Self-oxygenation microorganism degradation filler and preparation method thereof

A microbial degradation and self-oxygenation technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of consuming huge investment and operating costs, restricting the time and amount of sewage biochemical treatment, etc. , to achieve the effect of shortening the film-hanging time, facilitating the growth of microorganisms, and enhancing the strength of the filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

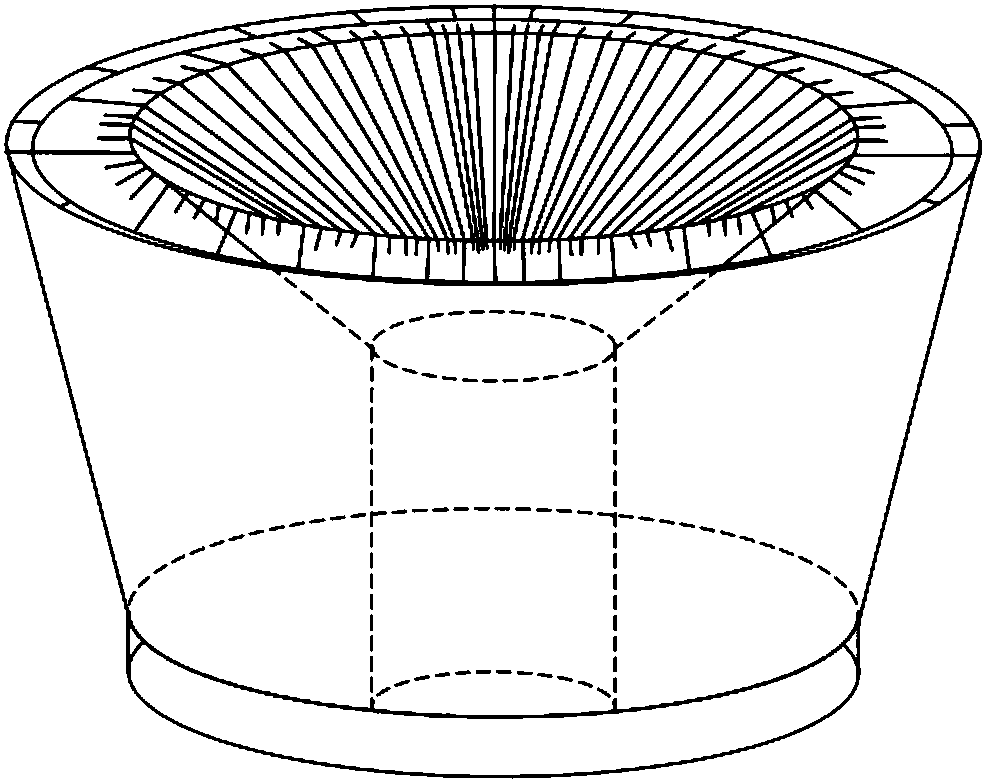

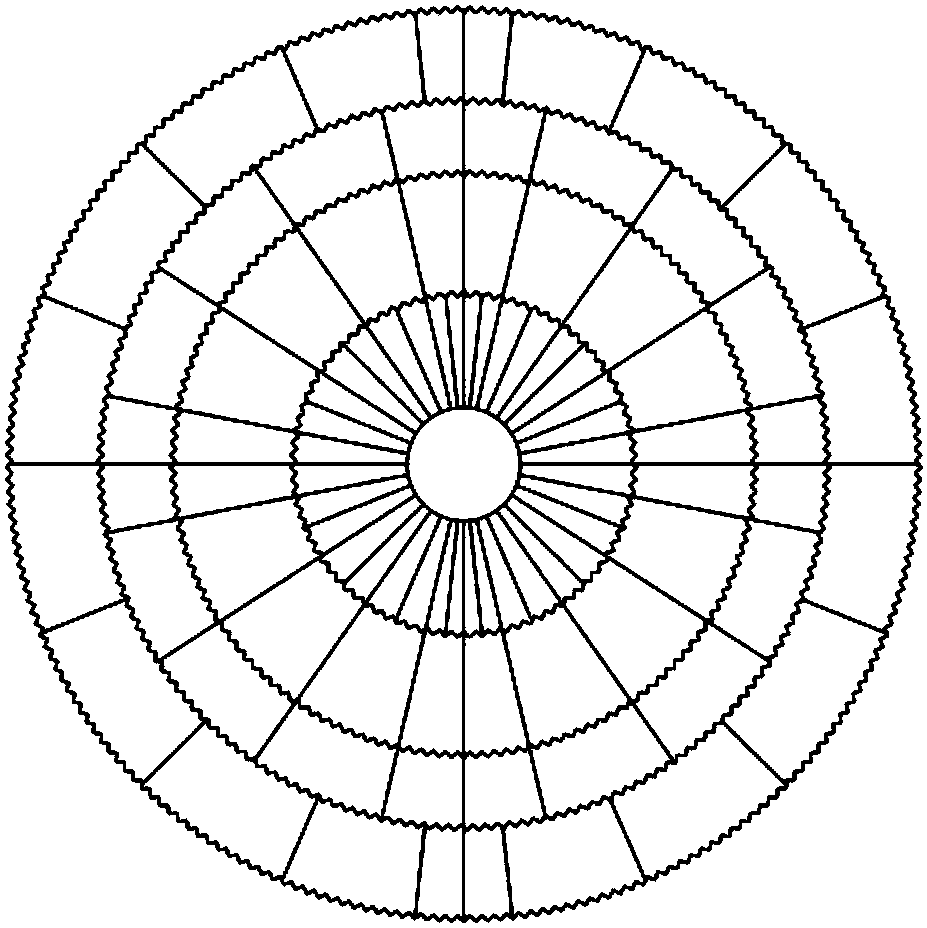

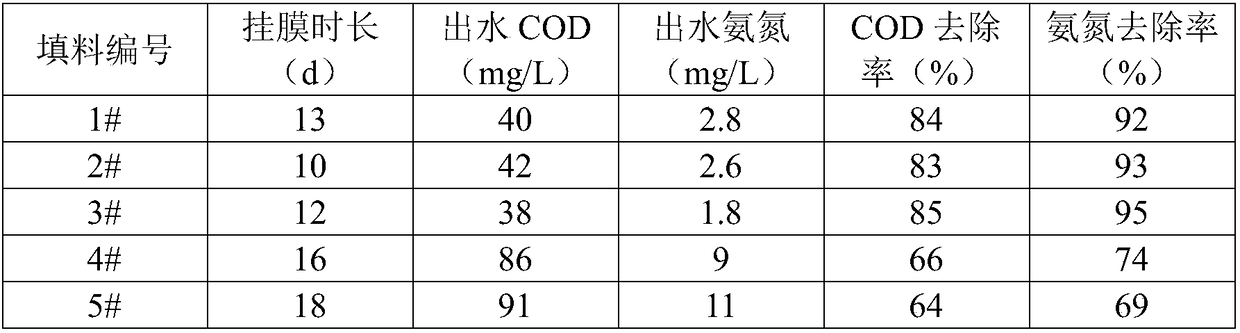

[0016] Embodiment 1: self-aerobic microbial degradation filler and preparation method thereof, calculated in parts by mass, including 35 parts of polyhydroxyalkanoate, 30 parts of polylactic acid, 10 parts of light calcium carbonate, 18 parts of natural biomass walnut sand, 3 parts of maleic anhydride, 0.3 parts of ferrous sulfate, 0.2 parts of magnesium chloride, 0.5 parts of composite coupling agent, 0.5 parts of white oil, 1.5 parts of polyvinyl alcohol, 0.5 parts of stearic acid, 0.5 parts of calcium chloride and dipalmitoyl phospholipid 6 parts of acylcholine are the raw materials for preparation; the natural biomass material walnut sand needs to be pulverized in advance with an ultrafine pulverizer, and the mesh size after pulverization is greater than 320 mesh.

[0017] The self-aerobic microbial degradation filler comprises a preparation method of a filler skeleton material and a functional blended material, and each component is taken by the above-mentioned parts by ma...

Embodiment 2

