Device for reducing wire jumping rate in silicon rod cutting and cutting method

A cutting method and wire skipping rate technology, which is applied in the field of devices for reducing the wire jumping rate of silicon rod cutting, can solve the problems of wire jumping, reduce the wire jumping rate of silicon rod cutting, diamond wires are easily squeezed out of the groove by foreign objects, and achieve Make up for the hidden danger of disconnection and avoid the effect of jumping wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

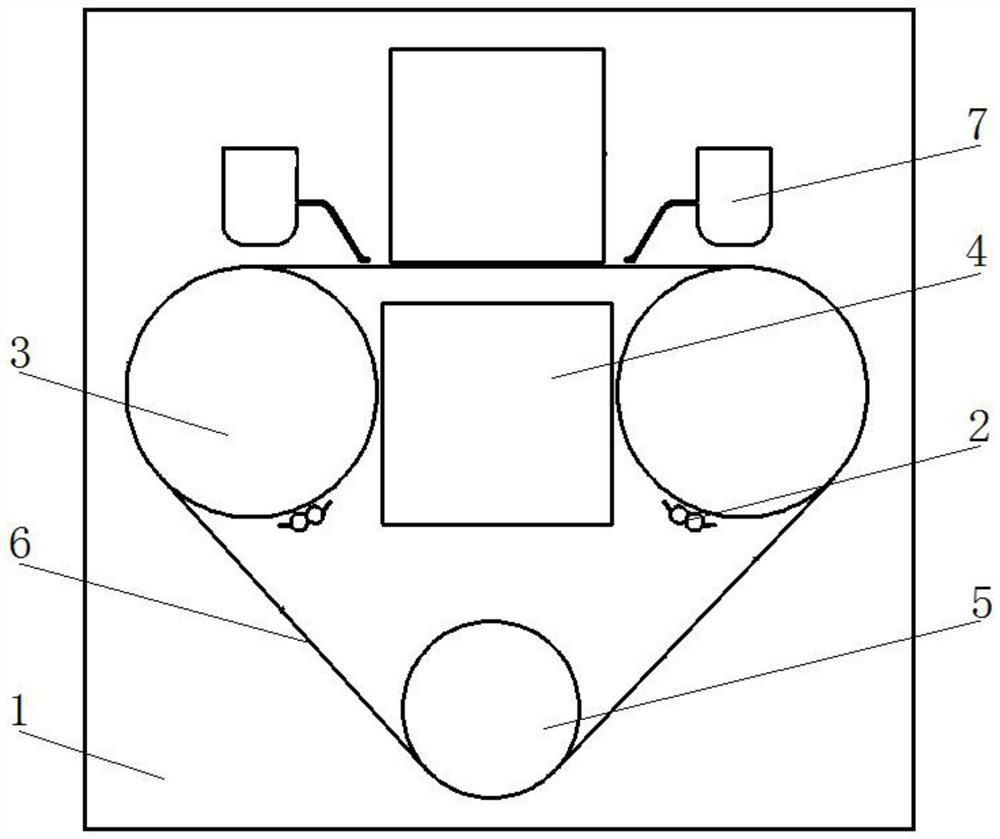

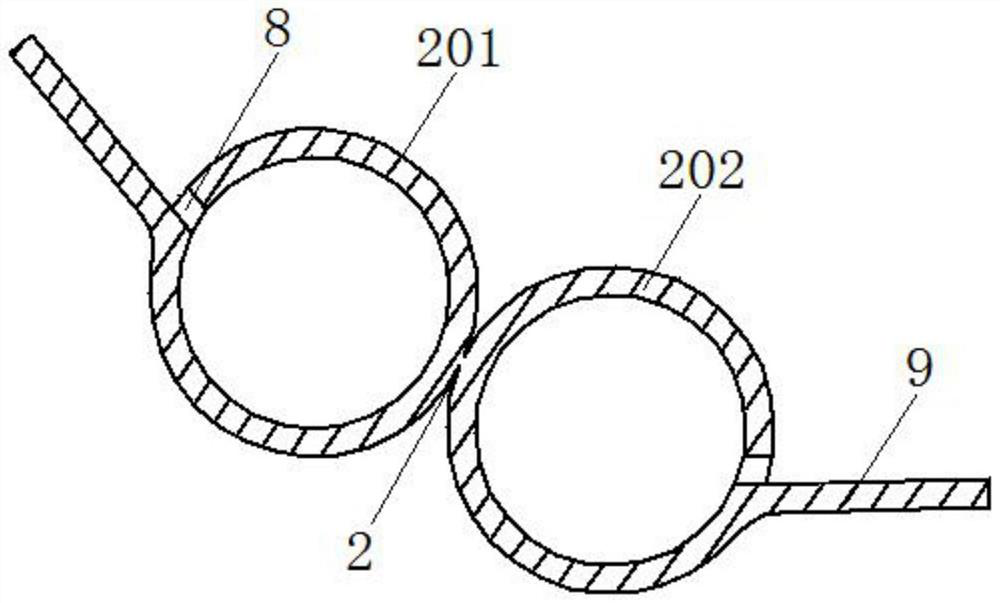

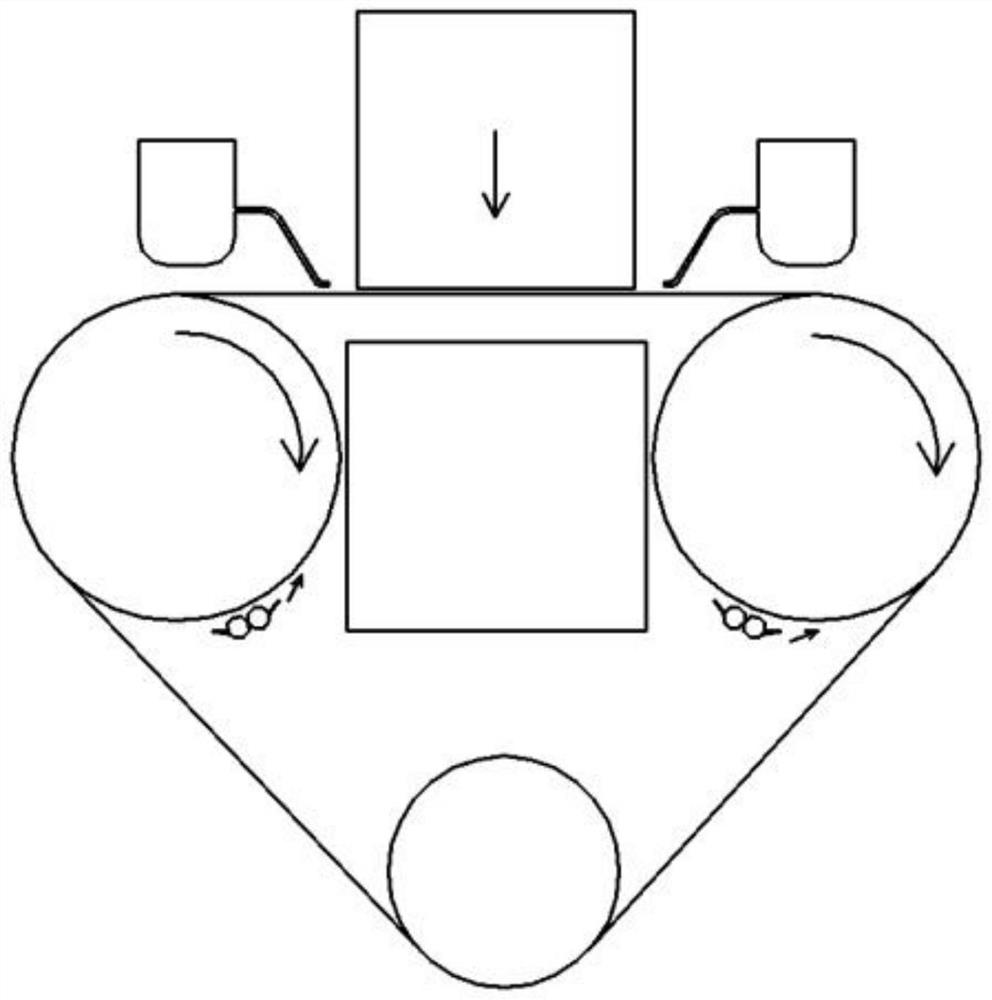

[0028] see figure 1 , figure 2 , this embodiment provides a device for reducing wire skipping rate in silicon rod cutting, which includes a slicer body 1 and an air duct assembly 2, the slicer body 1 is symmetrically provided with main rollers 3, and between the two main rollers 3 is a Fragment groove 4, a small roller 5 is arranged below the fragment groove 4, diamond wire 6 is arranged on the main roller 3 and the small roller 5, and the diamond wire 6 is arranged in the wire groove on the main roller 3 and the small roller 5, and the upper part of the main roller 3 A mortar pipe 7 is provided, and the air duct assembly 2 is arranged below the main roller 3. One end of the air duct assembly 2 is fixed on the inner wall of the slicer body 1, and the other end of the air duct assembly 2 is connected to the bronchial interface on the inner wall of the slicer body 1. Both sides of the air duct assembly 2 are provided with air outlets 8, and both sides of the air duct assembly ...

Embodiment 2

[0039] see figure 1 , figure 2 , this embodiment provides a device for reducing wire skipping rate in silicon rod cutting, which includes a slicer body 1 and an air duct assembly 2, the slicer body 1 is symmetrically provided with main rollers 3, and between the two main rollers 3 is a Fragment groove 4, a small roller 5 is arranged below the fragment groove 4, diamond wire 6 is arranged on the main roller 3 and the small roller 5, and the diamond wire 6 is arranged in the wire groove on the main roller 3 and the small roller 5, and the upper part of the main roller 3 A mortar pipe 7 is provided, and the air duct assembly 2 is arranged below the main roller 3. One end of the air duct assembly 2 is fixed on the inner wall of the slicer body 1, and the other end of the air duct assembly 2 is connected to the bronchial interface on the inner wall of the slicer body 1. Both sides of the air duct assembly 2 are provided with air outlets 8, and both sides of the air duct assembly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com