Integrated check system for emergency cut-off valve

A cut-off valve, emergency technology, applied in the direction of measuring the increase and decrease rate of the fluid, measuring devices, instruments, etc., can solve the problems of bulky calibration devices, large errors, and low calibration accuracy, so as to reduce errors and The effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

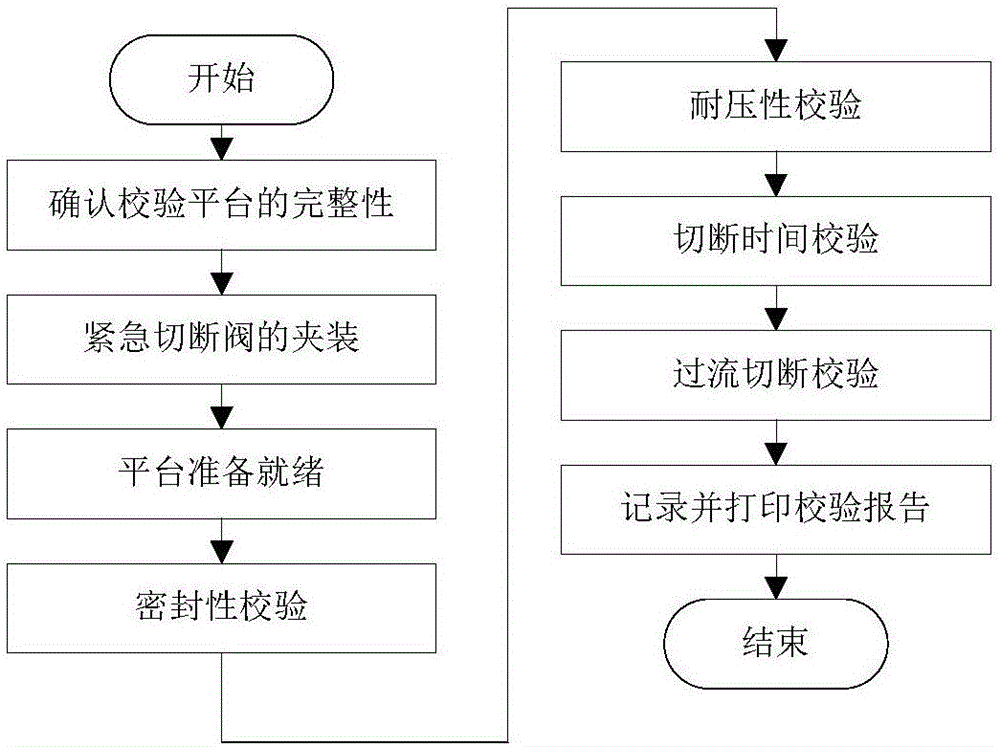

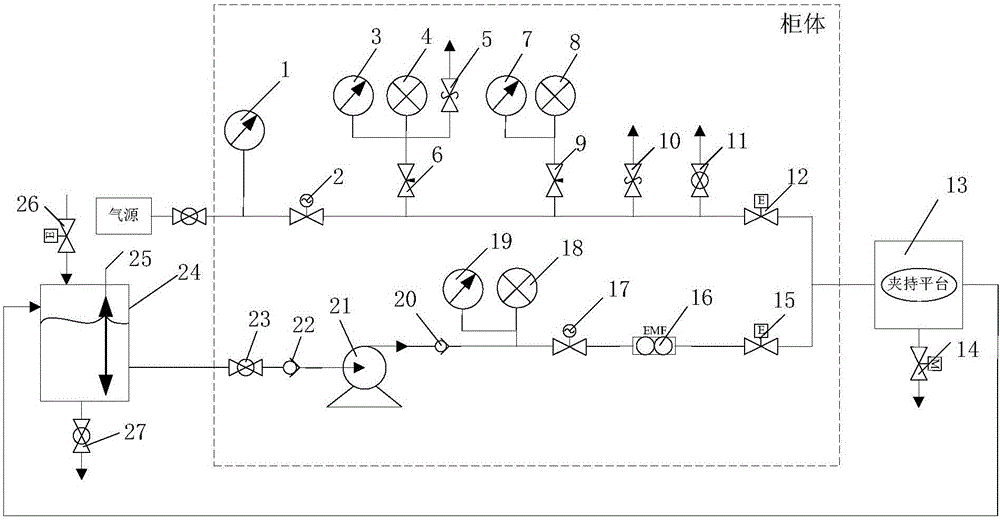

[0018] The emergency shut-off valve comprehensive verification system of the present invention is composed of a pipeline system, a clamping platform, a verification operation platform and a control system. Such as figure 1 As shown, the operation process of the calibration system is as follows: before the calibration operation starts, first check and confirm the integrity of the inspection operation platform, and clamp the emergency shut-off valve on the clamping platform to ensure that the shut-off valve is installed securely, and the system calibration When the test conditions are ready, start the test operation. The calibration sequence is: tightness calibration, pressure resistance calibration, cut-off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com