Method for knitting grid knitted fabric composed of bent stripes

A technology of knitted fabrics and stripes, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of no weaving method and achieve the effect of smooth appearance, smooth weaving process and enlarged coil length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

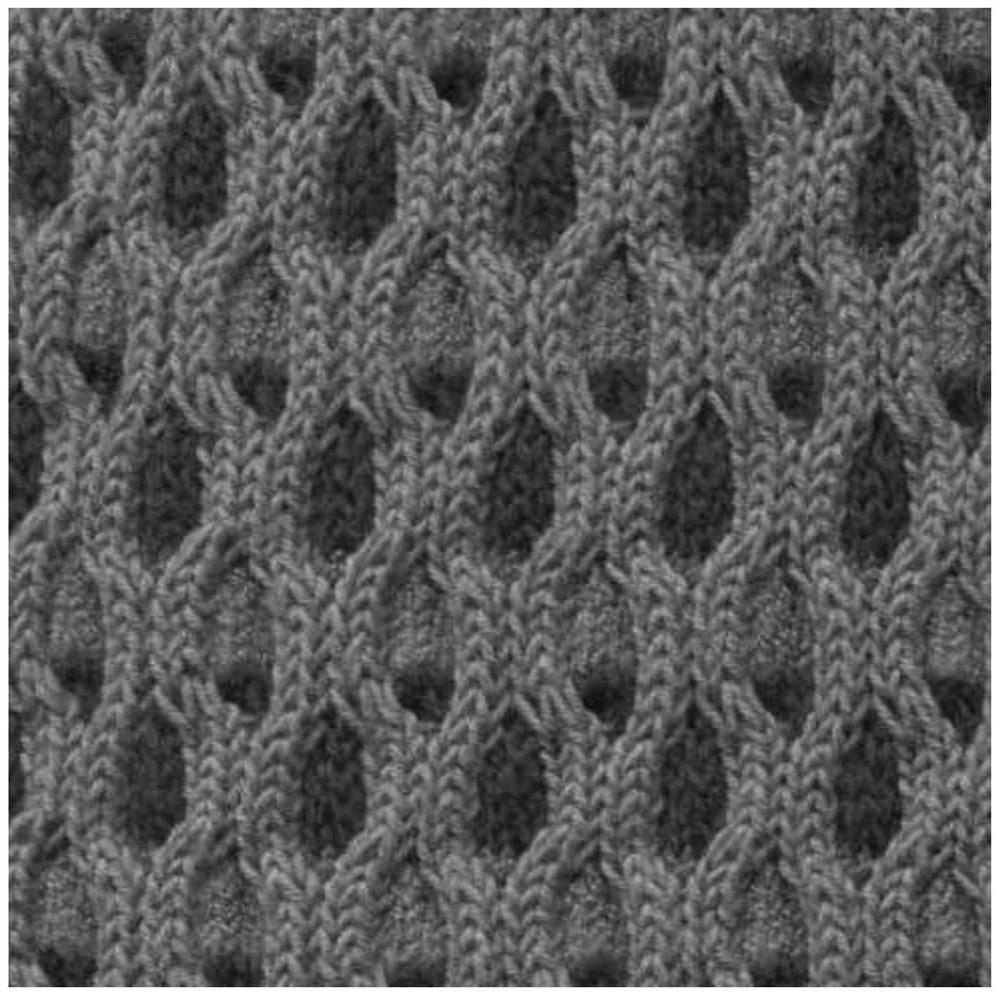

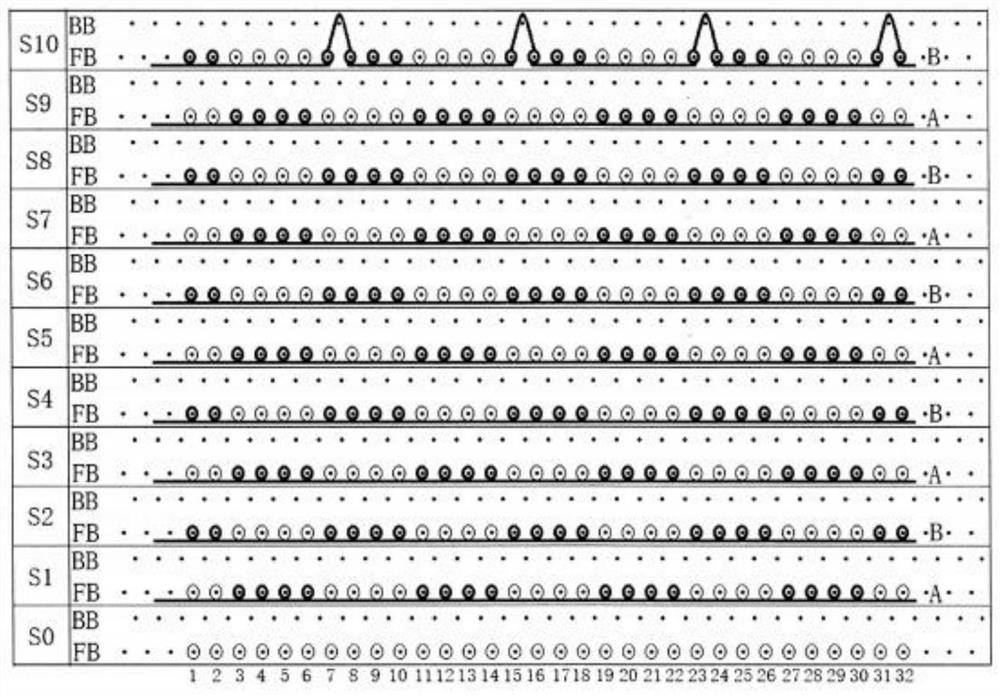

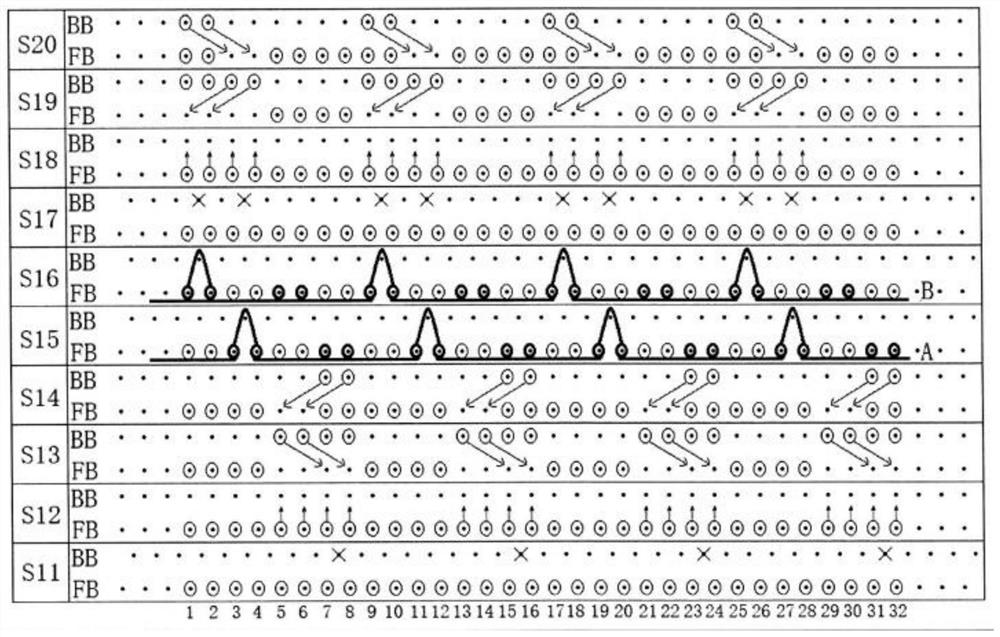

[0038] figure 1 It is a physical picture corresponding to the specific implementation method, which is woven by three color yarns. If the color of the yarn used for the curved stripes is set to color A, and the yarns of the other two colors are set to color B and color C, the bending The stripes consist of two vertical stripes of stitches of color A that are misplaced, and left and right cable slanted stitches, and the stitches of the yarn of color A are on the front side of the knitted fabric, and the stripes of yarn of color B or C It is inlaid with the vertical stripes of the A color coil, and the left and right twisted slanted stitches are on the opposite side of the knitted fabric. In addition, some slanted stitches have enlarged stitches. figure 2 With figure 1 The corresponding weaving process diagram, image 3 With figure 2 Continuing weaving process diagram, Figure 4 With image 3 Continuing weaving process diagram, Figure 5 With Figure 4 The continuous kn...

specific Embodiment approach 2

[0101] The second embodiment is woven with yarns of two colors. If the color of the yarn used for the curved stripes is set to color A, and the yarn of the other color is set to color B, Image 6 It is the weaving process diagram corresponding to the second specific embodiment, Figure 7 With Image 6 Continuing weaving process diagram, Figure 8 With Figure 7 Continuing weaving process diagram, Figure 9 With Figure 8 The continuous weaving process diagram, in the figure, the "T+ number" in the left column indicates the weaving process number, and the meanings of other symbols are the same figure 2 , image 3 , Figure 4 and Figure 5 .

[0102] T0, there are 30 old stitches on the knitting needles at positions 1, ~, and 30 on the front needle bed. The number of old stitches is related to the width of the pattern and the number of patterns in the left and right cycles. The width of the pattern in Embodiment 1 is 10 pieces Knitting needles, pattern width cycle numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com