Impedance-pH electrode catheter and processing method thereof

An electrode catheter and processing method technology, applied in the field of medical devices, can solve the problems such as the inability to meet the production capacity demand of impedance-pH electrode catheters, the winding of insulated wires, and the low efficiency, so as to avoid uneven glue, avoid disconnection, and ensure reliable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

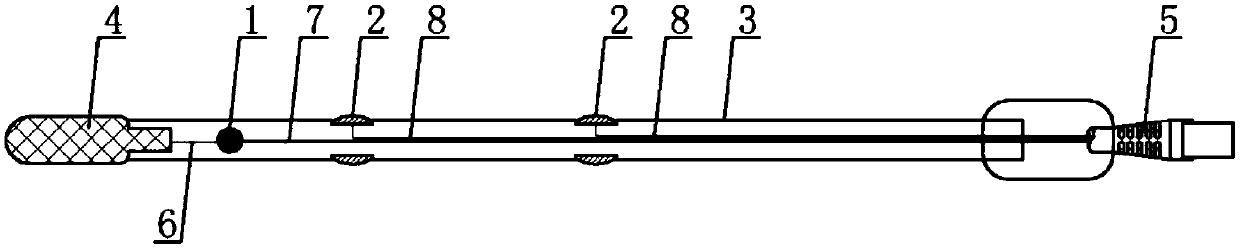

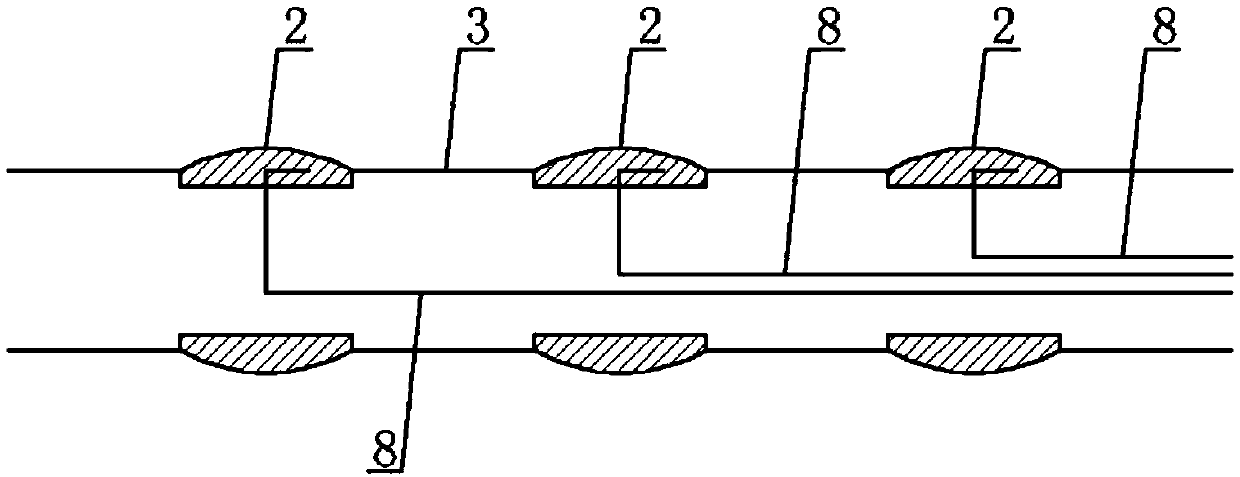

[0038] Such as figure 1 The impedance-pH electrode catheter shown includes a catheter body 3 with an antimony electrode 1 and an impedance component 2 on the side, a reference electrode 4 is arranged at the front end of the catheter body 3, and a connection module is arranged at the rear end of the catheter body 3 5. The first insulated wire 6, the second 7 insulated wire 7 and the third 8 insulated wire whose rear end is connected to the connection module 5 are perforated in the conduit body 3, wherein the first 6 insulated wire, the second 7 insulated wire 7 and the third 8 insulated wire are all enameled wire, and the front end of the insulated wire 6 is connected to the reference electrode 4, and the front end of the insulated wire 2 7 is connected to the antimony electrode 1.

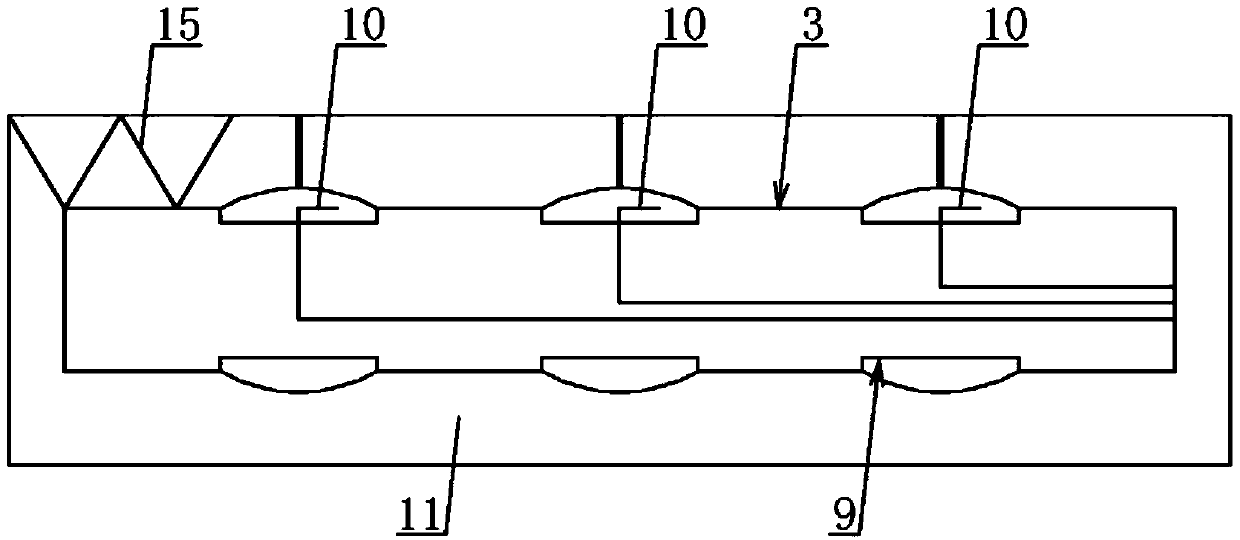

[0039] Such as image 3As shown, there is an annular positioning groove 9 recessed radially along the catheter body 3 on the side of the catheter body 3. The impedance component 2 is closed and an...

Embodiment 2

[0054] The structural principle of this embodiment is basically the same as the structural principle of Embodiment 1, the difference is that the mold 11 is set in a cylindrical or elliptical shape as a whole, and when heating in step 5, the mold 11 is put into a reflow furnace as a whole for heating .

Embodiment 3

[0056] The structural principle of this embodiment is basically the same as that of the first embodiment, except that the raw material is a tin-bismuth alloy solder paste with a tin content of 42%, a bismuth content of 58%, and a heating temperature of 138°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com