Plastic adhesion layer cleaning agent as well as plastic cleaning process and equipment adopting same

A technology for cleaning and attaching layers of plastics, applied in the fields of plastic recycling, detergent compositions, soap detergent compositions, etc., can solve the problems of non-recycling for one-time use, health hazards for operators, and reducing the quality of recycled plastics, and achieves a Conducive to metal recovery, economical and practical quality, and the effect of reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

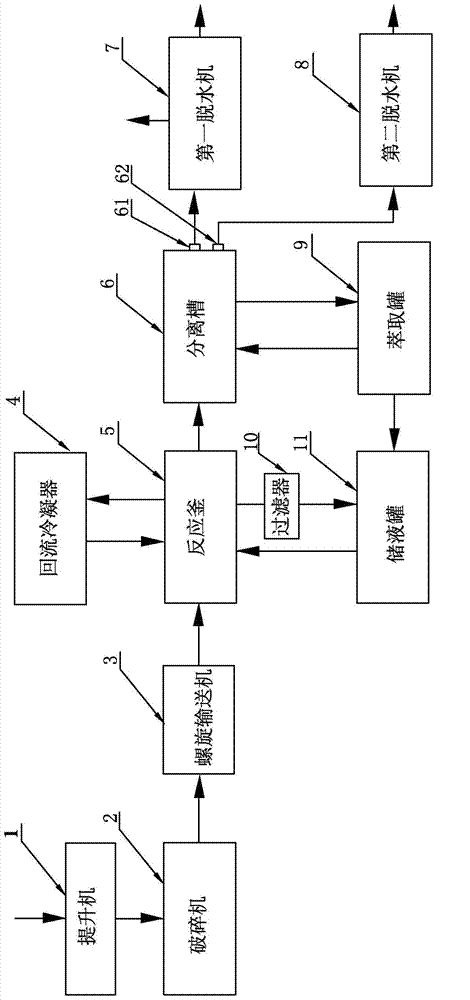

Method used

Image

Examples

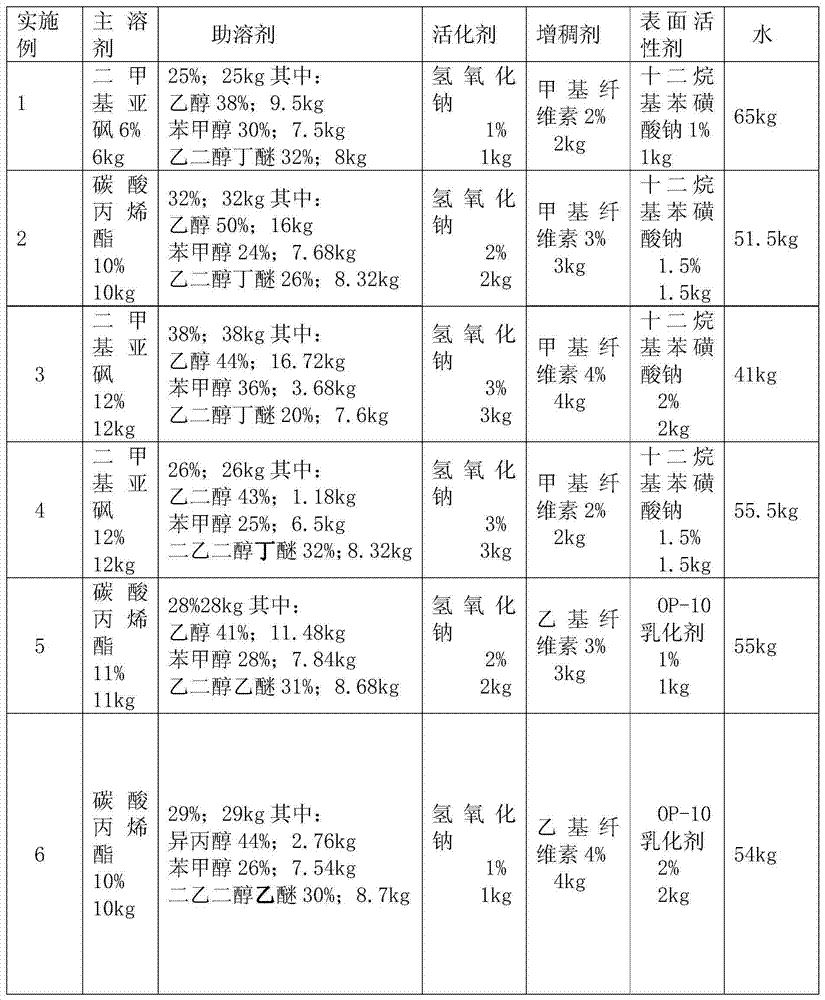

Embodiment 1

[0053] Using the plastic cleaning process of plastic adhesion layer cleaning agent, the processed plastics are colorless and transparent PC (polycarbonate) waste DVDs and CDs. They were purchased from a waste plastic distribution center in Xingtan County, Shunde City, Guangdong Province. The ink needs to be cleaned off layer, aluminum foil layer, anti-oxidation protective film layer. The cleaning process includes the following steps:

