Wire binding device of transposed conductor

A technology for transposed wires and wire harnesses, which is used in the manufacture of wire harnesses, cable/conductor manufacturing, electrical components, etc. Quality, anti-bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

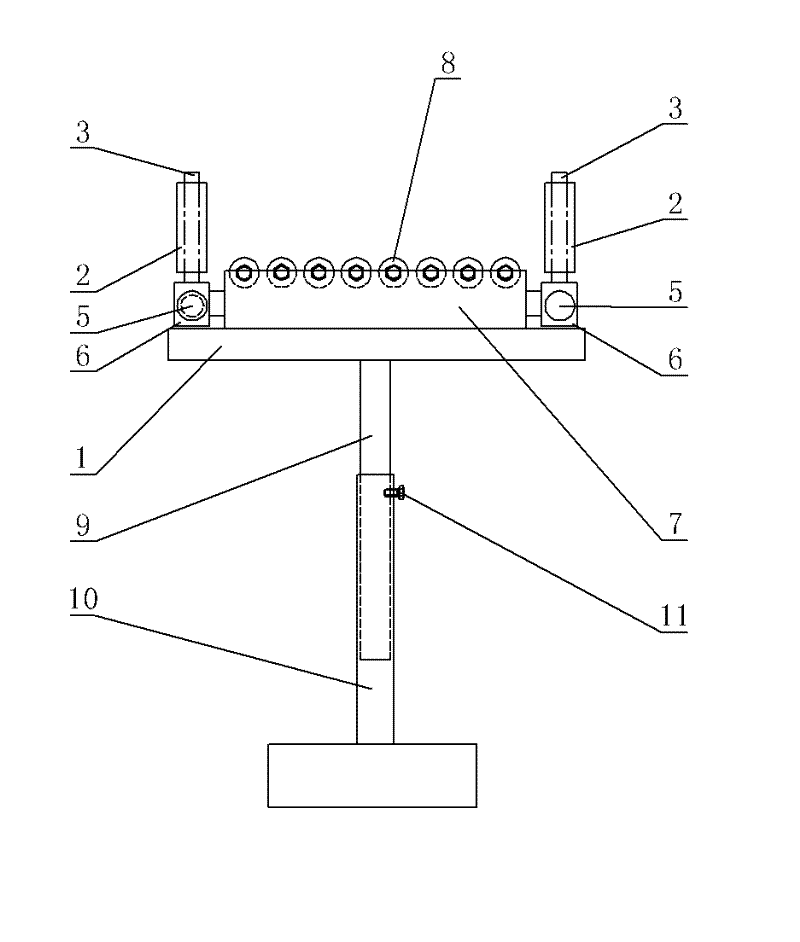

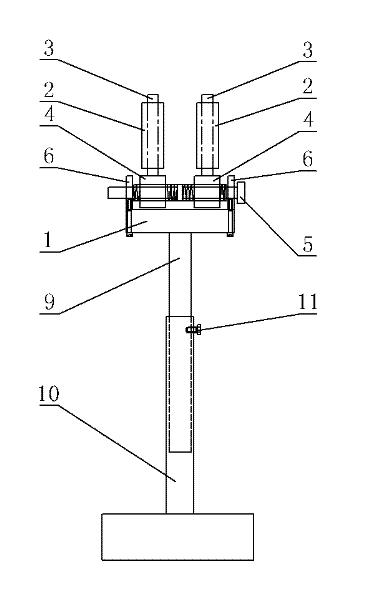

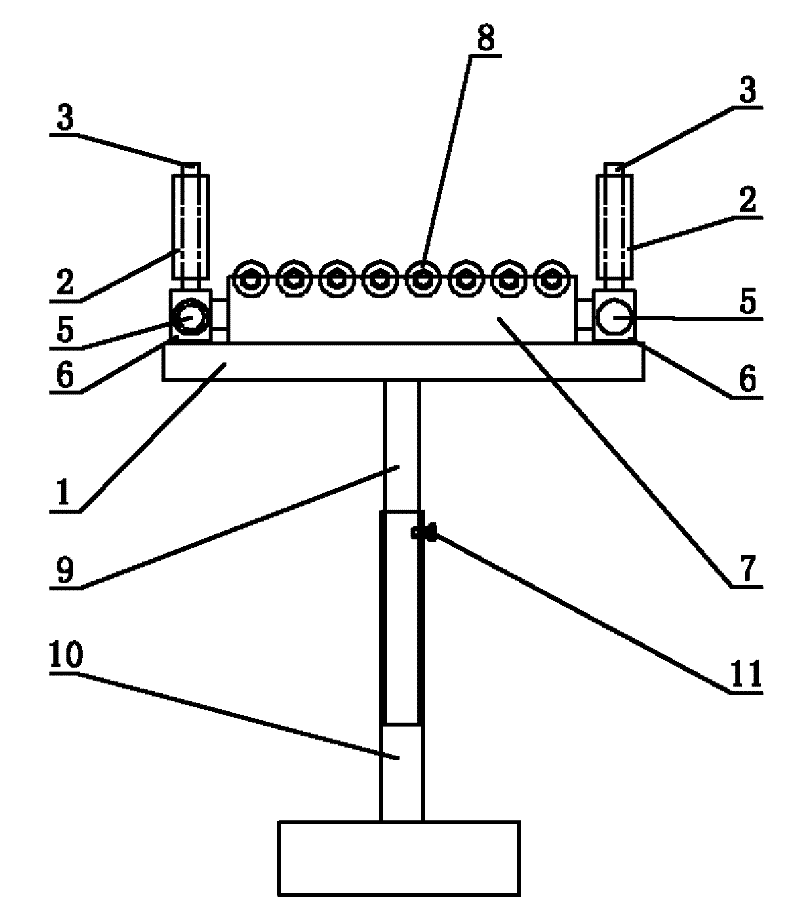

[0009] See figure 1 and figure 2 , The structure of the present invention includes a base 1, two groups of beam roller devices are installed symmetrically at both ends of the base 1, a transposition wire support frame device is installed laterally along the base 1, and a vertical adjustment mechanism is installed at the bottom of the base. Both sets of wire harness roller devices include two wire harness rollers 2, which are arranged longitudinally along the base 1; the wire harness rollers 2 are set on the wire beam rod 3, and the wire beam rod 3 is installed on the wire beam roller base 4. The two beam roller seats 4 are longitudinally connected and fixed to the connecting block 6 through the adjusting screw 5; the thread of the adjusting screw 5 is left and right symmetrical threads; the connecting block 6 is installed on the base 1; the transposition wire support frame device includes a balance support frame 7. The balance support frame 7 is horizontally arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com