Stripping liquid regeneration device and process

A regeneration device and stripping liquid technology, which is applied to the photoplate making process, distillation separation, and separation methods of the patterned surface, can solve the problems of low regeneration efficiency, affecting the recycling effect of photoresist stripping liquid waste liquid, and low yield, etc. problem, to achieve high efficiency and uniform preheating process, and improve the effect of primary separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

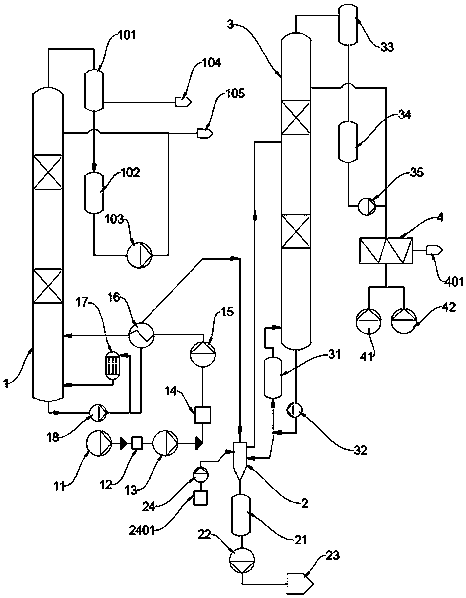

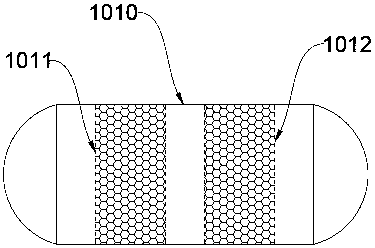

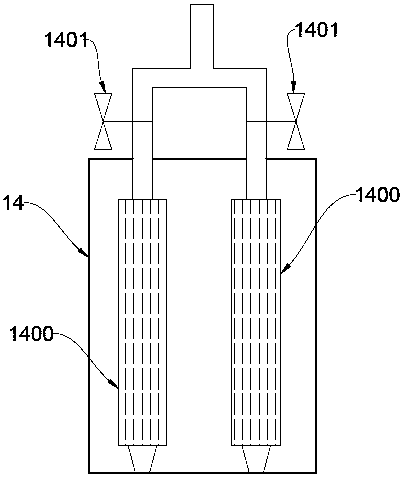

[0057] See attached figure 1 , figure 2 and image 3 The present invention is further described.

[0058] The present invention is realized through the following technical solutions:

[0059] A stripping liquid regeneration process, is characterized in that, comprises the following steps:

[0060] Step 1) Use the raw material feed pump (11) to pump the stripping liquid waste liquid to the stripping liquid waste liquid smelting pool (12), and the stripping liquid waste liquid is melted and liquefied in the stripping liquid waste liquid melting pool (12) to obtain complete Liquefied primary stripper waste liquid;

[0061] Step 2) Use the waste liquid delivery pump (13) to pump the completely liquefied first-level stripping liquid waste liquid in step 1) to the inside of the first-level membrane filter tank (14), and use the first-level membrane filter tank (14) to The metal ions are separated by membrane filtration to obtain the waste liquid of the secondary stripping liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com