[0054] (1) Configure 100kg of cleaning agent, and take materials according to the proportion of each component in Example 1 in Table 1. The preparation steps are: ① Dissolve 6 kg of main solvent dimethyl sulfoxide in 25 kg of co-solvent, 9.5 kg of ethanol, benzene Methanol 7.5kg, ethylene glycol butyl ether 8kg; ②Dissolve activator sodium hydroxide 1kg, thickener methyl cellulose 2kg, surfactant sodium dodecylbenzene sulfonate 1kg in 65kg water; ③Step ① Mix with the solution obtained in step ② to prepare 100Kg of cleaning agent.

[0055] (2) C...

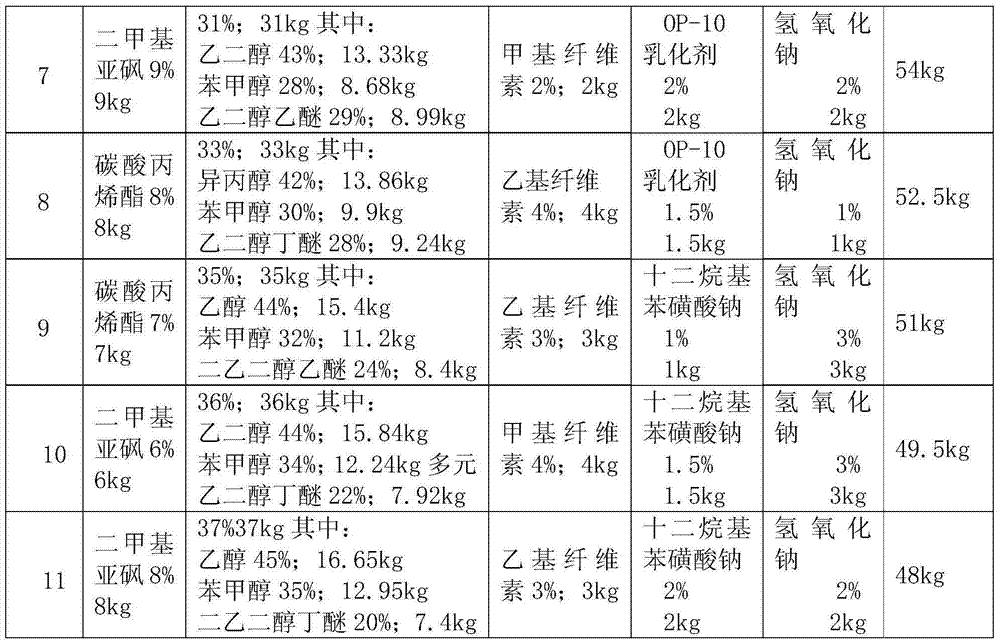

Embodiment 2

[0060] In this embodiment, the types, processing items and sources of plastics with an adhesive layer to be processed are the same as those in Embodiment 1. The plastic cleaning process includes the following steps:

[0061] (1) prepare plastic adhesion layer cleaning agent, preparation method is the same as embodiment 1, and difference is to take material according to each component ratio of embodiment 2 in table 1, main solvent dimethyl sulfoxide 10kg, auxiliary solvent 32kg, wherein ethanol 16kg, Benzyl alcohol 7.68kg, ethylene glycol butyl ether 8.32kg; activator sodium hydroxide 2kg, thickener methylcellulose 3kg, surfactant sodium dodecylbenzenesulfonate 1.5kg, water 51.5kg.

[0062] Thereafter, the plastic cleaning process is the same as that of Example 1 except for the following steps: in step (2), put the plastic fragments and cleaning agent into the reactor 5, seal and heat to 70° C. and stir for 30 minutes.

Embodiment 3

[0064] The type, processing item and source of the plastic with an adhesive layer to be processed in this embodiment are the same as in Embodiment 1. The plastic cleaning process includes the following steps:

[0065] (1) prepare plastic adhesion layer cleaning agent, preparation method is the same as embodiment 1, and difference is to take materials according to the ratio of each component in embodiment 3 in table 1, main solvent dimethyl sulfoxide 12kg, auxiliary solvent 38kg, wherein: ethanol 16.72 kg, benzyl alcohol 13.68kg, ethylene glycol butyl ether 7.6kg, activator sodium hydroxide 3kg, thickener methylcellulose 4kg, surfactant sodium dodecylbenzenesulfonate 2kg, water 41kg.

[0066] Thereafter, the plastic cleaning process is the same as in Example 1 except for the following steps: in step (2), put the plastic fragments and cleaning agent into the reactor 5, seal and heat to 65° C. and stir for 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com