Axial-flow centrifugal separator and oil-gas separation method

An oil-gas separator and axial flow technology, which is applied in the direction of machines/engines, variable-capacity pump components, liquid variable-capacity machinery, etc., can solve problems such as pressure loss and secondary entrainment, so as to prolong service life and improve efficiency , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

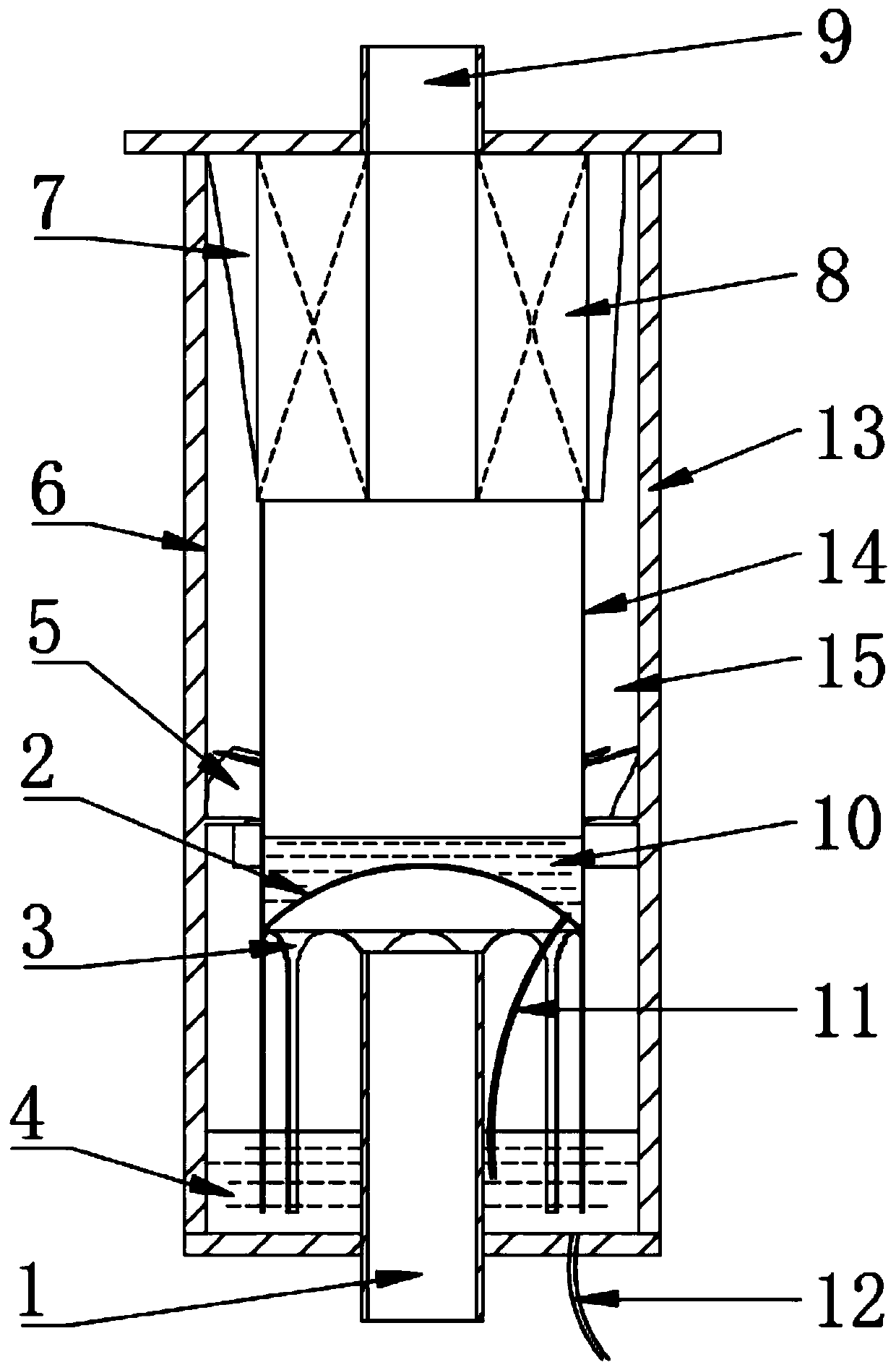

[0030] The following figures will further illustrate the present invention in conjunction with the accompanying drawings.

[0031] Existing oil-gas separators for oil-injected compressors usually use a combination of cyclone separators and filter elements for separation, which has poor adaptability to compressors with a large range of operating conditions. The problem of re-entrainment of air flow into the oil-air mixture and the inevitable pressure loss when the rotating air flow enters the filter element. For this reason, the present invention proposes the following axial-flow centrifugal oil-gas separator.

