Suspended biological film filler of composite trace metal ions and preparation method of suspended biological film filler

A trace metal, biofilm technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of unsatisfactory microbial metabolism, affecting the purification efficiency of biofilm packing, and low efficiency of microbial purification of sewage and other problems, to achieve the effect of increasing efficiency, reducing emissions, and improving removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

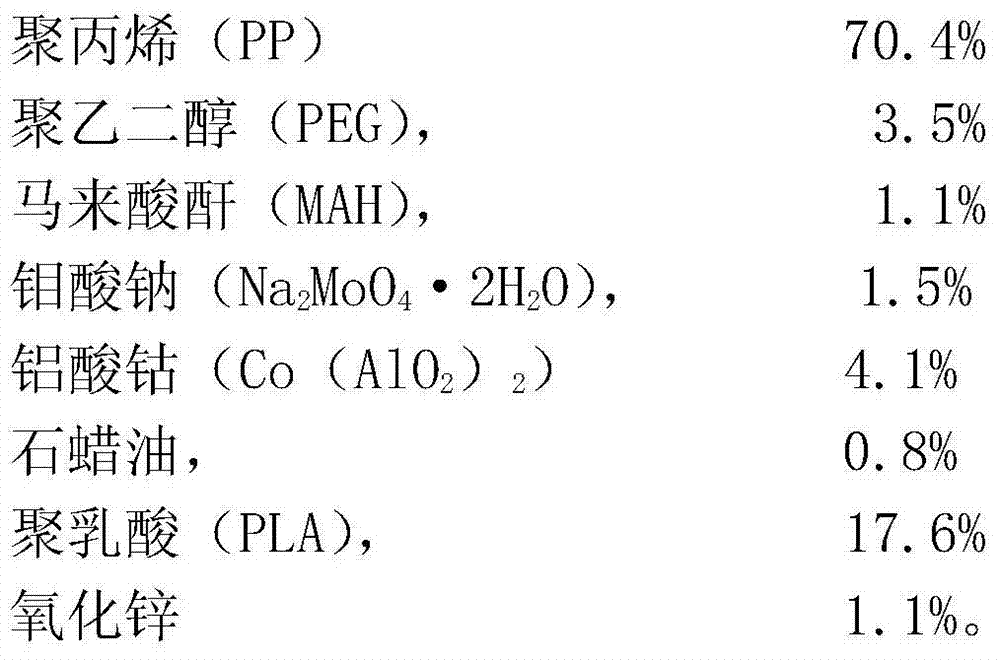

[0033] Raw material consumption:

[0034] In the present embodiment, the preparation raw material consumption of the microbial film filler used is as follows (mass percentage):

[0035]

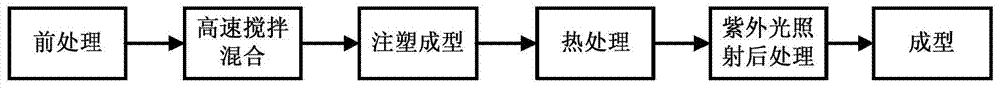

[0036] Preparation:

[0037] (1) Dry polypropylene (PP), polyethylene glycol (PEG), and maleic anhydride (MAH) at 90°C for 2 hours; metal compound sodium molybdate (Na 2 MoO 4 2H 2 O) and cobalt aluminate (Co(AlO 2 ) 2 ) were placed in a drying oven at 150°C for dehydration for 12 hours, taken out, and ground;

[0038] (2) Put the various raw materials that have been pretreated in the high-speed mixer according to the above mass ratio and mix them for 10 minutes to make them fully mixed;

[0039] (3) The measured density of the mixed raw material is 0.963g / cm 3 ;

[0040] (4) Take the above-mentioned mixed raw materials and place them in the hopper of an injection molding machine, and use a spherical biofilm filler mold for injection molding, and the injection molding temperature i...

