X-ray digital nondestructive detection device and method of welding seam of storage tank

A non-destructive testing, X-ray technology used in materials analysis using radiation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

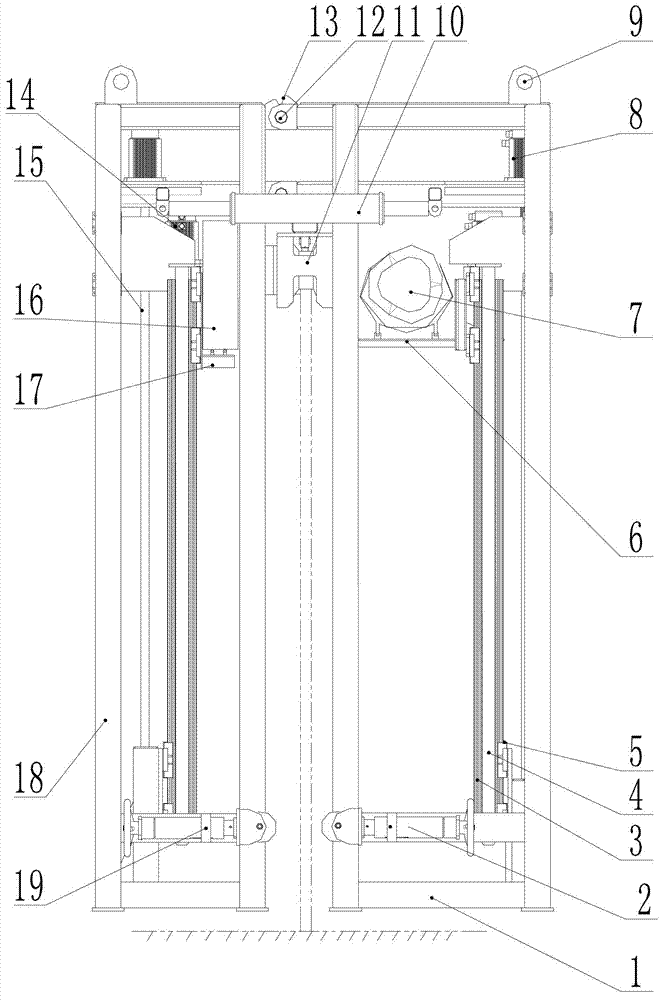

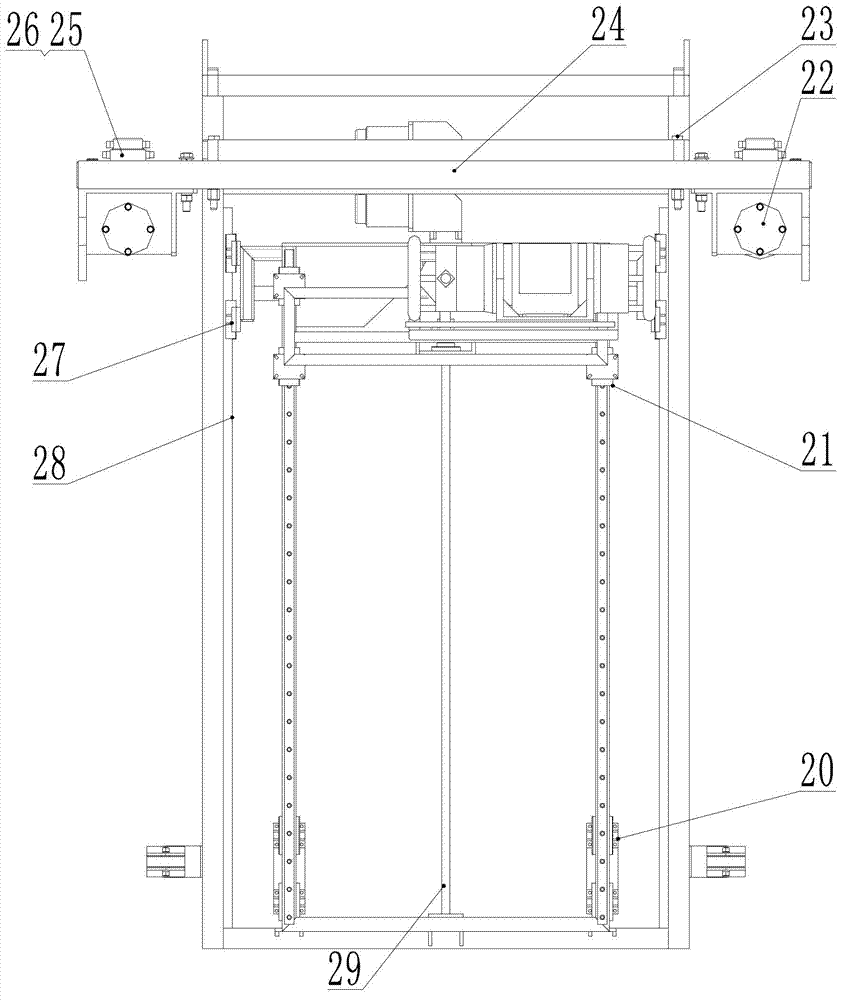

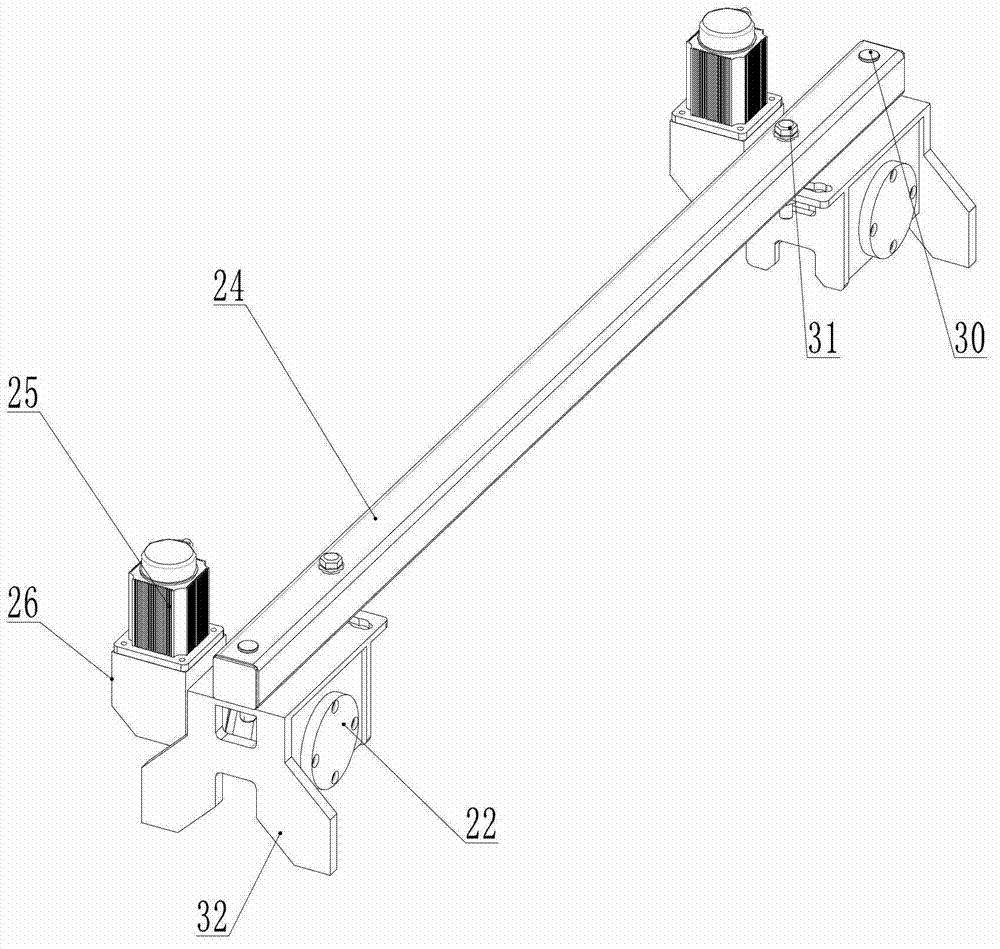

[0018] Depend on Figure 1 to Figure 4 As shown, the storage tank weld X-ray digital non-destructive testing device mainly includes a riding door frame, a motion guiding mechanism 2, a lateral moving mechanism 11, a longitudinal moving mechanism and a digital imaging system; the riding door The frame is composed of an outer frame 1 and an inner frame 18, the outer frame 1 and the inner frame 18 are connected by a fixed pin 12, and a mechanical buffer 10 and a positioning mechanism are installed between the inner and outer frames (1, 18). A limit mechanism composed of blocks 13; the upper end of the outer frame 1 is equipped with a lateral movement mechanism 11; the lower part of the outer frame 1 and the inner frame 18 are respectively equipped with two sets of motion guide mechanisms 2; the inner and outer frames (1, 18) A set of longitudinal motion mechanisms are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com