Cutting method of workpiece

A technology for workpiece cutting and processing, which is applied to work accessories, manufacturing tools, stone processing equipment, etc., can solve problems such as poor wafer quality, and achieve the effects of avoiding the risk of disconnection, improving processing quality, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

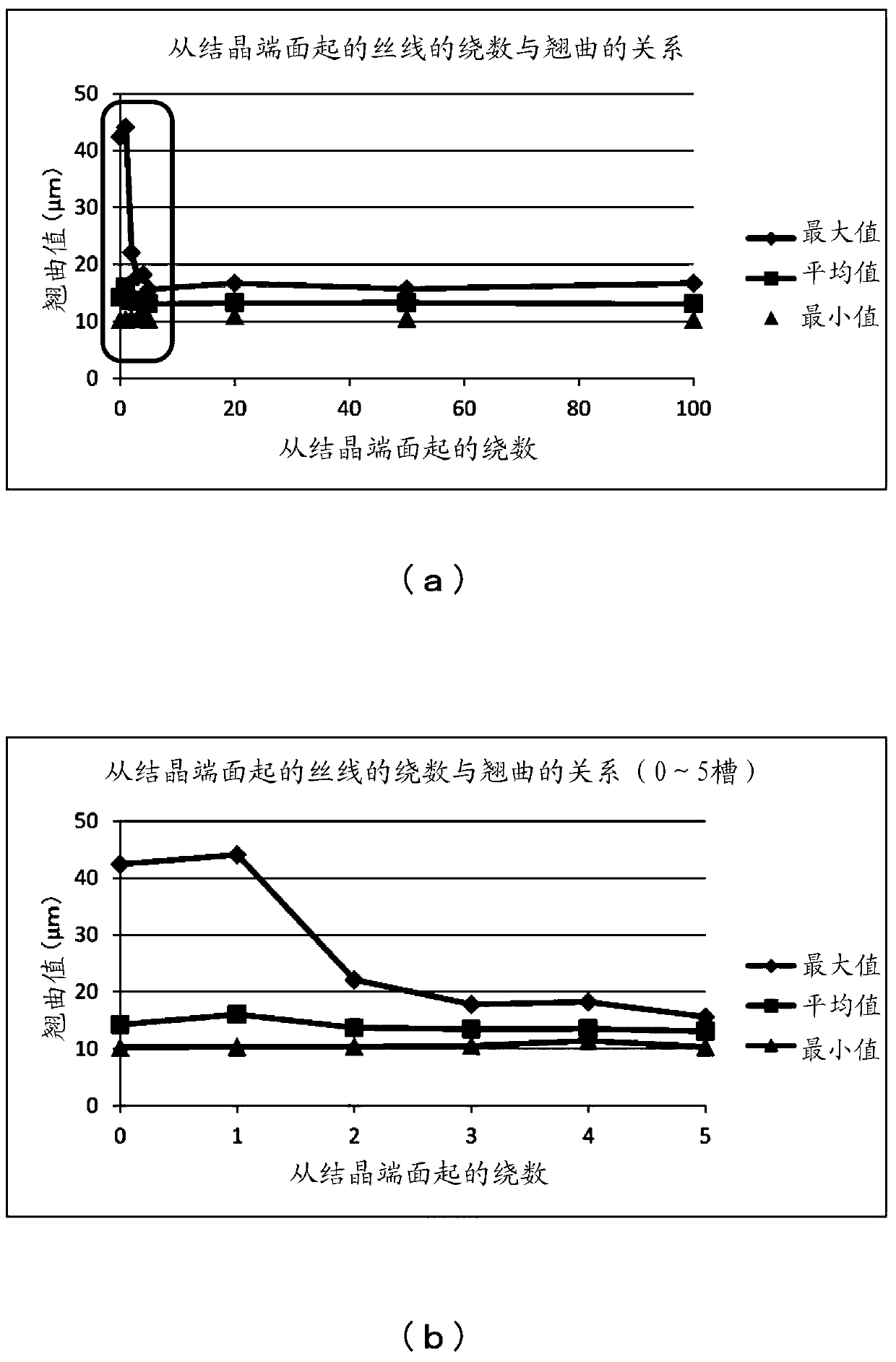

Examples

Embodiment Construction

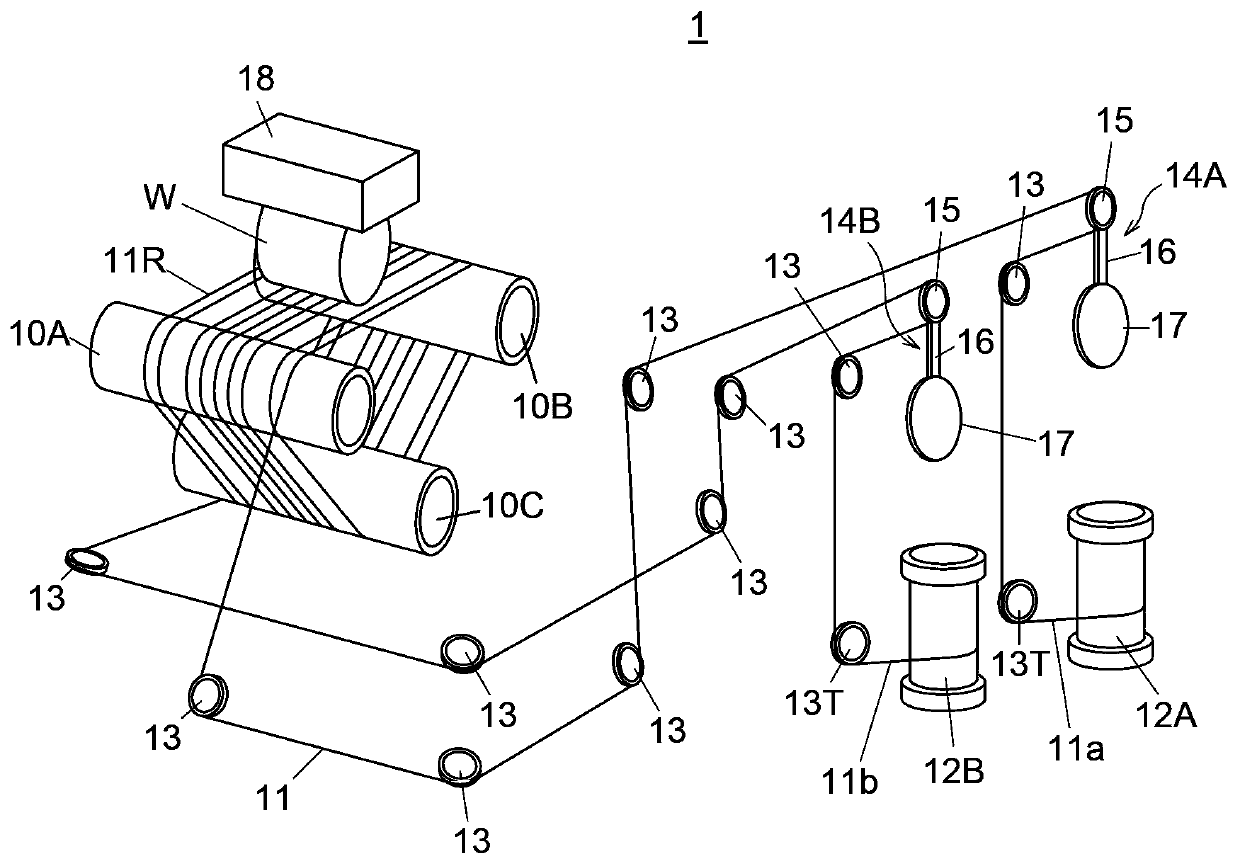

