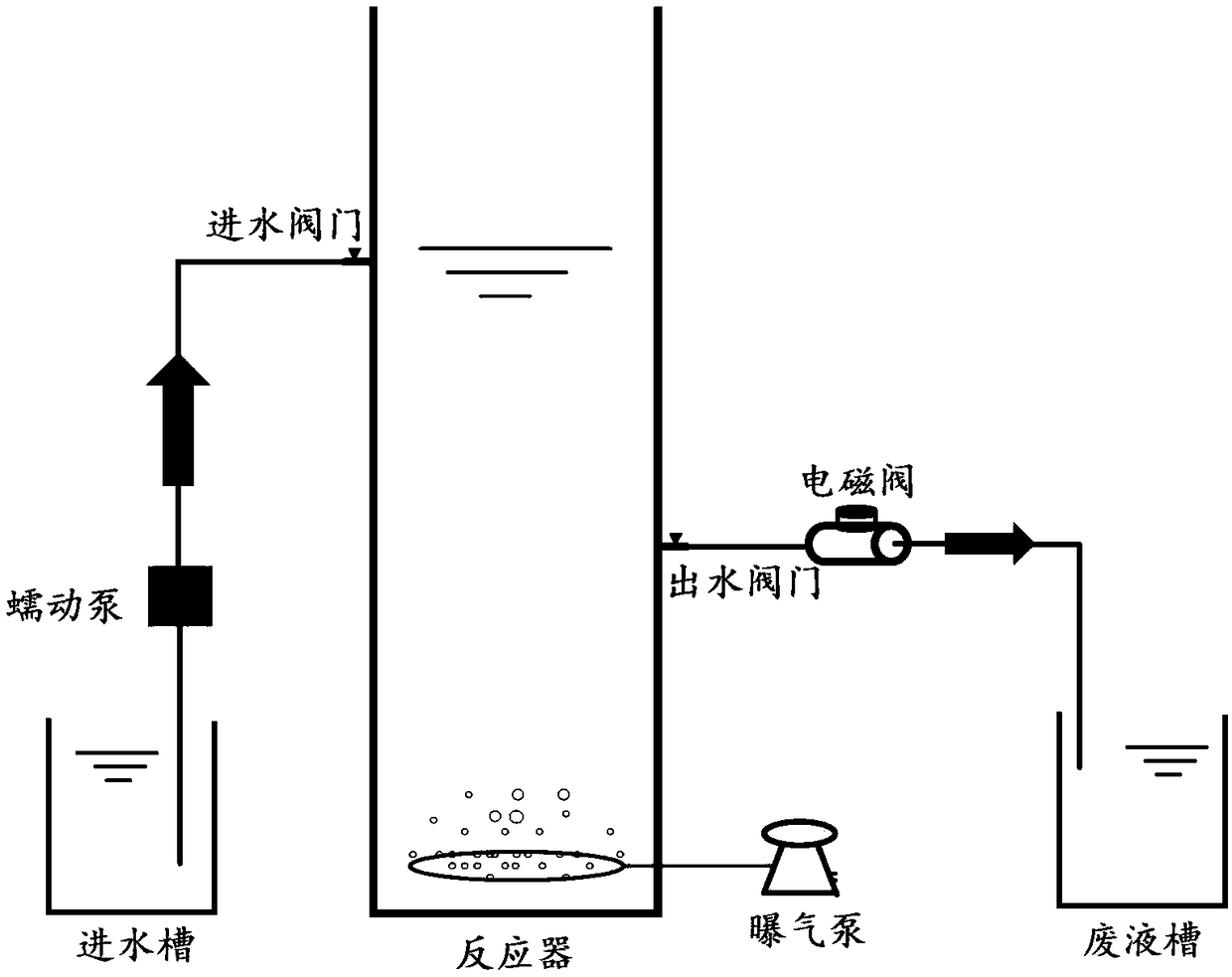

[0019] The reactor adopts a cylindrical structure, the diameter of the reaction zone is 5cm, the height is 100cm, and the volume of the reaction zone is 2L. The hydraulic retention time of the sequencing batch reactor is 4 hours, the volume exchange ratio of each cycle is 50%, and the composition of each cycle is: water inflow for 5 minutes, aeration for 111 minutes, standing for 2 minutes, and water outlet for 2 minutes. The organic load is 6g / (L·d), and the air flow rate is 2.4cm / s (the air flow rate in the reactor is controlled by aeration). The reactor inoculation sludge was collected from the aeration tank of the urban sewage treatment plant, and the initial sludge concentration of the reactor was 6000mg / L. Sodium acetate was used as an organic carbon source, and the COD concentration was 1000 mg / L. The reactor was operated at room temperature and the pH was maintained at 6.5-8.5. Add filler on the second day of reactor operation, the filling ratio of the filler is 20%,...

Embodiment 2

[0021] The reactor adopts a cylindrical structure, the diameter of the reaction zone is 5cm, the height is 100cm, and the volume of the reaction zone is 2L. The hydraulic retention time of the sequencing batch reactor is 4 hours, the volume exchange ratio of each cycle is 50%, and the composition of each cycle is: water inflow for 5 minutes, aeration for 111 minutes, standing for 2 minutes, and water outlet for 2 minutes. The organic load is 12g / (L·d), and the air velocity is 2.4cm / s. The reactor inoculation sludge was collected from the aeration tank of the urban sewage treatment plant, and the initial sludge concentration of the reactor was 6000mg / L. Sodium acetate is used as an organic carbon source, and the COD concentration is 2000mg / L. The reactor was operated at room temperature and the pH was maintained at 6.5-8.5. Filler was added on the second day of reactor operation, the filling ratio of filler was 20%, and the thickness of biofilm reached 2mm on the second day a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com