Method for cutting workpiece and device for changing rolling width of wire cutting workpiece

A technology for wire coils and workpieces, which is applied to fine working devices, working accessories, and knives of sawing machine devices, which can solve problems such as retention and achieve the effect of preventing wire jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

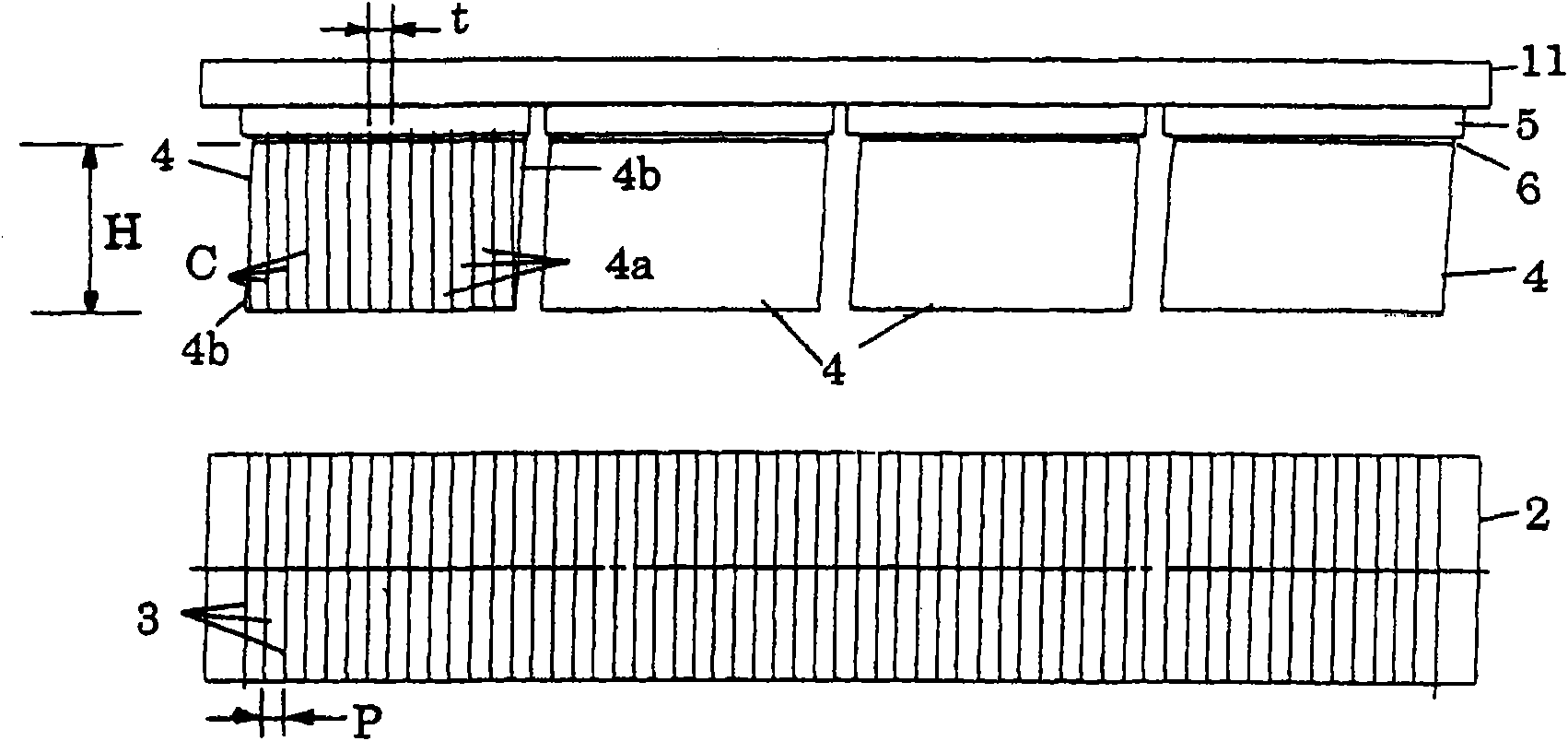

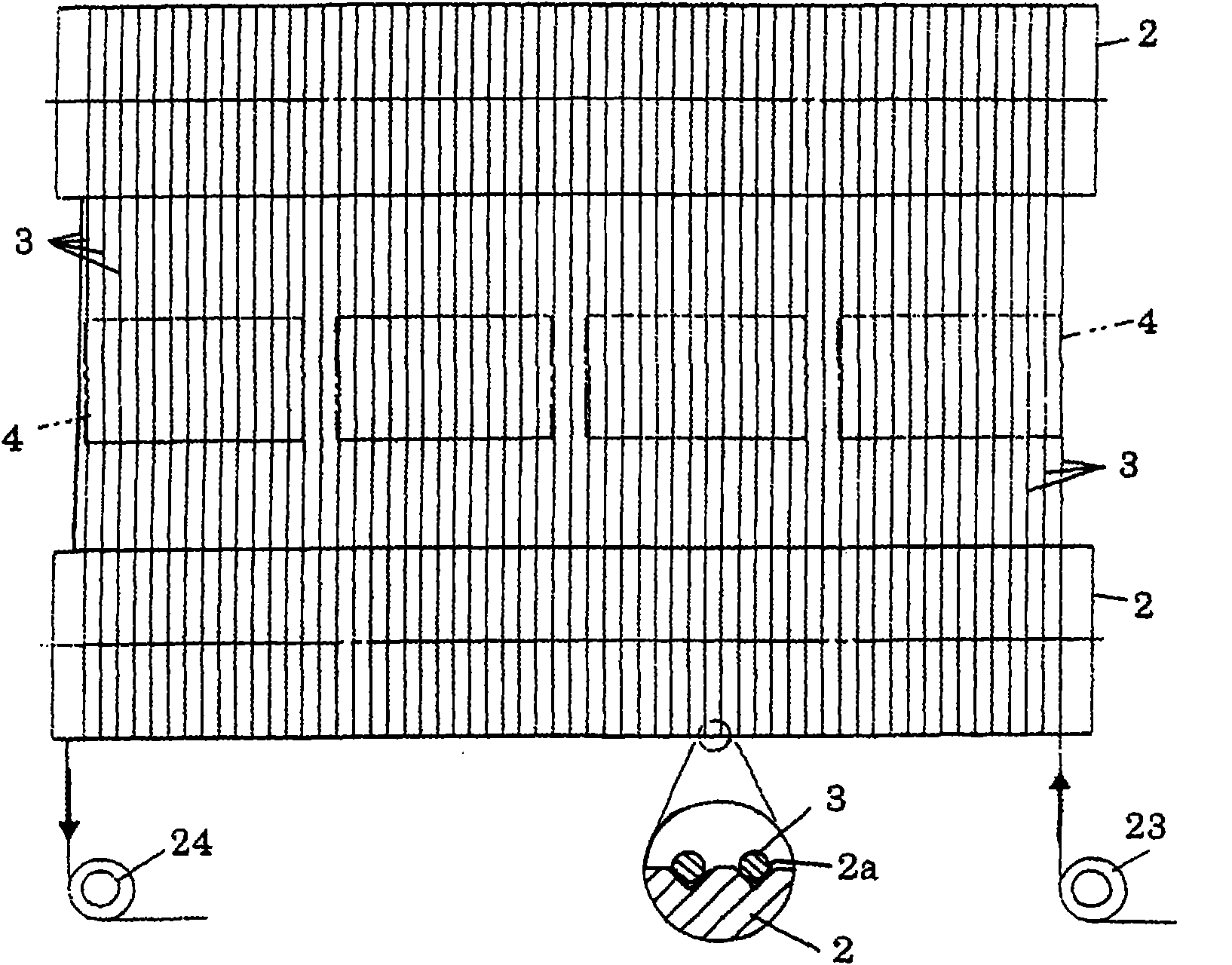

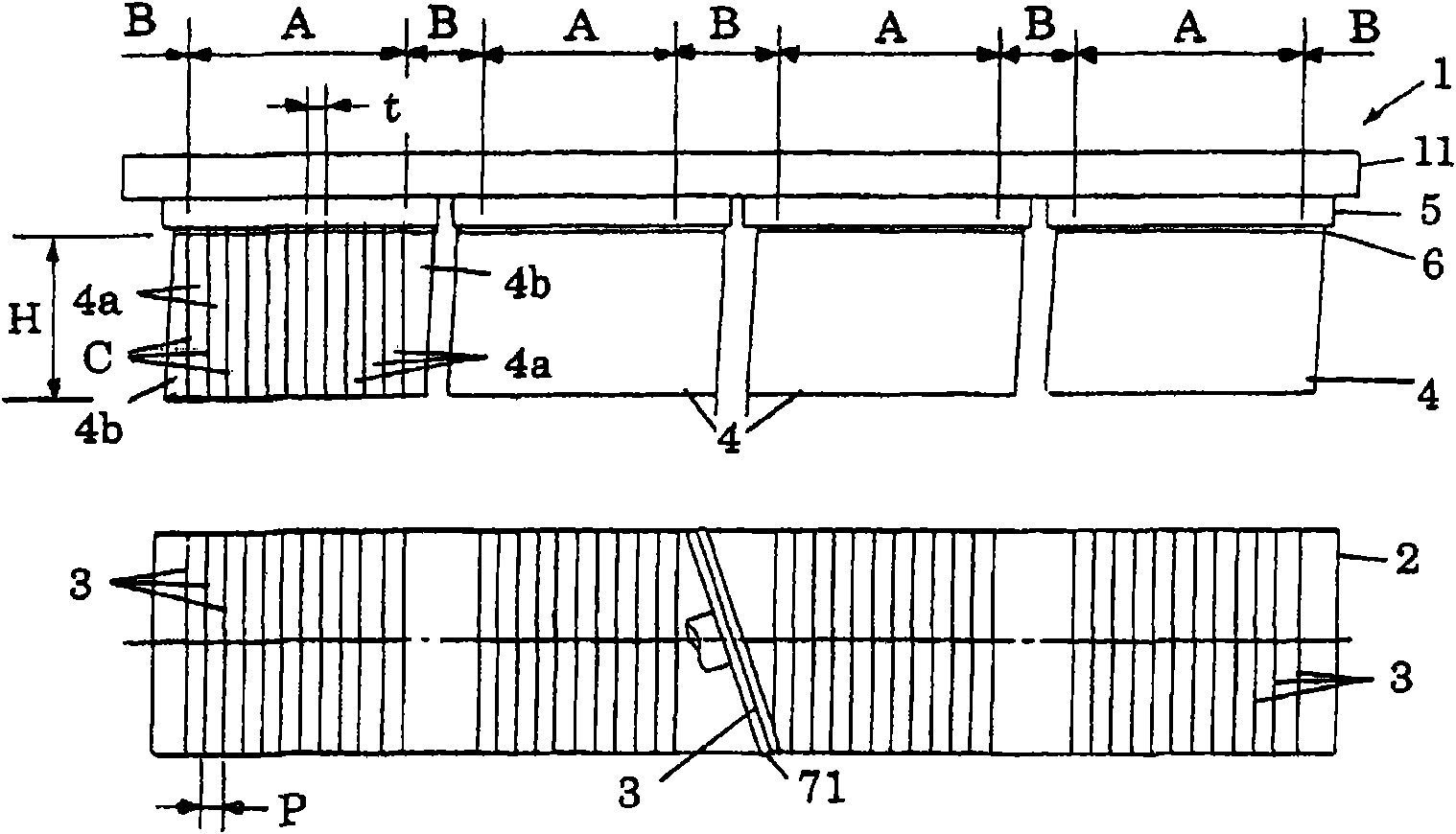

[0048] image 3 and Figure 4 It shows a method when a plurality of, for example, four workpieces 4 are simultaneously cut using the workpiece cutting method according to the present invention. At that image 3 as well as Figure 4 In, as an example of the wire saw 1, the multi-wound wire 3 is moved between two parallel main rollers 2, and four workpieces 4 are abutted on the wire 3 in the running state, thereby the workpiece 4 Cut to the target thickness t.

[0049] The wire 3 is pulled out by a delivery device not shown, and is wound in multiple times along the grooves 2a of the main rollers 2 between the plurality of main rollers 2 via the guide roller 23 with grooves, and is wound with the workpiece After forming parallel cutting areas at the positions facing each other, it is sent out to a winding device not shown via a guide roller 24 with grooves.

[0050] The grooves 2a of the main roller 2, such as Figure 4 As shown in the enlarged cross-sectional view in the circle, V-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com