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

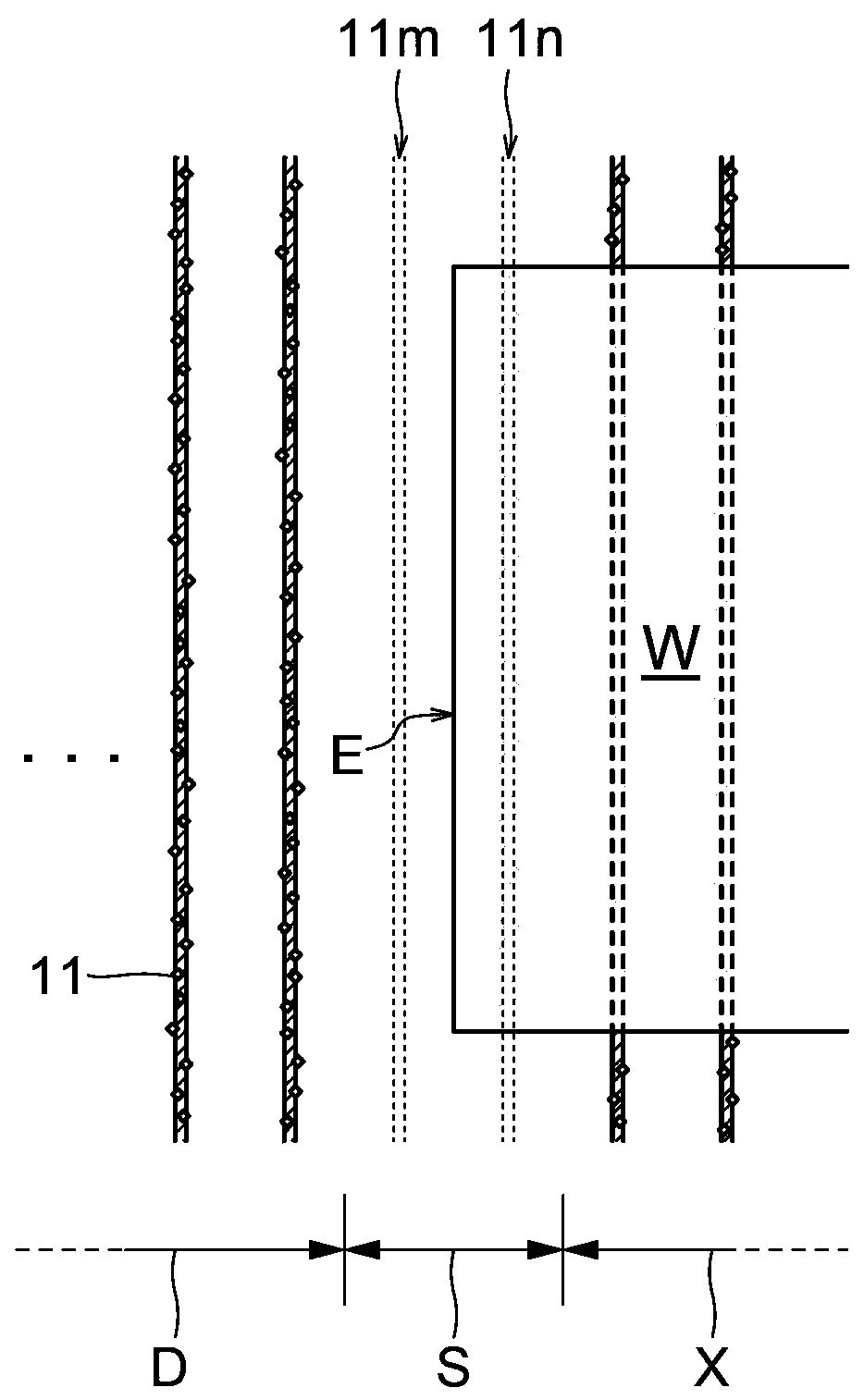

[0022] figure 1 It is a perspective view which schematically shows the whole structure of the wire saw 1 which concerns on embodiment of this invention.

[0023] Such as figure 1 As shown, the wire saw 1 includes three main rollers 10A, 10B, and 10C arranged in parallel to each other, and a wire row 11R formed by winding one wire 11 multiple times between the three main rollers 10A, 10B, and 10C. First and second reels 12A, 12B for winding one end 11a and the other end 11b of the wire 11, a plurality of guide rollers 13 including a traverse roller 13T, and a pair of tension regulators for adjusting the tension of the wire 11 Mechanisms 14A, 14B.

[0024] The main rolls 10A, 10B, and 10C are grooved rolls, and a large number of annular grooves are formed at regular intervals on the outer peripheral surface. As the main roll, for example, a structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com