Membrane bioreactor for denitrification and waste water denitrification method

A membrane bioreactor and denitrification technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. High energy consumption, many return pipelines, etc., achieve the effect of reducing membrane fouling, overcoming high energy consumption, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

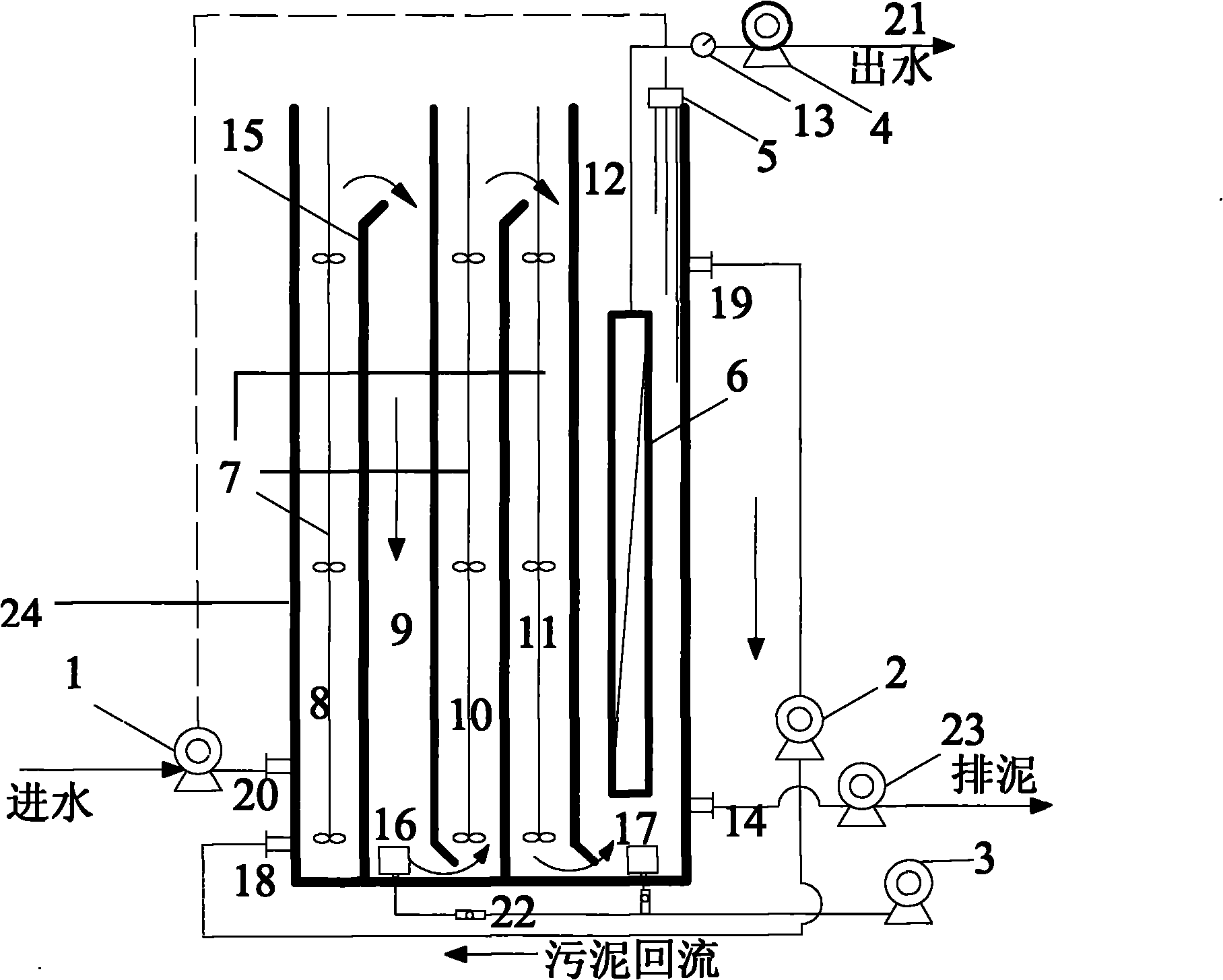

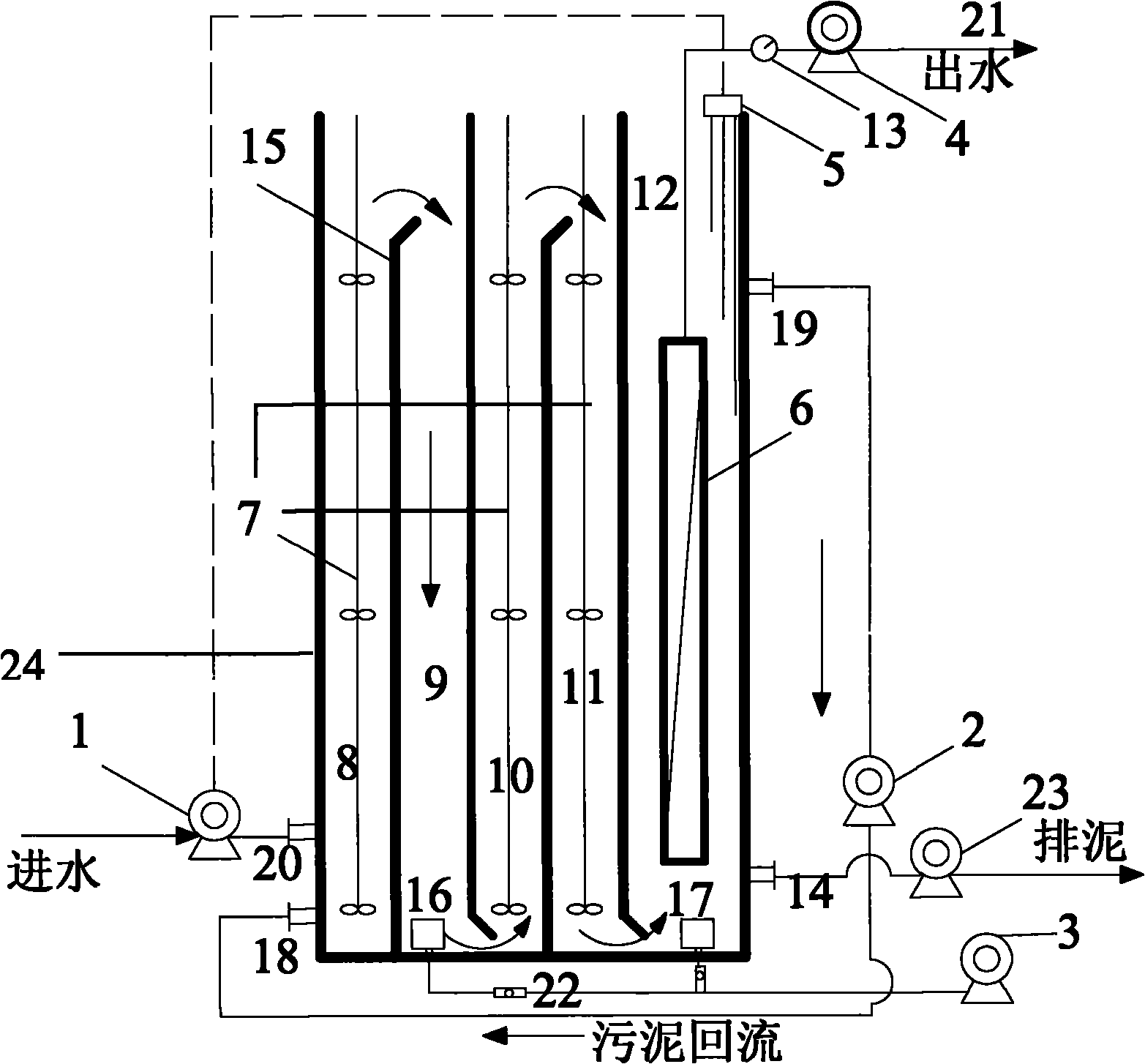

[0032] Reactor build:

[0033] In a reactor 24 with a total volume of 50L, the reactor is divided into five small tanks connected in series with four vertical guide baffles 15, which are respectively the first anoxic tank 8 with a volume of 8.69L, and the first anoxic tank 8 with a volume of 8.69L. The aerobic pool 9 with a volume, the second anoxic pool 1 with a volume of 8.69L, the anaerobic pool 11 with a volume of 8.69L and the membrane pool 12 with a volume of 14L, the ratios of the height and diameter of the five reaction pools are 13, 13, 13, 13 and 8.33; the membrane module 6 is vertically placed in the membrane pool 12, which is a PVDF flat microfiltration membrane with a membrane pore size of 0.1 μm and a membrane area of 0.23m 2 .