Embodiment 2

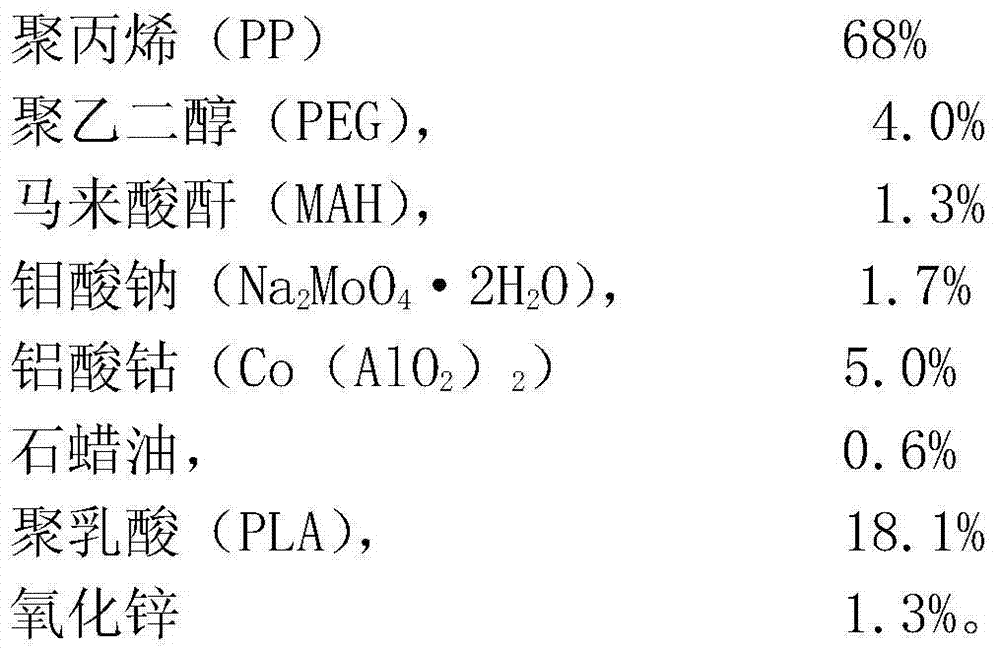

[0045] Raw material consumption:

[0046] In the present embodiment, the preparation raw material consumption of the microbial film filler used is as follows (mass percentage):

[0047]

[0048] The preparation method is the same as that described in Example 1.

[0049] Effect test:

[0050] The target wastewater to be treated is knitted fabric printing and dyeing wastewater, in which the pH value of the wastewater is 10, the chroma is 290 times, the BOD value is 250mg / L, the COD value is 850mg / L, and the suspended matter is 250mg / L. Activated sludge is taken from a sewage treatment plant and cultivated and domesticated so that it can stably treat printing and dyeing wastewater. The activated sludge system and the ordinary biofilm filler and the new composite trace metal element suspended biofilm filler are added to the wastewater, the MLSS in the wastewater is 4000mg / L, the sludge load is 0.2kgCOD / kgMLSS·d, and the filler is filled The rate is 30%, using uninterrupted a...

Embodiment 3

[0052] Raw material consumption:

[0053] In the present embodiment, the preparation raw material consumption of the microbial film filler used is as follows (mass percentage):

[0054]

[0055]

[0056] The preparation method is the same as that described in Example 1.

[0057] Effect test:

[0058] The target treated wastewater is pure cotton printing and dyeing wastewater, in which the pH value of the wastewater is 10, the chroma is 300 times, the BOD value is 350mg / L, the COD value is 1500mg / L, and the suspended matter is 300mg / L. The activated sludge is taken from a sewage treatment plant, and it is cultivated and domesticated so that it can treat printing and dyeing wastewater very stably. The activated sludge system is added to the In the waste water, the MLSS in the waste water is 6000mg / L, the sludge load is 0.2kgCOD / kgMLSS·d, the filling rate of the filler is 40%, and the uninterrupted air compressor is used for aeration operation, accompanied by stirring, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com