Novel waste pitch heating device

A technology of used asphalt and heating device, which is applied to roads, road repair, roads, etc., can solve the problems of difficult temperature control, flammability, and low recycling utilization rate of used asphalt, achieve effective and convenient control, improve service life, The effect of preventing the phenomenon of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

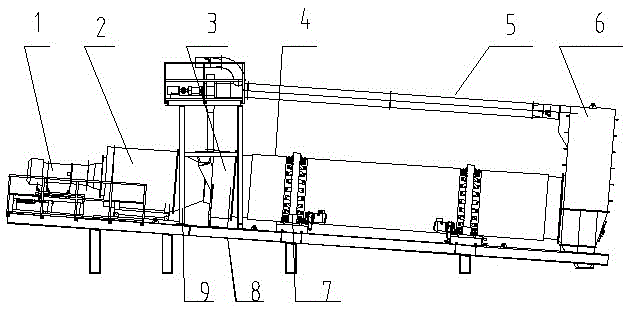

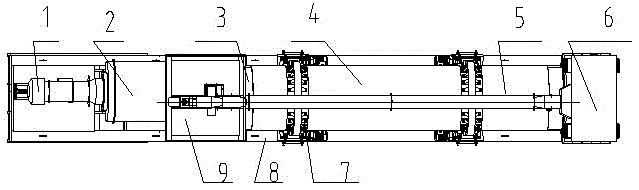

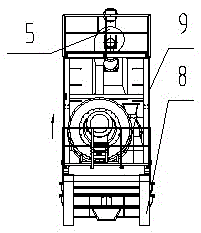

[0046] refer to Figure 1-Figure 19 , a new type of asphalt old material heating device in this embodiment, it includes a base 8, a burner 1, and also includes a combustion chamber 2, a heating assembly, a moving assembly, a driving assembly 7 and a hot air circulation assembly 5, the burner 1, the combustion The chamber 2 and the heating assembly are placed on the base 8 in turn from left to right. The burner 1 is sealed and fixedly connected with the combustion chamber 2. Both the burner 1 and the combustion chamber 2 are fixedly connected with the base 8 through the moving assembly. The base 8 is fixed, and the middle is fixed to the base 8 through the drive assembly 7. There is a 4° inclination between the heating roller 4 of the heating assembly and the horizontal plane. The combustion chamber 2 is in sealing contact with the heating assembly. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com