[0021] Embodiment 2: self-aerobic microbial degradation filler and preparation method thereof, calculated in parts by mass, including 45 parts of polyhydroxyalkanoate, 25 parts of polylactic acid, 12 parts of light calcium carbonate, 12 parts of natural biomass walnut sand, 4 parts of maleic anhydride, 0.5 parts of ferrous sulfate, 0.3 parts of magnesium chloride, 0.8 parts of ferrous sulfate and magnesium chloride, 0.8 parts of composite coupling agent, 0.8 parts of white oil, 2.5 parts of polyvinyl alcohol, 1 part of stearic acid, chlorinated 1 part of calcium and 8 parts of dipalmitoylphosphatidylcholine are the raw materials for preparation; the natural biomass material walnut sand needs to be pulverized in advance with an ultrafine pulverizer, and the mesh size after pulverization is greater than 320 mesh.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0023] Embodiment 3: self-aerobic microbial degradation filler and preparation method thereof, calculated in parts by mass, including 44 parts of polyhydroxyalkanoate, 30 parts of polylactic acid, 8 parts of light calcium carbonate, 6 parts of natural biomass walnut sand, 5 parts of maleic anhydride, 0.6 parts of ferrous sulfate, 0.4 parts of magnesium chloride, 1.0 parts of composite coupling agent, 1.0 parts of white oil, 4 parts of polyvinyl alcohol, 1.25 parts of stearic acid, 1.25 parts of calcium chloride and dipalmitoyl phospholipid 10 parts of acylcholine is the raw material for preparation; the natural biomass material walnut sand needs to be pulverized in advance with an ultrafine pulverizer, and the mesh size after pulverization is greater than 320 mesh.

[0024] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com