Silicone diaphragm, speaker module and method for reprocessing the silica gel diaphragm

A technology of silicone diaphragm and welding part, which is applied in the direction of fixing/tightening the diaphragm, planar diaphragm, sensor, etc. It can solve the problems of easy falling off of the conductive layer, poor acoustics, unbalanced vibration system, etc., and avoid the risk of fracture , Improve product stability and avoid the risk of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

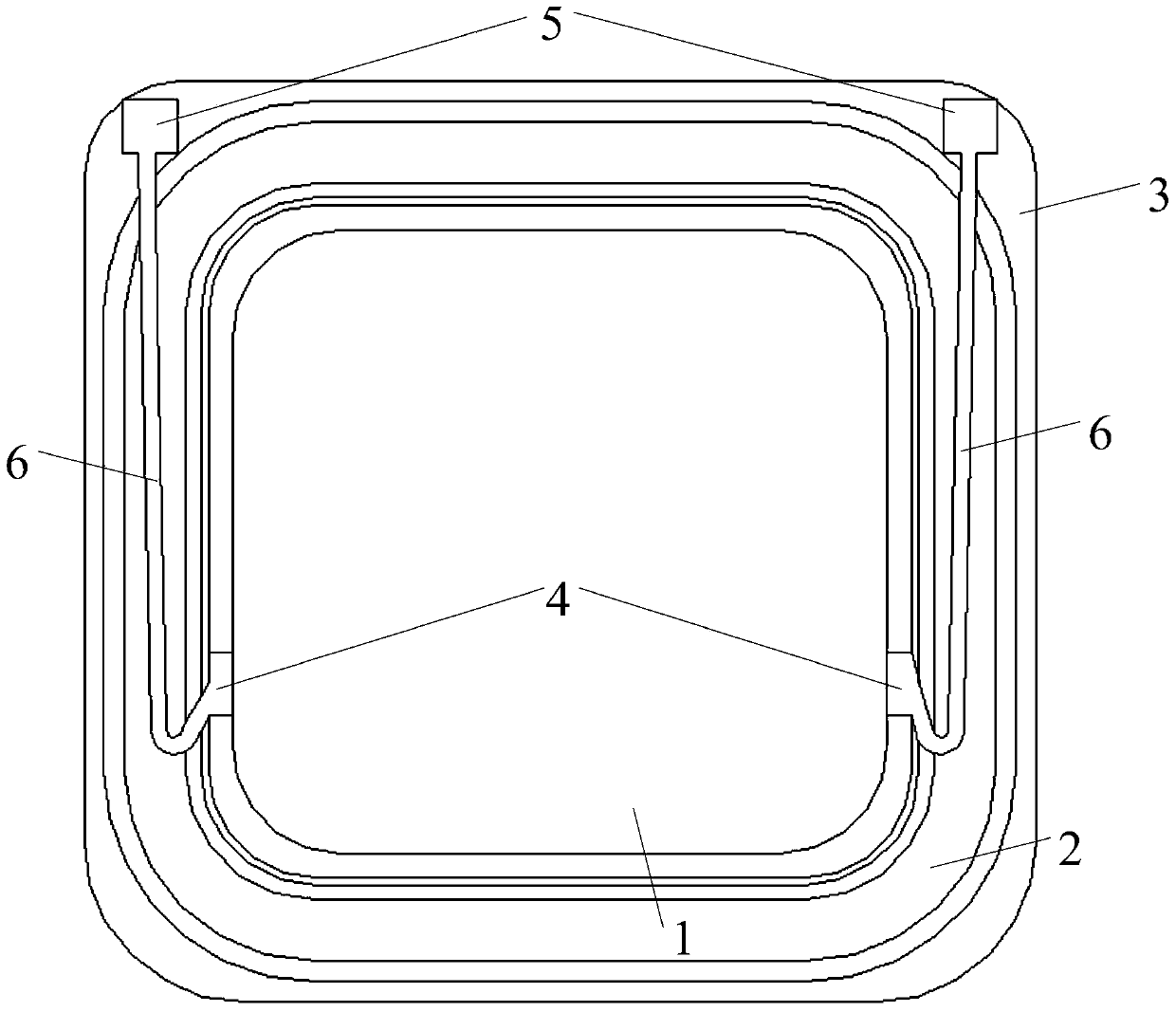

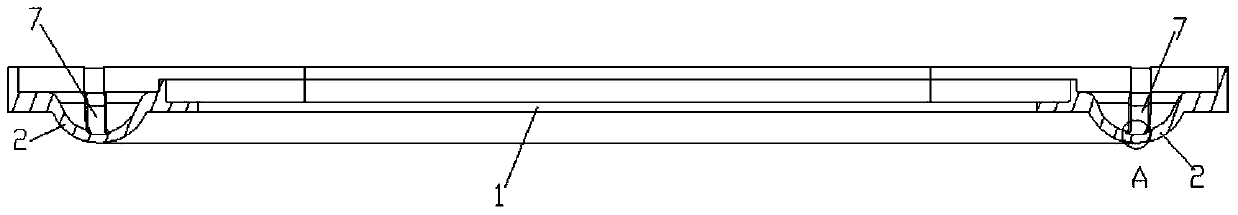

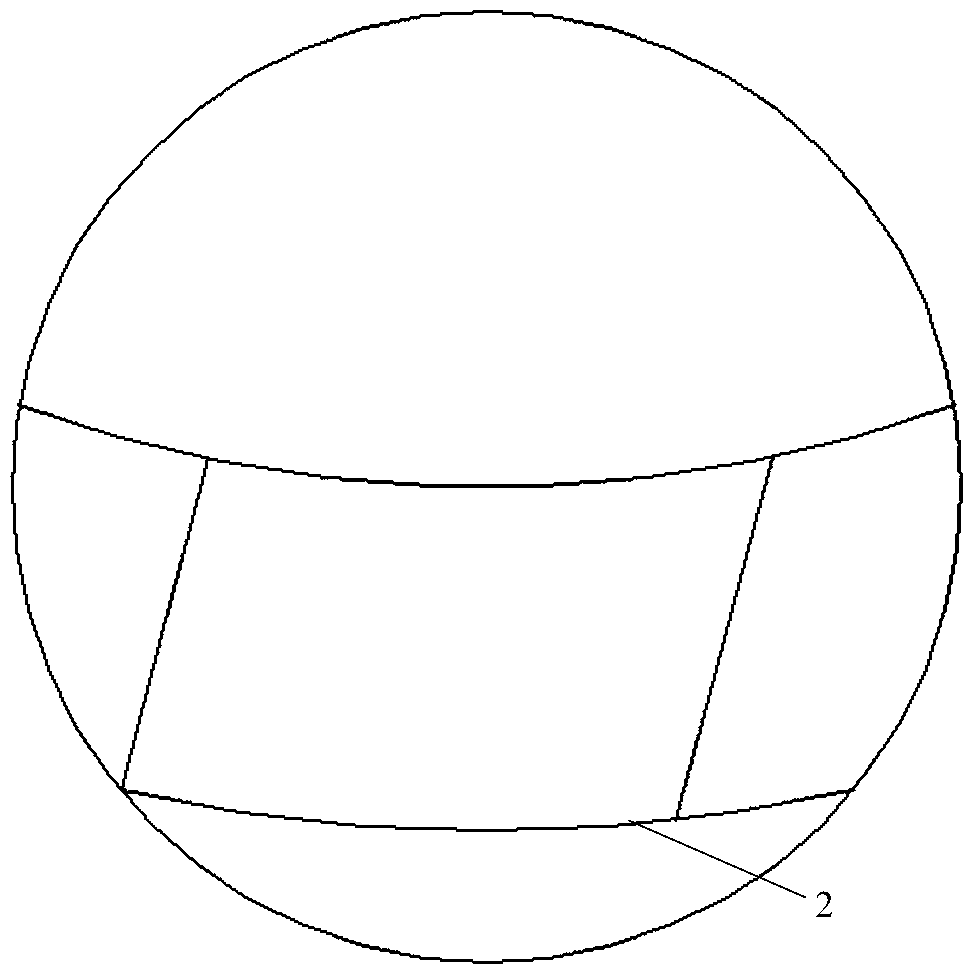

[0030] Such as figure 1 and figure 2 Commonly shown, this embodiment provides a silicone diaphragm, including a plane part 1 located in the center, a ring part 2 arranged on the edge of the plane part 1, and a fixing part connected to the periphery of the ring part 2 for bonding the shell 3.

[0031] In this embodiment, laser etching technology is used to etch two symmetrical line grooves on the surface of the silica gel diaphragm to ensure the balance of the diaphragm.

[0032] Wherein, each line groove is deposited with a conductive metal layer, and the two ends of each conductive metal layer are provided with a first welding part 4 and a second welding part 5, and the first welding part 4 is deposited on the silicone diaphragm ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com