Preparation method of immobilized microbial filler

A technology for immobilizing microorganisms and microorganisms, applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc. performance, improved purification capacity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

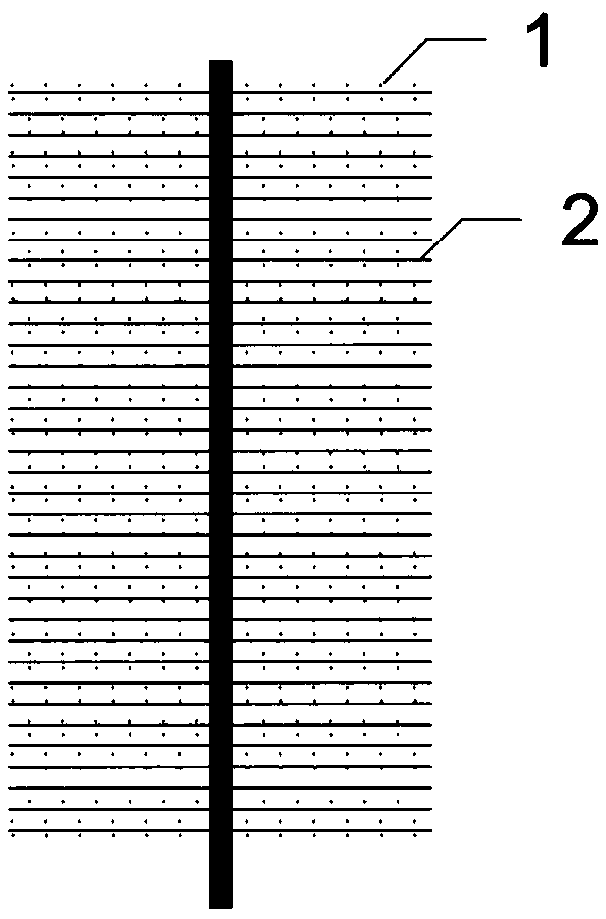

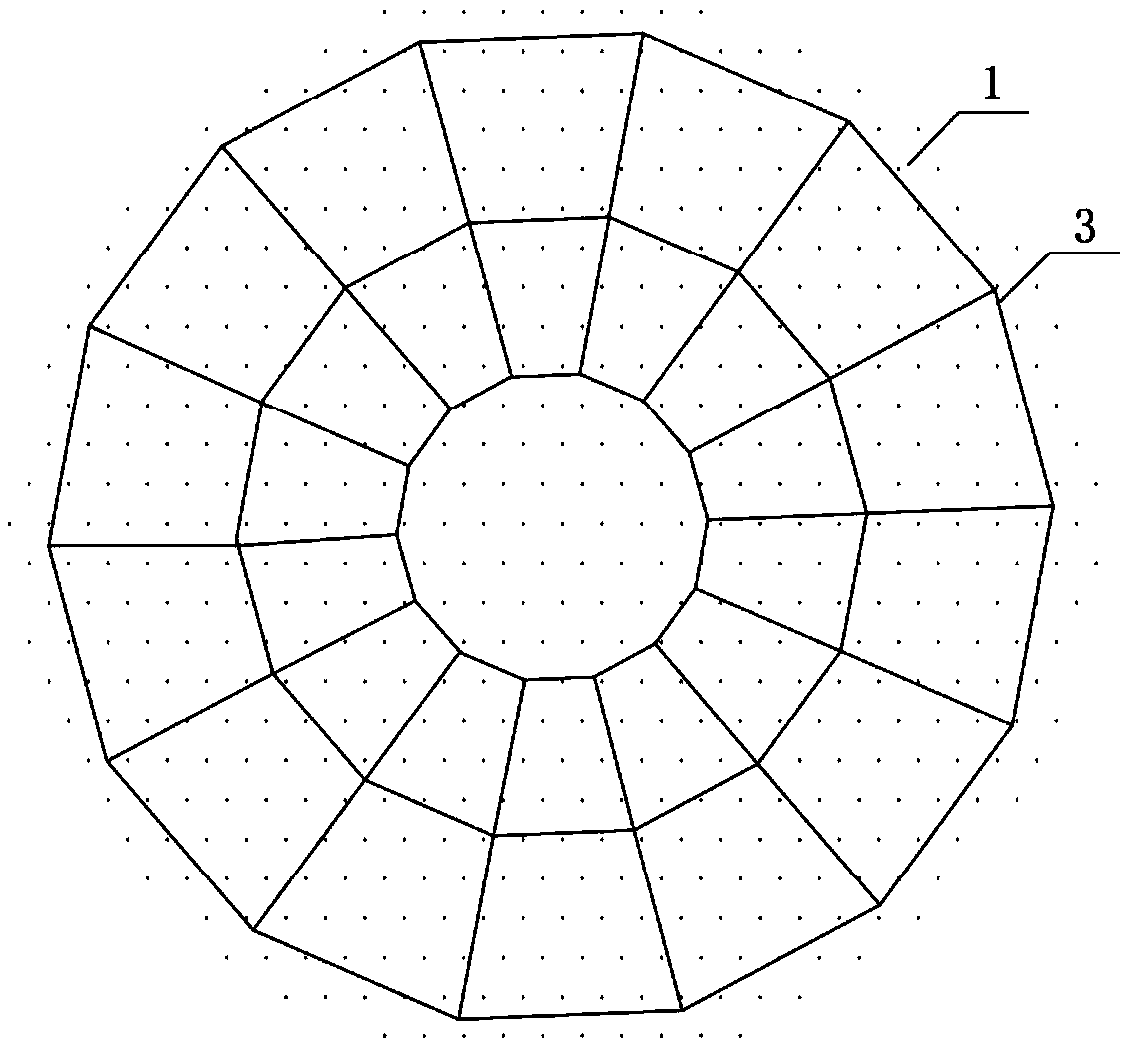

Image

Examples

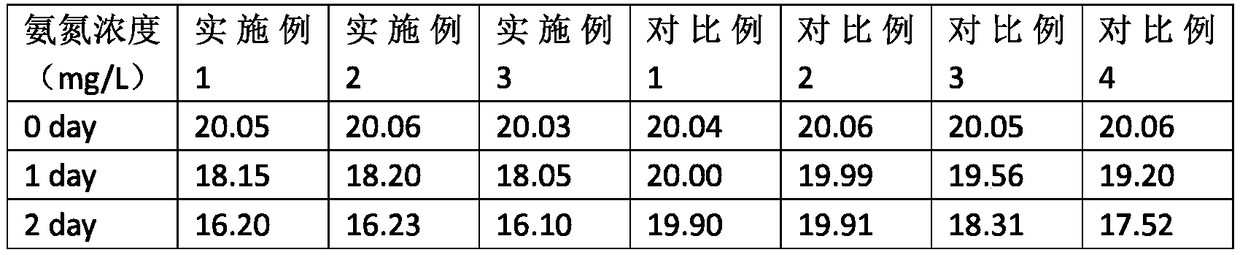

Embodiment 1

[0025] A preparation method of microbial filler, the steps are as follows:

[0026] (1) Sodium alginate and polyvinyl alcohol are dissolved in water to prepare sodium alginate-polyvinyl alcohol solution, the content of sodium alginate in the sodium alginate-polyvinyl alcohol solution is 1wt.%, and the content of polyvinyl alcohol is 10wt.%. ;

[0027] (2) Mix the nitrifying bacteria liquid (commercially available general-purpose nitrifying bacteria liquid, the same below) with zeolite and aerate for 8 hours, then add it to the sodium alginate-polyvinyl alcohol solution prepared in step (1), and stir thoroughly Mix evenly to obtain a sodium alginate-polyvinyl alcohol mixed solution containing nitrifying bacteria, wherein the bacterial liquid content in the mixed solution is 2wt.%, and the zeolite content is 6wt.%.

[0028] (3) boric acid and calcium chloride are dissolved in water to prepare boric acid-calcium chloride solution, the content of boric acid in the boric acid-calc...

Embodiment 2

[0033] A preparation method of microbial filler, the steps are as follows:

[0034] (1) Sodium alginate and polyvinyl alcohol are dissolved in water to prepare sodium alginate-polyvinyl alcohol solution, the content of sodium alginate in the sodium alginate-polyvinyl alcohol solution is 0.5wt.%, and the content of polyvinyl alcohol is 5wt. %;

