Steam-water separation type vertical oil-gas fired once-through steam boiler

A steam-water separation and steam boiler technology, which is applied to water-tube steam boilers, steam boilers, steam separation devices, etc., can solve the problems of poor steam-water separation effect of boilers, reduced boiler efficiency, high steam humidity, etc., to achieve enhanced steam-water separation effect, The effect of improving boiler efficiency and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

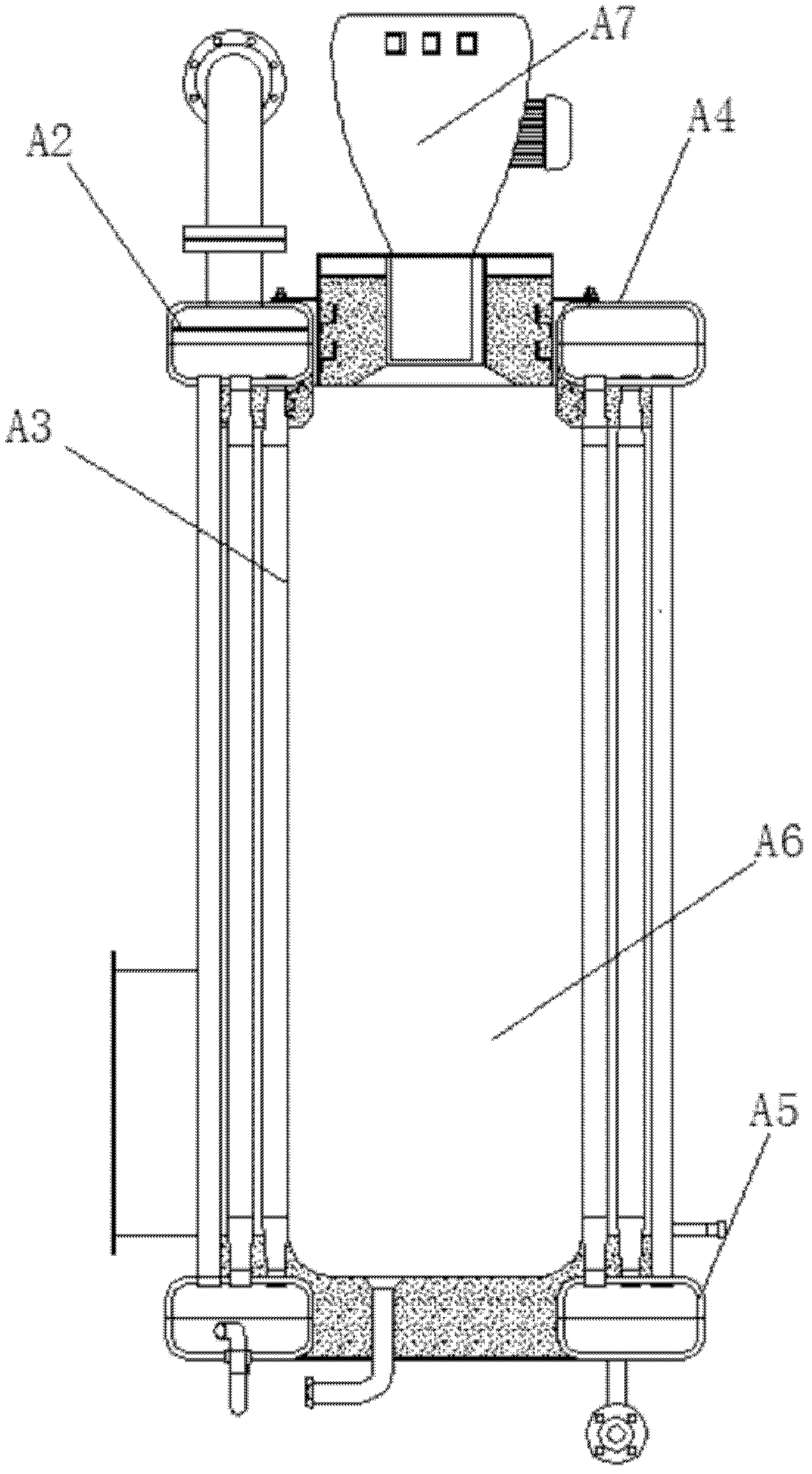

