Clothes drying machine microswitch control device with roller

A micro switch and control device technology, applied in the direction of clothesline, washing device, other drying devices, etc., can solve the wear and tear of the micro switch drive rod, the lack of clothesline limit mechanism, and the detachment of the micro switch control device and other problems to achieve the effect of avoiding friction, reducing friction, and preventing wire jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

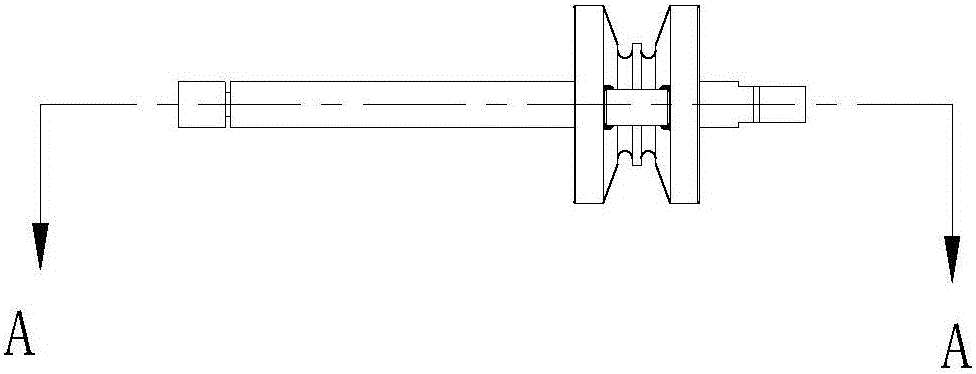

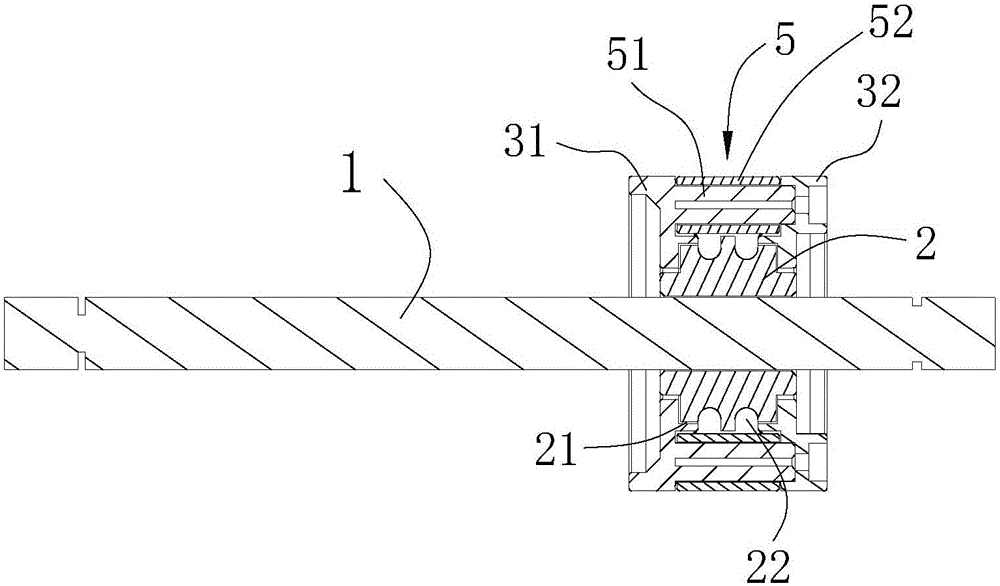

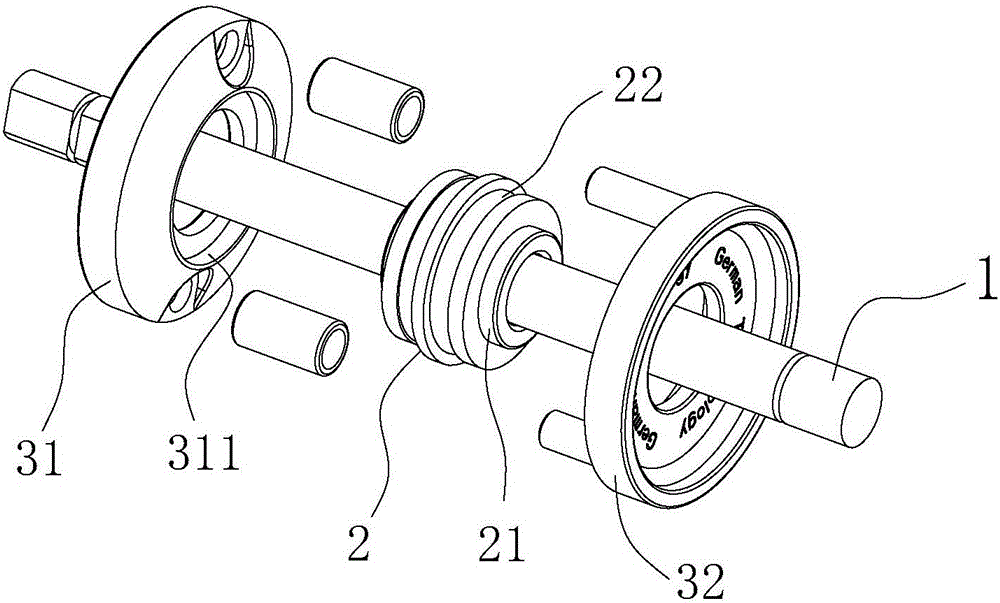

[0020] as attached figure 1 to attach Figure 4 As shown, a clothes dryer micro switch control device with rollers includes a micro switch driving rod 1, and also includes a roller mechanism that slides left and right along the micro switch driving rod 1, and the roller mechanism includes a sleeve The left roller wall 31 and the right roller wall 32 of the micro switch driving rod 1 are sandwiched between the left roller wall 31 and the right roller wall 32 for surrounding the micro switch under the friction of the clothesline 4 The rolling wheel 2 that drives the rod 1 to rotate, and the limit mechanism for preventing the clothesline 4 from detaching from the rolling wheel mechanism.

[0021] Preferably, the scroll wheel 2 is sheathed on the micro switch driving rod 1 and is in clearance fit with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com