[0035] (2) Mix the nitrifying bacteria liquid with the zeolite and then aerate for 5 hours, then add it into the sodium alginate-polyvinyl alcohol solution prepared in step (1), fully stir and mix to obtain the sodium alginate-polyvinyl alcohol containing nitrifying bacteria Vinyl alcohol mixed solution, wherein the bacterial liquid content in the mixed solution is 2wt.%, and the zeolite content is 6wt.%.

[0036] (3) boric acid and calcium chloride are dissolved in water to prepare boric acid-calcium chloride solution, the content of boric acid in the boric acid-calcium chloride solution is 2.5wt.%, and the content of calcium chloride...

Embodiment 3

[0041] A preparation method of microbial filler, the steps are as follows:

[0042] (1) Sodium alginate and polyvinyl alcohol are dissolved in water to prepare sodium alginate-polyvinyl alcohol solution, the content of sodium alginate in the sodium alginate-polyvinyl alcohol solution is 1.5wt.%, and the content of polyvinyl alcohol is 15wt. %;

[0043] (2) Mix the nitrifying bacteria liquid with the zeolite and then aerate for 10 hours, then add it into the sodium alginate-polyvinyl alcohol solution prepared in step (1), stir and mix well to obtain the sodium alginate-polyvinyl alcohol containing nitrifying bacteria Vinyl alcohol mixed solution, wherein the bacterial liquid content in the mixed solution is 2wt.%, and the zeolite content is 6wt.%.

[0044] (3) Boric acid and calcium chloride are dissolved in water to prepare boric acid-calcium chloride solution, the content of boric acid in the boric acid-calcium chloride solution is 4wt.%, and the content of calcium chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com