Combined transformer

A transformer and combined technology, applied in the field of transformers, can solve problems such as reducing the production cost of transformers, and achieve the effects of ensuring stability, convenient disassembly and integration, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

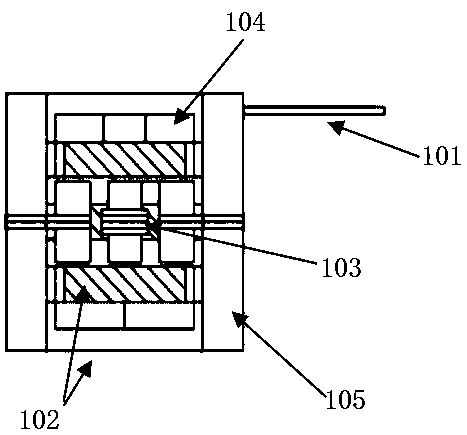

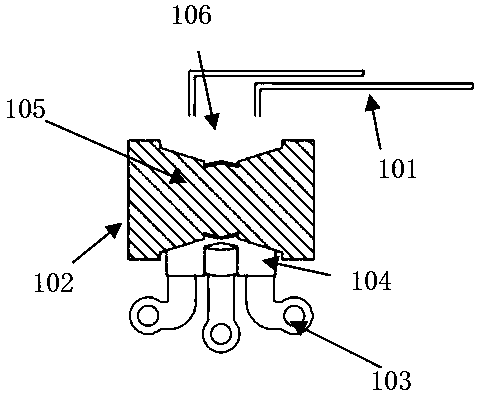

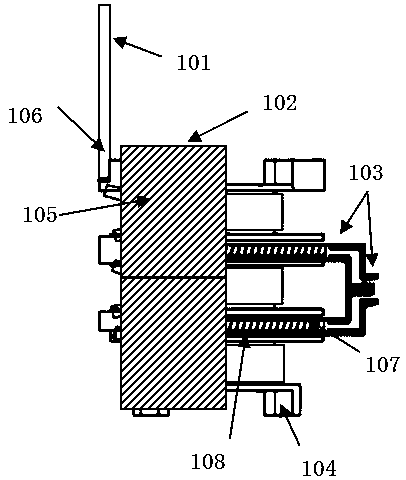

[0017] Such as image 3 , figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 As shown, the skeleton 104 and the magnetic core 105 of the present invention are in the shape of PQ, three winding slots are processed on the outer wall of the skeleton 104, a skeleton hole 109 is processed in the middle of the skeleton 104, and the skeleton 104 between adjacent winding slots is also processed There is an annular limiting hole 108 parallel to the winding slot, thereby forming a first limiting hole and a second limiting hole, and two annular copper sheets 103 are respectively inserted in the first limiting hole and the second limiting hole , the ring-shaped copper sheet 103 is processed with a broken seam 113, and the ring-shaped copper sheet at both ends of the broken seam 113 is respectively processed with a direct wire terminal 111 and a bent wire terminal 112, and the end of the direct wire terminal 111 and the end of the bent wire terminal 112 Parts are processed with ...

Embodiment 2

[0020] Such as Figure 4 , figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 As shown, the skeleton 104 and the magnetic core 105 of the present invention are in the shape of PQ, three winding slots are processed on the outer wall of the skeleton 104, a skeleton hole 109 is processed in the middle of the skeleton 104, and the skeleton 104 between adjacent winding slots is also processed There is an annular limiting hole 108 parallel to the winding slot, thereby forming a first limiting hole and a second limiting hole, and two annular copper sheets 103 are respectively inserted in the first limiting hole and the second limiting hole , the ring-shaped copper sheet 103 is processed with a broken seam 113, and the ring-shaped copper sheet at both ends of the broken seam 113 is respectively processed with a direct wire terminal 111 and a bent wire terminal 112, and the end of the direct wire terminal 111 and the end of the bent wire terminal 112 Parts are processed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com