Glass-ceramic decoration face light ceramic composite brick and preparation method thereof

A technology of glass-ceramics and lightweight ceramics, which is applied in the direction of ceramic layered products, chemical instruments and methods, glass/slag layered products, etc., which can solve the problems of low stability, difficulty in base layer thickness, and decreased wear resistance, etc. problems, to achieve the effects of energy saving and environmental protection in the production process, promoting sustainable development, and excellent decorative performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

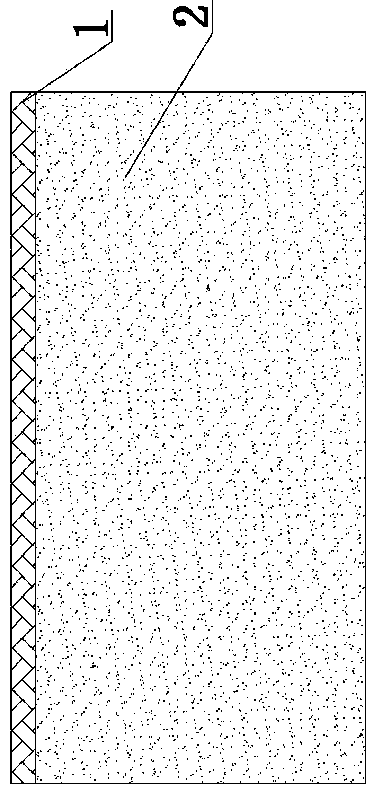

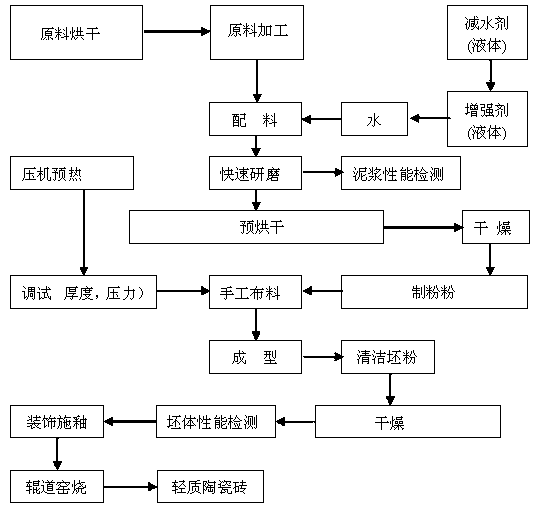

[0030] Such as figure 1 , figure 2 A light-weight ceramic composite brick with a glass-ceramic finish as shown, including a thermal insulation base layer 2 and a decorative wear-resistant layer 1 arranged on the thermal insulation base layer 2, the thermal insulation base layer is a closed-cell foamed ceramic layer with a thickness of 4mm ~60mm, bulk density 230~980Kg / m 3 Between; the decorative wear-resistant layer is a glass-ceramic layer with a thickness of 2mm to 4mm and a bulk density of 2000 to 3000Kg / m 3 between.

[0031] The bottom material of the thermal insulation base layer 2 and the fabric of the decorative wear-resistant surface layer 1 are formed by the secondary distribution of the overpressing machine, and the primary firing of the roller kiln.

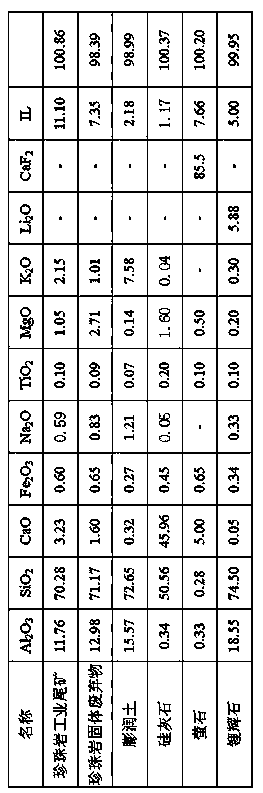

[0032] The closed-cell foamed ceramic layer is mainly made of industrial tailings and solid waste produced during the mining and processing of perlite, and a foaming agent-5000 mesh green silicon carbide (99.5%), w...

Embodiment 1

[0046] Example 2

Embodiment 2

[0048] Example 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com