High concentration waste emulsion deep treatment system

A technology for advanced treatment of waste emulsion, applied in the field of advanced treatment system of waste emulsion, can solve the problems of complex operation of treatment technology, high energy consumption, easy corrosion of equipment, etc., and achieves easy availability of reagents, low energy consumption, and non-corrosion. The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

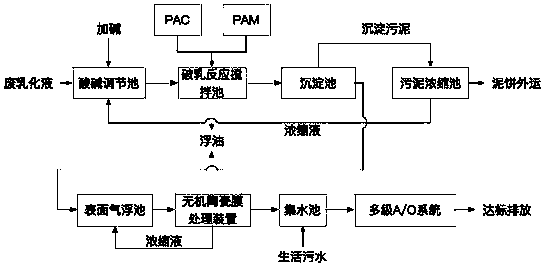

Method used

Image

Examples

Embodiment 1

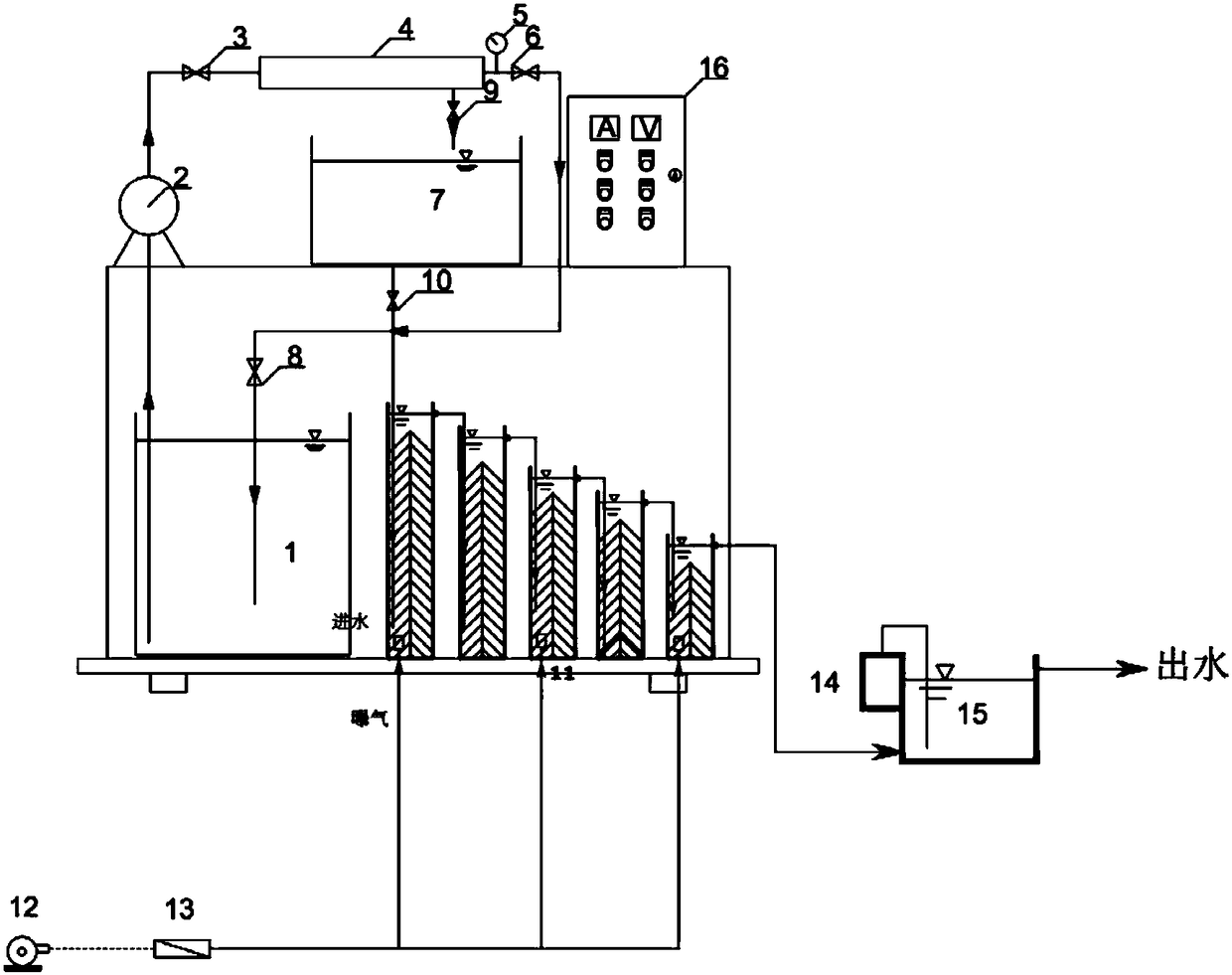

[0037] In this embodiment, 80 L / h of waste emulsion 1 is treated: the pH is 6.5-7, the total oil concentration is 112.267 mg / L, and the COD concentration is 1516 mg / L. First, collect the waste emulsion in the water collection tank 1, control the temperature of the waste emulsion to 40°C, adjust the pH of the waste emulsion to 7, and add 80 mL / h of a mixed solution of PAC and PAM with a mass fraction of 1%, and stir well 5min, then naturally settle for 30min, and drain the lower layer of sludge. Rotate the water inlet shut-off valve 3, pressure control valve 6, and water outlet shut-off valve 8 counterclockwise to the maximum position, press the high-pressure pump 2 running button on the panel of the electric control cabinet 16, so that the high-pressure pump 2 is powered on, and the high-pressure pump 2 will turn the acid-base The waste emulsion in the adjustment tank 1 is pumped into the tubular inorganic ceramic membrane purifier 4, and then returned to the acid-base adjustm...

Embodiment 2

