Biological desulfurizing and deodorizing trickling-filtration tower device and biological desulfurizing and deodorizing method

A technology of biological desulfurization and trickling filter tower, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of hydrogen sulfide poisoning to bacteria and blockage of start-up time, and reduce system start-up time and filler use time. Long-term, reduce the effect of increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

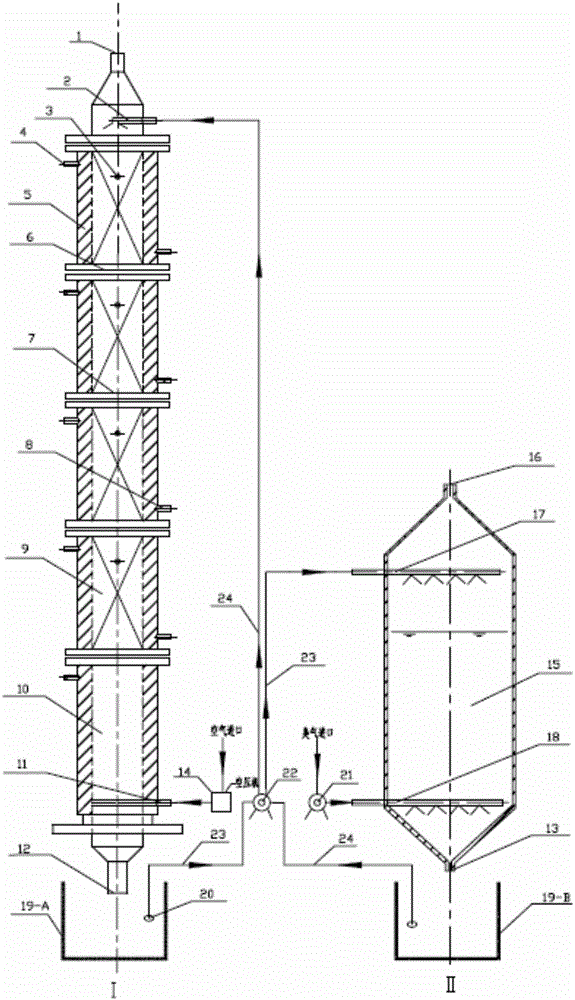

[0040] Such as figure 1 Shown is a schematic structural view of a biological desulfurization and deodorization trickling tower device of the present invention, the device includes a biological oxidation tower I, a chemical absorption desulfurization and deodorization tower II and a circulating spray device; the biological oxidation tower I is made up of a plurality of independent biological oxidation units and the intake buffer zone 10 below the biological oxidation units are connected by a flange 7. The lean liquid inlet 2 and the air discharge port 1 are respectively arranged on the top of the tower, and the rich liquid is arranged at the bottom of the tower. Discharge port 12; said biological oxidation unit contains filler 9, air inlet 11 is set below said intake buffer zone 10, and air compressor 14 is connected to air inlet 11 through air inlet pipe; said chemical absorption The desulfurization and deodorization tower II contains a chemical absorption liquid 15, and the t...

Embodiment 2

[0045] Utilize the device described in embodiment 1 to biological desulfurization and deodorization of odorous gas, use wood chips as filler 9 in the biological biological oxidation unit, and hydrogen sulfide-containing odor is transported to the chemical industry through the odor air inlet 18 and the nano-explosion head by the blower 21 At the bottom of the absorbing liquid 15, after the contact with the chemical absorbing liquid 15, the hydrogen sulfide is absorbed and the odor is discharged through the odor discharge port 16. The air is transported to the bottom of the biological oxidation tower through the air compressor 14 through the air pipe, valve and air inlet 11 for the necessary growth of microorganisms and the gas source used for backwashing. The spray liquid in the lean liquid collection tank 19B at the bottom of the chemical absorption desulfurization and deodorization tower is transported to the top of the biological oxidation tower through the peristaltic pump 2...

Embodiment 3

[0049] Using the same device as in Example 1, the spray density is 0.5 to 1.0m 3 Spray liquid / m 3 Filling h; The hydraulic retention time of the spray liquid in the biological oxidation tower is 2 months. Other conditions are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com