[0034]The bottom of the first anoxic pool 8 is connected with a water inlet 20, and the water inlet 20 is connected with a water inlet pump 1; the membrane module 6 is connected with a water outlet 21, and the water outlet 21 is conne...

Embodiment 2

[0038] Nitrogen removal treatment of sewage:

[0039] The equipment constructed in Example 1 is used for sewage treatment. The sewage enters from the water inlet and passes through the reaction tanks at all levels. 200%; membrane water output 16.2L h -1 m - The sludge concentration in the reactor is 6000-7000mg / L, the temperature is about 20°C, the dissolved oxygen concentration in the aerobic pool 9 is about 1mg / L, and the dissolved oxygen concentration in the membrane pool 12 is about 3mg / L; the first anoxic pool 8 , The dissolved oxygen in the second anoxic tank 10 and the anaerobic tank 11 is 0.11mg / , 0.12mg / , almost zero. The present invention sets different reaction pH conditions, between 6.5-8.5, the changes of pH and dissolved oxygen are shown in Table 1.

[0040] Influent water is simulated domestic wastewater, COD content 300-500mg / L, NH 4 -N content 30-50mg / L, TN content 60-100mg / L, COD / TN about 5; effluent COD 30-60mg / L, average removal rate about 90%, NH 4 -N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com