[0039]In this embodiment, 80 L / h of waste emulsion 2 is treated: the pH is 5.5-6, the total oil concentration is 112.267 mg / L, and the COD concentration is 1516 mg / L. First, collect the waste emulsion in the acid-base adjustment tank 1, control the temperature of the waste emulsion to 30°C, adjust the pH of the waste emulsion to 7, and add 60 mL / h of a mixed solution of PAC and PAM with a mass fraction of 1%. Stir thoroughly for 5 minutes, then settle naturally for 30 minutes, and drain the lower layer of sludge. Rotate the water inlet shut-off valve 3, pressure control valve 6, and water outlet shut-off valve 8 counterclockwise to the maximum position, press the high-pressure pump 2 running button on the panel of the electric control cabinet 16, so that the high-pressure pump 2 is powered on, and the high-pressure pump 2 will turn the acid-base The waste emulsion in the adjustment tank 1 is pumped into the tubular inorganic ceramic membrane purifier 4, and then returned to th...

Embodiment 3

[0041] In this embodiment, 80 L / h of waste emulsion 3 is treated: the pH is 6.5-7, the total oil concentration is 112.267 mg / L, and the COD concentration is 1516 mg / L. First, collect the waste emulsion in the acid-base adjustment tank 1, control the temperature of the waste emulsion to 30°C, adjust the pH of the waste emulsion to 7, and add 60 mL / h of a mixed solution of PAC and PAM with a mass fraction of 1%, fully Stir for 5 minutes, then settle naturally for 30 minutes, and drain the lower layer of sludge. Rotate the water inlet shut-off valve 3, pressure control valve 6, and water outlet shut-off valve 8 counterclockwise to the maximum position, press the high-pressure pump 2 running button on the panel of the electric control cabinet 16, so that the high-pressure pump 2 is powered on, and the high-pressure pump 2 will turn the acid-base The waste emulsion in the adjustment tank 1 is pumped into the tubular inorganic ceramic membrane purifier 4, and then returned to the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com