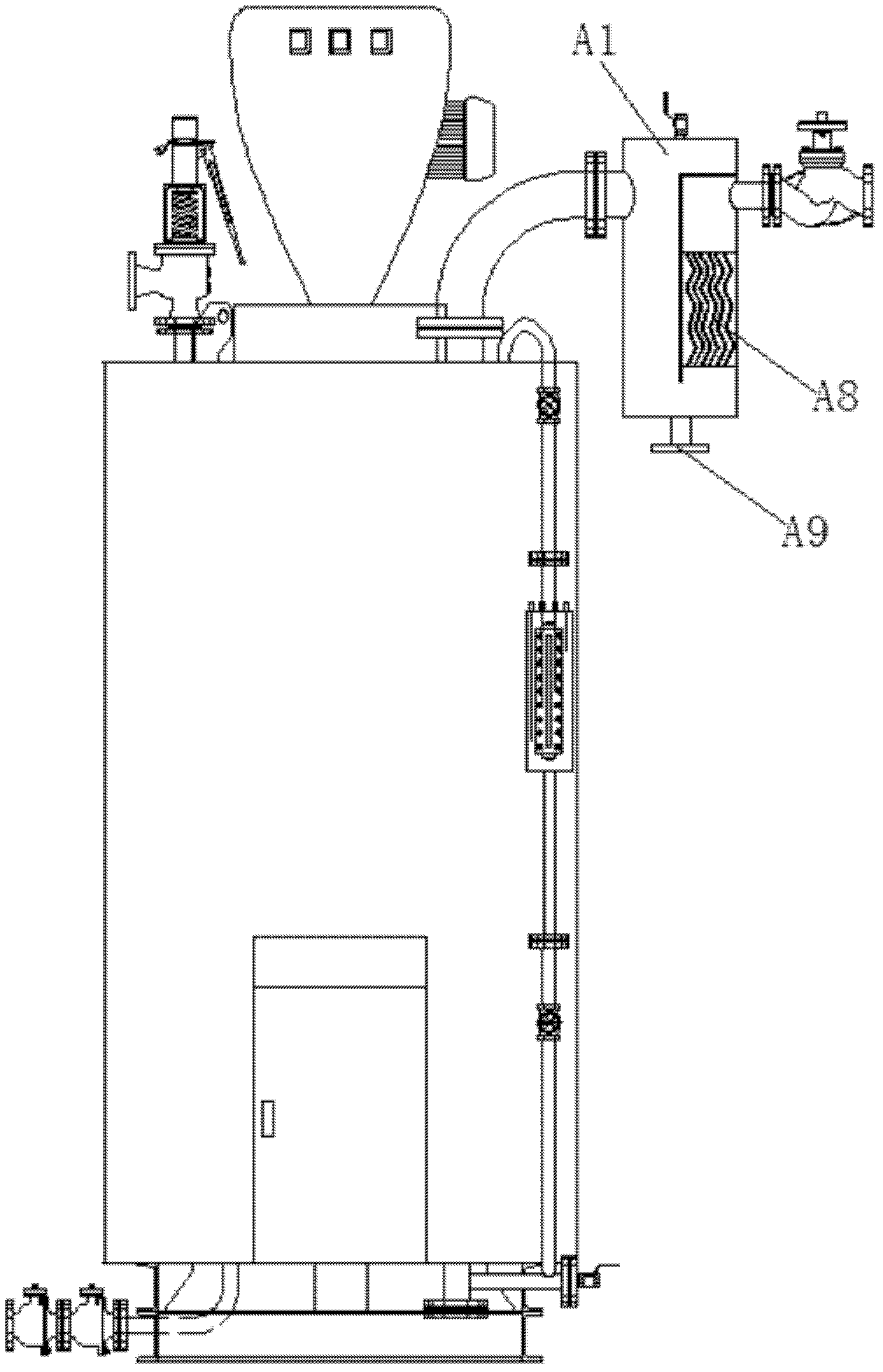

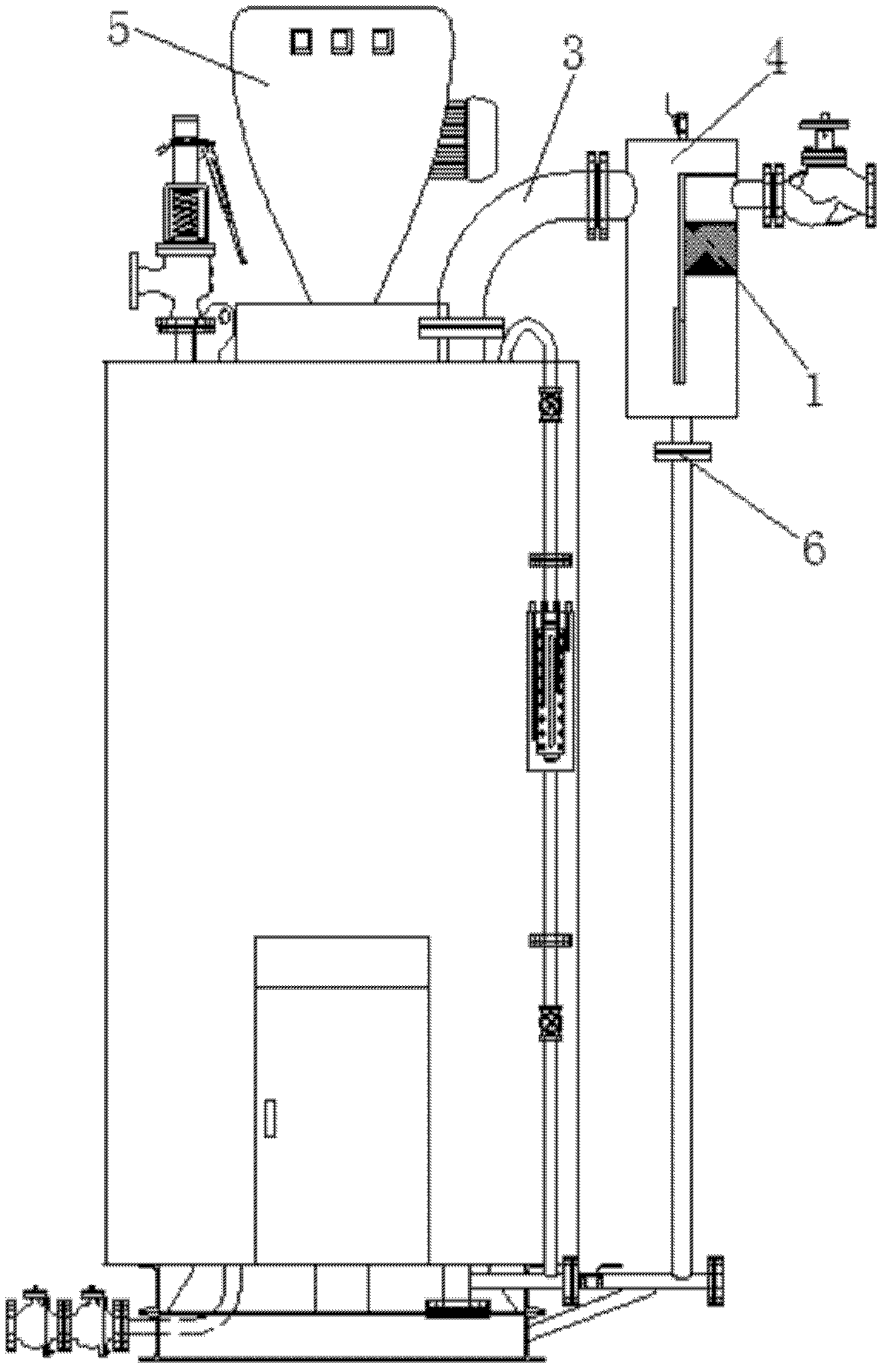

[0032] Embodiment: a kind of steam-water separation type fuel gas vertical cross-flow steam boiler, such as image 3 As shown, it includes a heating surface pipe, an upper annular header 2, a lower annular header, a secondary steam-water separation header 4 and a burner 5, and the heating surface pipe communicates with the upper annular header 2 and the lower annular header. A combustion chamber is formed between the heating surface tube, the upper annular header 2 and the lower annular header, the burner 5 is arranged above the combustion chamber, and the upper annular header 2 is connected to the secondary The steam-water separation header 4 communicates with each other. There is a steam channel inside the secondary steam-water separation header 4, and a stainless steel wire ball 1 is arranged on the steam channel. In the secondary steam-water separation, the traditional corrugated plate in the secondary steam-water separation header is replaced by stainless steel wire balls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com