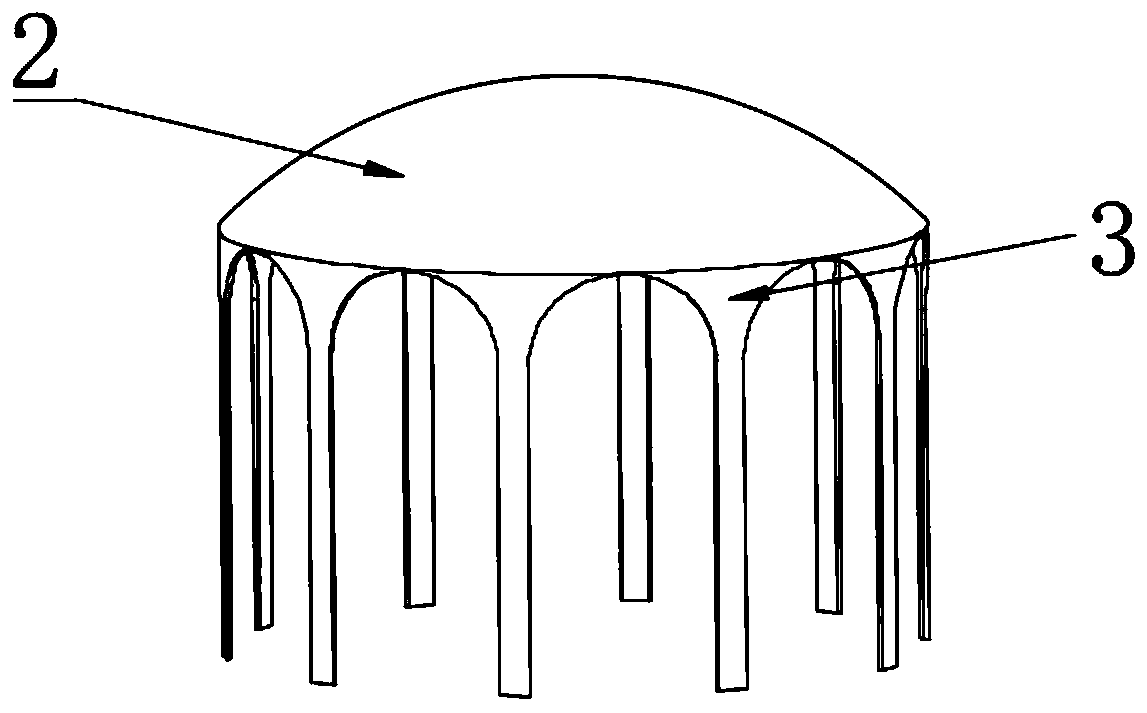

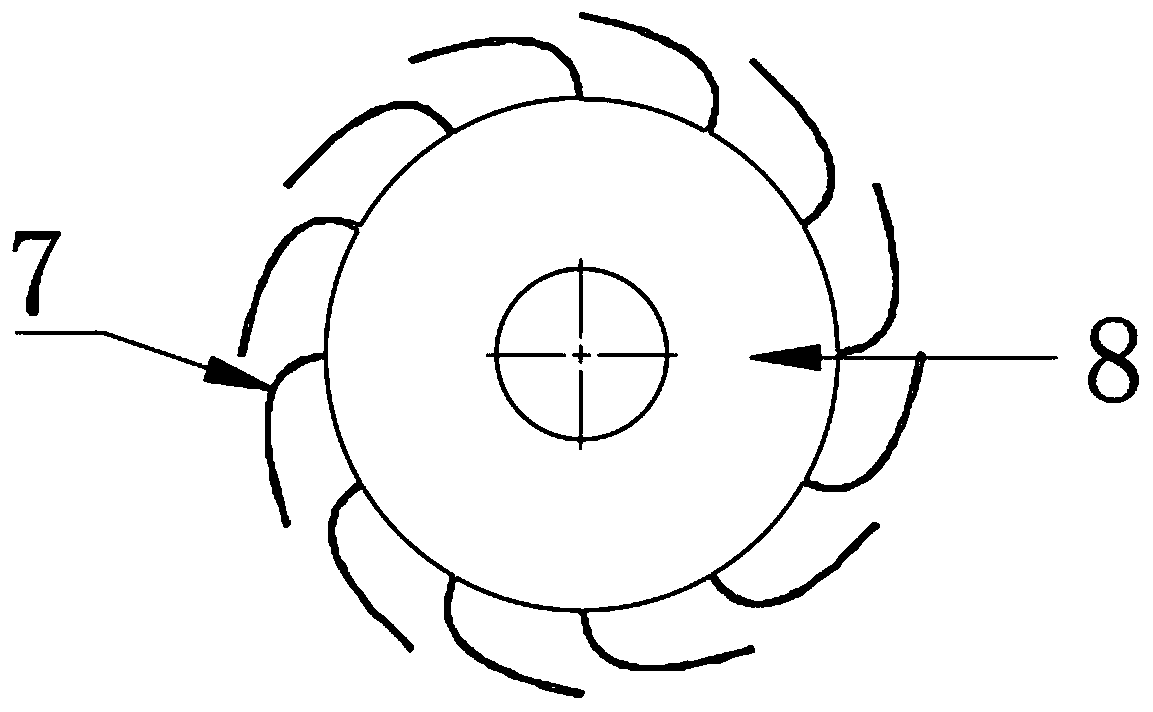

[0032] see figure 1 , the axial-flow centrifugal oil-gas separator of the present invention comprises an outer cylinder 13, an inner cylinder 14, an arc surface coarse separation device, a cyclone, a deflector and a filter element 8, and the outer cylinder 13 and the inner cylinder 14 are cylindrical cylinders , the upper and lower ends of the outer cylinder 13 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com